Method for preparing battery-grade lithium carbonate by freezing and recycling lithium precipitation concentrated mother liquor

A technology of recycling and sinking lithium mother liquor, applied in the direction of lithium carbonate;/acid carbonate, etc., can solve the problem of low lithium content, achieve the effect of improving utilization rate, reducing production cost and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

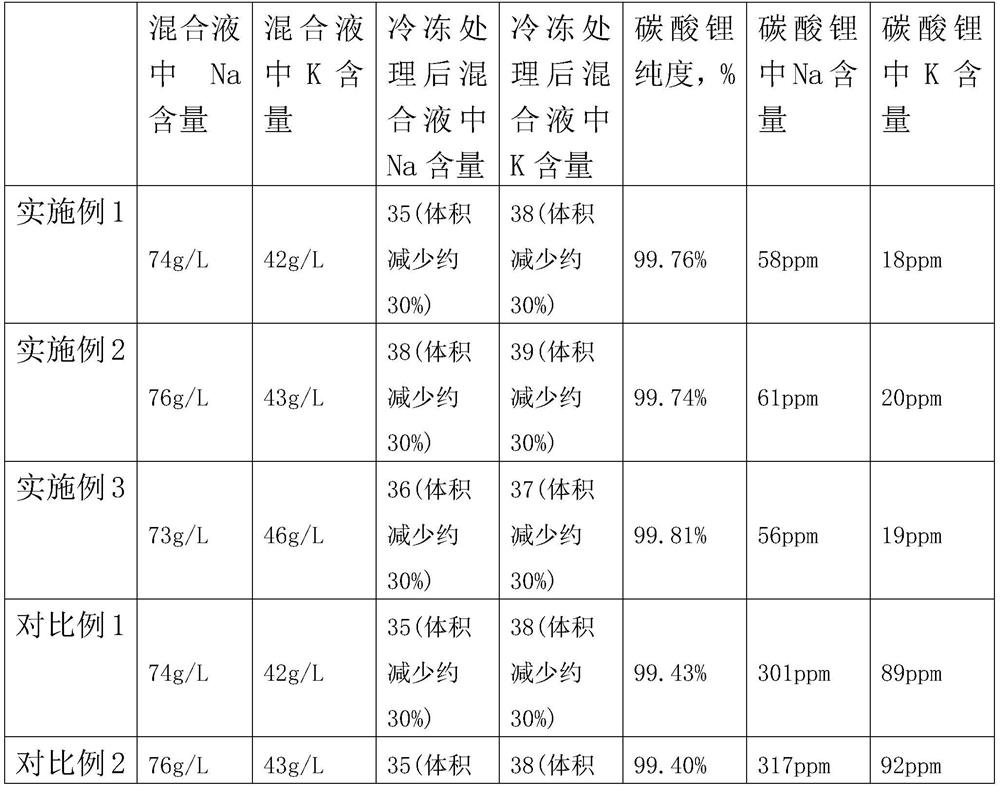

Embodiment 1

[0016](1) Lepidolite is roasted and leached to obtain a leachate, and the leachate is purified, concentrated and evaporated (MVR), lithium precipitation, and filtered to obtain lithium carbonate and lithium precipitation mother liquor;

[0017](2) Lithium precipitation mother liquor is concentrated and evaporated to obtain lithium precipitation concentrated mother liquor;

[0018](3) Add the concentrated mother liquor of lithium precipitation in step (2) to the leachate in step (1) to obtain a mixed solution. The mixed solution is purified, concentrated, evaporated, frozen at 5°C to remove potassium and sodium salts, and filtered. Import ion exchange resin to remove calcium and magnesium, and obtain battery-grade lithium carbonate and lithium precipitation mother liquor after sedimentation;

[0019](4) After being processed in step (2), the mother liquor for lithium precipitation is mixed with the leachate prepared in step (1) to perform the operation of step (3), and is recycled.

[0020]Where...

Embodiment 2

[0023](1) Lepidolite is roasted and leached to obtain a leachate, and the leachate is purified, concentrated and evaporated (MVR), lithium precipitation, and filtered to obtain lithium carbonate and lithium precipitation mother liquor;

[0024](2) Lithium precipitation mother liquor is concentrated and evaporated to obtain lithium precipitation concentrated mother liquor;

[0025](3) Add the concentrated mother liquor of lithium precipitation in step (2) to the leachate in step (1) to obtain a mixed solution. The mixed solution is purified, concentrated, evaporated, and frozen at 0°C to remove potassium and sodium salts. After filtration Import ion exchange resin to remove calcium and magnesium, and obtain battery-grade lithium carbonate and lithium precipitation mother liquor after sedimentation;

[0026](4) After being processed in step (2), the mother liquor for lithium precipitation is mixed with the leachate prepared in step (1) to perform the operation of step (3), and is recycled.

[002...

Embodiment 3

[0030](1) Lepidolite is roasted and leached to obtain a leachate, and the leachate is purified, concentrated and evaporated (MVR), lithium precipitation, and filtered to obtain lithium carbonate and lithium precipitation mother liquor;

[0031](2) Lithium precipitation mother liquor is concentrated and evaporated to obtain lithium precipitation concentrated mother liquor;

[0032](3) Add the concentrated mother liquor of lithium precipitation in step (2) to the leachate in step (1) to obtain a mixed solution. The mixed solution is purified, concentrated, evaporated, frozen at 10°C to remove potassium and sodium salts, and filtered. Import ion exchange resin to remove calcium and magnesium, and obtain battery-grade lithium carbonate and lithium precipitation mother liquor after sedimentation;

[0033](4) After being processed in step (2), the mother liquor for lithium precipitation is mixed with the leachate prepared in step (1) to perform the operation of step (3), and is recycled.

[0034]Wher...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com