Sludge calorific value control method

A control method and sludge technology, applied in the direction of dewatering/drying/concentrating sludge treatment, etc., can solve problems such as the inability to solve calorific value control, and achieve the goal of solving the technical problems of calorific value control, facilitating industrial production and improving dewatering efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

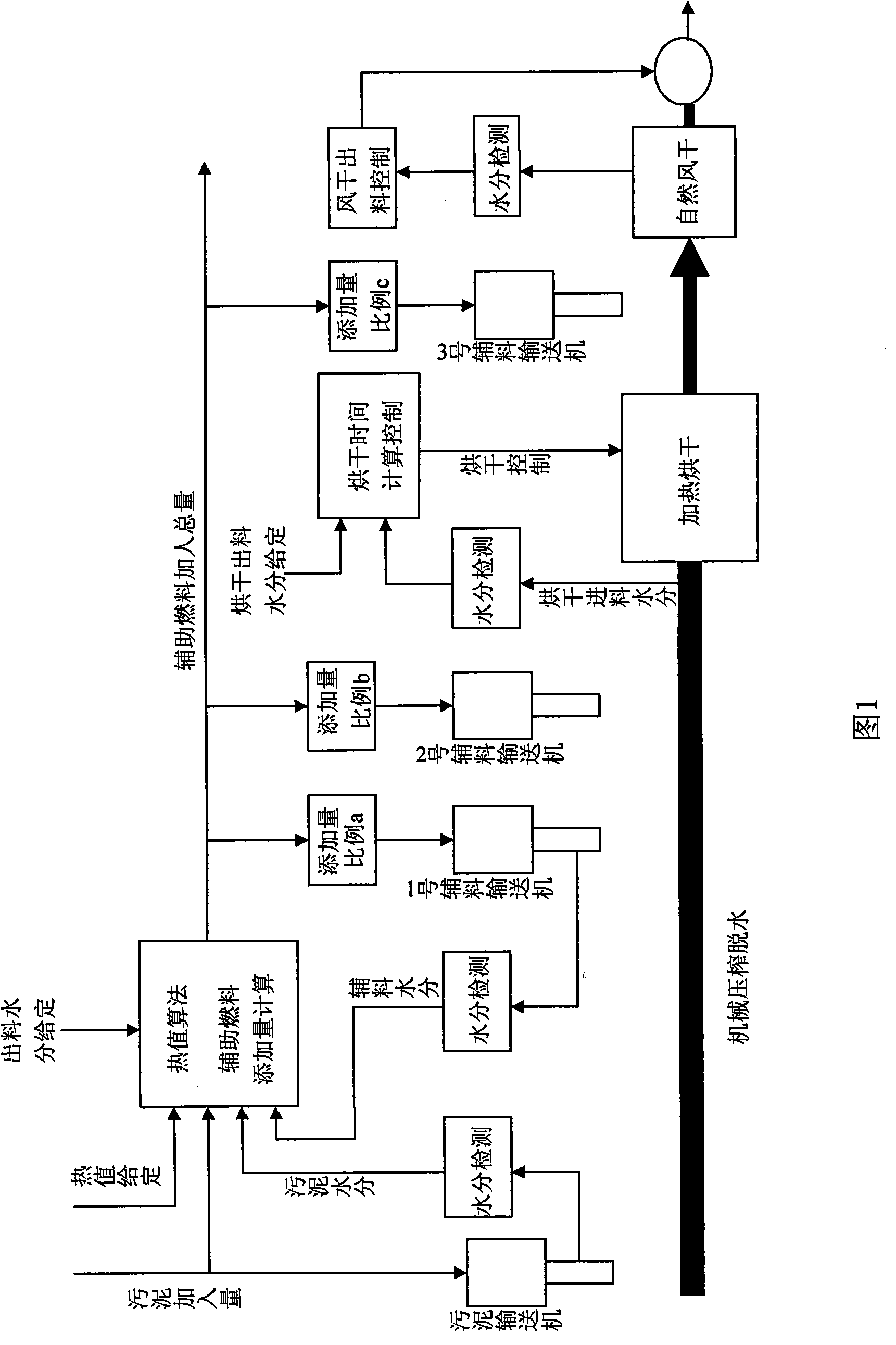

Embodiment 1

[0027] In this example, the calorific value of the sludge is controlled by adding an auxiliary fuel that can not only help the sludge to be squeezed and dehydrated but also provide heat value to the initially concentrated and dewatered sludge, and carry out dehydration and drying methods of mechanical pressing and dehydration and drying to remove water. Auxiliary fuel is added when the sludge is dewatered by mechanical pressing and dewatered by drying. During mechanical press dehydration, the auxiliary fuel is added to the sludge by laying on the filter medium of the tension press or counter press of the mechanical press dewatering equipment. The method of adding this auxiliary fuel is the same as that disclosed by the applicant in Chinese Patent Application 200810059917.2 "A Method for Bridging and Dewatering Sludge" by laying an overhead tank composed of one or more solid particle auxiliary materials between the filter medium and the sludge. layer method. By adding auxiliar...

Embodiment 2

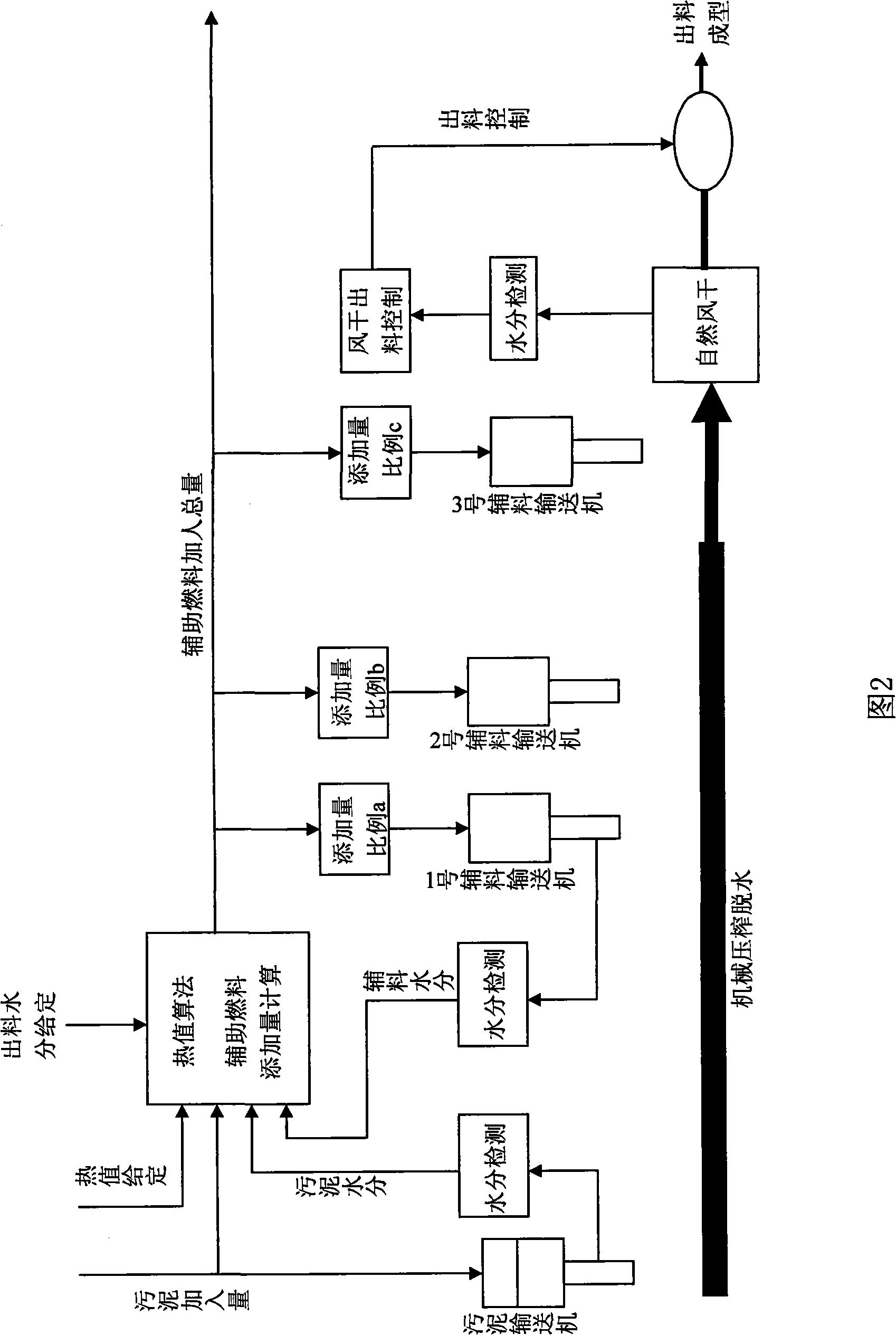

[0035] In this embodiment, the drying and dewatering process adopts the natural air-drying drying and dewatering process, and the sludge that has been dehydrated by mechanical pressing and added with auxiliary fuel is then dried and dewatered by natural air drying. The method of controlling the calorific value of the sludge includes mechanical pressing Dehydration and natural air-drying, Figure 2 is the control flow of the combined process control method of mechanical press dehydration + natural air-drying. The auxiliary fuel is added at the feed port of the belt filter press, the feed port of the high-pressure press dehydration zone, and before natural air-drying. The moisture content of the sludge dewatered by mechanical pressing basically meets the conditions for pressing and forming. Before forming, according to the specific conditions of the cohesiveness of the treated industrial sludge, auxiliary fuel is added to further increase the calorific value of the sludge and impro...

Embodiment 3

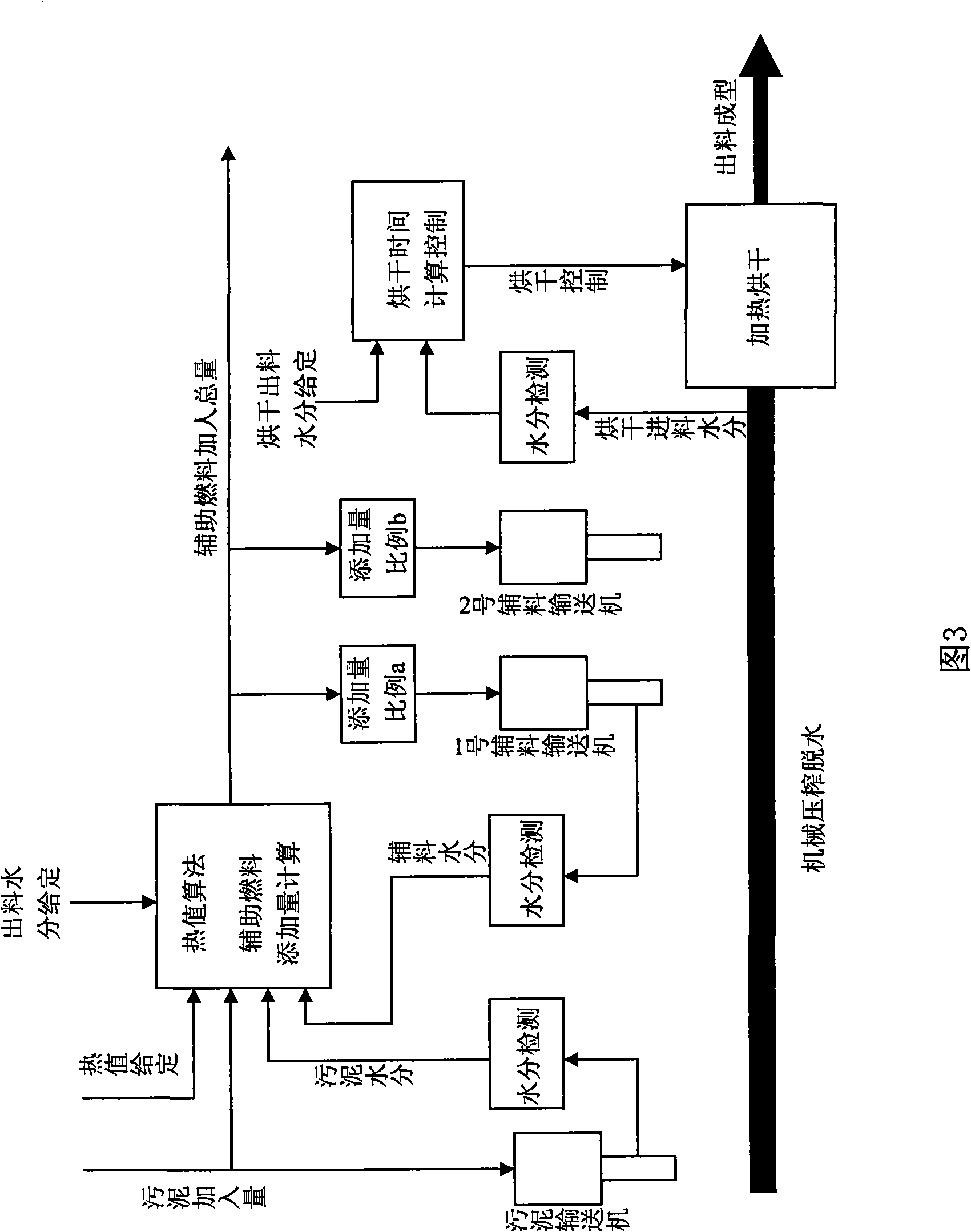

[0038] Referring to Fig. 3, the dry dewatering process of this embodiment adopts the drying dewatering process of heating and drying, and the drying dewatering process of heating and drying the sludge added with auxiliary fuel after mechanical pressing and dehydration. Auxiliary fuel is added at the feed inlet of the press and the feed inlet of the high-pressure press dehydration zone. The addition amount of the press feed port is given by the press process, and auxiliary fuel is added to the feed port of the high-pressure press dehydration zone to help the sludge to dehydrate further. According to the requirements of the conditions for the discharge moisture, the required drying time can be known through the process data, and the drying time is set in the control system. When the set time is up, the control system sends out a discharge signal. Whether to add auxiliary fuel before heating and drying, according to the amount of auxiliary fuel added during mechanical pressing an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com