Tin dioxide/polypyrrole nanocomposite and preparation method thereof

A composite material, pyrrole nanotechnology, applied in the field of material science, can solve the problems of electrode material particles losing electrical contact, material dimension instability, electrode pulverization, etc., to achieve the effect of reducing production costs and simplifying the synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

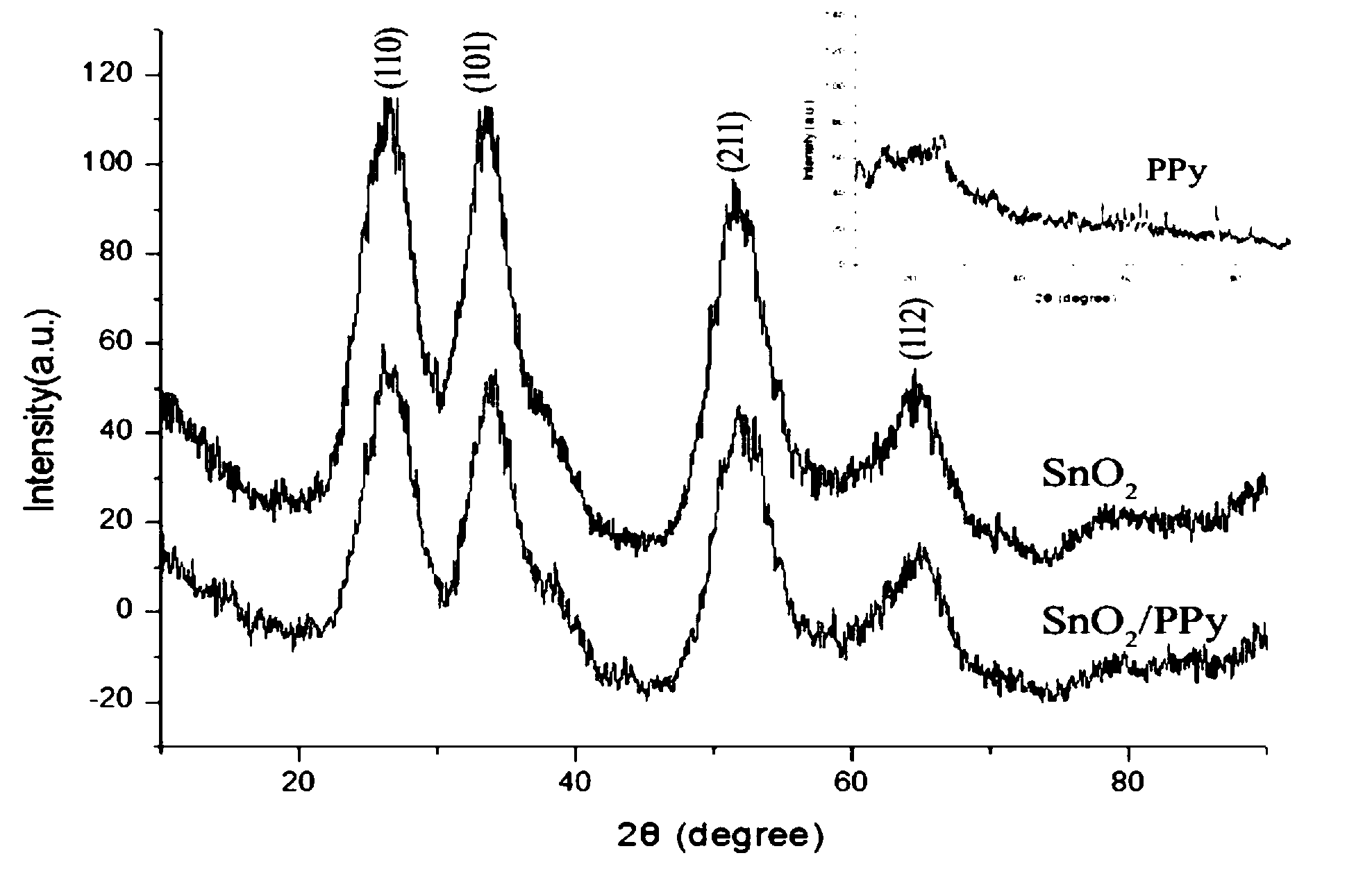

Image

Examples

Embodiment 1

[0016] Embodiment 1 prepares a kind of tin dioxide / polypyrrole composite material, concrete steps are as follows:

[0017] a. Weigh 1.635g of cetyltrimethylammonium bromide, 5.723g of n-pentanol, and 40.883g of n-hexane with an electronic balance to form a transparent microemulsion system, weigh 0.204g of urea and measure 3ml of tetrachloromethane Aqueous tin chloride solution (0.1mol / L) was added to the above microemulsion and stirred magnetically for 30min and ultrasonically for 15min to mix evenly. The obtained solution was transferred to a 100ml hydrothermal reaction kettle, and the reaction temperature was controlled at 130°C for 9 hours. The resulting solution was naturally cooled to room temperature.

[0018] d. Transfer the solution in the hydrothermal reaction kettle to a 100ml beaker, add 0.0245g of pyrrole monomer dropwise to the beaker and stir it magnetically. Place the beaker in an ice-water bath, and slowly add an aqueous solution of ferric chloride (0.144g of...

Embodiment 2

[0020] Embodiment 2 prepares a kind of tin dioxide / polypyrrole composite material, concrete steps are as follows:

[0021] a. Use an electronic balance to weigh 2.453g cetyltrimethylammonium bromide, 4.088g n-pentanol, and 40.883g n-hexane, mix and stir to form a transparent microemulsion system, weigh 0.245g urea and measure 4ml tetrachloromethane Aqueous tin chloride solution (0.1mol / L) was added to the above microemulsion and stirred magnetically for 30min and ultrasonically for 15min to mix evenly. The obtained solution was transferred to a 100ml hydrothermal reaction kettle, and the reaction temperature was controlled at 150°C for 6h. The resulting solution was naturally cooled to room temperature.

[0022] b. Transfer the solution in the hydrothermal reaction kettle to a 100ml beaker, add 0.0266g of pyrrole monomer dropwise to the beaker and stir it magnetically. Place the beaker in an ice-water bath, and slowly add an aqueous solution of ferric chloride (0.164g of fer...

Embodiment 3

[0024] Embodiment 3 prepares a kind of tin dioxide / polypyrrole composite material, concrete steps are as follows:

[0025] a. Weigh 3.271g of cetyltrimethylammonium bromide, 7.359g of n-pentanol, and 40.883g of n-hexane with an electronic balance, mix and stir to form a transparent microemulsion system, weigh 0.286g of urea and measure 5ml of tetrachloromethane Aqueous tin chloride solution (0.1mol / L) was added to the above microemulsion and stirred magnetically for 30min and ultrasonically for 15min to mix evenly. The obtained solution was transferred to a 100ml hydrothermal reaction kettle, and the reaction temperature was controlled at 140°C for 12h. The resulting solution was naturally cooled to room temperature.

[0026] b. Transfer the solution in the hydrothermal reaction kettle to a 100ml beaker, add 0.0286g of pyrrole monomer dropwise to the beaker and stir it magnetically. Place the beaker in an ice-water bath, and slowly add an aqueous solution of ferric chloride ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com