Fusion type wire connector

A kind of wire connector and fusion type technology, applied in the direction of connection insulation, modification of power electronics, multi-core cable end parts, etc., can solve problems such as power supply failure, complicated wiring process, poor contact, etc., to reduce the occurrence of electric accidents, and quickly Effects of connecting electric wires and reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

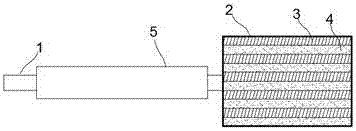

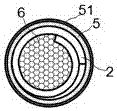

[0021] exist Figure 1 to Figure 5 In the shown embodiment, the fusion type wire joint includes a wire harness (1) 1,

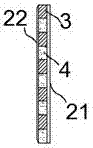

[0022] A fusion component 2 is fixedly connected to the end of the wire harness (1) 1; the fusion component 2 includes a heat conduction layer 21, and the heat conduction layer 21 is made of an easily bendable shaped material, such as aluminum metal coated with an insulating layer sheet; conductive strips 3 and fusion strips 4 are arranged equidistantly and parallelly on the heat conduction layer 21, and the conductive strips 3 and fusion strips 4 are distributed at intervals; the conductive strips 3 are electrically connected to the conductive wires in the wiring harness (1) 1 , anti-slip lines are engraved on the conductive strip 3; gel and fusion silk are doped in the fusion strip 4, and the fusion silk can be solder wire material or solder particles; in the fusion strip 4 and the top of the conductive strip 3 is covered with a sealing film 22;

[0023] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com