Producing method of double-metal composite band

A manufacturing method and technology of composite strips, which are applied in metal rolling, metal rolling, manufacturing tools, etc., can solve the problems of low cost, complicated process, and inability to popularize and apply.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

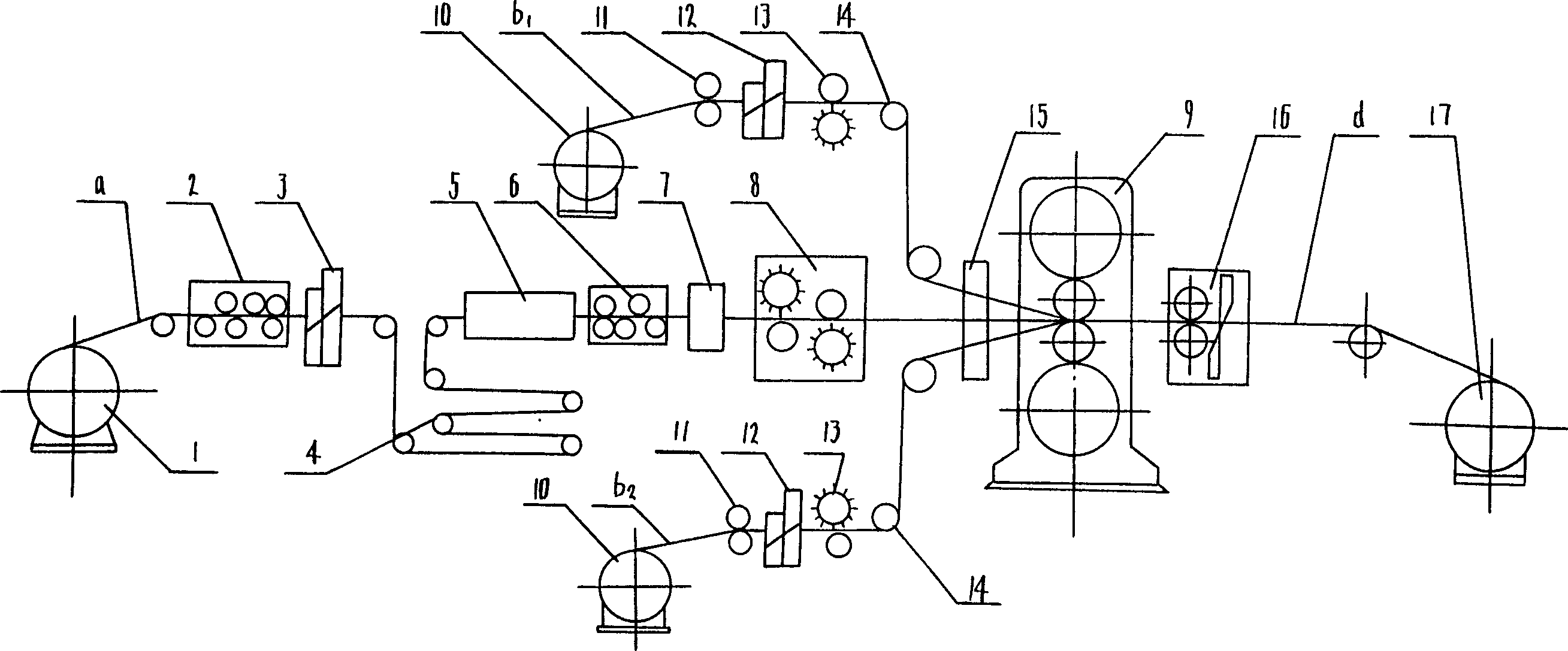

Method used

Image

Examples

Embodiment 1

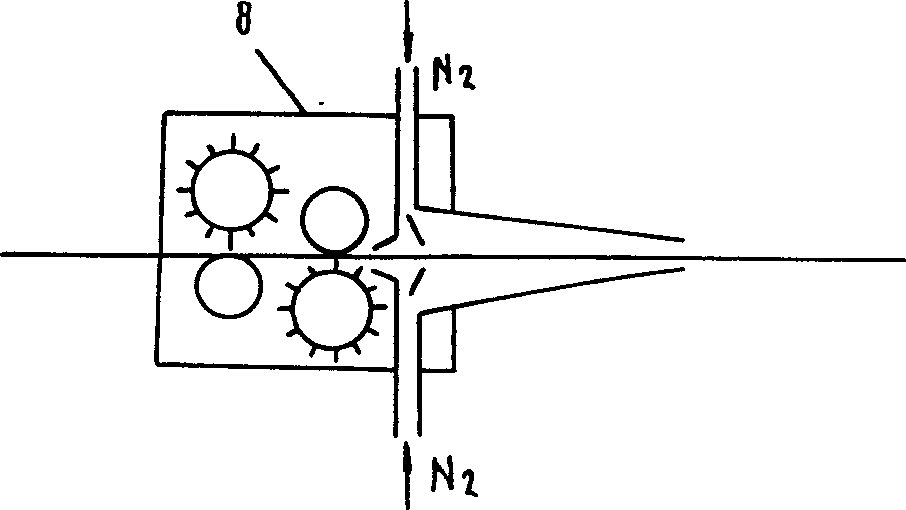

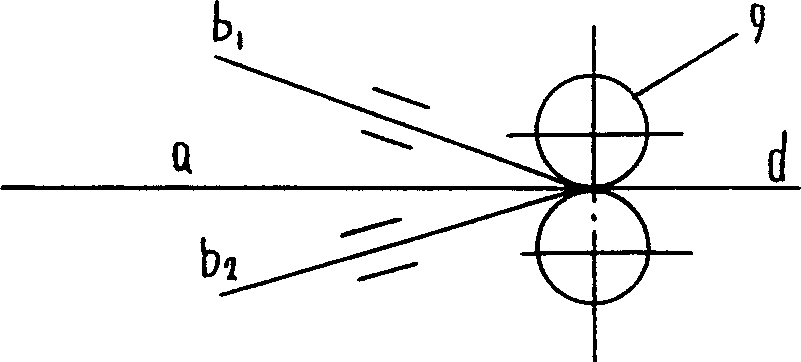

[0023] Example 1: Production of aluminum, steel, and aluminum three-layer composite tapes. The production process is as mentioned above. According to different product performance requirements, the metal composite surface is subjected to surface pretreatment and initial adsorption treatment respectively. The initial adsorption on the surface such as figure 2 As shown, spray N on the clean metal surface 2 . The rolling composite deformation is 10%-40%, using induction heating or direct current heating (the first and third methods), the heating temperature of the aluminum strip is 260-600℃, the temperature of the steel strip is 150-350℃, and the rolling speed is 0.2 ~0.5 m / sec, the tensile stress of the strip is 0.1 ~ 0.5σs. The composite belt is annealed in a bell-type annealing furnace with a protective atmosphere. The heat treatment system is: rising temperature 10-30°C / min, annealing temperature 280-600°C, annealing time 0.5-8 hours.

Embodiment 2

[0024] Example 2: Steel and stainless steel two-layer composite belt production: the production process is as described above. The width of the rolled composite strip is 300-500mm. The composite surface of the strip is subjected to surface pretreatment and initial adsorption treatment respectively. The tensile stress of the strip is 0.1~0.6σs, the deformation degree is 25%~40%, direct heating by high frequency (the second method), the current frequency is 440kHz, and the power 200-400kW, the heating temperature at the entrance of the deformation zone is 600-900℃, and the rolling speed is 0.2-0.5 m / s. The composite belt is annealed in a hood-type annealing furnace protected by hydrogen, the heating temperature is 700-900°C, and the holding time is 1-8 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com