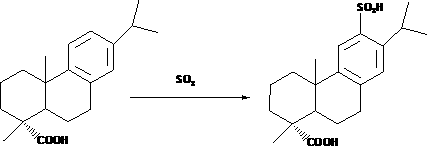

Sulfonation preparation method of sulfur trioxide halogenated hydrocarbon solution of Ecabet

A technology of sulfur trioxide and ecabet, which is applied in the field of medicine and chemical industry, can solve the problems of low yield and large amount of waste sulfuric acid, and achieve the effects of high yield, less pollution of three wastes, and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

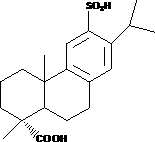

Image

Examples

Embodiment 1

[0024] Preparation of ecabet (I)

[0025] Add liquid sulfur trioxide (58.6g, 0.733mol) into 100ml of dichloromethane solvent, mix well, and set aside. Add compound (II) (200g, 0.666mol) and 1000ml of dichloromethane into a three-necked flask, stir until dissolved, cool to 10°C~15°C, add the pre-prepared sulfur trioxide-dichloromethane solution dropwise, stir After reacting for 1.0~1.5h, dichloromethane was concentrated under reduced pressure, and the residue was poured into 400g of ice water, a large amount of off-white precipitate was precipitated, filtered, and the filter cake was dried under reduced pressure to obtain compound (I) as a white solid (HPLC purity>99.0% , yield 90%).

Embodiment 2

[0027] Preparation of ecabet (I)

[0028] Add liquid sulfur trioxide (53.3g, 0.833mol) into 100ml of dichloromethane solvent, mix well, and set aside. Add compound (II) (200g, 0.666mol) and 1000ml of dichloromethane into a three-necked flask, stir until dissolved, cool to 10°C~15°C, add the pre-prepared sulfur trioxide-dichloromethane solution dropwise, stir After reacting for 1.0~1.5h, dichloromethane was concentrated under reduced pressure, and the residue was poured into 400g of ice water, a large amount of off-white precipitate was precipitated, filtered, and the filter cake was dried under reduced pressure to obtain compound (I) as a white solid (HPLC purity>99.0% , yield 84.5%).

Embodiment 3

[0030] Preparation of ecabet (I)

[0031] Add liquid sulfur trioxide (64.0g, 0.799mol) into 100ml of dichloromethane solvent, mix well, and set aside. Add compound (II) (200g, 0.666mol) and 1000ml of dichloromethane into a three-necked flask, stir until dissolved, cool to 10°C~15°C, add the pre-prepared sulfur trioxide-dichloromethane solution dropwise, stir After reacting for 1.0~1.5h, dichloromethane was concentrated under reduced pressure, and the residue was poured into 400g of ice water, a large amount of off-white precipitate was precipitated, filtered, and the filter cake was dried under reduced pressure to obtain compound (I) as a white solid (HPLC purity>99.0% , yield 85%).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com