Patents

Literature

37results about How to "High lithium content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Recovery method of waste lithium iron phosphate positive electrode material

ActiveCN112441572AImprove leaching rateRealize full recyclingAluminium oxide/hydroxide preparationWaste accumulators reclaimingPregnant leach solutionO-Phosphoric Acid

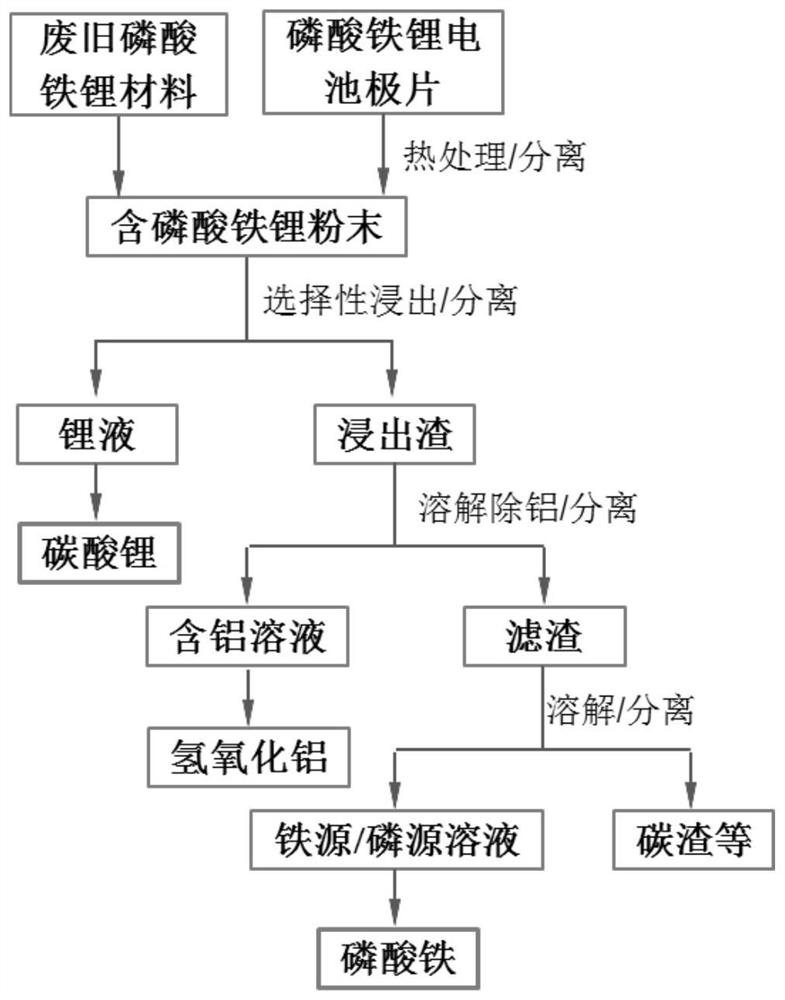

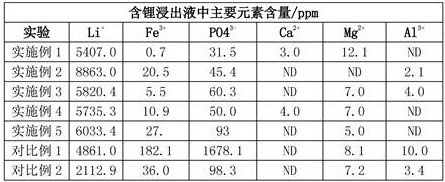

The invention provides a recovery method of a waste lithium iron phosphate positive electrode material. The method comprises the following steps: S1, adding waste lithium iron phosphate powder to a leaching agent A, slowly adding a leaching agent B, adjusting the pH value to be more than or equal to 2, and carrying out solid-liquid separation to obtain a lithium-containing leaching agent and a leaching residue; S2, adding a precipitator into the lithium-containing leachate to obtain lithium carbonate; S3, adding a first alkaline solution into the leaching residues, and filtering to obtain an aluminum-containing solution and filter residues; S4, adjusting the pH value of the aluminum-containing solution to obtain an aluminum hydroxide precipitate; S5, adding the filter residue into a firstacidic solution, performing filtering, adding a second alkaline solution into the obtained filtrate, adjusting the pH value to 2.0-2.7 to obtain basic iron phosphate, and adding phosphoric acid to obtain iron phosphate. The leaching agent A comprises a mixed solution of at least one of a weak base solution or a weak acid solution and a first oxidizing agent; and the leaching agent B comprises a mixed solution of a second acidic solution and a second oxidant. By the adoption of the method, the leaching rate of lithium is high, impurities are few, the purification and wastewater treatment cost during lithium carbonate preparation is reduced, and meanwhile iron phosphate can be efficiently recycled.

Owner:BYD CO LTD +1

Method for recycling lithium carbonate from lithium iron phosphate battery

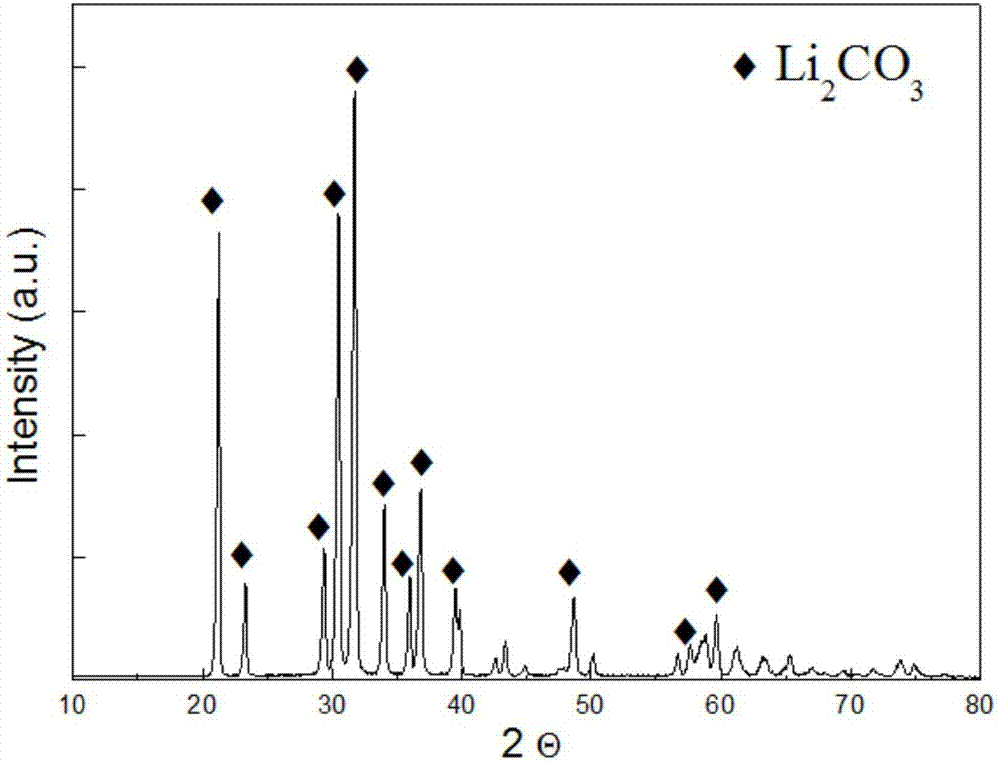

ActiveCN107381604AAchieve recyclingReduce recycling costsLithium carbonates/bicarbonatesSodium carbonateLithium carbonate

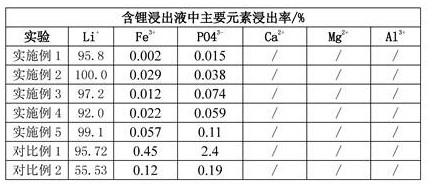

The invention discloses a method for recycling lithium carbonate from a lithium iron phosphate battery. The method comprises the following steps: (S0) discharging, decomposing and sorting the lithium iron phosphate battery and taking lithium iron phosphate powder; (S1) calcining under high temperature; (S2) performing oxidizing acid-pickling reaction, wherein the pH value is 0-1.5; (S3) filtering, thereby taking a filtrate I; (S4) adding alkali, regulating the pH value to be 2-4, filtering and taking the filtrate; (S5) adding alkali, regulating the pH value to be 8-11, filtering and taking the filtrate; (S6) performing evaporative crystallizing, sintering at 250-550 DEG C and taking the residual block powder; (S7) adding water for dissolving, filtering and taking the filtrate; (S8) dropwise adding a sodium carbonate solution, thereby acquiring lithium carbonate. According to the method, the technological process is simple, the cost is low, lithium iron phosphate batteries can be recycled in batches and the yield and the purity of lithium carbonate are high.

Owner:深圳佳彬科技有限公司 +1

Process For Concentration Of Lithium Containing Solutions

InactiveUS20180147532A1Reduce moistureHigh enthalpy of hydrationWaste water treatment from quariesMembranesPhysical chemistrySalt solution

A forward osmosis process for concentration of lithium-containing salt solutions is described. A difference in osmotic pressure between a lithium-containing salt solution and a second salt solution of higher osmotic pressure is used as a driving force to pass water through a semi-permeable forward osmosis membrane from said lithium-containing salt solution of lower osmotic pressure to the salt solution of higher osmotic pressure. Also, a two-part operation is described wherein reverse osmosis process technology and forward osmosis process technology are used in tandem to concentrate lithium-containing salt solutions and to recover water that can be recycled to the process. The forward osmosis process is conducted without requiring (i) use of superatmospheric pressure or (ii) use of subatmospheric pressure or (iii) use of both such pressures, or (iv) use of one or more additives to assist in causing the flow of water through a forward osmosis membrane.

Owner:ALBEMARLE CORP

Recovery method of waste lithium ion battery negative electrode material

ActiveCN111430831AHigh recovery rateHigh lithium contentCarbon compoundsNegative electrodesMetal leachingElectrical battery

The invention discloses a recovery method of a waste lithium ion battery negative electrode material. The method comprises the following basic steps of 1) mixing the waste lithium ion battery negativeelectrode powder with molten salt; 2) carrying out heat treatment on the mixed powder at a temperature not lower than the melting point of molten salt; and 3) soaking the material subjected to heat treatment in water, uniformly stirring, carrying out solid-liquid separation, recovering lithium and other valuable metals by using the liquid phase, and drying the solid phase to obtain the regenerated negative electrode material. According to the invention, the purification and structure repair of the negative electrode material in the waste lithium ion battery negative electrode material and therecovery of valuable metals are realized. The method has the advantages of short treatment flow and low cost, and the obtained regenerated negative electrode material is high in purity, good in crystallinity and high in valuable metal leaching rate and is suitable for the large-scale production.

Owner:湖南烯富环保科技有限公司

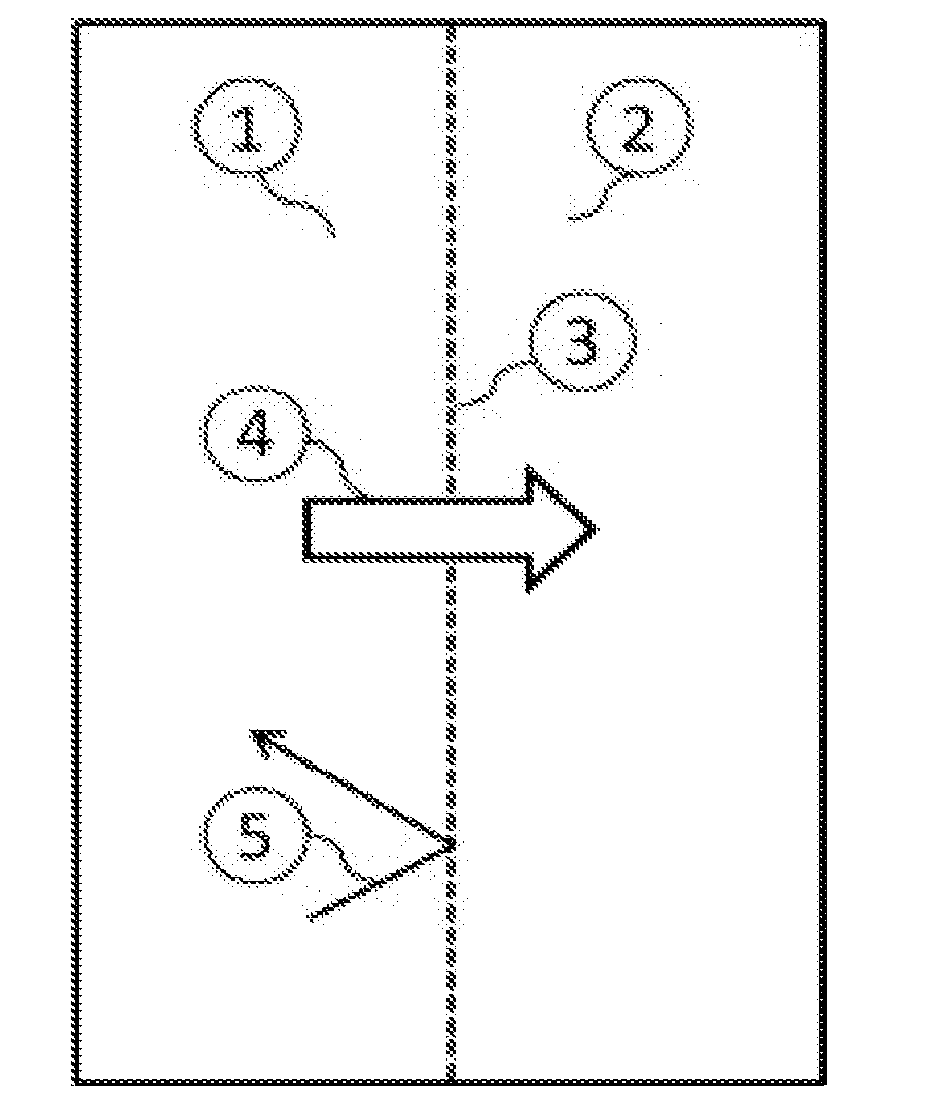

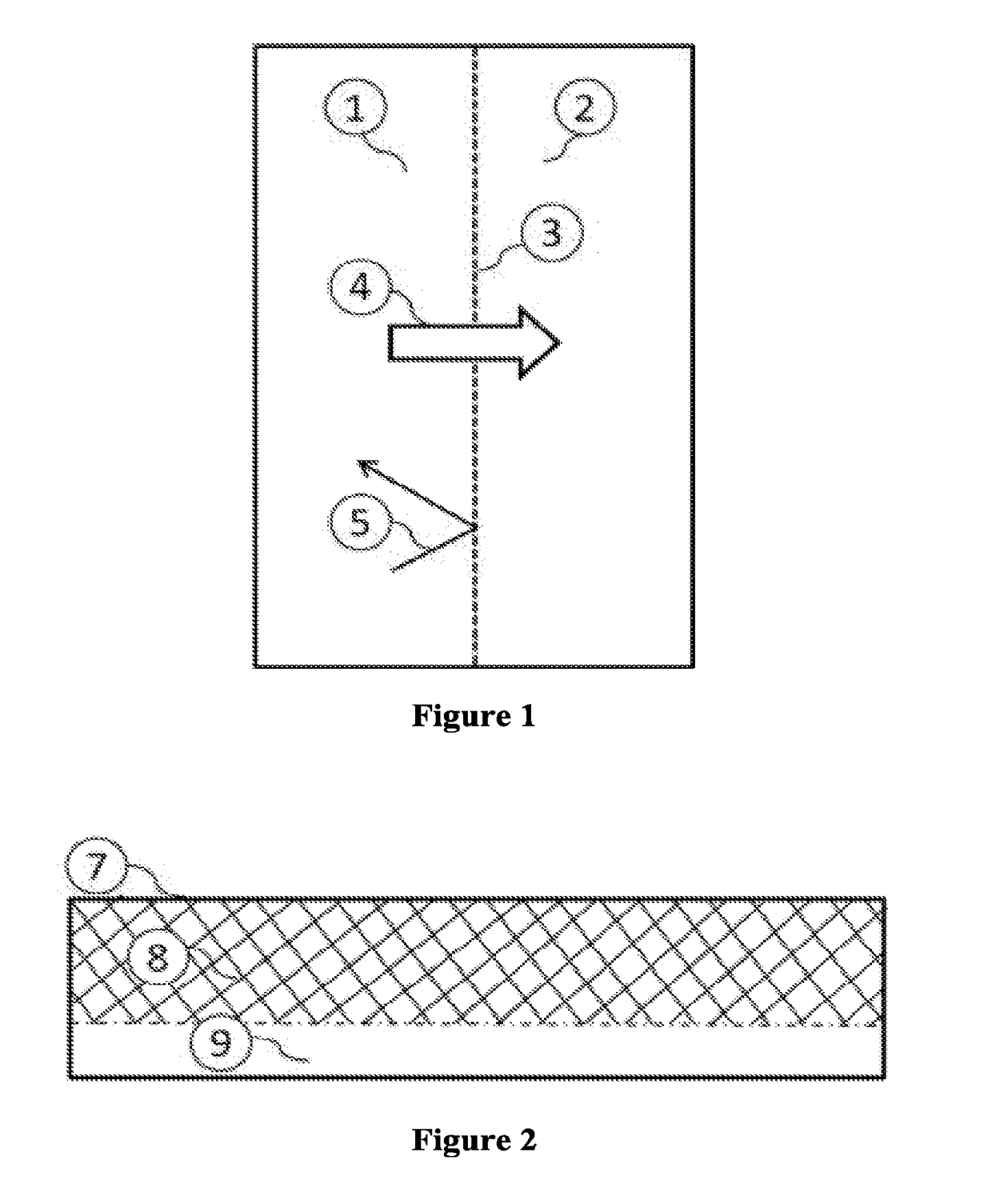

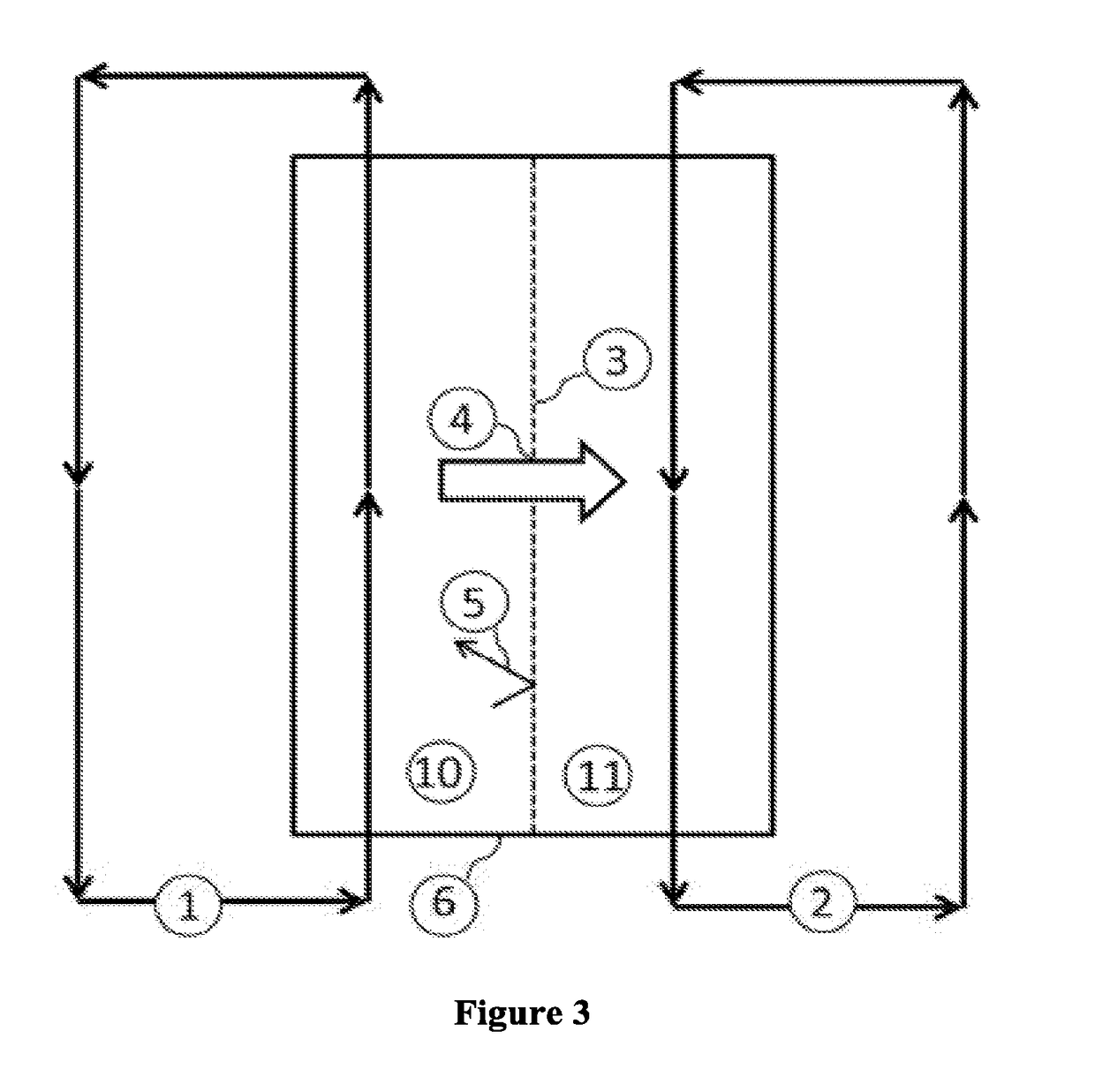

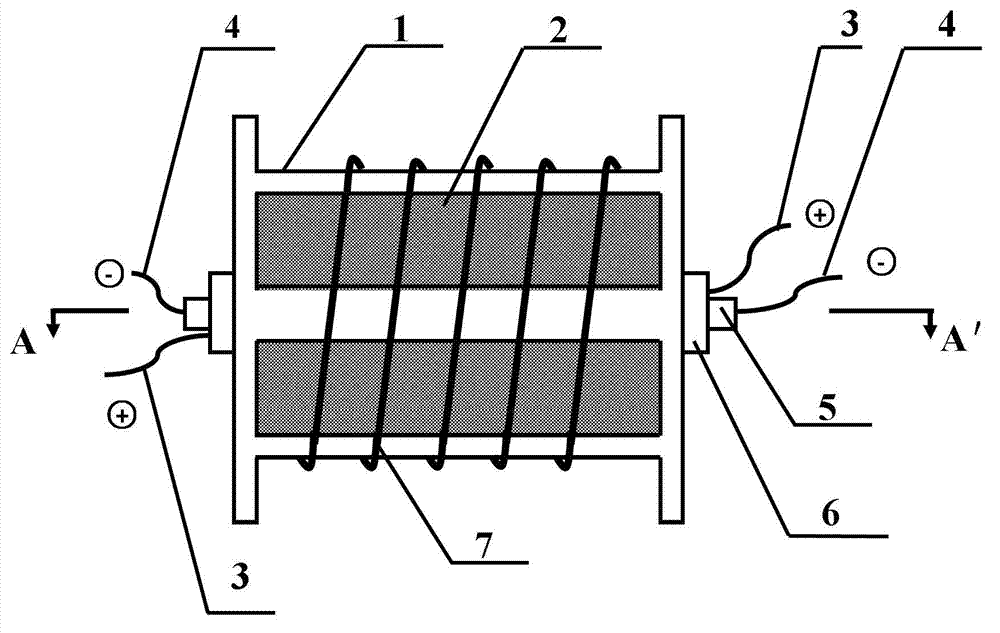

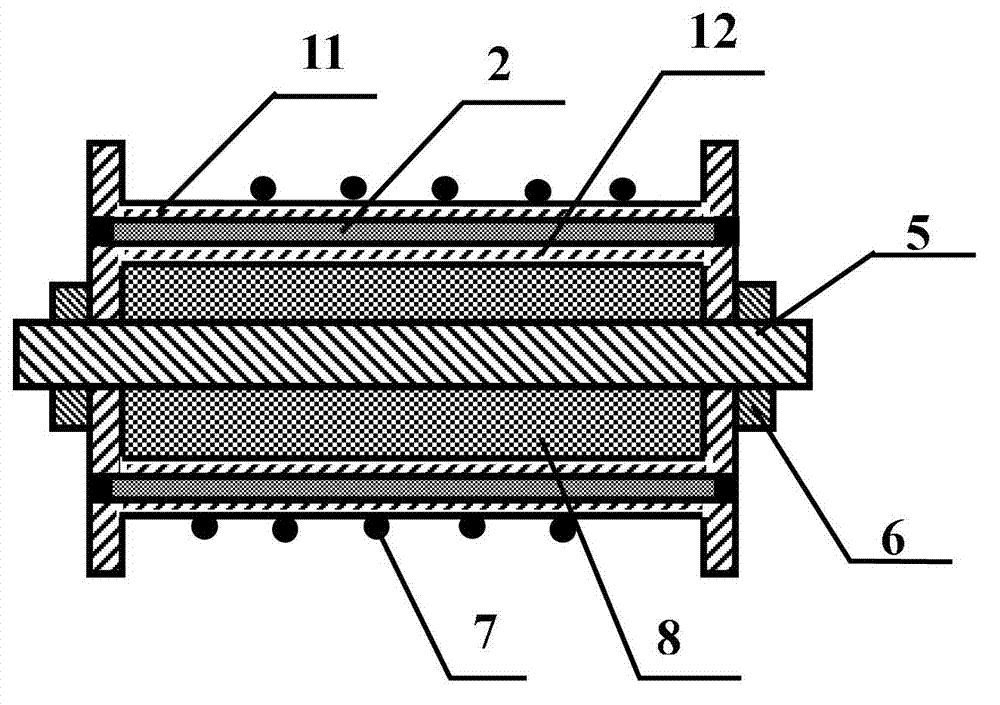

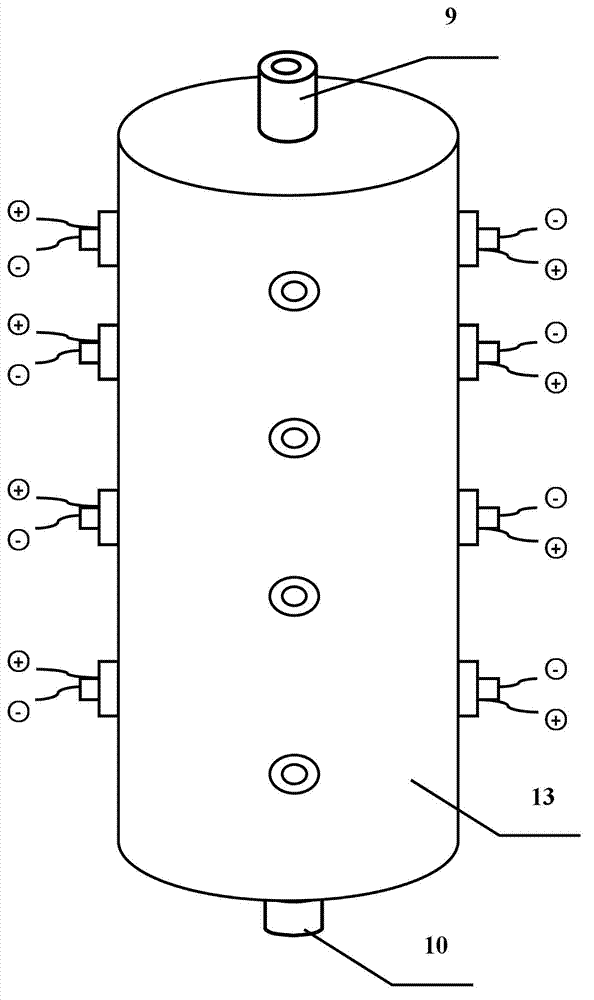

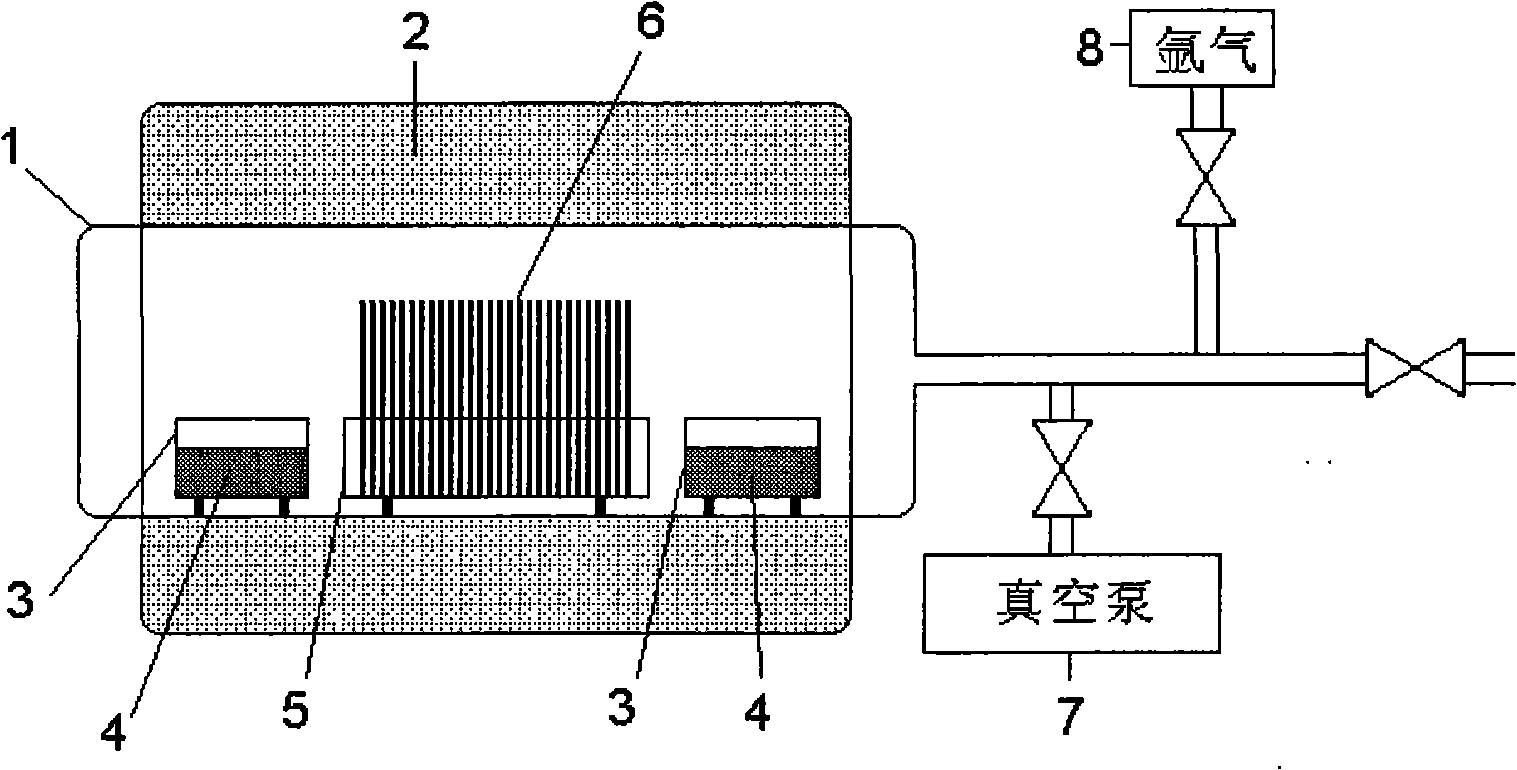

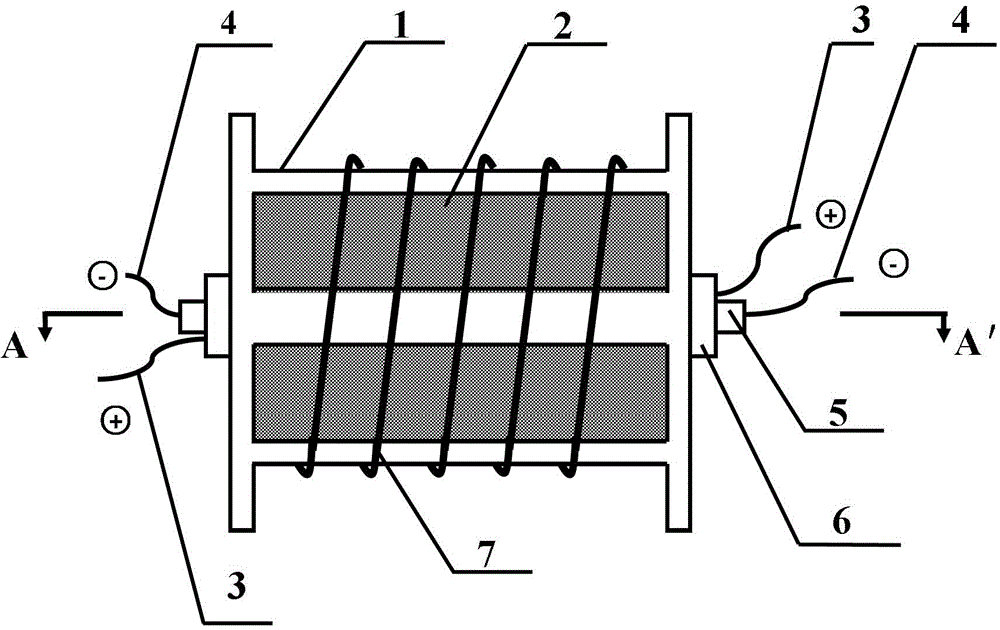

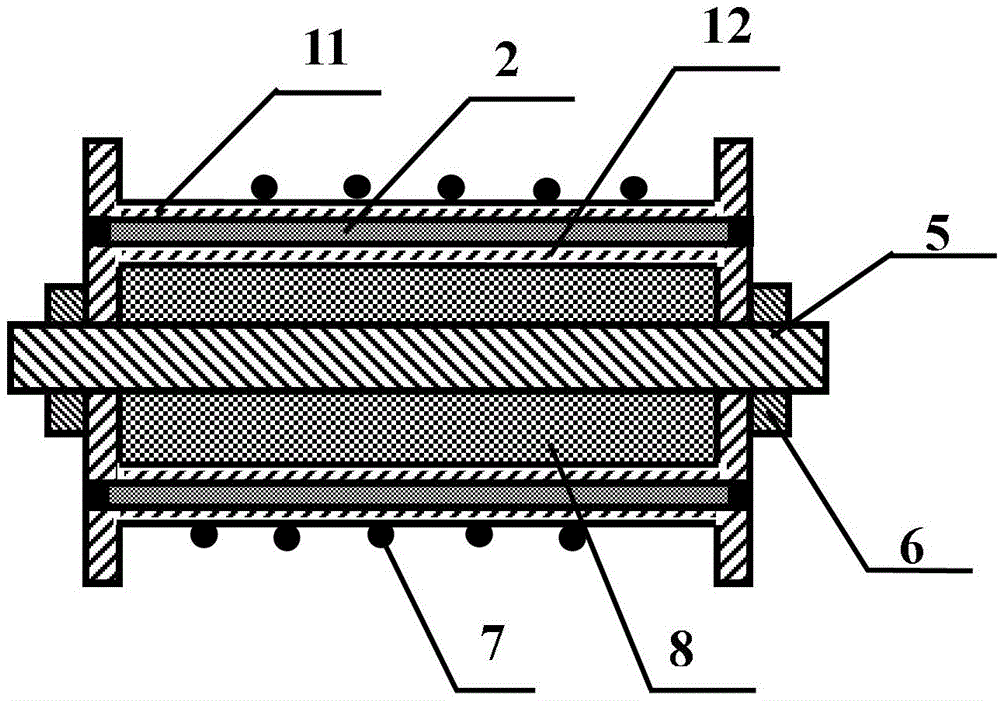

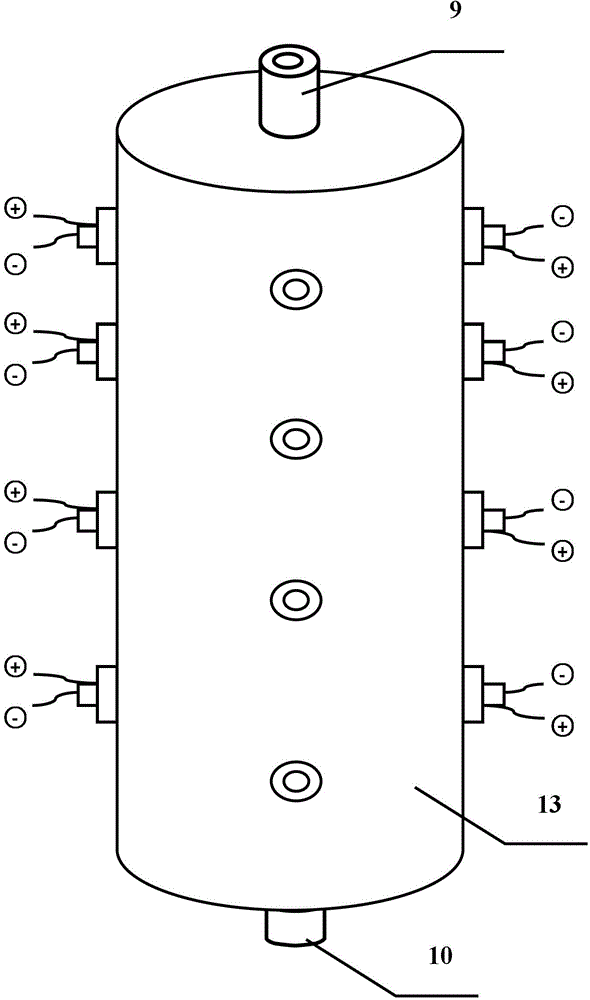

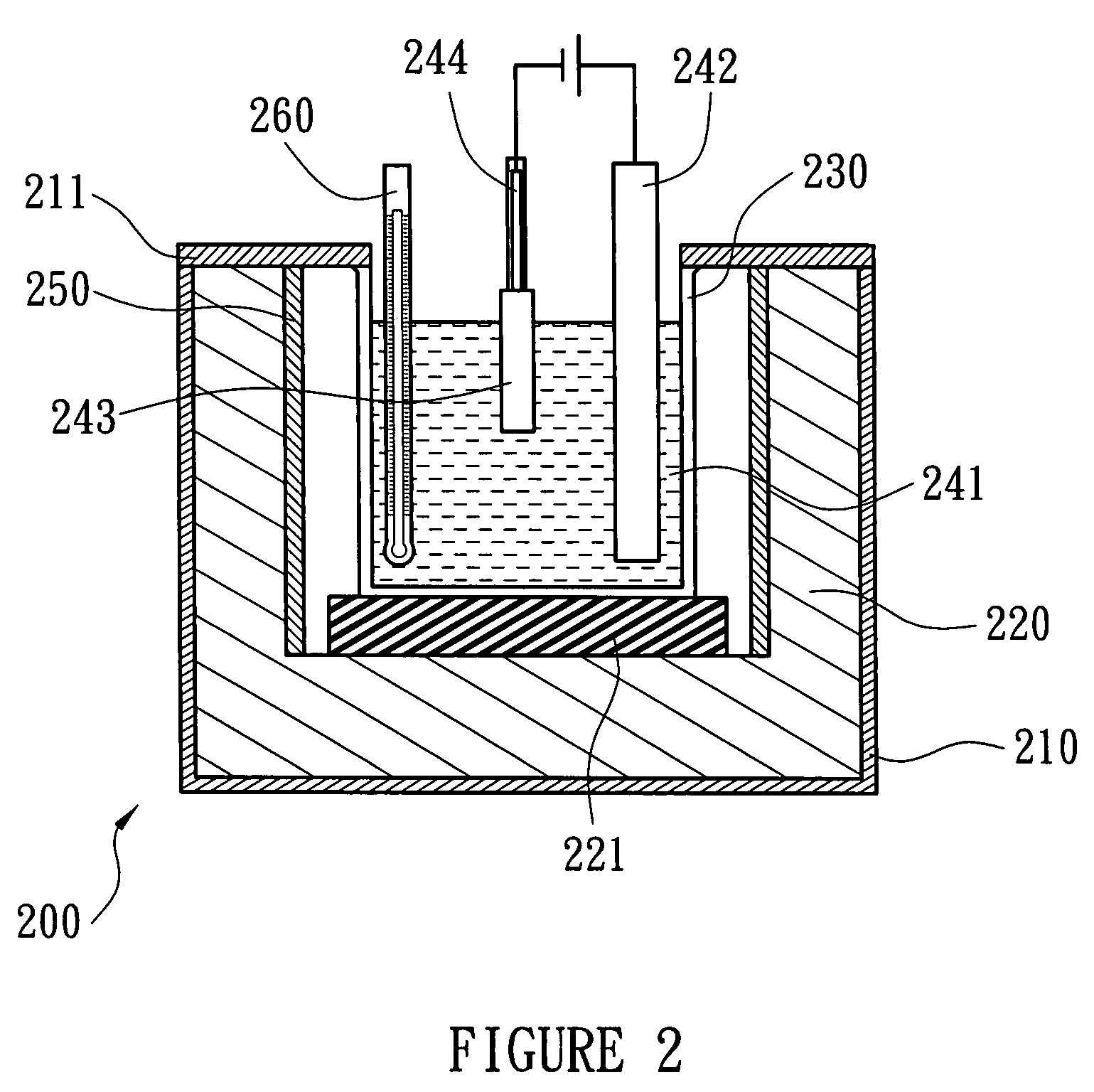

Lithium flow battery reactor and electrode suspension liquid lithium intercalated synthesis method

ActiveCN103117406AHigh lithium contentImprove performanceFinal product manufactureRegenerative fuel cellsSynthesis methodsElectric capacity

The invention discloses a lithium flow battery reactor and an electrode suspension liquid lithium intercalated synthesis method. The battery reactor is formed by fixing one or more assembled structures respectively consisting of a negative current collection core, a lithium negative electrode, a hollowed bushing, a porous diaphragm and a positive current collection core in a reaction tank. Lithium intercalation is performed on electrode suspension liquid by utilizing the battery reactor in an electrochemical synthesis way, the electrode suspension liquid is injected into the reaction tank, lithium ions which are separated from the lithium negative electrode in the reaction tank are finally intercalated into active material particles of the electrode suspension liquid, and the electrochemical synthesis process and the lithium intercalation degree of the electrode suspension liquid in the reaction tank are controlled by adjusting the flow rate, the voltage and the circular reaction times of the electrode suspension liquid. Due to the adoption of the method, a stable lithium-enriched electrode material or a metastable-phase lithium-containing alloy with high electric capacity can be obtained, and the energy density and the cycle life of a battery can be improved.

Owner:BEIJING HAWAGA POWER STORAGE TECH +1

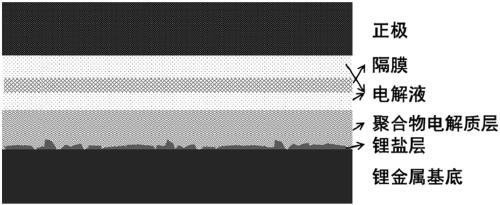

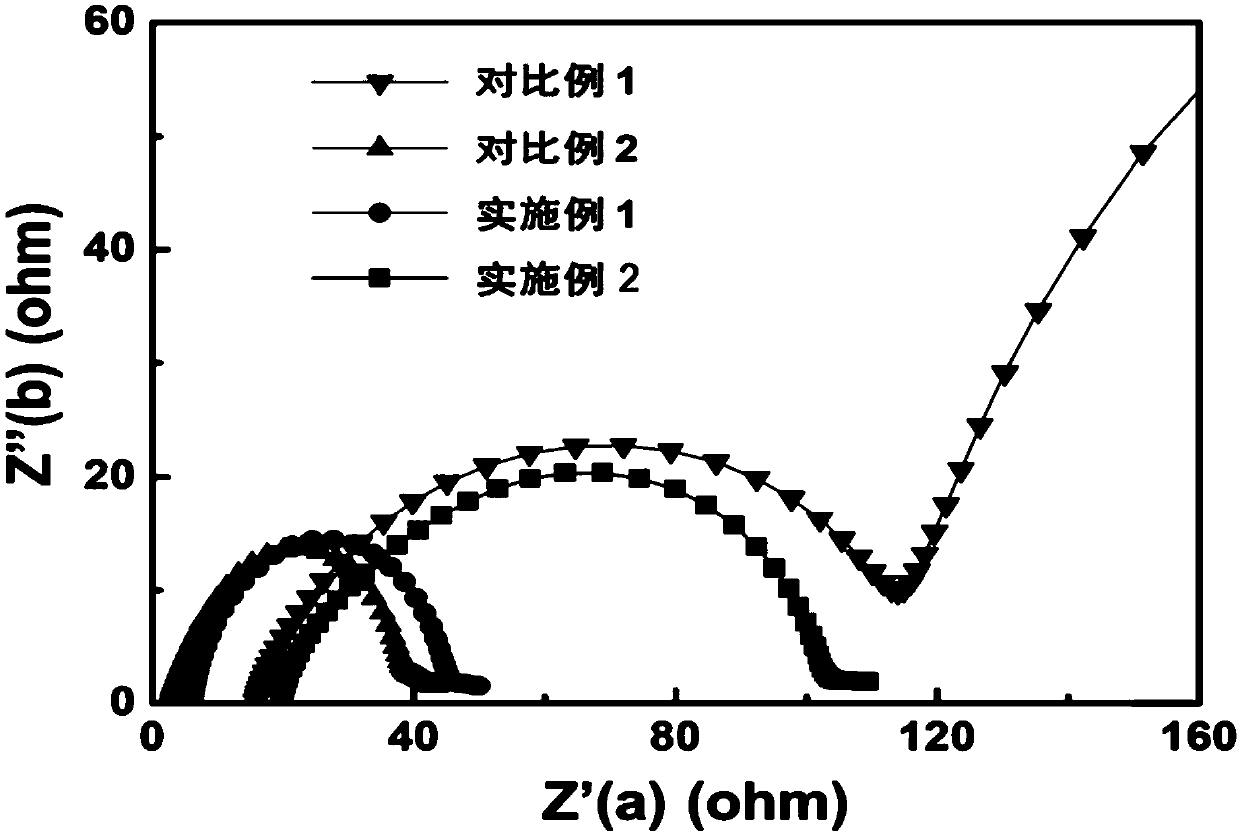

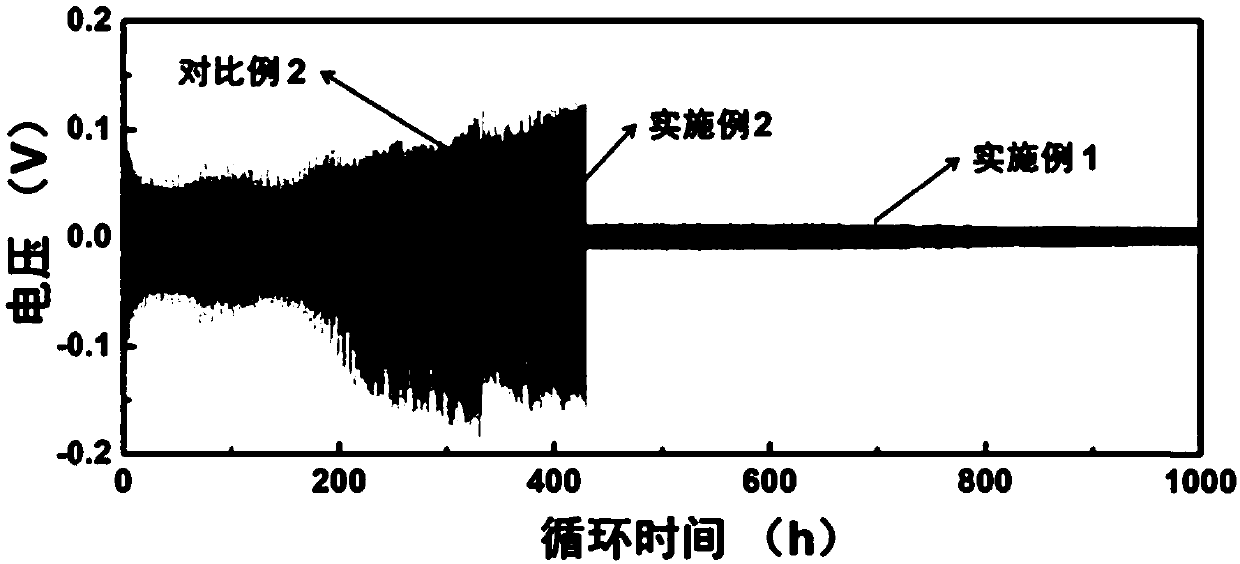

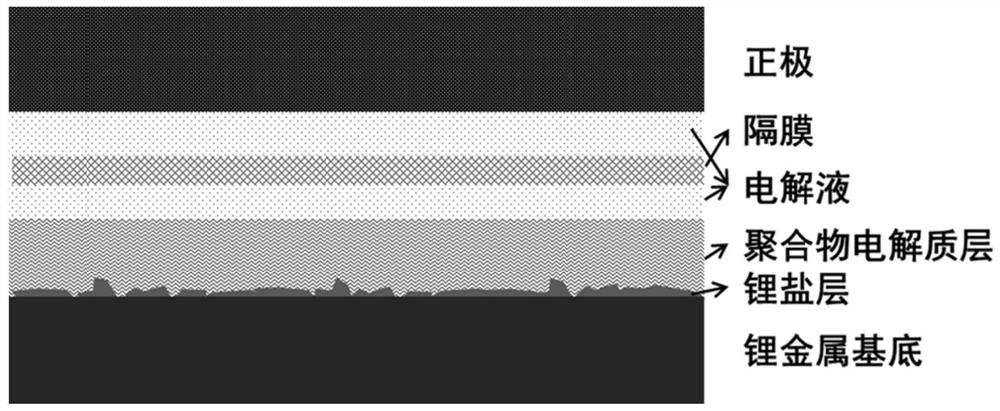

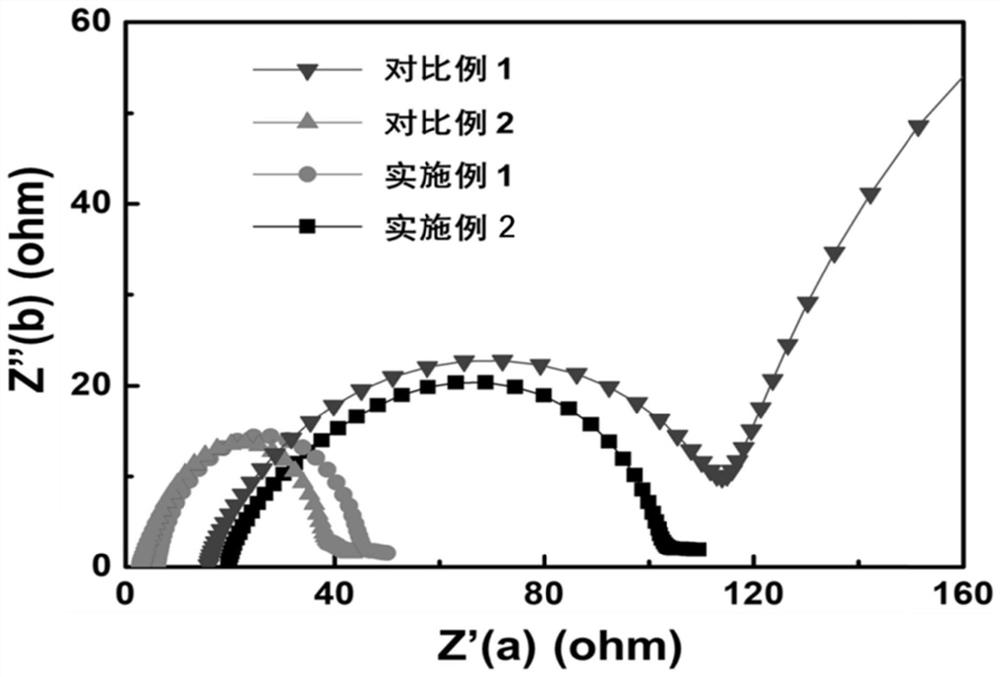

Lithium metal negative electrode, preparation thereof and application of lithium metal negative electrode

ActiveCN111293287ALow concentration of lithium ionsLow viscosityNegative electrodesLi-accumulatorsSolid state electrolytePolymer electrolytes

The invention relates to a lithium metal negative electrode, a preparation thereof and application of the lithium metal negative electrode. According to the lithium metal negative electrode, lithium metal is taken as a substrate; the surface, facing a positive electrode, of the substrate is sequentially coated with a solid lithium salt layer and a polymer electrolyte layer. When the lithium metalnegative electrode is applied to a lithium metal battery, an electrolyte system in which lithium ion concentration from a positive electrode to the negative electrode is in low-to-high gradient distribution can be formed. With the electrolyte with lithium ions in gradient distribution adopted, the problems of low ionic conductivity and high interface contact impedance in a solid electrolyte can beeffectively solved, and the problem of poor stability of an SEI film in a liquid electrolyte can be also solved; lithium dendritic crystal growth can be inhibited; and the cycling stability of a lithium battery can be improved. The electrolyte has important practical application value.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

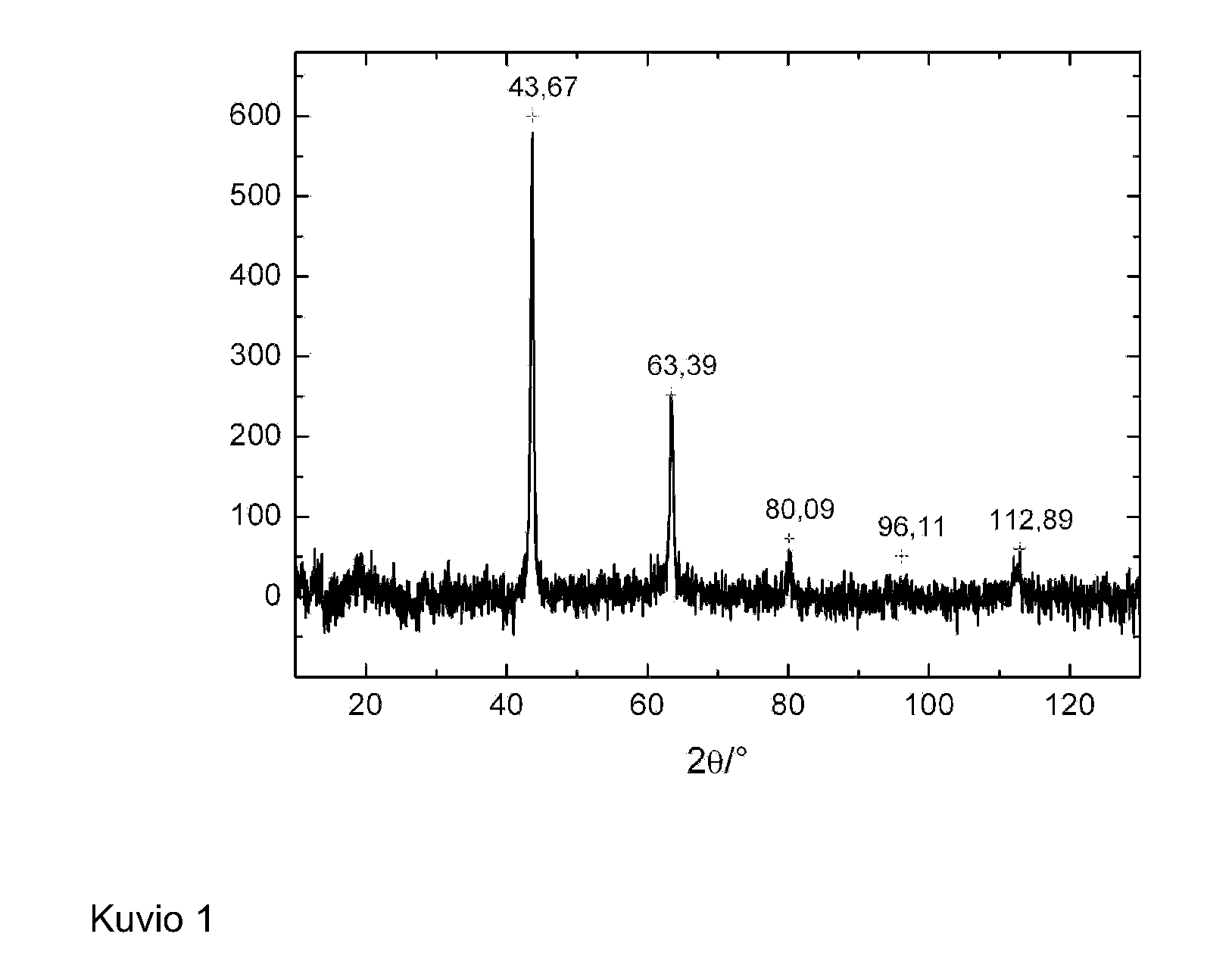

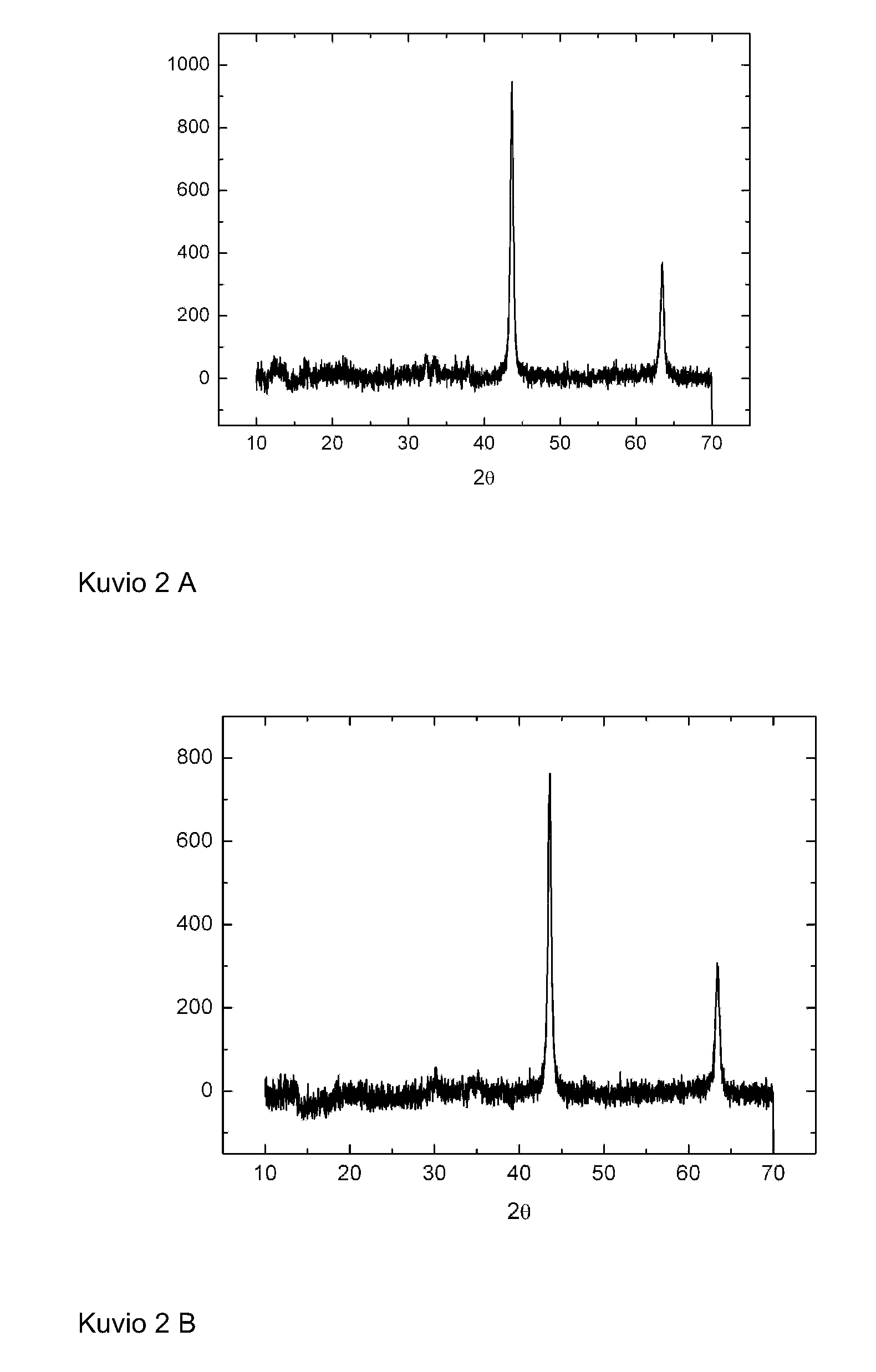

Process of preparing alkali metal titanates

ActiveUS20110278495A1Simple wayReduce the temperatureMaterial nanotechnologyAlkali titanatesPolymer scienceSlurry

A lithium titanate product, the formula of which is in the form of LixTiyOz, and wherein, when y is 1, the x:y molar ratio is 1.1-1.8, while the z:y molar ratio is 2.0-4.5. Also disclosed is a method of preparing alkali metal titanates, such as lithium titanate, at a low temperature of below 100° C., from an aqueous titanium-containing slurry and an alkali metal compound.

Owner:VENATOR P&A FINLAND OY

Zinc-lithium alloy material and preparation method thereof

InactiveCN101748313ASolve the problem of adding difficultyHigh lithium contentVacuum evaporation coatingSputtering coatingVacuum pumpingAlloy

The invention discloses a zinc-lithium alloy material and a preparation method thereof. The content of lithium is 0.5-4.0% (by mass) in the zinc-lithium alloy material and the balance is Zn. The invention also discloses a technology of producing plasma sputtering target materials used in the silicon chip of an integrated circuit. The preparation method of the zinc-lithium alloy comprises the following steps: weighing high purity lithium and high purity zinc with the content of lithium 10-20% higher than the required ratio; putting the zinc into a high purity graphite crucible, putting the crucible into a vacuum furnace, wrapping the lithium with high purity zinc foil and placing the wrapped lithium into the feed hopper of the vacuum furnace; vacuum pumping; raising the temperature to 450-500 DEG C to melt the zinc; filling argon; adding the high purity lithium and refining for 10-15 minutes at the temperature of 600-650 DEG C; and casting to obtain the zinc-lithium alloy material.

Owner:BEIJING INST OF NONFERROUS METALS & RARE EARTH

Method for preparing stoichiometric proportion lithium niobate or lithium tantalate wafer

InactiveCN101275275AHigh lithium contentLow costPolycrystalline material growthSingle crystal growth detailsPhysical chemistryVacuum level

A method manufactures lithium niobate or lithium tantalite wafer in stoichiometric proportion. Specific process is that putting the lithium niobate or lithium tantalite wafer in a sealed container, vacuumizing inner side of the sealed container, enabling vacuum level to be less than 0.5 Pa and maintaining a certain high temperature in the container, regulating branch pressure of various components inside by highly purified argon to prevent from chap on surface of the wafer; processing 60h to 120h to obtain manufactures lithium niobate or lithium tantalite wafer in stoichiometric proportion. Compared with conventional method (patent application number; 0114332.4), firstly, the invention that replaces multi-crystal material with lithium-comprising compound, by repeat use, reduces cost greatly; secondly, the invention improves lithium content in the atmosphere, improves spread speed and reduces spread time; thirdly, regulating lithium content in the atmosphere by argon to use the lithium compound with different vapor tensions.

Owner:NANKAI UNIV

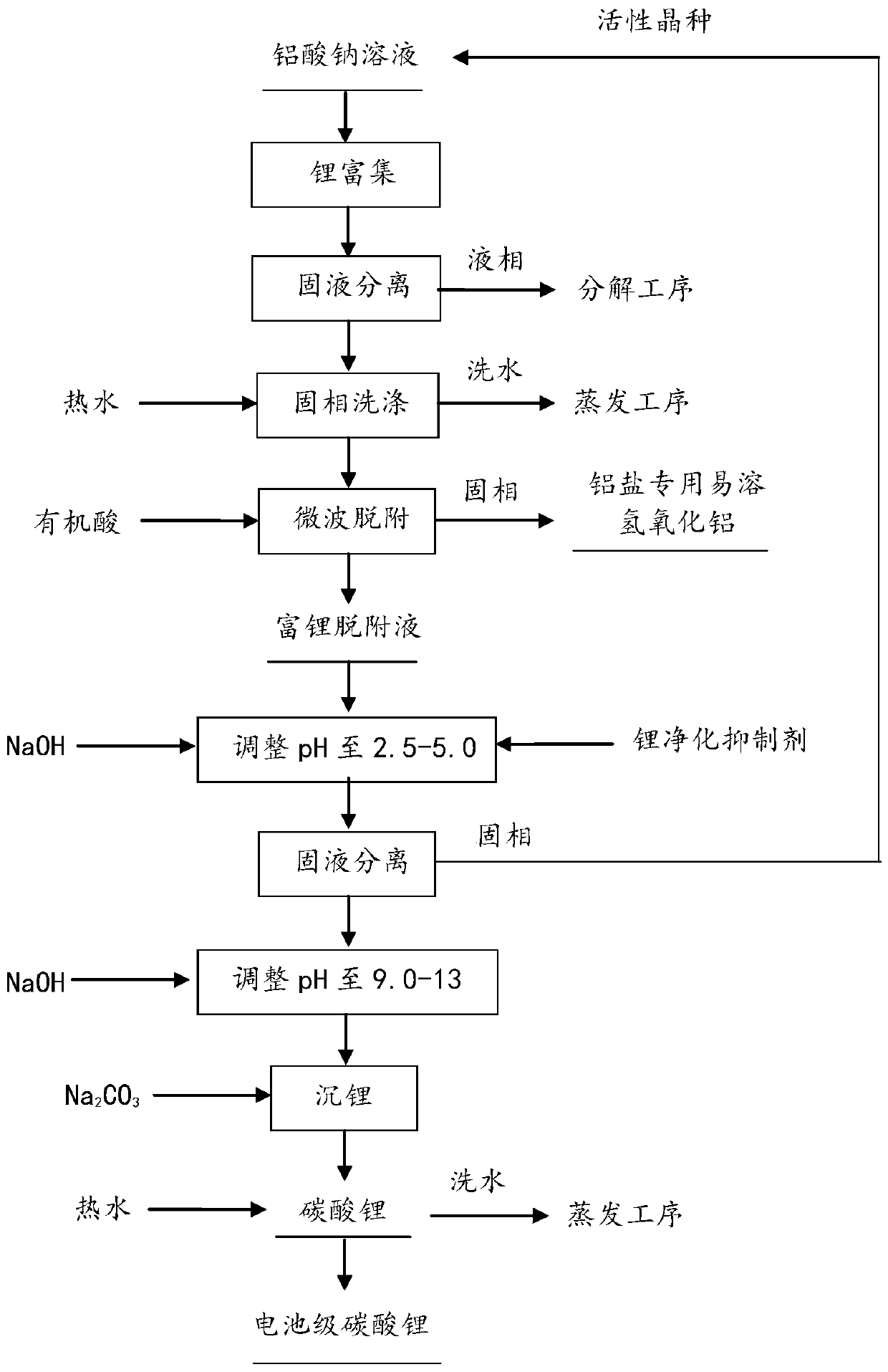

Method for extracting lithium from alumina production process and preparing battery-grade lithium carbonate

ActiveCN110627095AHigh extraction rateHigh lithium contentAluminates/aluminium-oxide/aluminium-hydroxide purificationProcess efficiency improvementAluminum IonOrganic acid

The invention relates to a method for extracting lithium from an alumina production process and preparing battery-grade lithium carbonate. The method comprises the following steps of: cooling a refined solution, and carrying out a reaction with an acidic compound to prepare an aluminum hydroxide active seed crystal; then, mixing the active seed crystal with a sodium aluminate solution to enrich lithium in the sodium aluminate solution to obtain lithium-rich aluminum hydroxide; mixing the lithium-rich aluminum hydroxide and an organic acid to carry out a microwave desorption reaction, and carrying out solid-liquid separation after the reaction is completed, wherein the solid is lithium-free aluminum hydroxide and the liquid is lithium-rich desorption liquid; adding alkali liquor to the lithium-rich desorption solution to adjust the pH value, and adding a lithium purification inhibition agent to remove aluminum ions, iron ions, calcium ions and magnesium ions to obtain a lithium-rich refined solution; and adding a saturated sodium carbonate solution to the lithium-rich refined solution to precipitate lithium to obtain crude lithium carbonate, and repeatedly the washing crude lithiumcarbonate with high-purity water to obtain the battery-grade lithium carbonate. The method realizes high-efficiency high-quality extraction of lithium in the alumina production process, and is in seamless connection with the existing alumina production process. The method has a simple process and low production cost and is suitable for industrial promotion.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

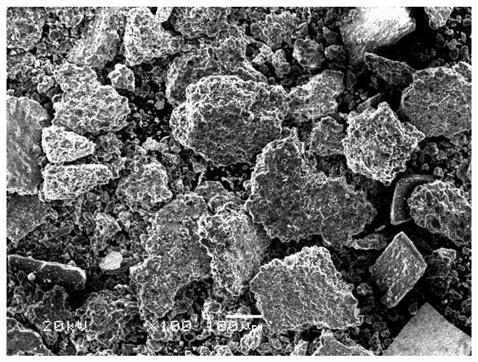

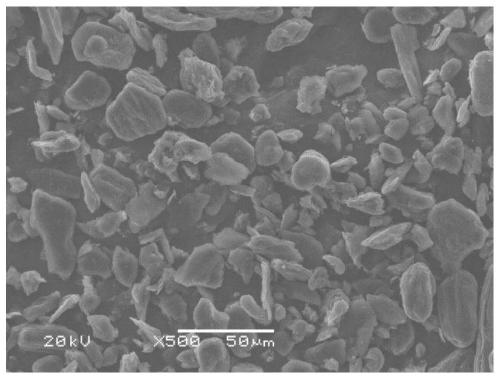

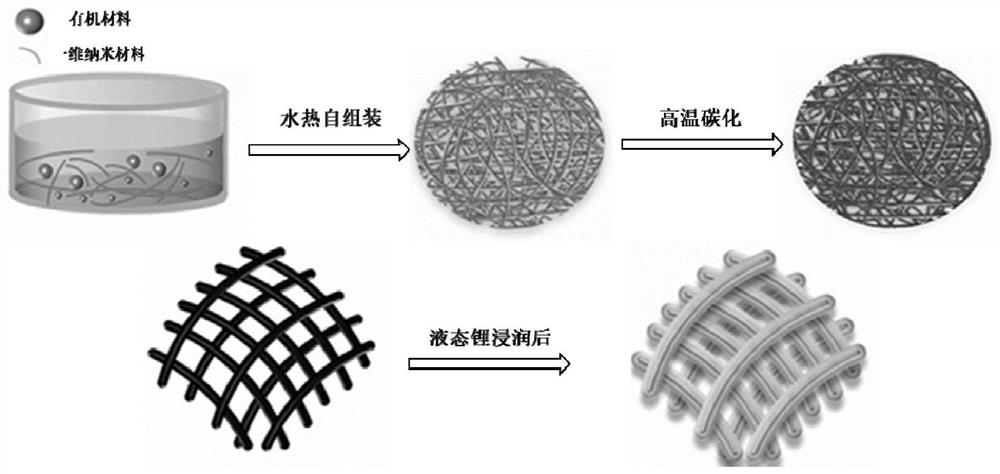

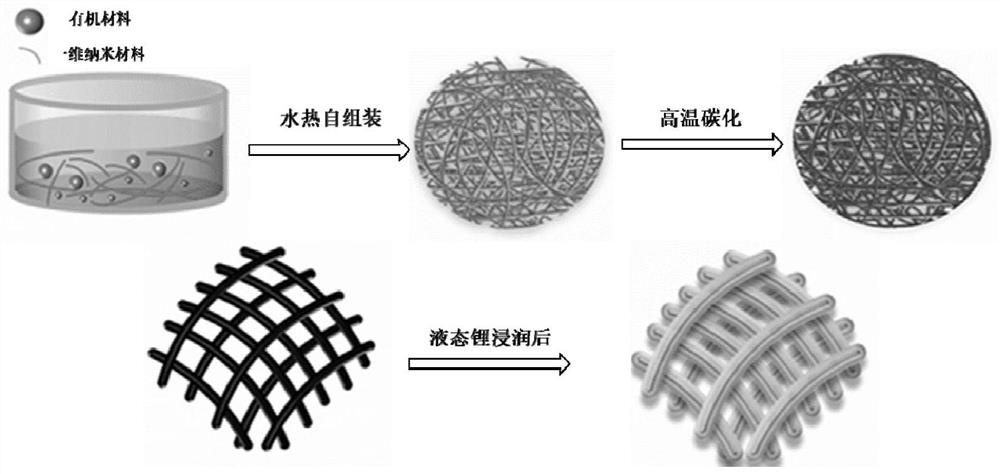

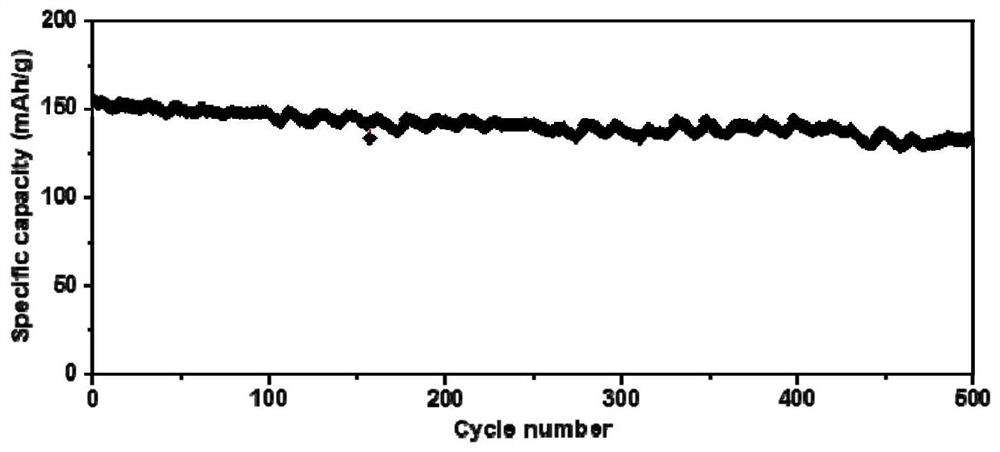

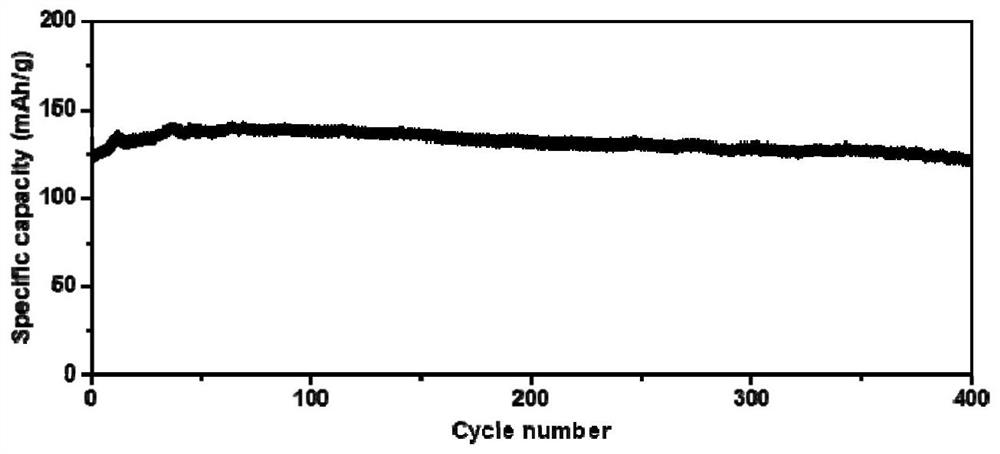

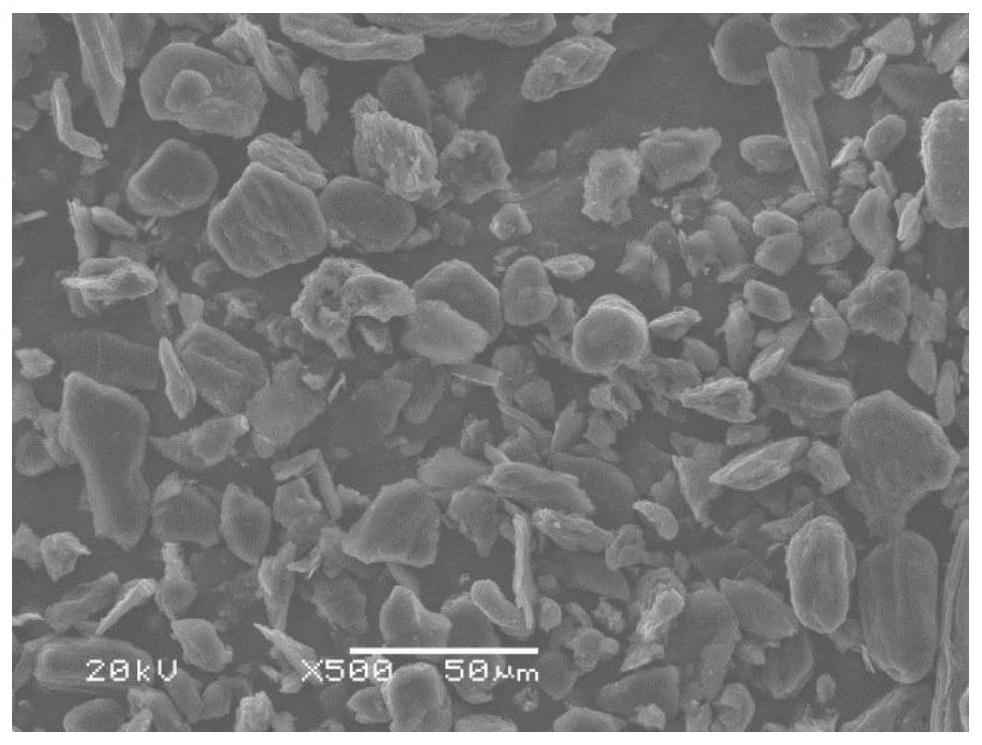

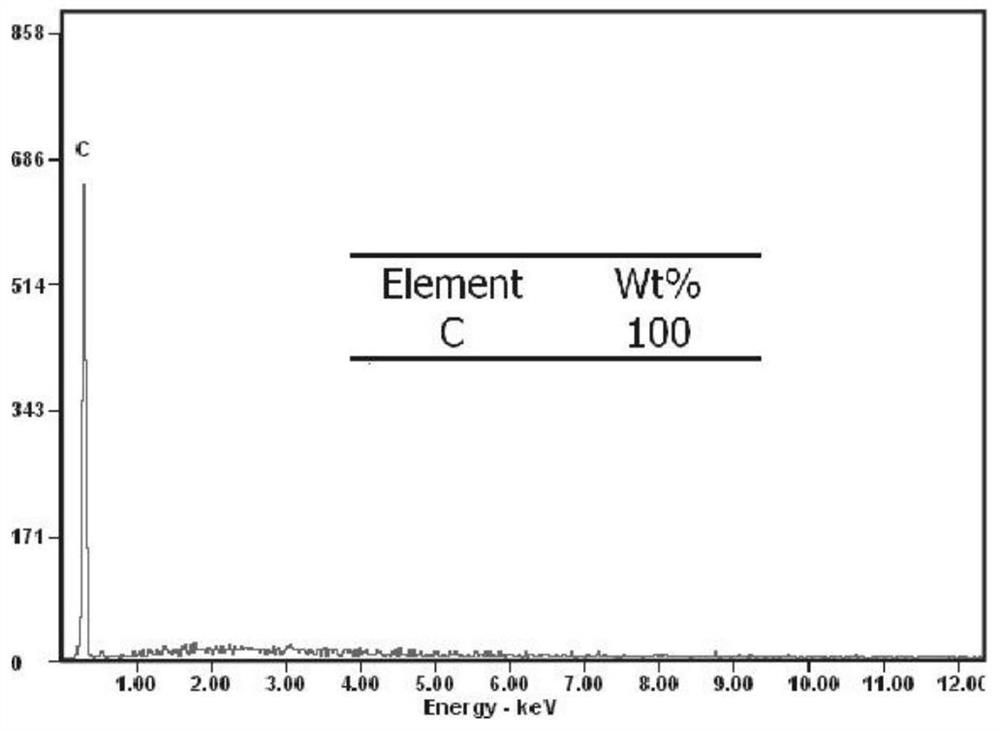

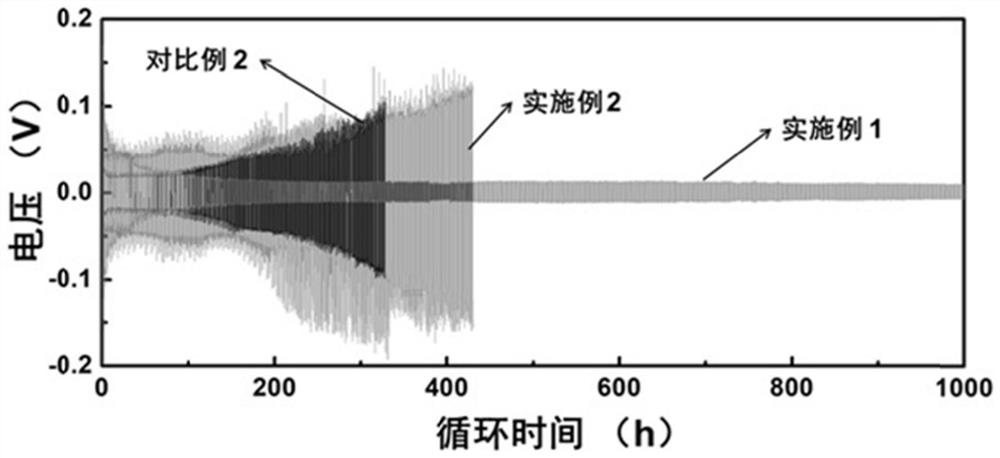

Preparation method of lithium metal negative electrode based on lithium-philic three-dimensional carbon-based current collector

ActiveCN112750987AHigh lithium contentImprove performanceElectrode carriers/collectorsNegative electrodesMetallic lithiumBattery cell

The invention belongs to the technical field of lithium metal batteries, and discloses a preparation method of a lithium metal negative electrode of a lithium-philic three-dimensional carbon-based current collector. The preparation method comprises the following steps of: firstly, self-assembling a one-dimensional nano material and an organic material to obtain a three-dimensional precursor framework material; secondly, carrying out high-temperature carbonization treatment on the three-dimensional precursor framework material to prepare the lithium-philic three-dimensional carbon-based current collector with good wettability on liquid metal lithium; and heating metal lithium to 180-500 DEG C to obtain liquid metal lithium, mixing the liquid metal lithium with the lithium-philic three-dimensional carbon-based current collector, and after the liquid metal lithium is fully infiltrated, naturally cooling the to prepare the composite lithium metal negative electrode. Compared with a lithium sheet negative electrode, the composite lithium metal negative electrode prepared by the invention can greatly inhibit the growth of lithium dendrites, alleviate the volume expansion effect of the lithium negative electrode in the deposition / stripping process, and realize long-life and high-stability circulation of lithium metal.

Owner:BEIHANG UNIV

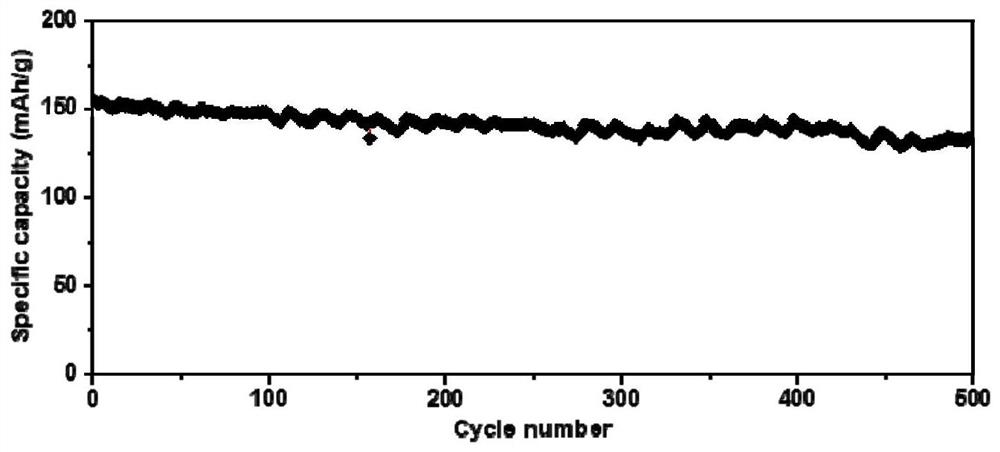

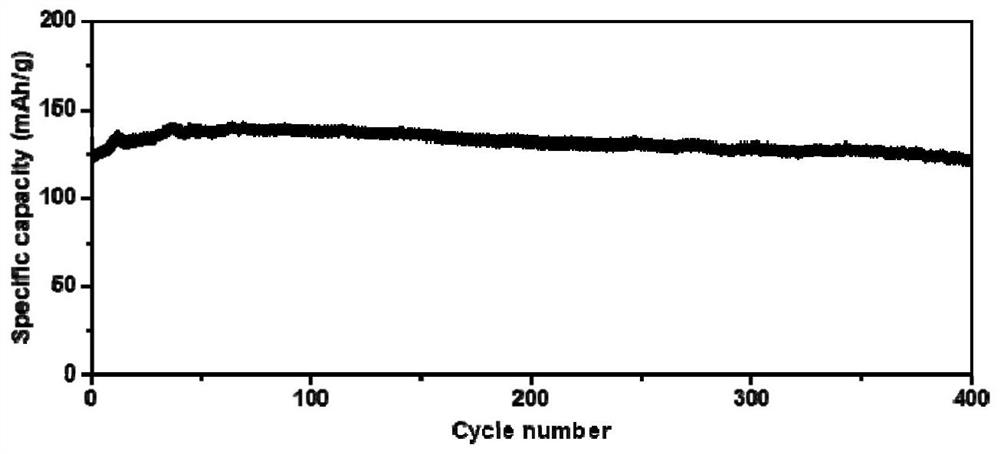

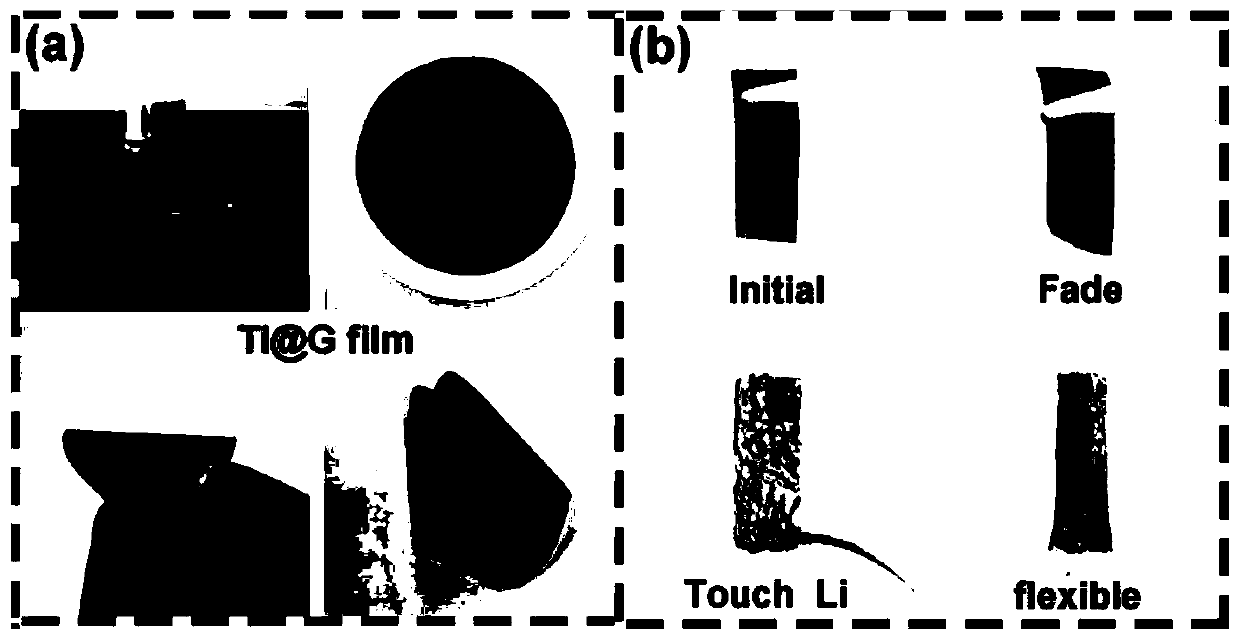

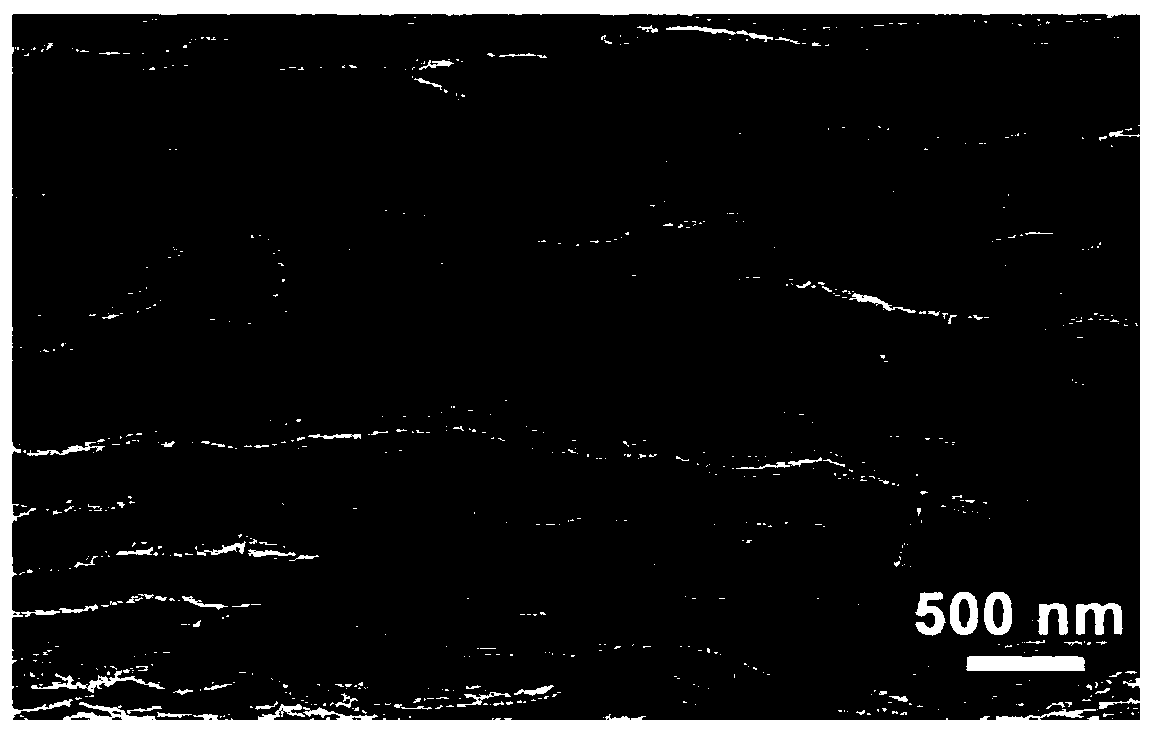

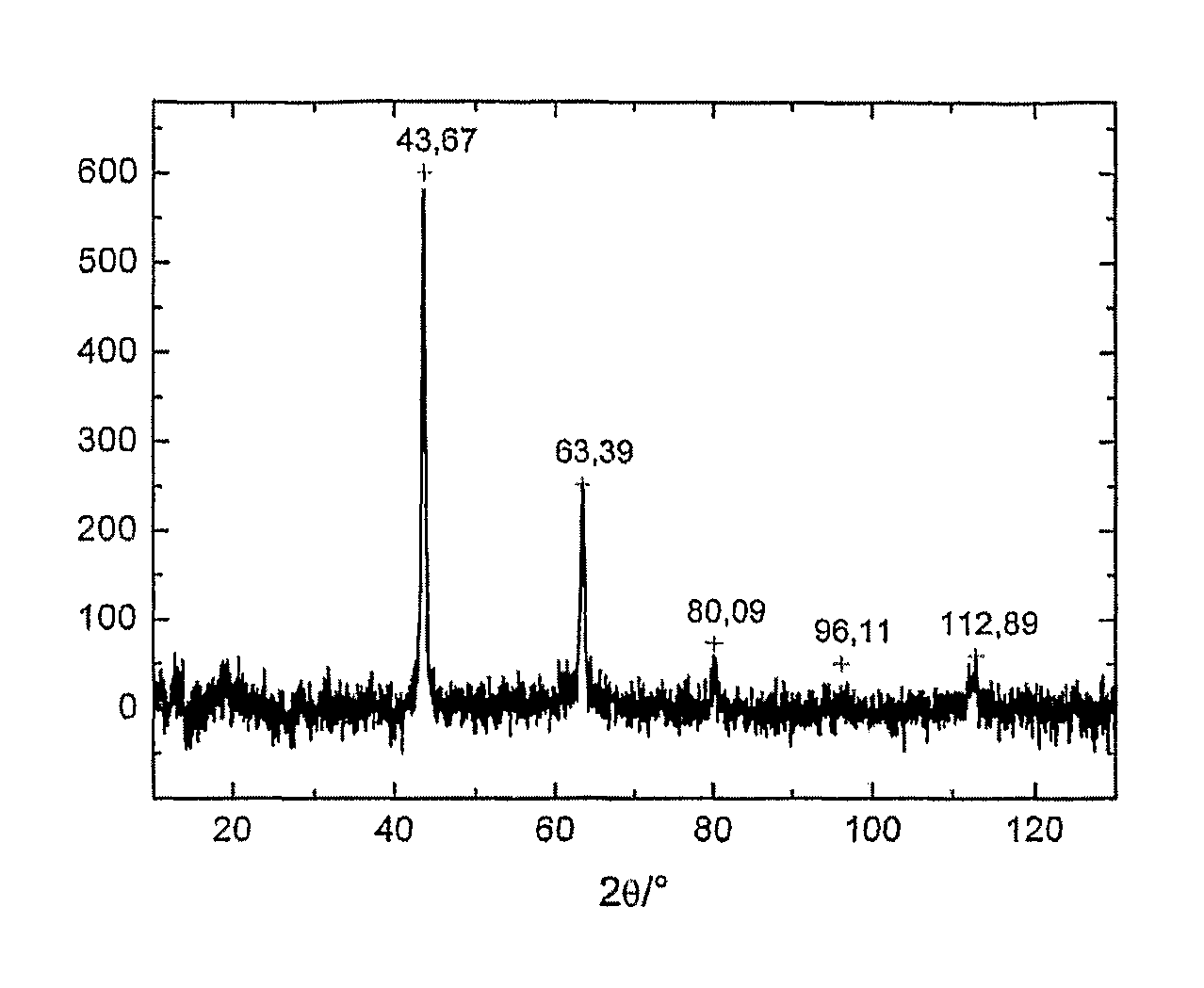

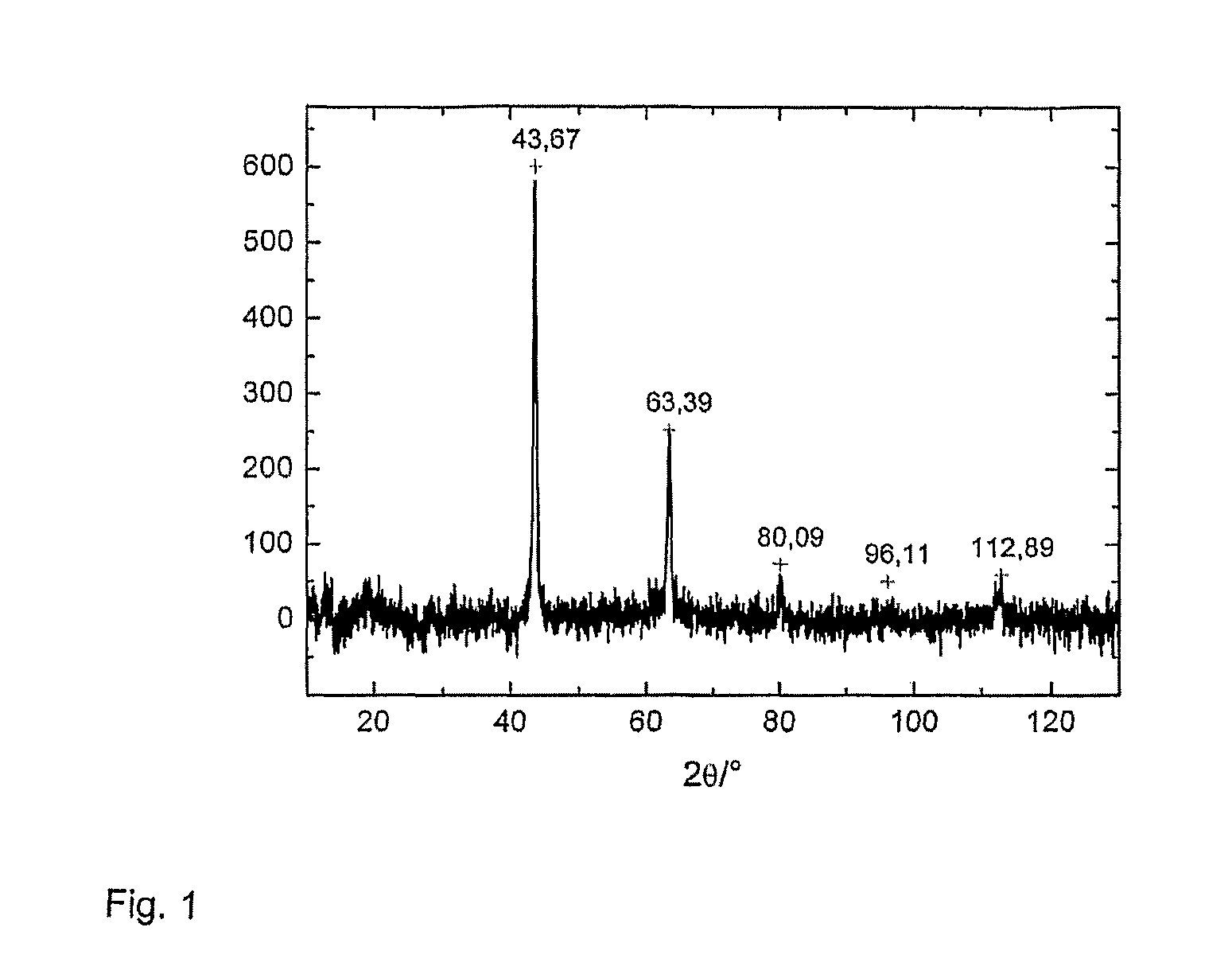

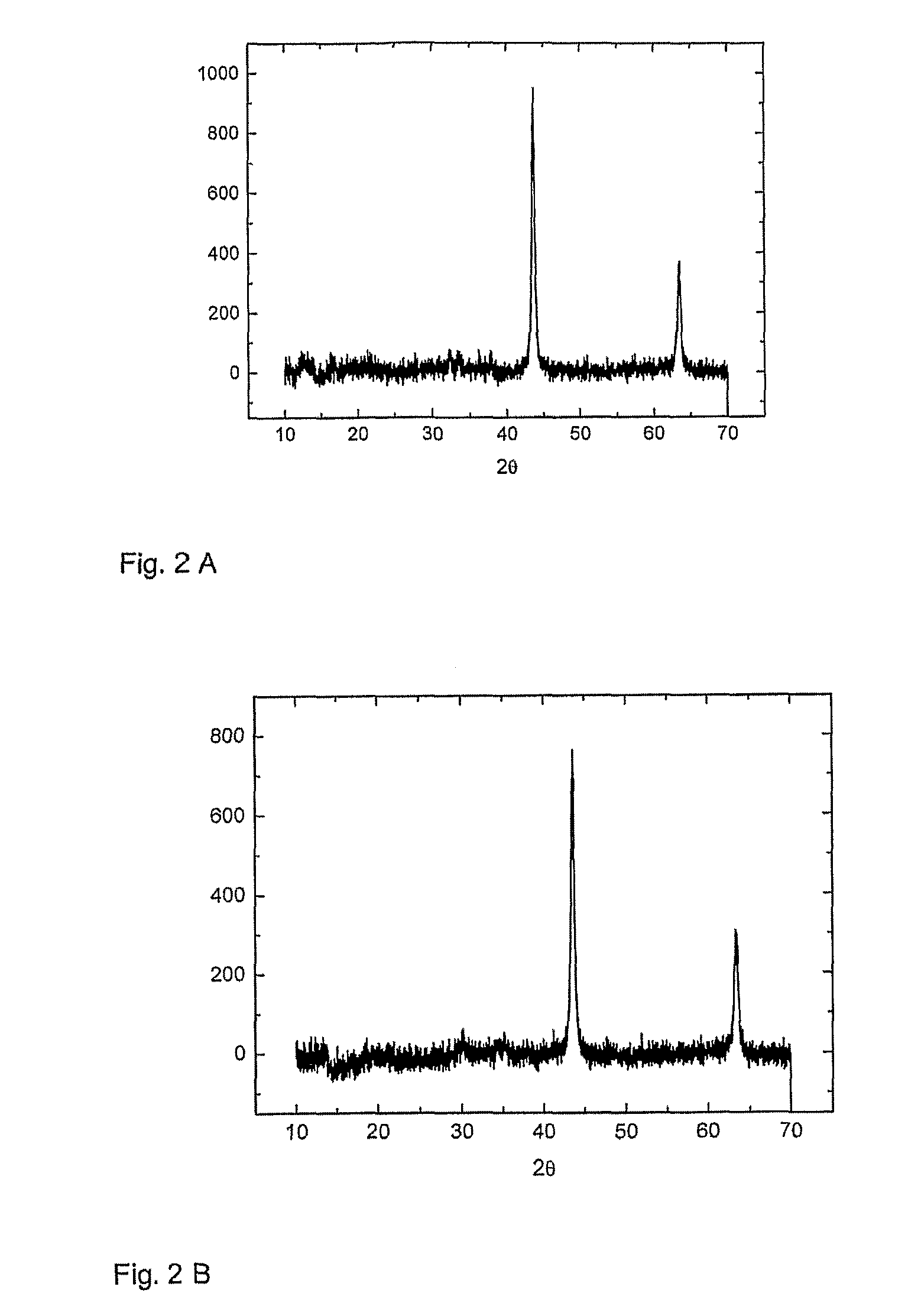

Li-Ti3C2-rGO composite thin film material and preparation method thereof

InactiveCN109755538AMass productionImprove mechanical propertiesElectrode manufacturing processesLi-accumulatorsComposite filmFiltration

The invention provides a Li-Ti3C2-rGO composite thin film material and a preparation scheme thereof. The Li-Ti3C2-rGO composite thin film material is prepared by the following steps that step 1, a GOdispersion solution and a Ti3C2 dispersion solution are prepared, the concentration of the GO dispersion solution and the Ti3C2 dispersion solution is 1-4mg / mL, after the GO dispersion solution and the Ti3C2 dispersion solution are mixed, stirring is carried out, and then ultrasonic treatment is carried out; step 2, the solution obtained in the step 1 is subjected to vacuum filtration in batches;step 3, a Ti3C2-GO thin film filtered by the step 2 is subjected to air drying naturally, a contact heat table is torn off from the filter film, so that the Ti3C2-GO thin film becomes a multihole Ti3C2-rGO thin film; and step 4, the multihole Ti3C2-rGO thin film in the step 3 is in contact with a molten lithium metal. According to the thin film prepared by the preparation scheme, the electrode hasgood flexibility, and is very useful for wearable electrode design; and the uniform and rapid combination of the lithium metal with the composite material can be realized, the lithium content of thethin film material is high, and the superstrong protection for the lithium metal can be realized.

Owner:HARBIN ENG UNIV

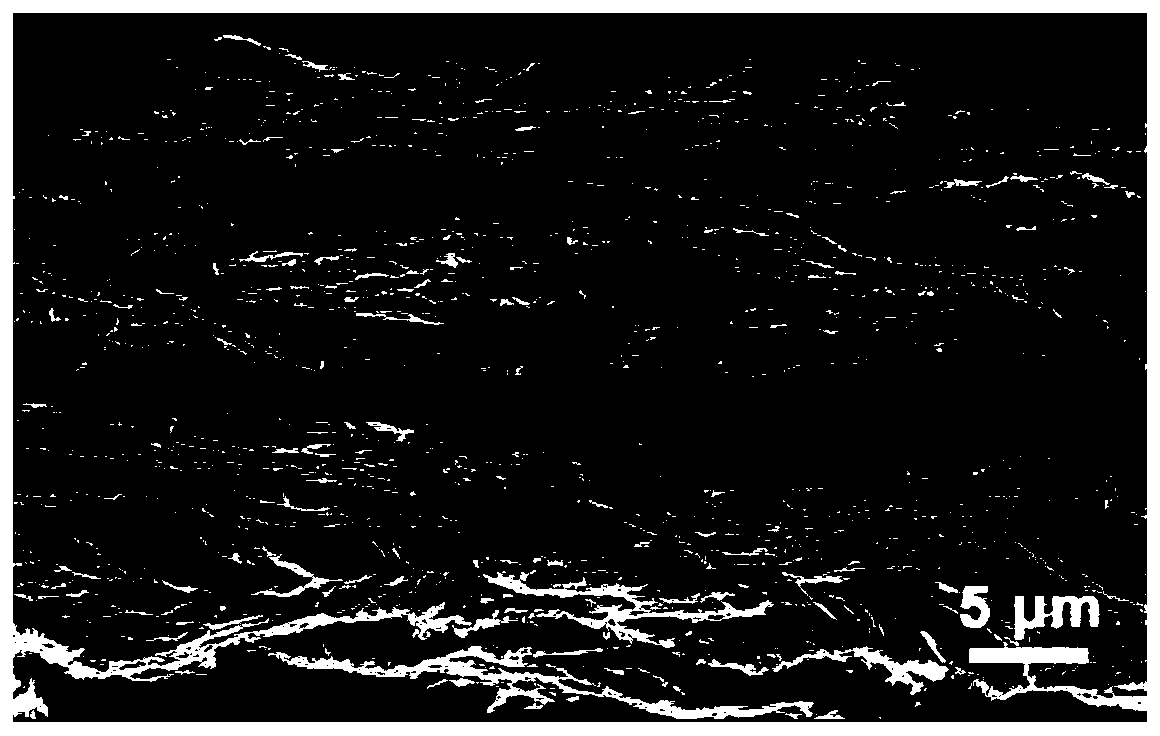

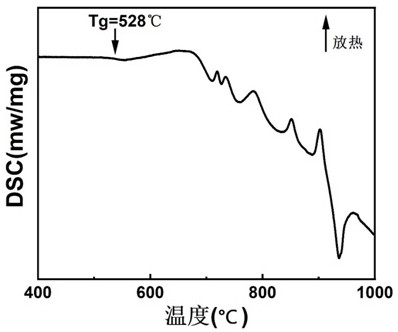

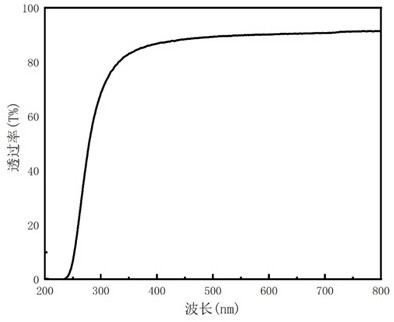

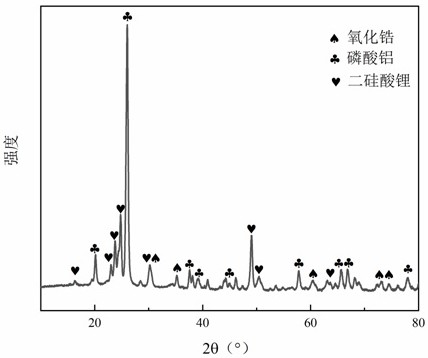

Glass material and preparation method and product thereof

ActiveCN113200678AHigh lithium contentHigh hardnessGlass reforming apparatusGlass severing apparatusPhosphate crystalsPhysical chemistry

The invention discloses a glass material and a preparation method and a product thereof. The glass material contains a lithium salt crystal phase and a phosphate crystal phase, the crystallinity of the whole material is 40-95%, the lithium salt crystal phase accounts for 40-90 wt%, the phosphate crystal phase accounts for 2-15 wt%, the lithium salt crystal phase is one or more of lithium silicate, lithium disilicate and petalite, and the phosphate crystal phase is aluminum phosphate or / and aluminum metaphosphate. The glass material has a Vickers hardness (Hv) of 900 kgf / mm<2> or more after tempering. The glass material or the substrate provided by the invention is suitable for protective members of mobile terminal equipment, optical equipment and the like, and has high hardness and strength. In addition, the material can also be used for outer frame members of portable electronic equipment and other decorations.

Owner:CHANGSHU JIAHE DISPLAY TECH CO LTD

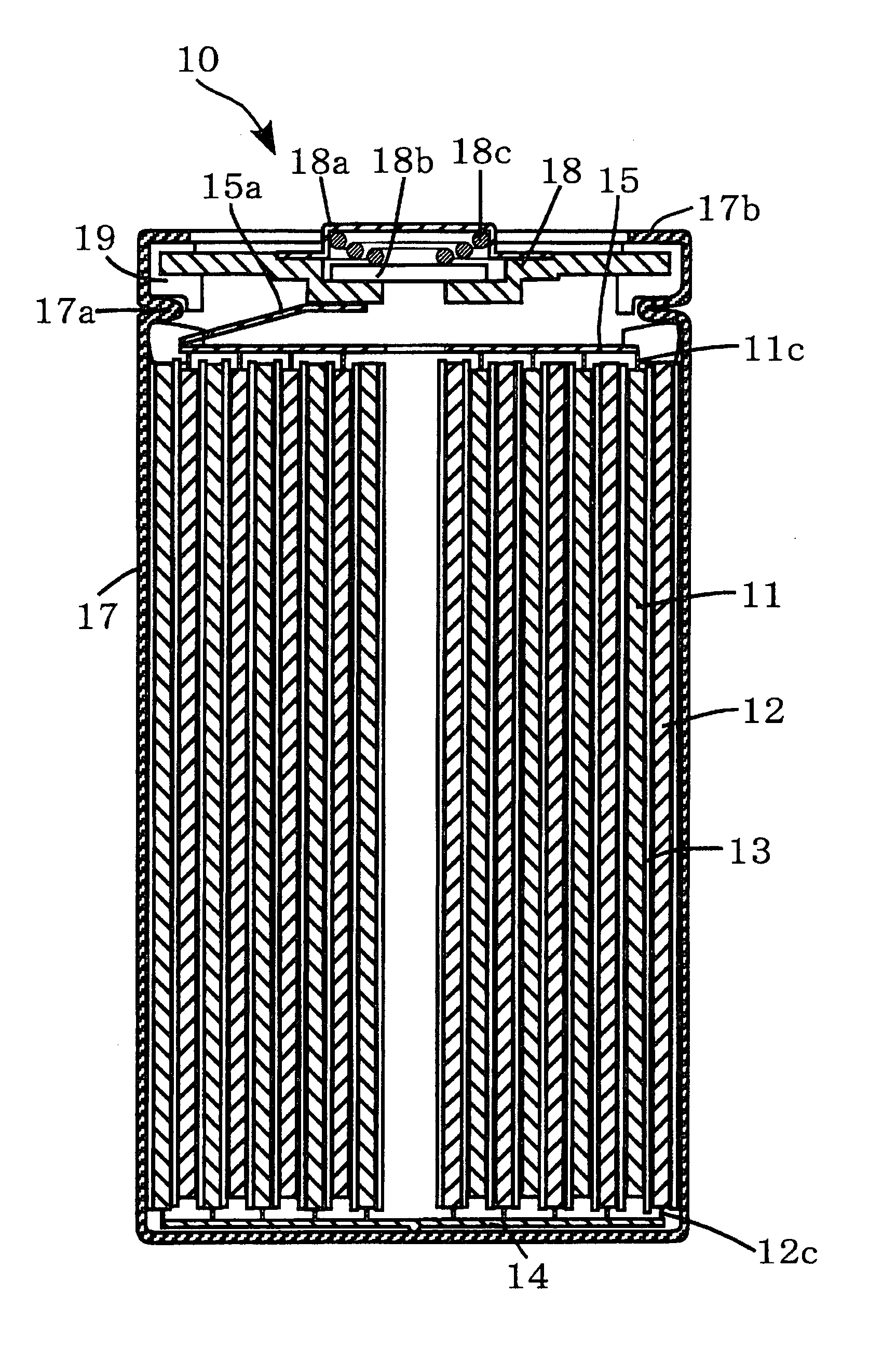

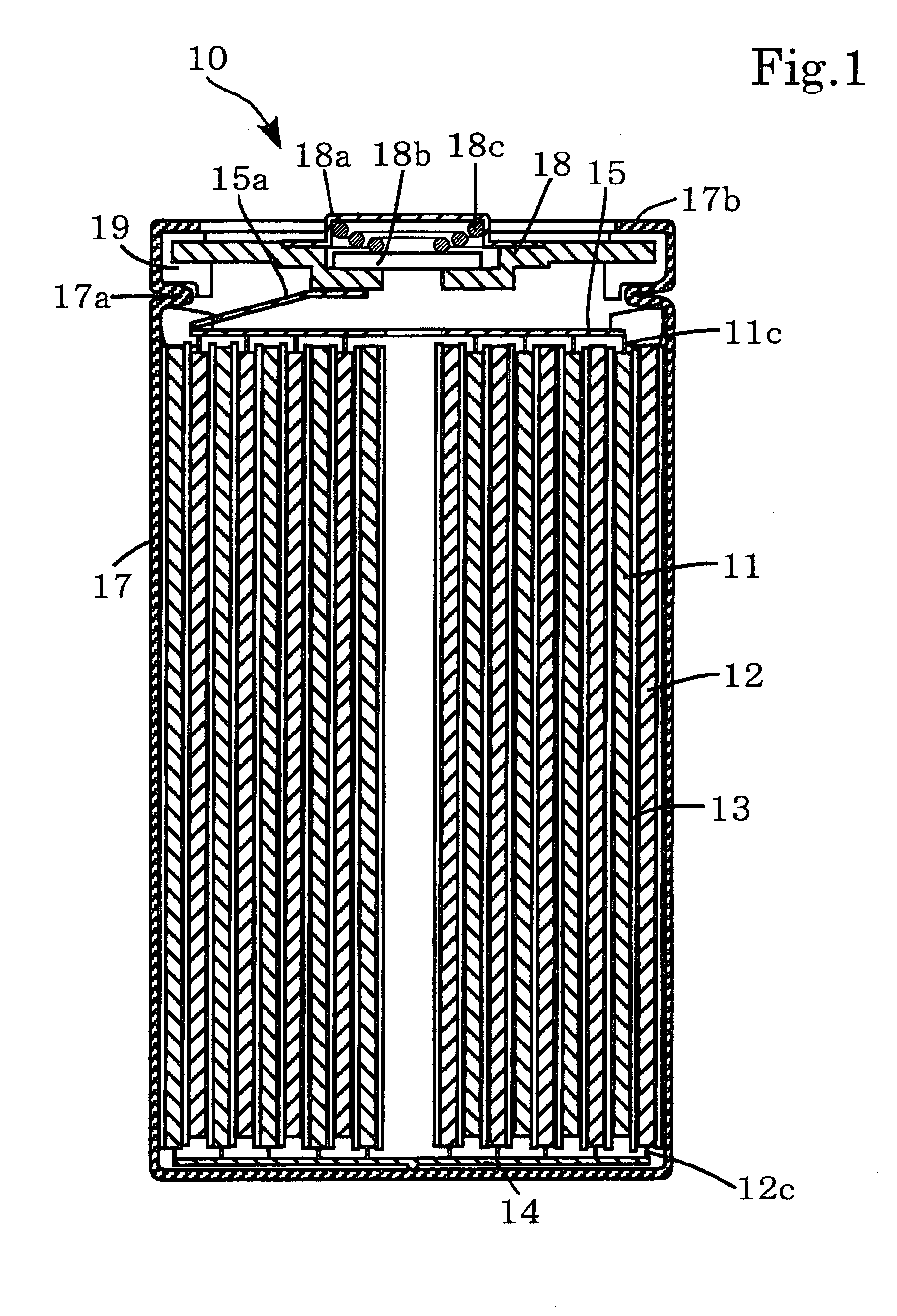

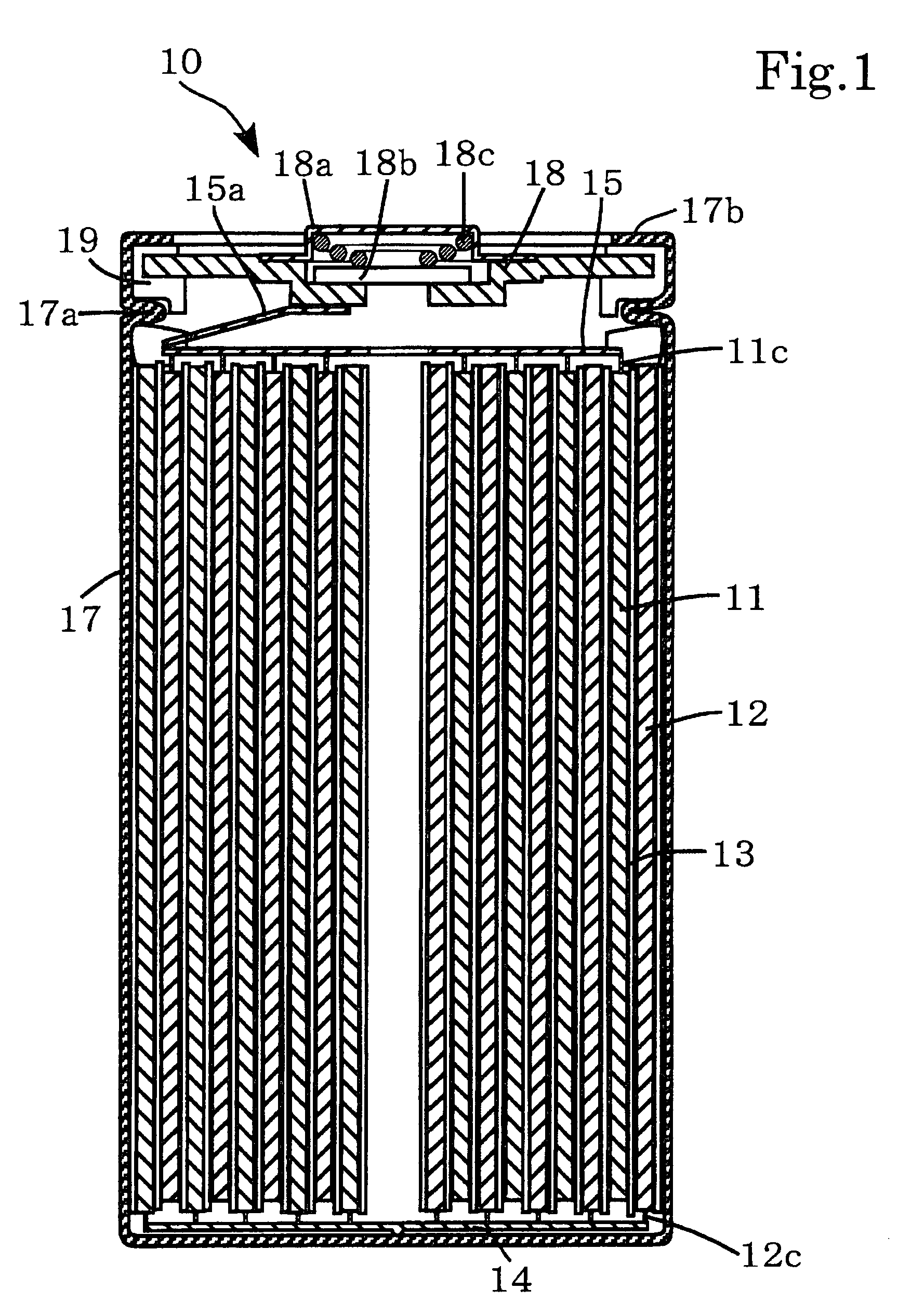

Alkaline storage battery system

InactiveUS20090087741A1Reduce addHigh lithium contentElectrode carriers/collectorsAlkaline accumulator electrodesLithiumPartial charge

An alkaline storage battery system according to an aspect of the present invention, with which a partial charging-discharging is performed, includes an alkaline storage battery 10 including an electrode group having a nickel positive electrode 11, a hydrogen storage alloy negative electrode 12, a separator 13; an alkaline electrolyte; and an outer can 14 accommodating the electrode group and the alkaline electrolyte, and further includes a partial charge-discharge control unit for controlling charging-discharging of the battery 10. In addition, zinc (Zn) is added to nickel hydroxide that is a main positive electrode active material in the nickel positive electrode 11 with an addition amount of 5% by mass or less with respect to the mass of nickel in the positive electrode active material. The concentration of the alkaline electrolyte is 6.5 mol / L or less and the content of lithium in the alkaline electrolyte is 0.3 mol / L or more.

Owner:SANYO ELECTRIC CO LTD

Method for recycling lithium from waste lithium ion battery

PendingCN113964407AHigh recovery rateHigh purityWaste accumulators reclaimingBattery recyclingPhosphoric acidLithium-ion battery

The invention discloses a method for recovering lithium from a waste lithium ion battery. The method comprises the following steps: discharging the waste lithium ion battery, cutting a positive plate obtained by disassembling the waste lithium ion battery into blocks, soaking the blocks in a mixed solution of N-methyl pyrrolidone and dimethylacetamide, adding a mixed solution of orange juice and water, stirring, carrying out ultrasonic treatment, picking out an aluminum foil, filtering and drying to obtain a positive active material, uniformly mixing with a citric acid, roasting, uniformly mixing with sodium citrate, roasting, mixing with sodium hydroxide and sodium persulfate, and carrying out microwave roasting; leaching the roasted product in water, carrying out solid-liquid separation to obtain a filtrate A, adjusting the pH value of the filtrate A to be neutral, filtering, adding sodium sulfide, adjusting the pH value to be 8-10, stirring, and carrying out solid-liquid separation to obtain a filtrate B; and adjusting the pH value of the filtrate B to 2-3, mixing the filtrate B with a mixture of 1-carboxymethyl-3-methylimidazolium hexafluorophosphate, the acetic acid and tributyl phosphate, stirring at a room temperature for 10-35 minutes, and centrifuging. The method provided by the invention is simple and feasible in process, high in lithium ion recovery rate and good in purity.

Owner:LONGNAN JINTAIGE COBALT IND CO LTD

Lithium flow battery reactor and electrode suspension liquid lithium intercalated synthesis method

ActiveCN103117406BHigh lithium contentImprove performanceFinal product manufactureRegenerative fuel cellsSynthesis methodsElectric capacity

The invention discloses a lithium flow battery reactor and an electrode suspension liquid lithium intercalated synthesis method. The battery reactor is formed by fixing one or more assembled structures respectively consisting of a negative current collection core, a lithium negative electrode, a hollowed bushing, a porous diaphragm and a positive current collection core in a reaction tank. Lithium intercalation is performed on electrode suspension liquid by utilizing the battery reactor in an electrochemical synthesis way, the electrode suspension liquid is injected into the reaction tank, lithium ions which are separated from the lithium negative electrode in the reaction tank are finally intercalated into active material particles of the electrode suspension liquid, and the electrochemical synthesis process and the lithium intercalation degree of the electrode suspension liquid in the reaction tank are controlled by adjusting the flow rate, the voltage and the circular reaction times of the electrode suspension liquid. Due to the adoption of the method, a stable lithium-enriched electrode material or a metastable-phase lithium-containing alloy with high electric capacity can be obtained, and the energy density and the cycle life of a battery can be improved.

Owner:BEIJING HAWAGA POWER STORAGE TECH +1

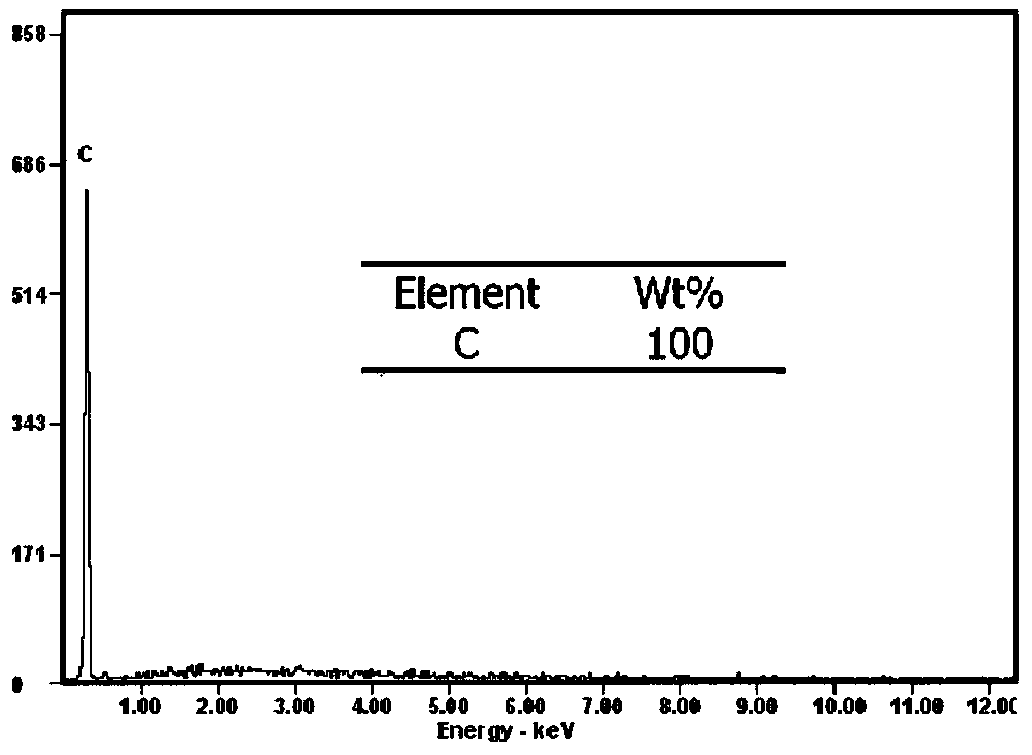

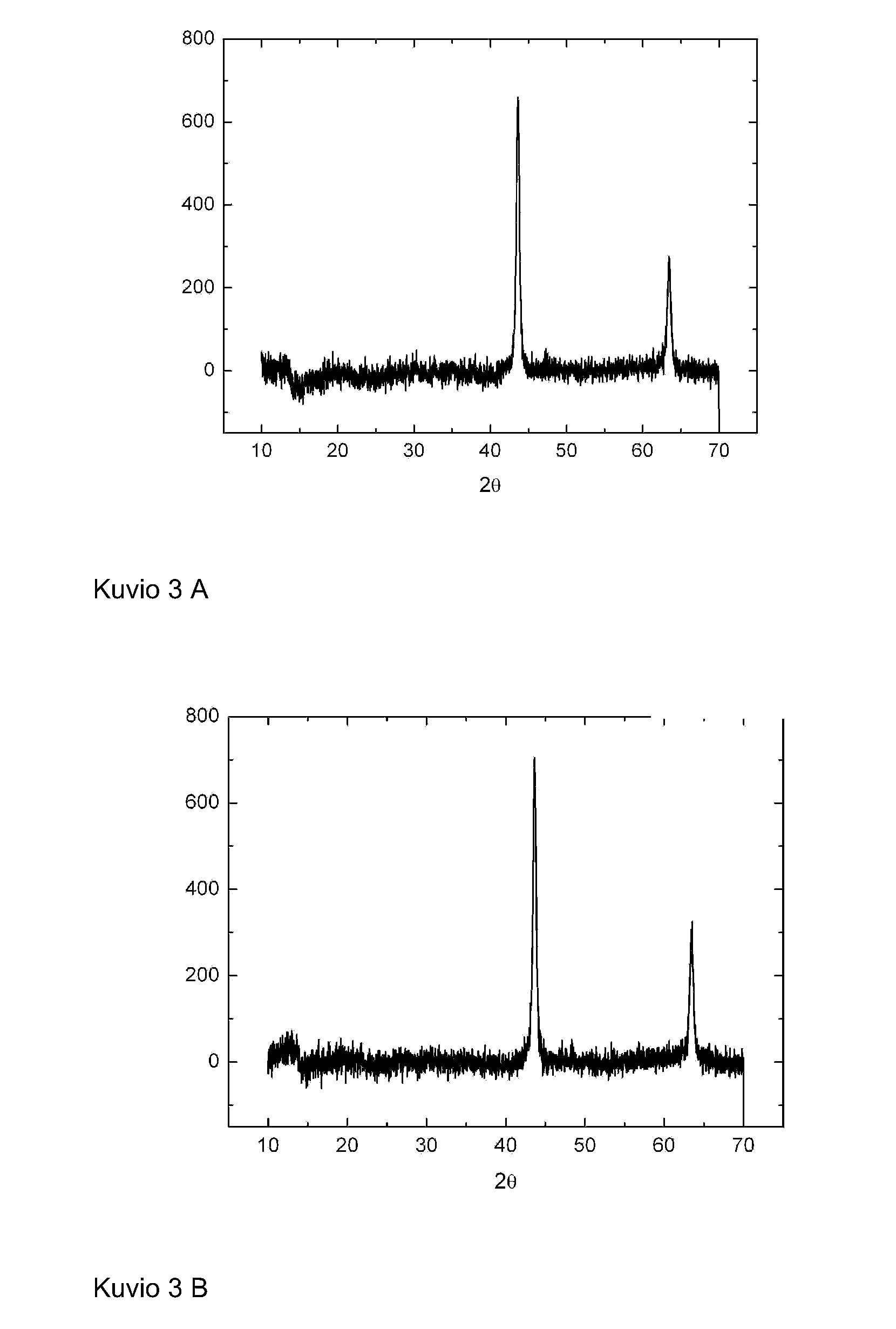

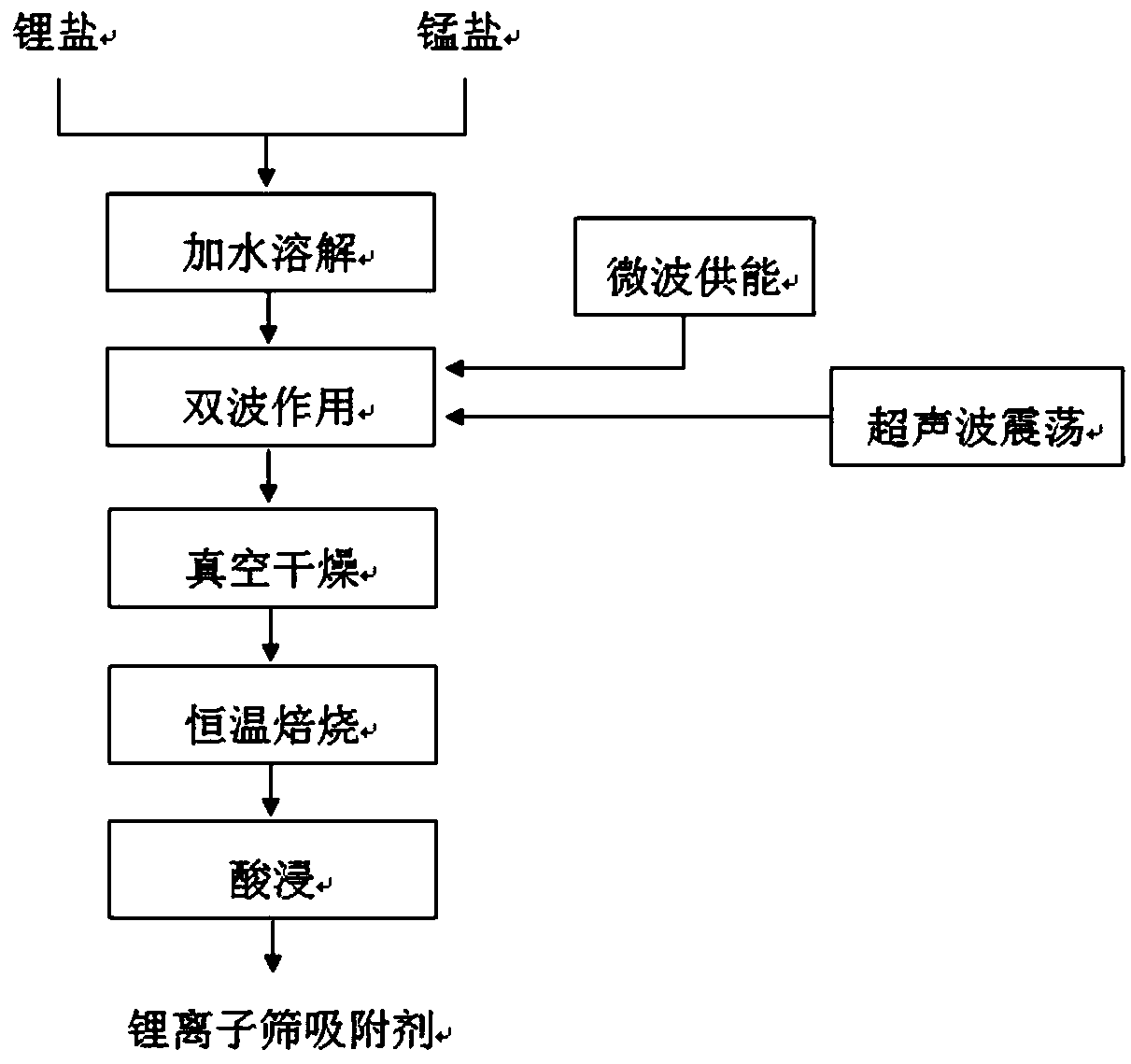

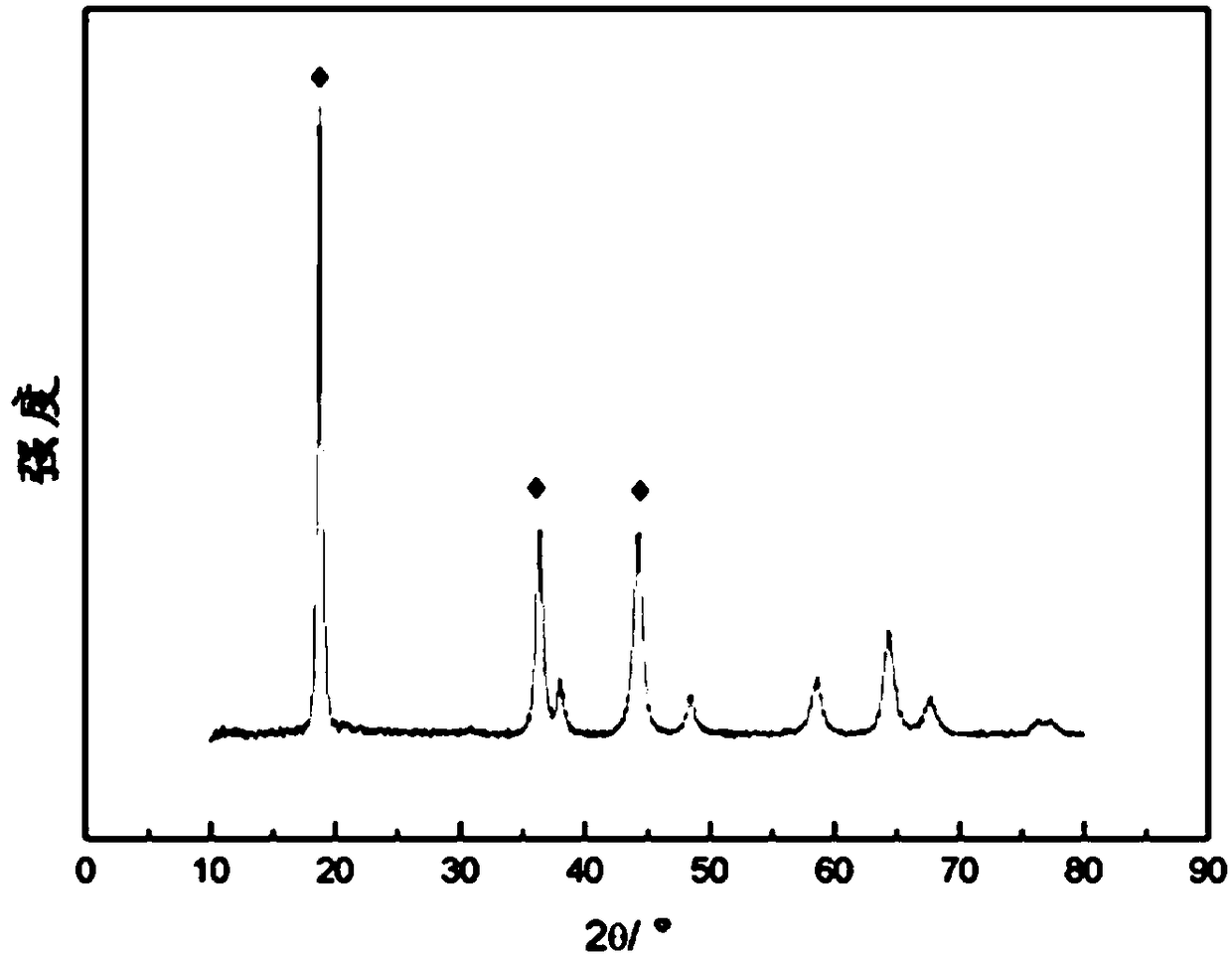

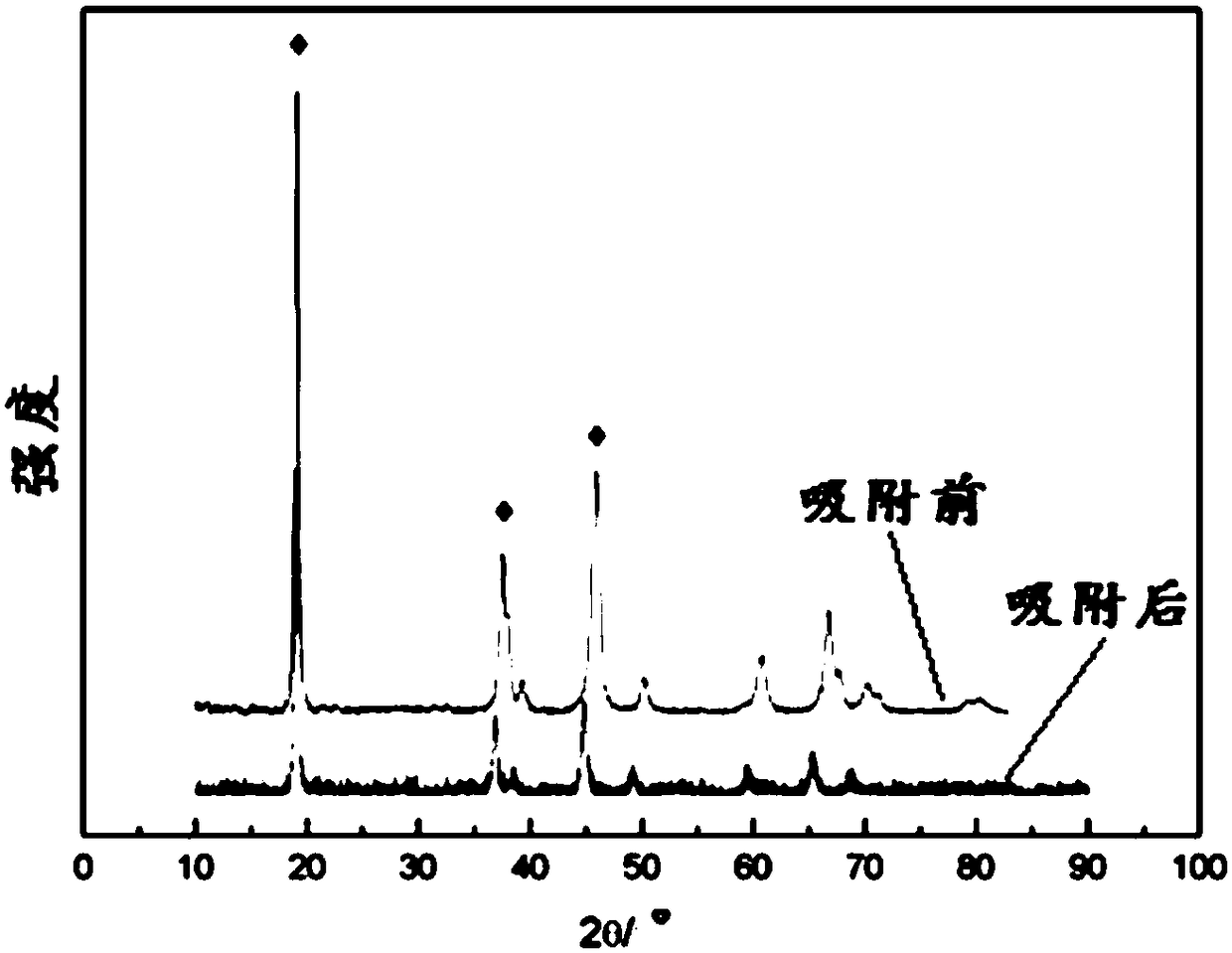

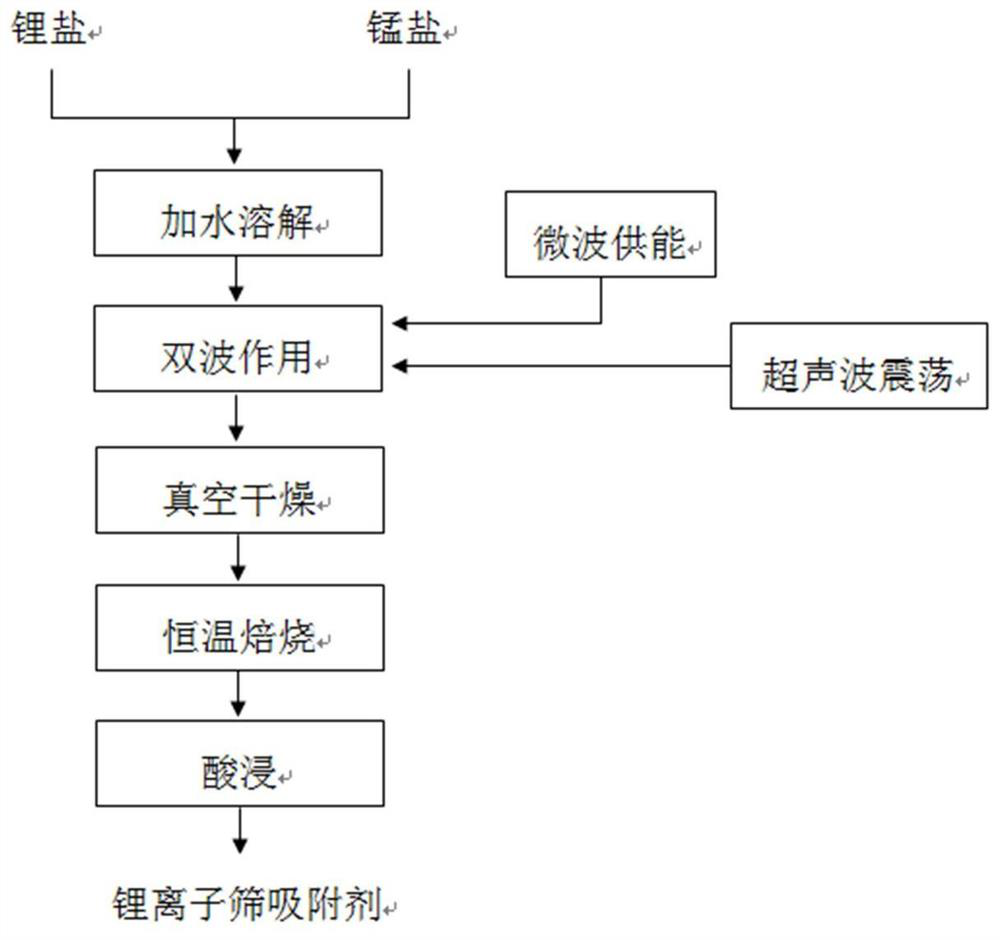

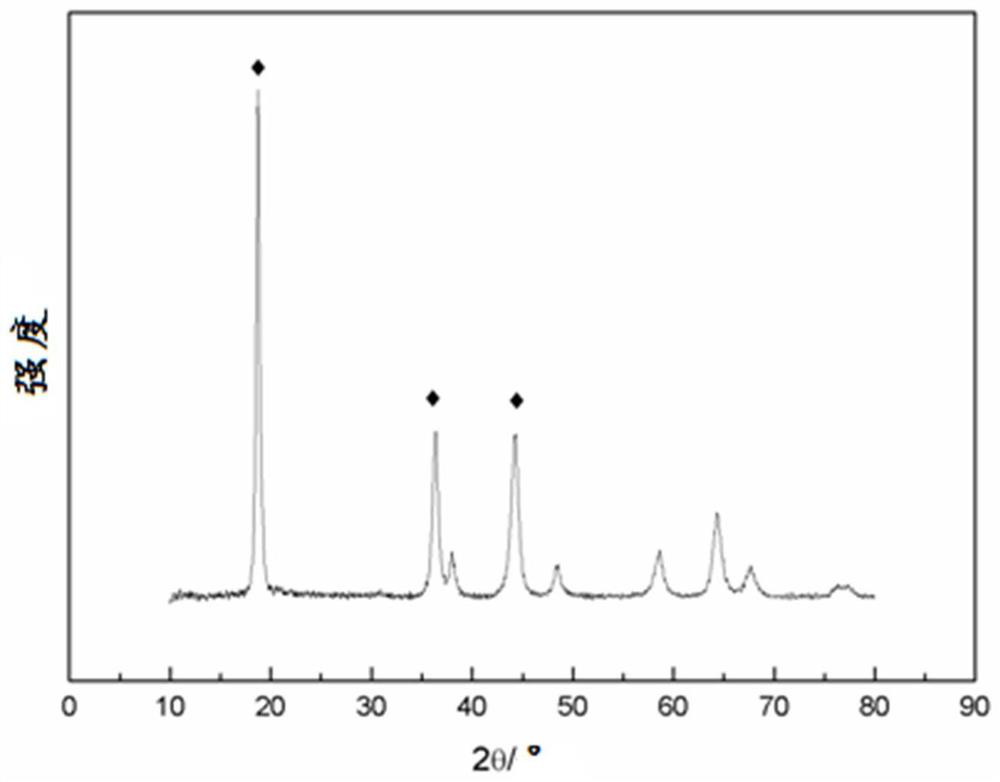

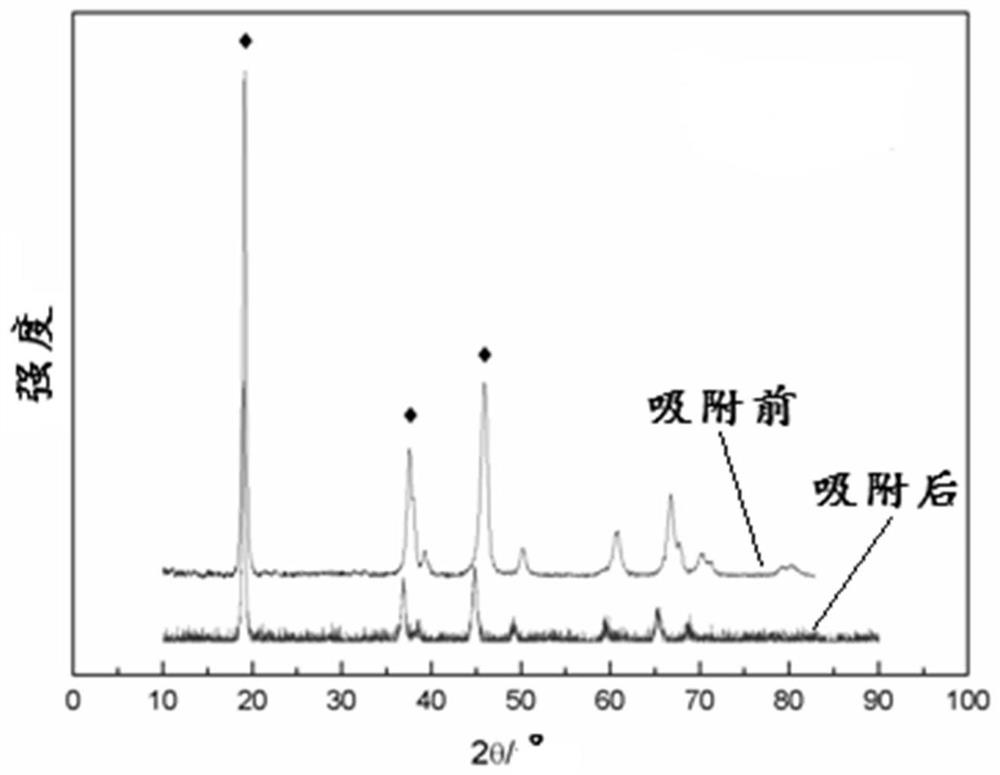

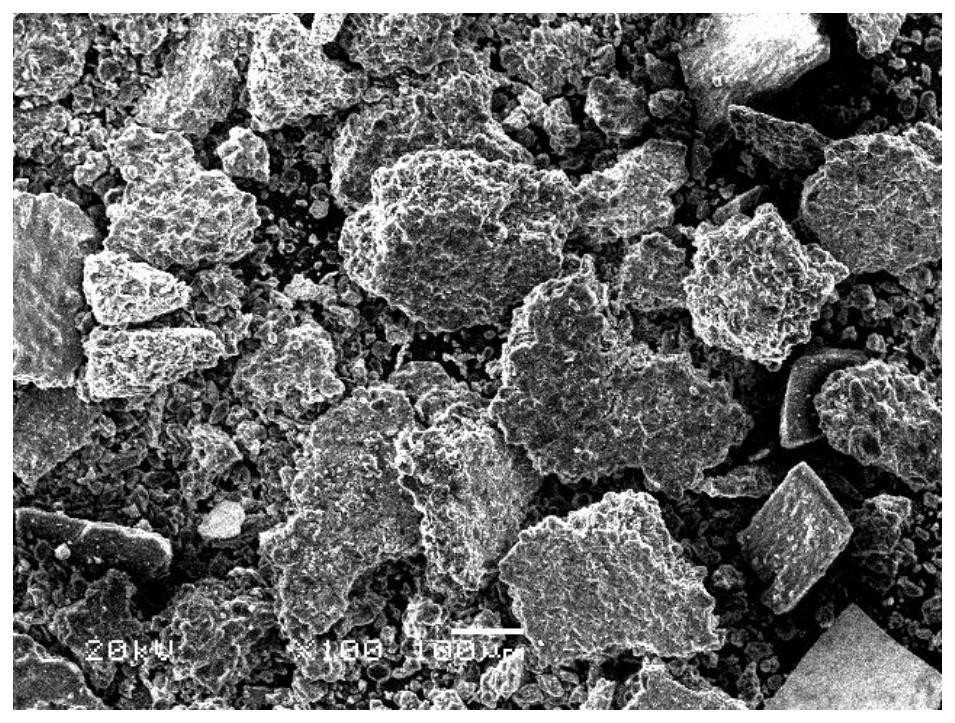

Method for preparing lithium ionic sieve adsorbent

ActiveCN109012564AImprove adsorption capacityStable structureOther chemical processesManganese oxides/hydroxidesMicrowaveLithium metal

The invention provides a method for preparing a lithium ionic sieve adsorbent. The method comprises the following steps: co-acting a raw material which is an aqueous solution of a lithium salt and a manganese salt by microwaves and ultrasonic waves to obtain a co-precipitation product, calcining the co-precipitation product to obtain a lithium ionic sieve precursor, and carrying out acid leachingon the lithium ionic sieve precursor to obtain the lithium ionic sieve adsorbent. The lithium salt and manganese salt mixed aqueous solution is used as the raw material, and precipitates under the co-action of the microwaves and the ultrasonic waves, the precipitate is calcined to obtain the lithium ionic sieve precursor with an ideal structure, a high purity and a high lithium content, and the lithium ionic sieve precursor is processed to obtain the lithium ionic sieve adsorbent. The lithium ionic sieve adsorbent has the advantages of stable structure and high adsorption capacity, and the method has the advantages of short time, low energy consumption and high controllability, and is of great significance to recycling lithium metal resources.

Owner:BEIJING UNIV OF TECH

Low-sodium aluminium-lithium intermediate alloy material and its preparation method

The invention discloses a low-sodium aluminium-lithium intermediate alloy material and its preparation method. The low-sodium aluminium-lithium intermediate alloy material contains, by weight, 8.0-25.0% of Li, less than or equal to 0.0001% of Na, less than or equal to 0.00005% of K and the balance Al. According to the preparation method, a mixed salt of pure lithium chloride and lithium fluoride is used as a covering agent; boron trioxide is used to remove sodium and potassium; and high-pure nitrogen or argon is used for gas refining. The melting operation process requires no inert gas or vacuum protection. The technology is simple. After the sodium removal technological process, the contents of sodium and potassium impurity in the alloy are low, wherein the mass fraction of sodium is less than or equal to 0.0001% and the mass fraction of potassium is less than or equal to 0.00005%. The technological method has advantages of high yield and little loss of raw materials, and can be adopted for quantitative preparation of the aluminium-lithium intermediate alloy with any lithium content.

Owner:HEBEI SITONG NEW METAL MATERIAL CO LTD +1

A preparation method of lithium metal negative electrode based on lithium-philic three-dimensional carbon-based current collector

ActiveCN112750987BHigh lithium contentImprove performanceElectrode carriers/collectorsNegative electrodesMetallic lithiumChemical physics

Owner:BEIHANG UNIV

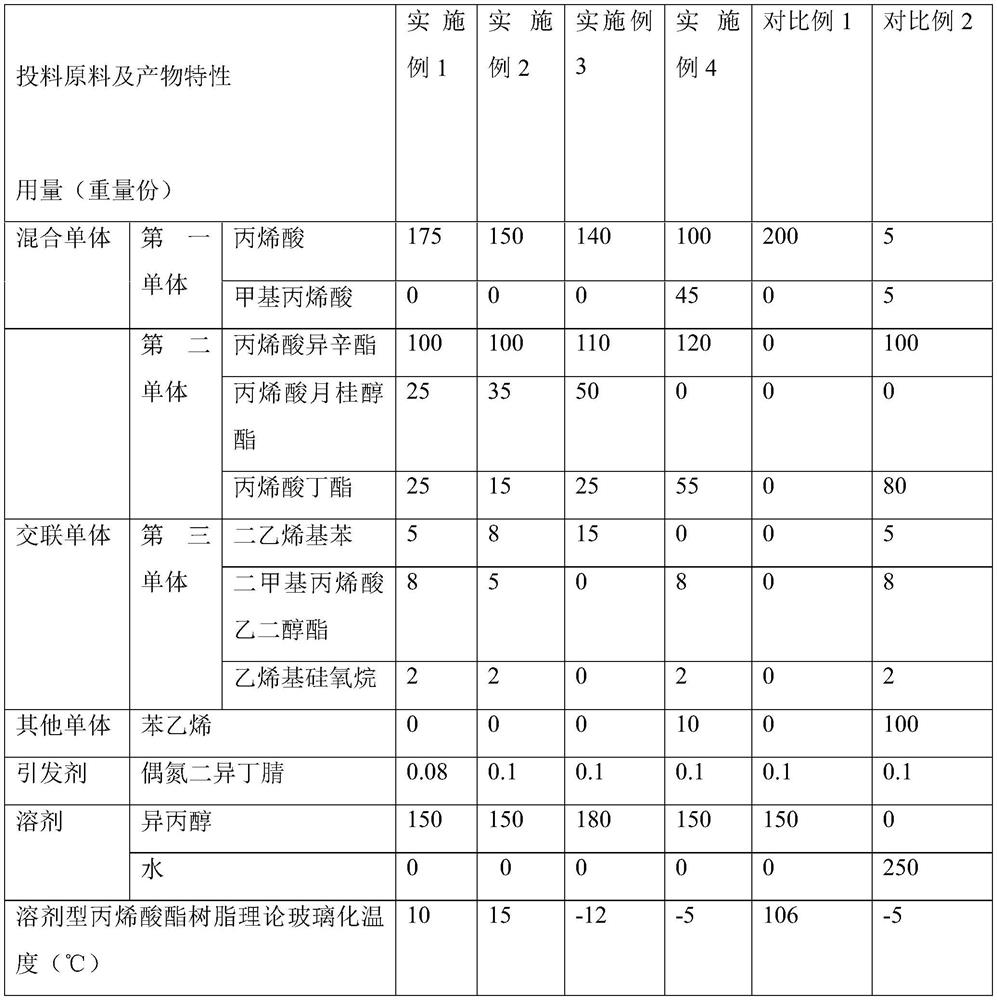

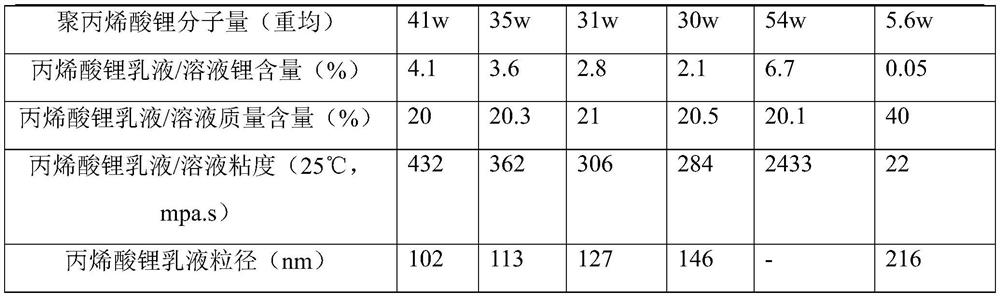

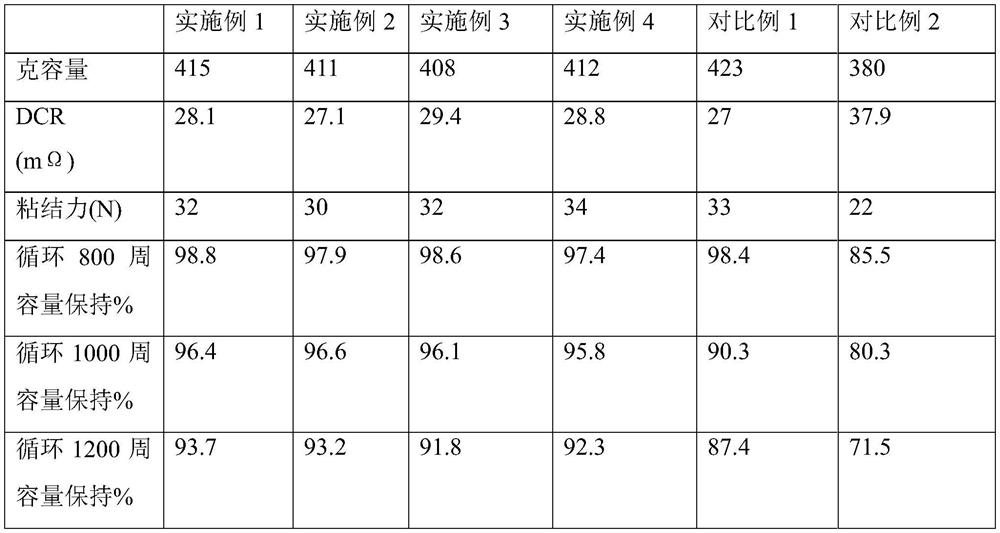

High-lithium-content and high-molecular-weight lithium acrylate emulsion as well as preparation method and application thereof

PendingCN114573746AGood controllabilityImprove electrochemical performanceCell electrodesSecondary cellsElectrochemistryAcrylate

The invention discloses a high-lithium-content high-molecular-weight lithium acrylate emulsion and a preparation method and application thereof in a lithium battery, and the method comprises the following steps: carrying out polymerization reaction on a polymer monomer in an organic solvent in the presence of an initiator to obtain solvent-type acrylate resin, wherein the composition of the polymer monomer is controlled such that the theoretical glass transition temperature of the solvent-based acrylate resin is-12 DEG C to 25 DEG C; and removing the organic solvent in the solvent-type acrylate resin, and adding a lithium hydroxide aqueous solution into the solvent-type acrylate resin at the same time, so as to obtain the lithium acrylate emulsion. The lithium content of the lithium acrylate emulsion can reach 5%, the molecular weight can reach 500,000, and the electrochemical performance of a lithium battery can be remarkably improved.

Owner:瑞红锂电池材料(苏州)有限公司

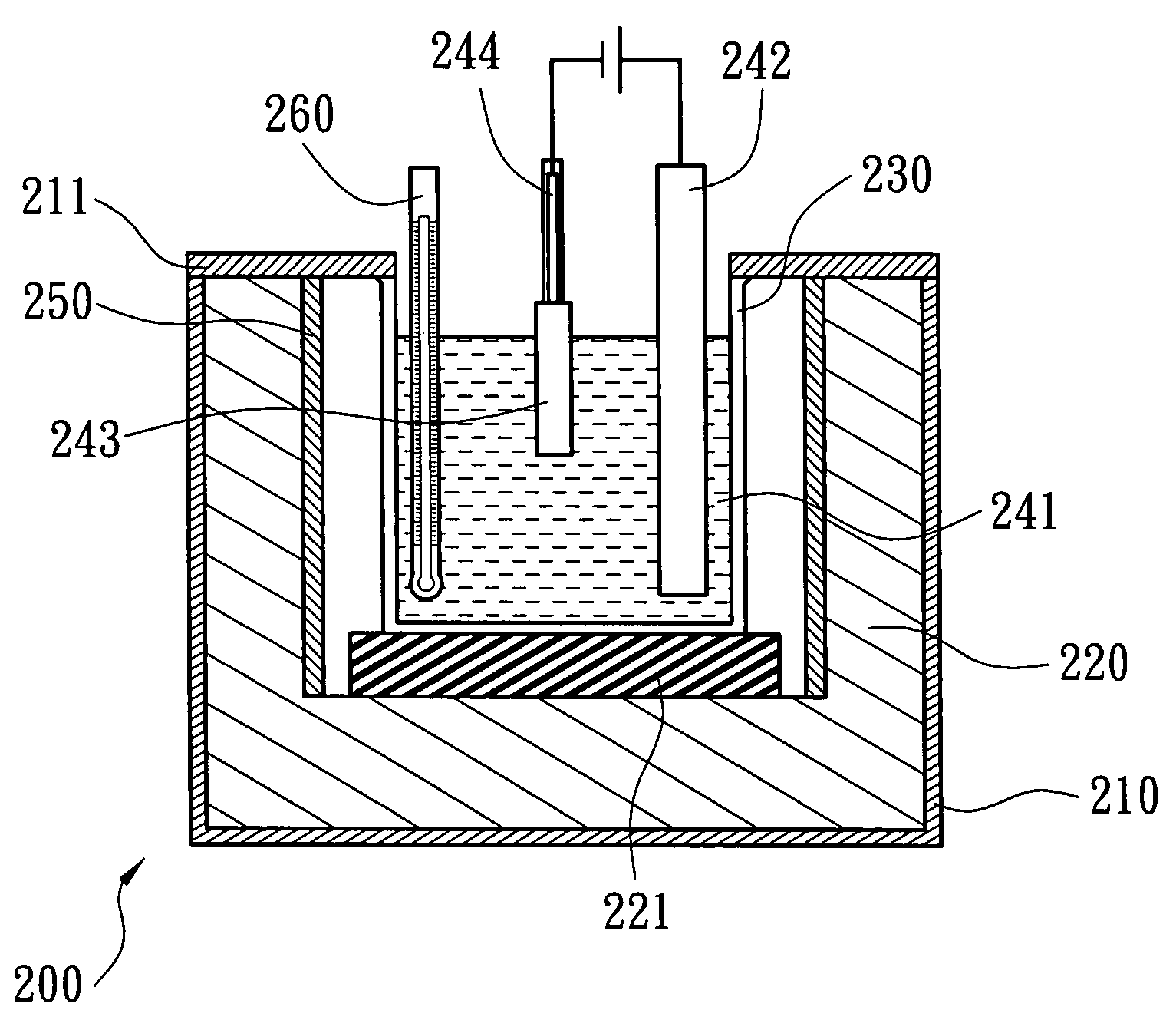

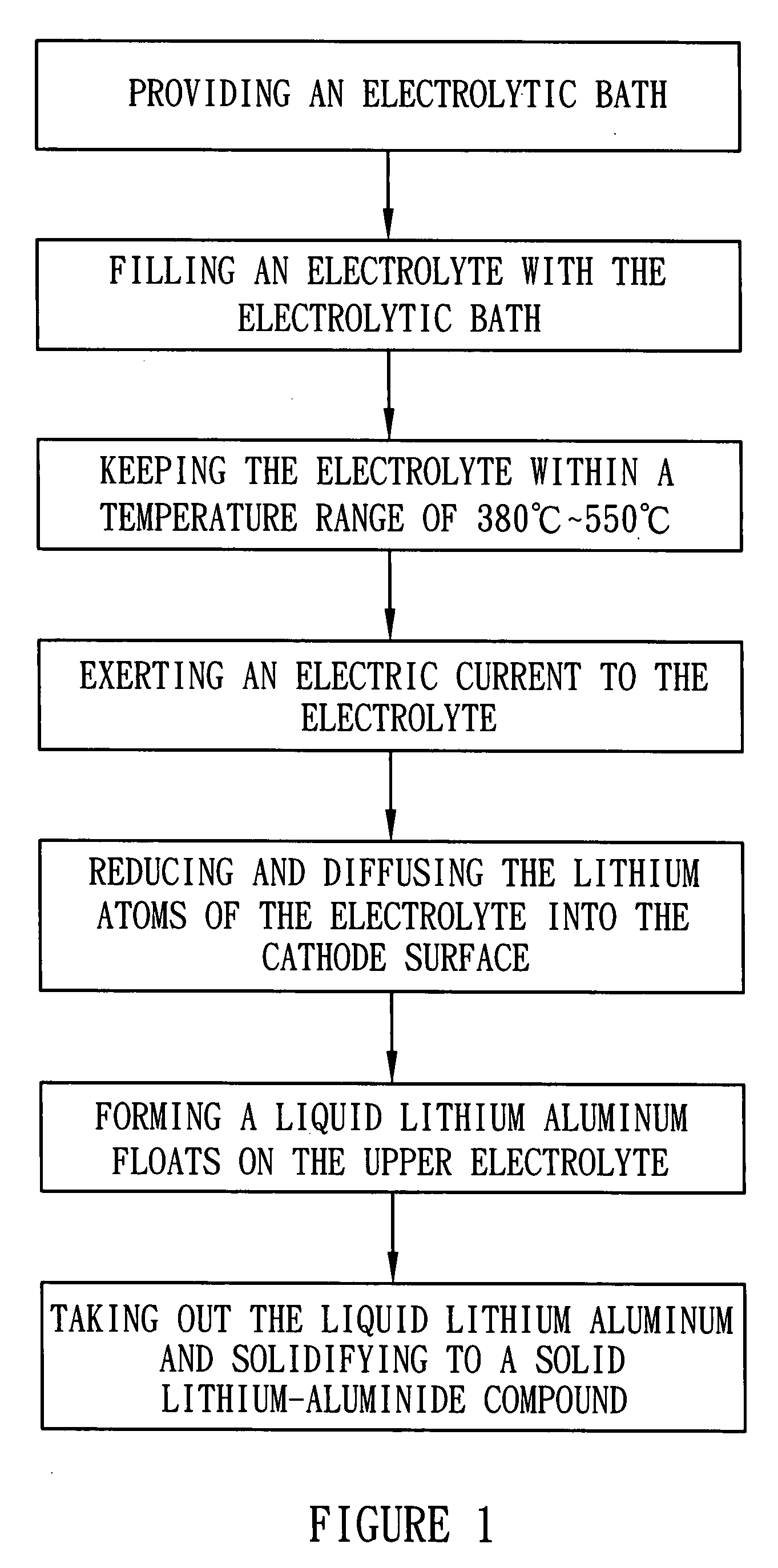

Method for making lithium aluminide compound with high lithium content

A method for making lithium aluminide compound with high lithium content is disclosed. The method includes applying an electrolyte composed of lithium chloride, potassium chloride, and calcium chloride to accomplish a diffusive electrolysis under 380˜550° C. temperature. The lithium atoms of the electrolyte are reduced and diffused into an aluminum cathode, and liquid lithium aluminide is formed and floats on the electrolyte. The liquid lithium aluminide is further scooped up from the upper electrolyte and solidified to a lithium aluminide compound with 40˜62 wt % lithium content.

Owner:UAN JUN YEN +1

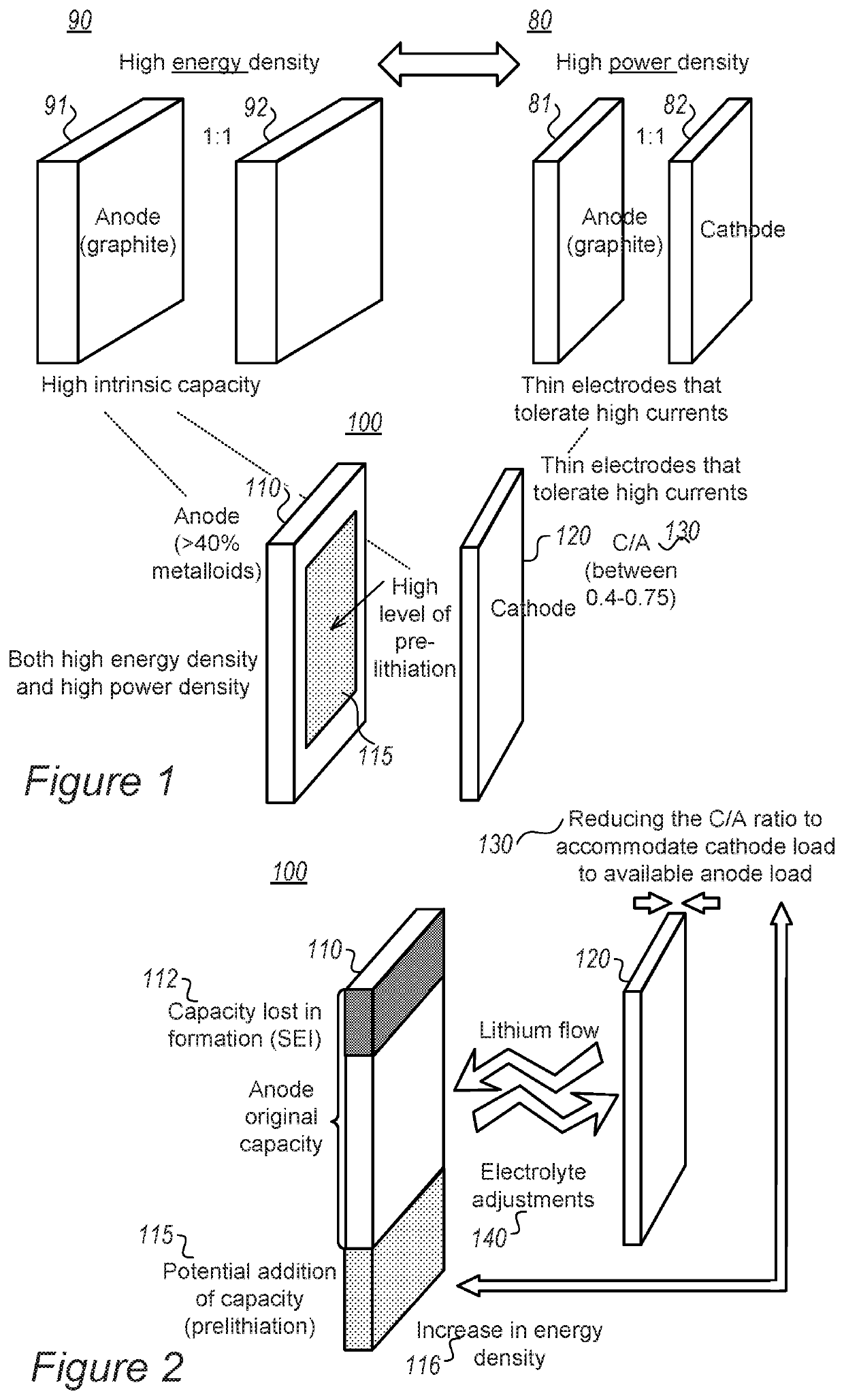

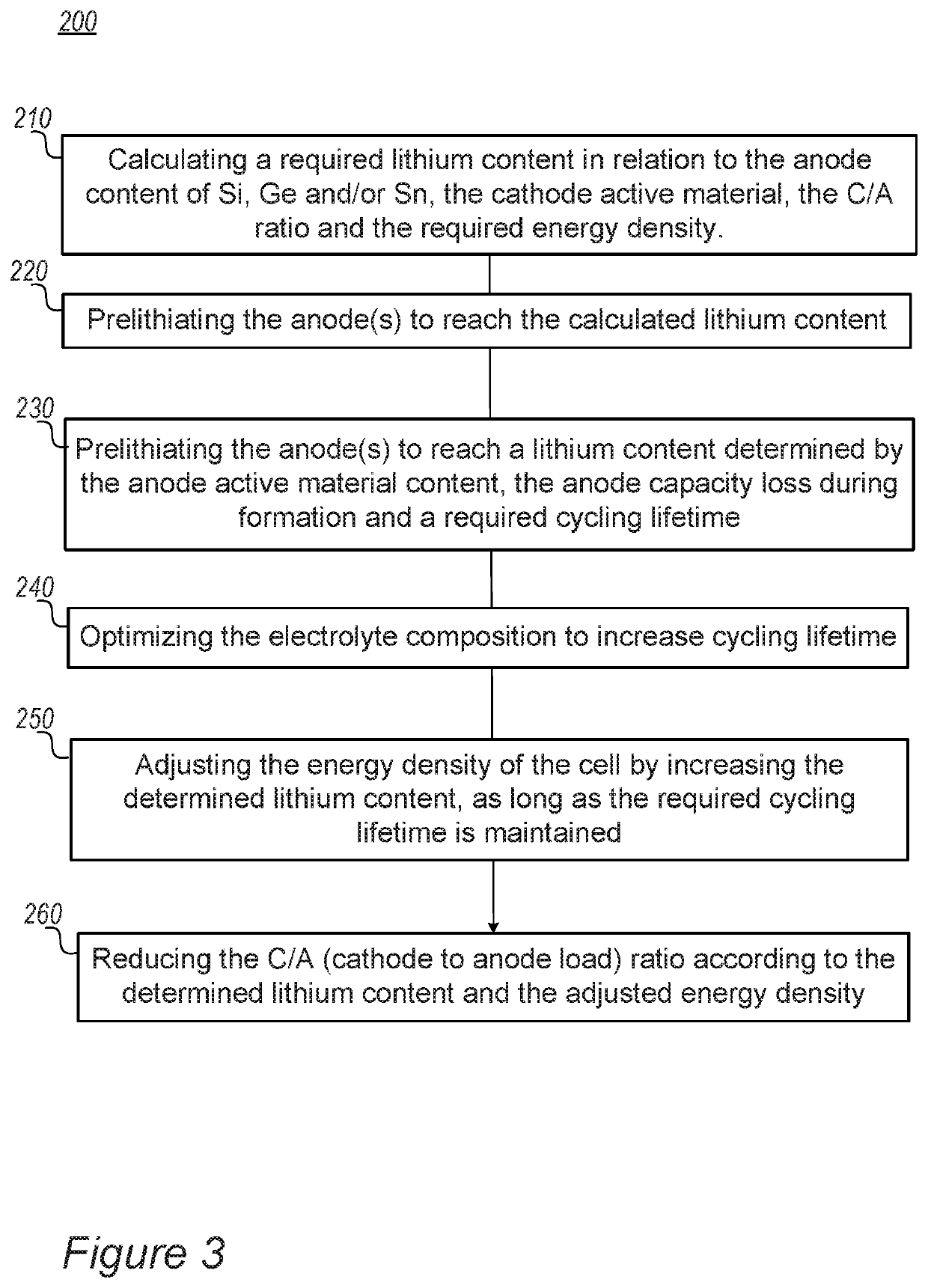

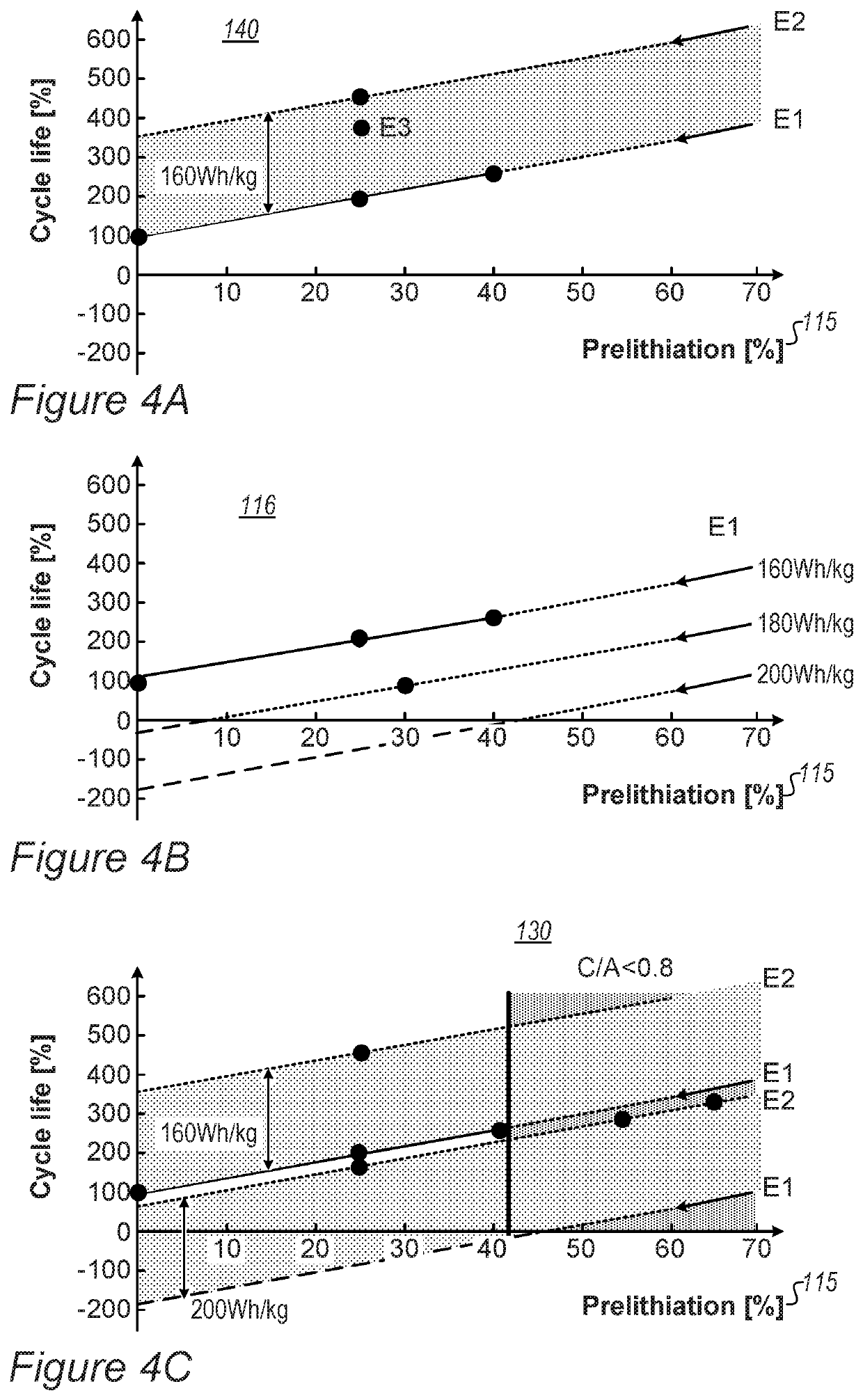

Energy and power dense fast-charging lithium ion batteries

ActiveUS20210210741A1Extended service lifeHigh lithium contentElectrode manufacturing processesNegative electrodesChemical physicsElectrical battery

Prelithiation methods and fast charging lithium ion cell are provided, which combine high energy density and high power density. Several structural and chemical modifications are disclosed to enable combination of features that achieve both goals simultaneously in fast charging cells having long cycling lifetime. The cells have anodes with high content of Si, Ge and / or Sn as principal anode material, and cathodes providing a relatively low C / A ratio, with the anodes being prelithiated to have a high lithium content, provided by a prelithiation algorithm. Disclosed algorithms determine lithium content achieved through prelithiation by optimizing the electrolyte to increase cycling lifetime, adjusting energy density with respect to other cell parameters, and possibly reducing the C / A ratio to maintain the required cycling lifetime.

Owner:STOREDOT

A kind of method for preparing lithium ion sieve adsorbent

ActiveCN109012564BImprove adsorption capacityStable structureOther chemical processesManganese oxides/hydroxidesLithium metalPhysical chemistry

The invention provides a method for preparing a lithium ion sieve adsorbent, comprising: using an aqueous solution of lithium salt and manganese salt as a raw material, using microwaves and ultrasonic waves to obtain a co-precipitation product, and then roasting the co-precipitation product to obtain lithium ions The sieve precursor is finally obtained by acid leaching the lithium ion sieve precursor. The method of the present invention uses the mixed aqueous solution of lithium salt and manganese salt as raw material, produces precipitation under the joint action of microwave and ultrasonic wave, and then obtains a lithium ion sieve precursor with ideal structure through roasting, which has high purity and high lithium content. The lithium ion sieve adsorbent finally obtained after the treatment of the ion sieve precursor has a stable structure and high adsorption capacity, and the method of the present invention consumes less time and energy and has high controllability, which is of great significance to the recycling and utilization of lithium metal resources.

Owner:BEIJING UNIV OF TECH

A kind of recycling method of waste lithium ion battery negative electrode material

ActiveCN111430831BHigh recovery rateHigh lithium contentCarbon compoundsNegative electrodesPhysical chemistryMolten salt

The invention discloses a method for recycling the negative electrode material of the waste lithium ion battery. The basic steps are as follows: 1) Mix the waste lithium-ion battery negative electrode powder with the molten salt; 2) Heat-treat the mixed powder at a temperature not lower than the melting point of the molten salt; 3) After the heat treatment, immerse the material in water and stir evenly for solid-liquid Separation, the liquid phase is used to extract lithium and the recovery of other valuable metals, and the solid phase is regenerated negative electrode material after drying. The invention realizes the purification and structure restoration of the negative electrode material in the waste lithium ion battery negative electrode material, and the recovery of valuable metals. The method has the advantages of short processing flow, low cost, high purity and good crystallinity of the obtained regenerated negative electrode material, high leaching rate of valuable metals, and is suitable for large-scale production.

Owner:湖南烯富环保科技有限公司

A kind of lithium metal negative electrode and its preparation and application

ActiveCN111293287BLow concentration of lithium ionsLow viscosityNegative electrodesLi-accumulatorsSolid state electrolytePolymer electrolytes

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Process of preparing alkali metal titanates

ActiveUS8840814B2Simple wayReduce the temperatureMaterial nanotechnologyAlkali titanatesLithiumPhysical chemistry

Owner:VENATOR P&A FINLAND OY

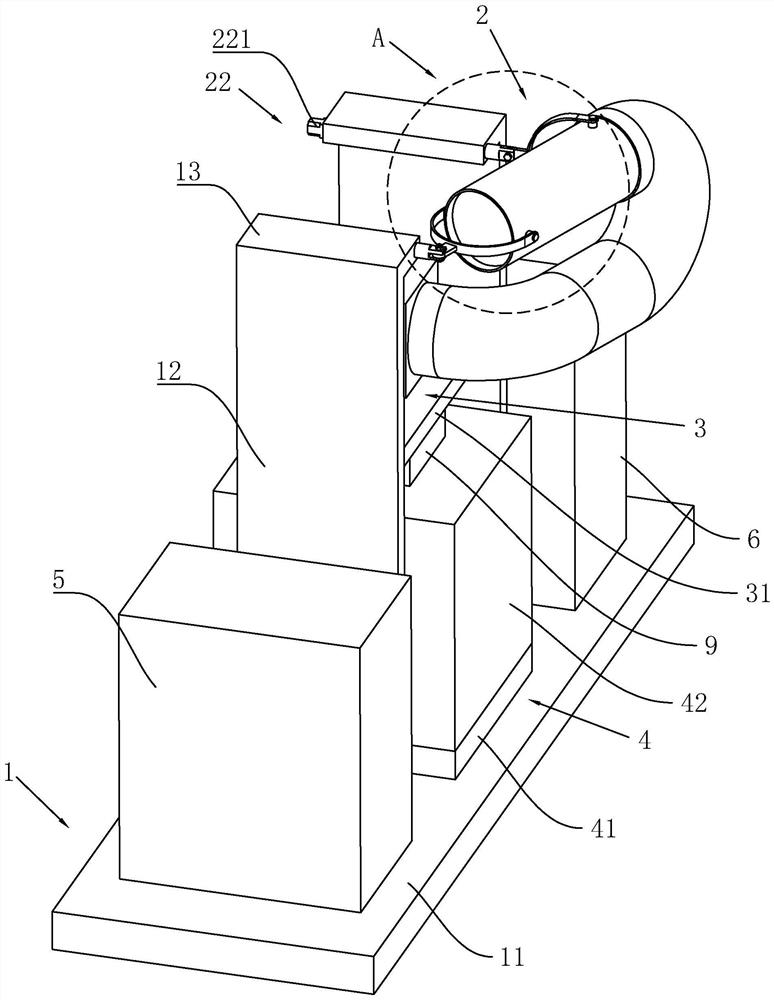

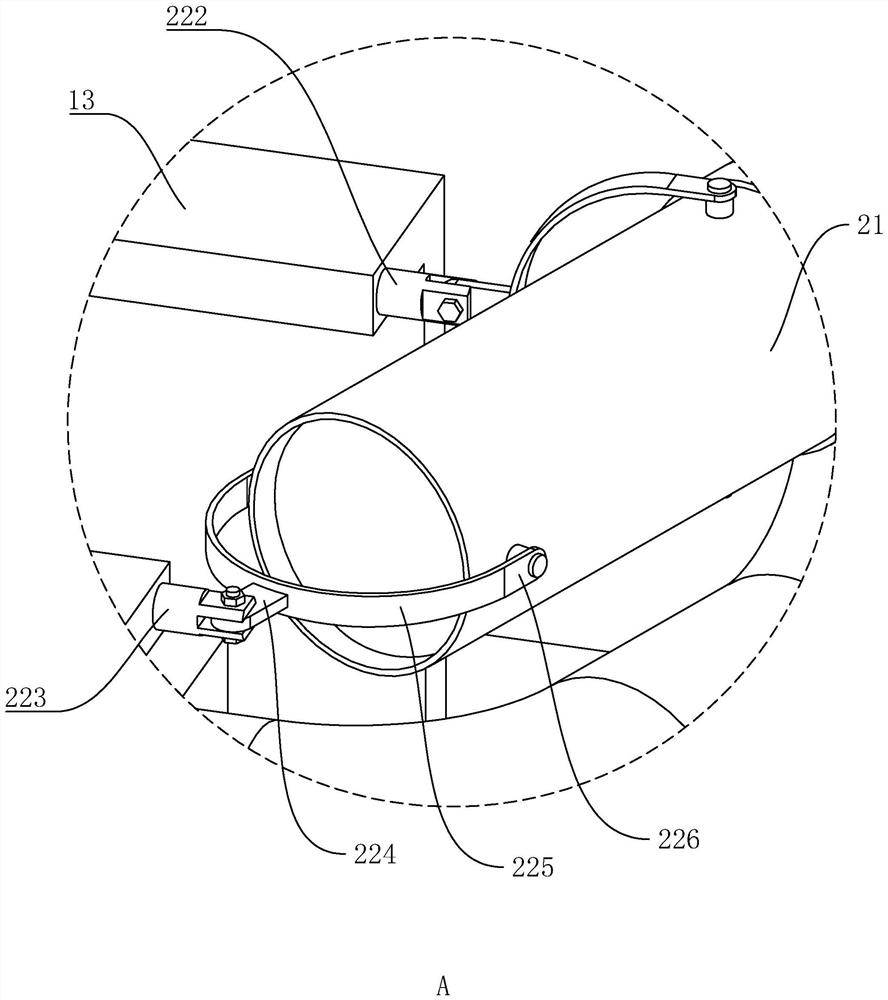

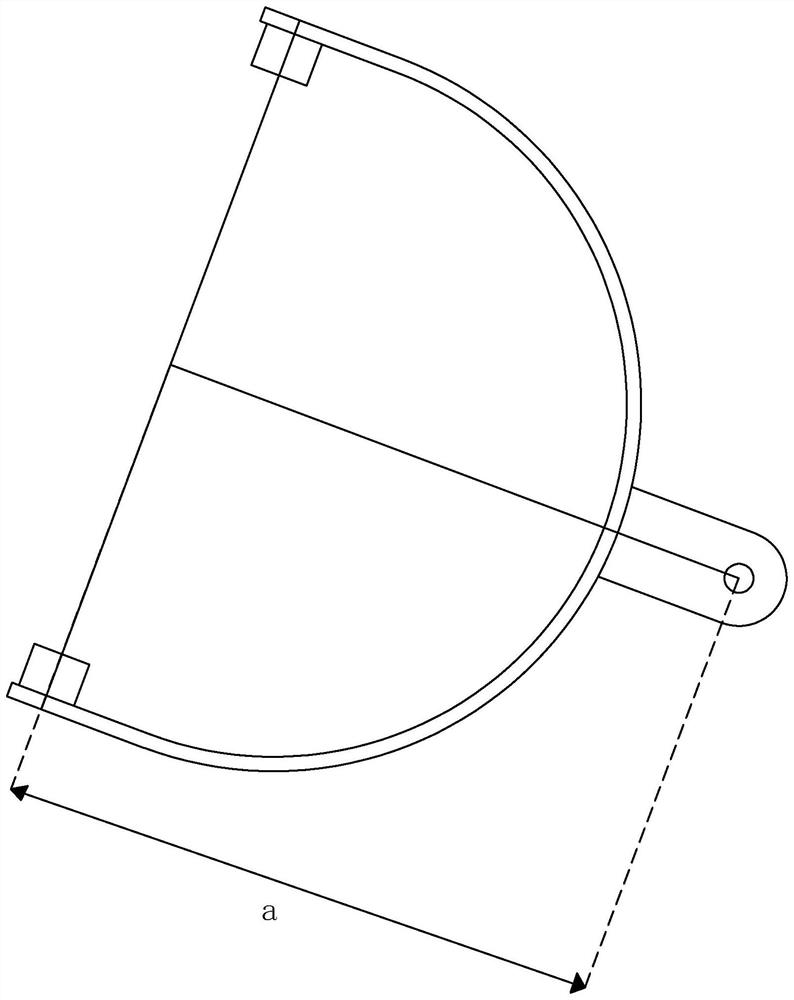

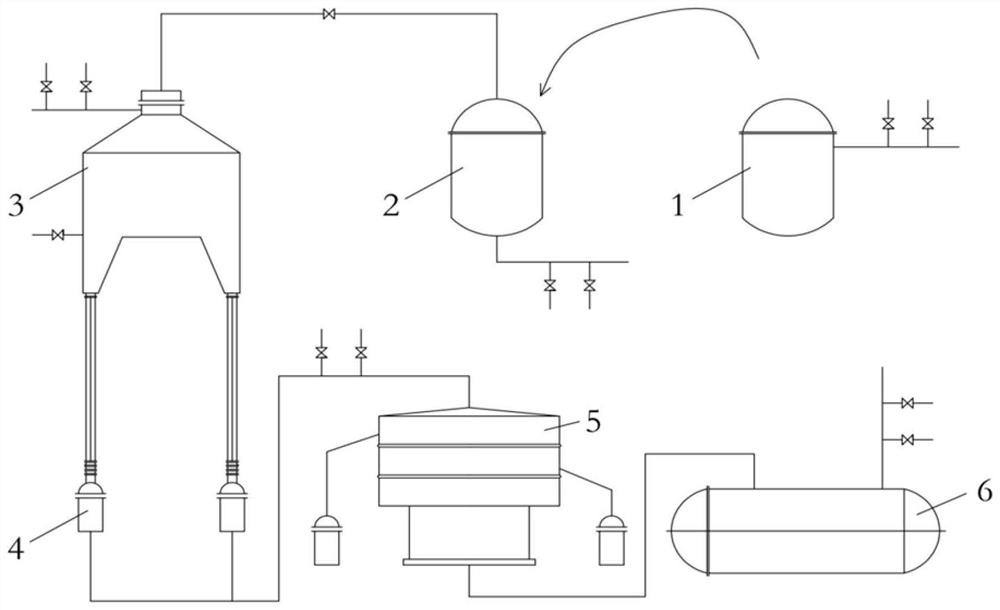

Lithium-based molecular sieve with oxygen generation function and preparation method and production equipment thereof

InactiveCN114477227AImprove heat stabilityLarge specific surface areaOther chemical processesMolecular-sieve and base-exchange compoundsMolecular sieveInorganic chemistry

The invention relates to the technical field of molecular sieves, and particularly discloses a lithium-based molecular sieve with an oxygen production function and a preparation method and production equipment thereof. The lithium-based molecular sieve with the oxygen generation function is prepared from the following raw material components in parts by weight: 30 to 50 parts of lithium hydroxide, 40 to 60 parts of kaolin, 60 to 80 parts of silica sol, 15 to 25 parts of alpha-linolenic acid and 15 to 25 parts of gamma-aminopropyltriethoxysilane. The invention relates to a preparation method of a lithium-based molecular sieve with an oxygen generation function, which comprises the following steps: uniformly mixing lithium hydroxide and kaolin, and heating at 200-250 DEG C for 40-80 minutes to obtain a mixture A; uniformly mixing the mixture A, deionized water, silica sol, alpha-linolenic acid and gamma-aminopropyltriethoxysilane, reacting at 150-170 DEG C to obtain a mixture B, performing suction filtration, washing a suction filtration product to be neutral, and drying to obtain a mixture C; and roasting to obtain the lithium-based molecular sieve.

Owner:南京永成分子筛有限公司

Low-sodium aluminium-lithium intermediate alloy material and its preparation method

The invention discloses a low-sodium aluminium-lithium intermediate alloy material and its preparation method. The low-sodium aluminium-lithium intermediate alloy material contains, by weight, 8.0-25.0% of Li, less than or equal to 0.0001% of Na, less than or equal to 0.00005% of K and the balance Al. According to the preparation method, a mixed salt of pure lithium chloride and lithium fluoride is used as a covering agent; boron trioxide is used to remove sodium and potassium; and high-pure nitrogen or argon is used for gas refining. The melting operation process requires no inert gas or vacuum protection. The technology is simple. After the sodium removal technological process, the contents of sodium and potassium impurity in the alloy are low, wherein the mass fraction of sodium is less than or equal to 0.0001% and the mass fraction of potassium is less than or equal to 0.00005%. The technological method has advantages of high yield and little loss of raw materials, and can be adopted for quantitative preparation of the aluminium-lithium intermediate alloy with any lithium content.

Owner:HEBEI SITONG NEW METAL MATERIAL CO LTD +1

Alkaline storage battery system

InactiveUS7867653B2Reduce addHigh lithium contentSilver accumulatorsElectrode carriers/collectorsLithiumPartial charge

An alkaline storage battery system according to an aspect of the present invention, with which a partial charging-discharging is performed, includes an alkaline storage battery 10 including an electrode group having a nickel positive electrode 11, a hydrogen storage alloy negative electrode 12, a separator 13; an alkaline electrolyte; and an outer can 14 accommodating the electrode group and the alkaline electrolyte, and further includes a partial charge-discharge control unit for controlling charging-discharging of the battery 10. In addition, zinc (Zn) is added to nickel hydroxide that is a main positive electrode active material in the nickel positive electrode 11 with an addition amount of 5% by mass or less with respect to the mass of nickel in the positive electrode active material. The concentration of the alkaline electrolyte is 6.5 mol / L or less and the content of lithium in the alkaline electrolyte is 0.3 mol / L or more.

Owner:SANYO ELECTRIC CO LTD

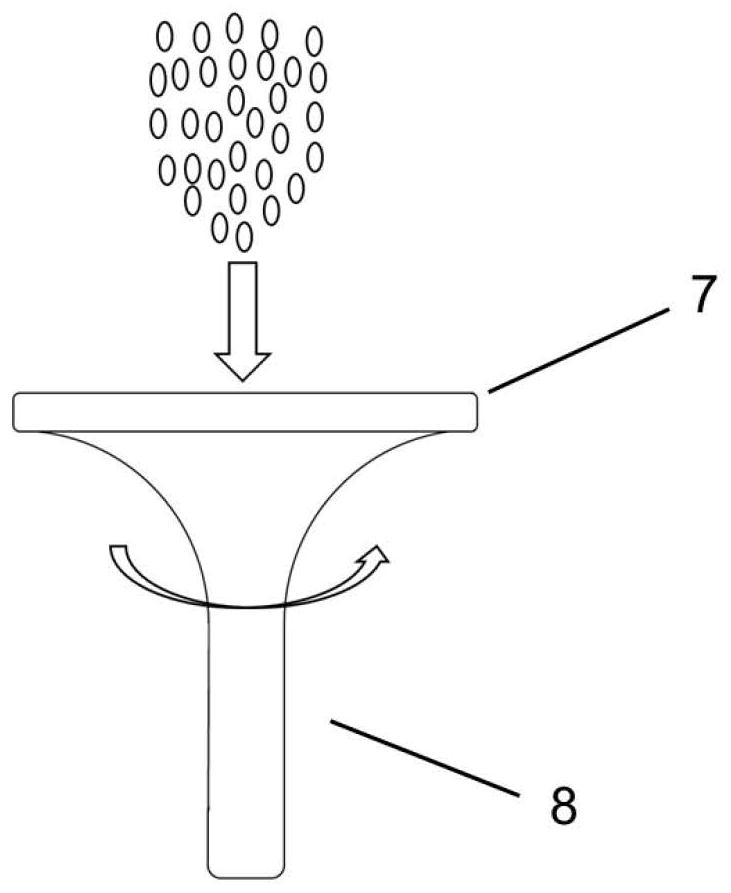

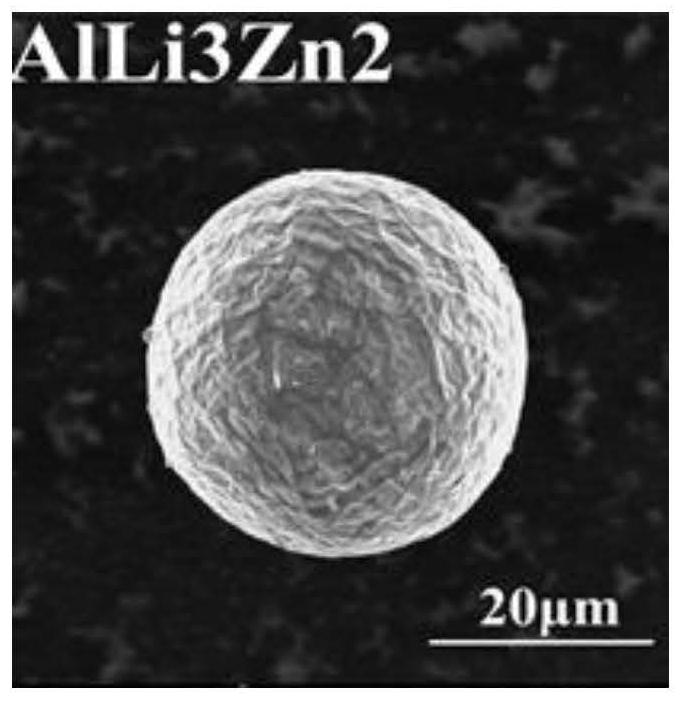

Surface deliquescence-resistant aluminum-lithium-based ternary alloy powder and preparation method thereof

ActiveCN114875275AImprove stabilityPrevent deliquescenceTransportation and packagingMetal-working apparatusCarbide siliconBinary alloy

The invention discloses surface deliquescence-resistant aluminum-lithium-based ternary alloy powder as well as a preparation method and a system of the surface deliquescence-resistant aluminum-lithium-based ternary alloy powder. The ternary alloy powder comprises aluminum, lithium and zinc, and the mass content of the aluminum is 70%-98%; the mass content of lithium is 1-20%, and the mass content of zinc is 1-10%. The preparation method comprises the steps that under the argon positive pressure condition, metal containing aluminum and lithium is smelted in a silicon carbide crucible smelting furnace, an aluminum-lithium binary alloy ingot is obtained, then the aluminum-lithium binary alloy ingot, aluminum and zinc are smelted in the silicon carbide crucible smelting furnace, an aluminum-lithium-zinc ternary alloy feed liquid is obtained, the aluminum-lithium-zinc ternary alloy feed liquid is conveyed to an atomization tank through a niobium alloy pipeline, and the atomization tank is used for atomization. And carrying out disc type centrifugal atomization and screening to obtain the surface deliquescence-resistant aluminum-lithium-based ternary alloy powder. The surface of the prepared aluminum-lithium-based ternary alloy powder has the characteristics of corrosion resistance and deliquescence resistance, and high activity and stability can be kept under common storage conditions.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com