Negative electrode active material, method for preparing same, and negative electrode and secondary battery comprising same

A technology of negative electrode active material and negative electrode material, applied in secondary batteries, active material electrodes, negative electrodes, etc., can solve the problems of reduced life characteristics, limitations, deterioration of high temperature storage characteristics, etc., and achieve the effect of stable electrical contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

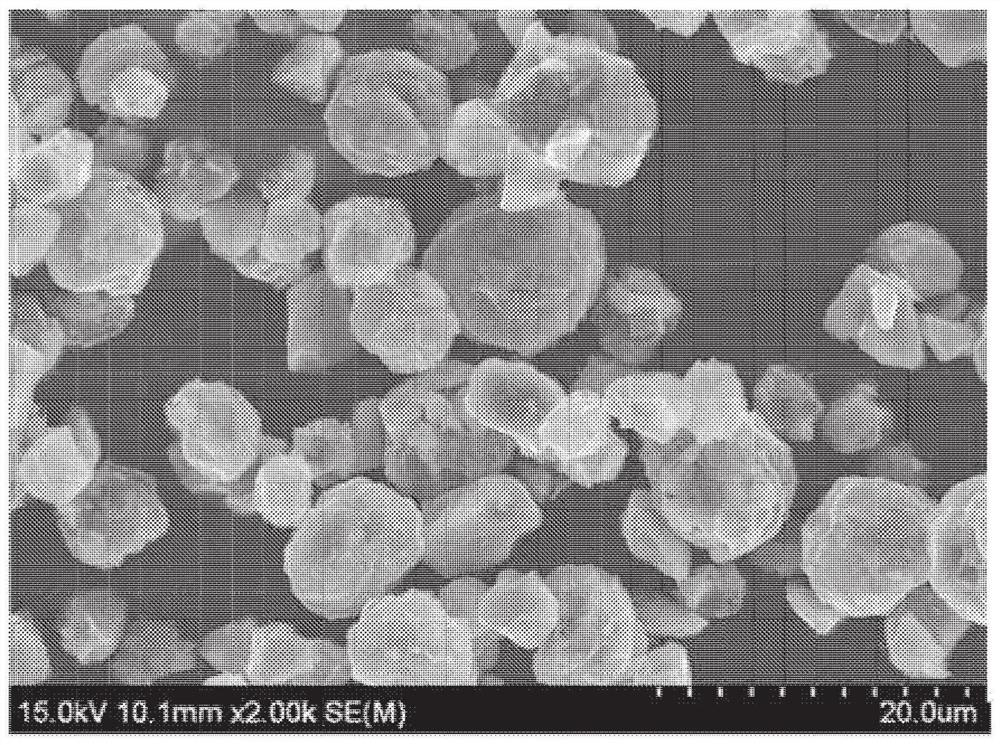

Image

Examples

preparation example Construction

[0065]

[0066] In addition, the present invention provides a method for preparing the above-mentioned negative electrode active material.

[0067] Specifically, the method for preparing the negative electrode active material of the present invention includes mixing silicon-based core particles and graphene sheets, and heat-treating the mixture.

[0068] The method for preparing the negative electrode active material of the present invention includes mixing silicon-based core particles and graphene sheets.

[0069] The silicon-based core particles have been described above.

[0070] The graphene sheets can be mixed with the silicon-based core particles and then heat treated to become a component of the outer carbon coating.

[0071] Specifically, the graphene sheet can be prepared by a method comprising the following steps.

[0072] (a) forming a dispersion comprising a graphitic material and a dispersant; and

[0073] (b) Make the dispersion liquid pass through the high-...

Embodiment 1

[0146] Embodiment 1: Preparation of negative electrode active material

[0147]

[0148] Plate graphite as a graphite-based material and polyacrylic acid as a dispersant were dispersed in water at a weight ratio of 95:5 to prepare a dispersion (solid content: 5% by weight).

[0149] Under an applied pressure of 1000 bar, 1 L of said dispersion liquid was introduced into the inlet of a high-pressure homogenizer, wherein said high-pressure homogenizer comprised said inlet, an outlet, and a micro flow path (diameter: 100 μm) connecting the inlet and the outlet, The dispersion was passed through the micro-channel at a speed of 100 m / s and circulated for 30 minutes. Through the above, the plate graphite was exfoliated to prepare graphene sheets.

[0150]The D / G ratio of the above-prepared graphene sheet was calculated by the Raman spectrum of a Raman spectrometer (trade name: Microscope Raman, manufacturer: Almega XR) (D / G ratio=0.2).

[0151]

[0152] As silicon-based core p...

Embodiment 2

[0156] Embodiment 2: Preparation of negative electrode active material

[0157] The negative electrode active material of Example 2 was prepared in the same manner as in Example 1, except that silicon-based core particles with an inner carbon coating and graphene sheets were mixed in a weight ratio of 90:10. In this negative electrode active material, the outer carbon coating was contained in the negative electrode active material in an amount of 10% by weight. In addition, the D / G ratio of the graphene sheet used in Example 2 and the graphene contained in the outer carbon coating was 0.2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com