High-strength hydrophobic high-reliability packaging adhesive film and preparation method thereof

An encapsulating film, high-strength technology, used in adhesives, film/sheet adhesives, non-polymer adhesive additives, etc., can solve problems such as battery corrosion, battery damage, and poor water vapor barrier ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] A preparation method of a high-strength hydrophobic and high-reliability encapsulation adhesive film, comprising the following steps:

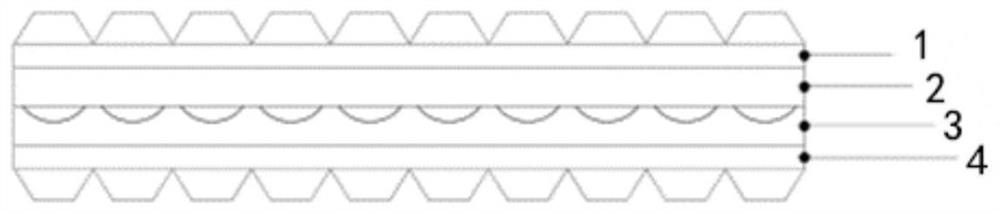

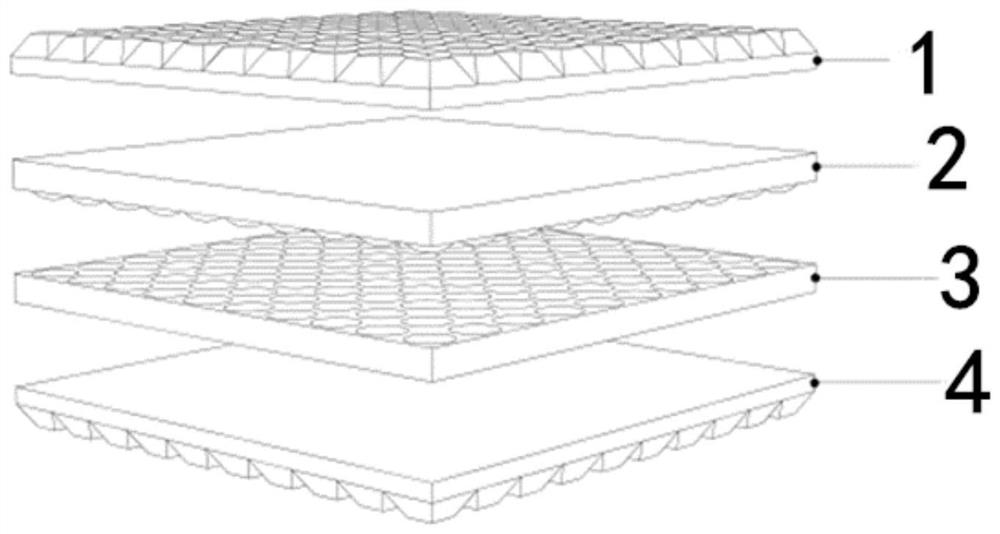

[0051] Step 1: Preparation of transparent high-strength hydrophobic layer 2: Add the copolymerized PVB resin, fluorine compound modified resin, light stabilizer, antioxidant, cross-linking agent and silane coupling agent into the mixer according to the proportion for dispersion and mixing, and then Add into the extruder to melt extrude the high-strength hydrophobic layer 2 with arc structure;

[0052]Step 2: Composite water-absorbing adhesive layer and high-strength hydrophobic layer 2 Preparation of functional film: According to EMA resin, polyolefin resin, polypropyl ether resin, hydroxypropylated modified fiber mixed in proportion and then cast and coated to the shown The arc structure surface of the high-strength hydrophobic layer 2 forms a two-layer composite functional film, and the cast coating temperature is 60-90°C;

[0053] S...

Embodiment 1

[0059] 90% copolymerized PVB resin (density at 1.05%, softening temperature at 55°C), 4% 2-trifluoromethyl-2-acrylic resin, 4% heptadecafluorodecyl triethoxysilane, 0.1% butanediol Polymer complex of acid and 4-hydroxy-2,2,6,6-tetramethyl-1-pyridineethanol and 2-hydroxy-4-n-octyloxybenzophenone complex, 0.1% triglyceride bis-3 - Complex of (3-tert-butyl-4-hydroxy-5-tolylphenyl) acrylate and tris(2,4-di-tert-butylphenyl) phosphite, 0.05% 2-ethylhexyl peroxide tert-Amyl Carbonate, 0.05% 2-Ethylhexyl Peroxide tert-Butyl Carbonate, 0.25% Trimethylolpropane Trimethacrylate and 0.25% Diethylene Glycol Dimethacrylate, 0.3% Vinyl Triple Peroxide Oxy-tert-butylsilane is added to the mixer for dispersion and mixing, and then added to the extruder. The temperature of each area of the die head of the extruder is set at 120-150°C to melt and extrude the high-strength Hydrophobic layer: 50% EMA resin (acrylate content is 15%, melting point is 55°C, melting index is 3g / 10min), 8% polyviny...

Embodiment 2

[0061] 86% copolymerized PVB resin (density at 1.05%, softening temperature at 55°C), 5% heptadecafluorodecyl triethoxysilane, 5% polydodecafluoroheptyl methacrylate, 0.8% succinic acid and 4-Hydroxy-2,2,6,6-tetramethyl-1-pyridineethanol polymer complex with 2-hydroxy-4-n-octyloxybenzophenone, 1.5% triglycerol bis-3-(3 Complex of -tert-butyl-4-hydroxy-5-tolylphenyl) acrylate and tris(2,4-di-tert-butylphenyl) phosphite, 0.55% 1,1-bis(tert-butyl peroxide base)-3,3,5-trimethylcyclohexane, 0.55% n-butyl 4,4-di(tert-amylperoxy)pentanoate, 0.5% triallyl cyanurate, 0.05% γ-mercaptopropyl trimethoxysilane, 0.05% γ-glycidyl etheroxypropyl trimethoxysilane is added to the mixer for dispersion mixing, and then added to the extruder, the temperature of each area of the extruder die Set at 120-150°C to melt-extrude a high-strength hydrophobic layer with a circular arc structure; 55% EMA resin (acrylate content is 15%, melting point is 55°C, melt index is 3 / 10min), 8% Polyvinyl alcohol ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com