A kind of recycling method of waste lithium ion battery negative electrode material

A technology for lithium-ion batteries and negative electrode materials, which is applied in the field of high-value resource utilization of waste lithium-ion battery negative electrode materials, can solve the problems of few researches on the recovery and treatment of negative electrode active materials, complex recycling schemes, and single recycling goals, and achieve resource utilization. The effect of modernization, safety and environmental protection, low cost and simplified process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

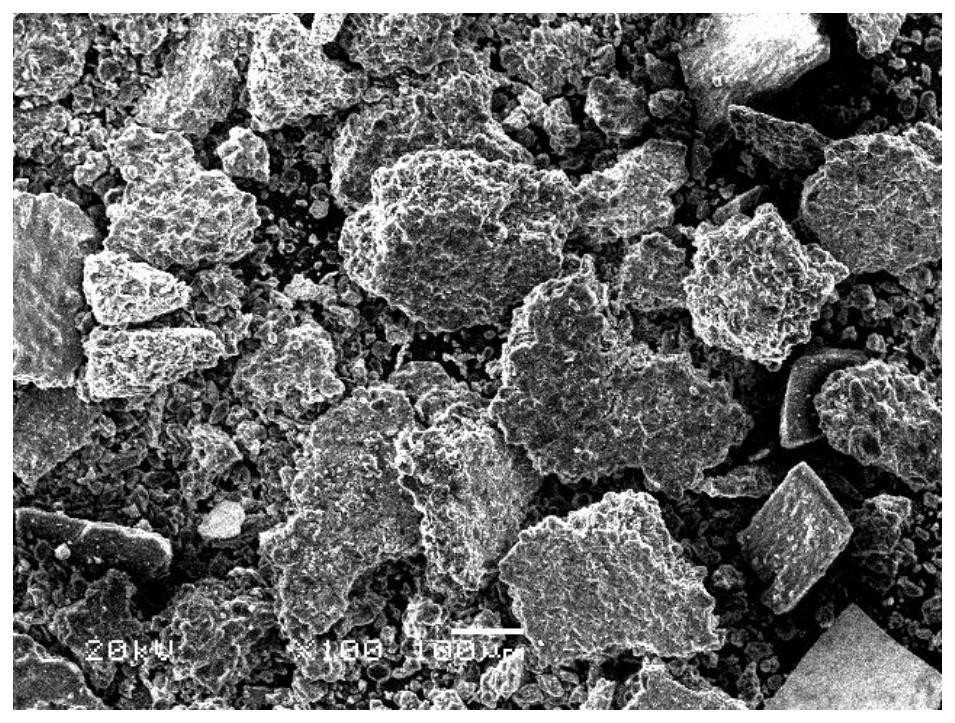

[0049]Take the waste lithium-ion battery, soak it in sodium chloride salt solution and discharge completely (short-circuit discharge until the residual voltage is 0V), then disassemble the negative electrode sheet, crush the negative electrode sheet, stir in water, separate, and dry to obtain the waste lithium-ion battery negative electrode powder;

[0050] Take 10g of waste lithium-ion battery negative electrode powder, mix it with sodium chloride evenly, and the mass ratio of sodium chloride to negative electrode powder is 0.5:1;

[0051] The homogeneously mixed materials were heated up to the melting point of sodium chloride at a heating rate of 5°C / min under an argon atmosphere, and the holding time was 1h. After the heat treatment, the temperature was naturally lowered.

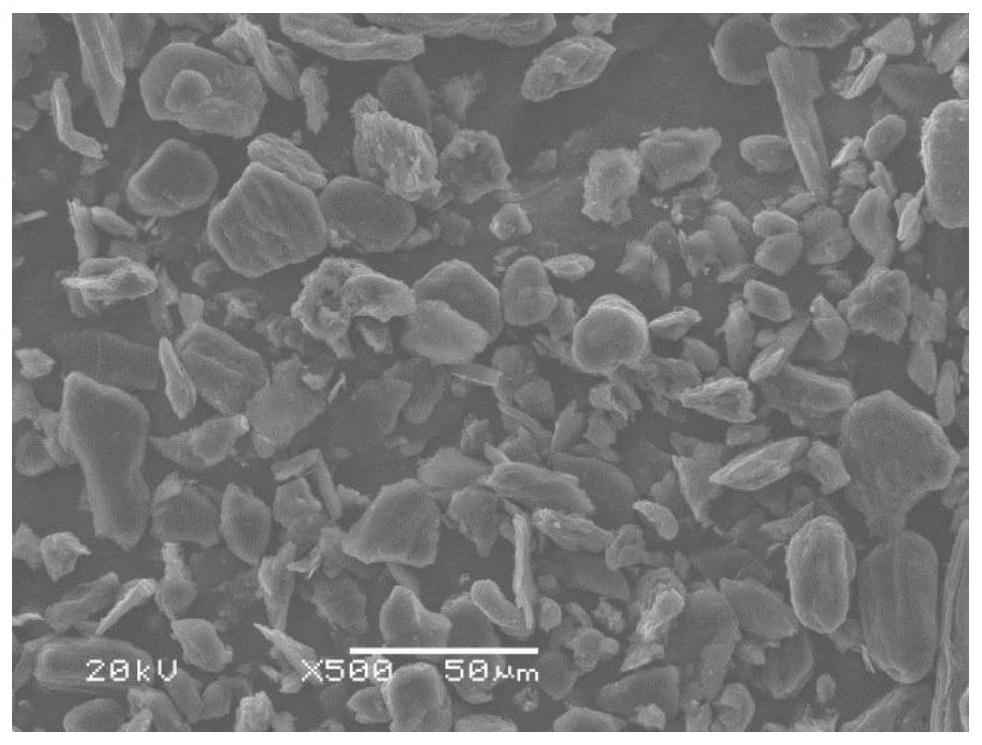

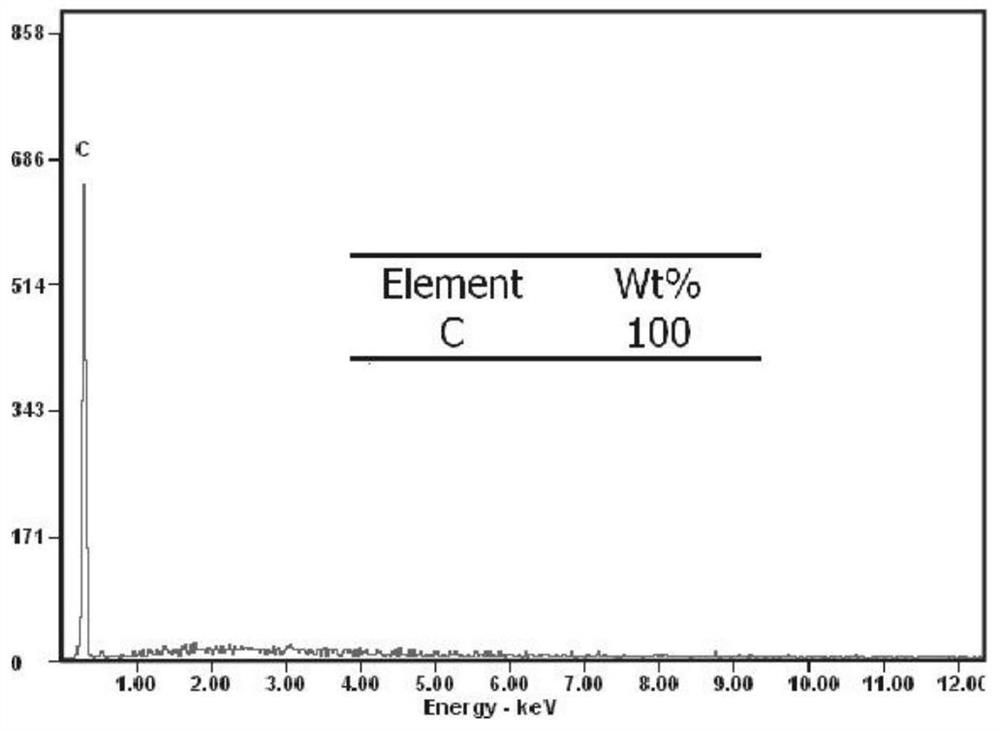

[0052] The heat-treated material was placed in deionized water at a solid-to-liquid ratio of 1:20, stirred at room temperature for 1 h, filtered and separated to obtain a lithium-containing filtrate and a...

Embodiment 2

[0055] Take the waste lithium-ion battery, disassemble it under the condition of pouring water (not fully discharged, residual voltage > 0V) to obtain the negative pole piece, crush the negative pole piece, stir in water, separate, and dry to obtain the waste lithium-ion battery negative pole powder (that is, not fully discharged negative electrode powder);

[0056] Take 10g of waste lithium-ion battery negative electrode powder, mix it with potassium chloride, and the mass ratio of potassium chloride to negative electrode powder is 0.5:1;

[0057] The homogeneously mixed materials were heated up to 800°C at a heating rate of 5°C / min under an argon atmosphere, and the holding time was 1h. After the heat treatment, the temperature was naturally lowered.

[0058] The heat-treated material was placed in deionized water at a solid-to-liquid ratio of 1:20, stirred at 40° C. for 1 h, filtered and separated to obtain a lithium-containing filtrate and a purified negative electrode mat...

Embodiment 3

[0061] Negative electrode powder is with embodiment 2;

[0062] Get 10g waste lithium ion battery negative electrode powder, mix with metal chloride, the mass ratio of metal chloride and negative electrode powder is 0.5:1, and wherein metal chloride is the mixture of sodium chloride and calcium chloride, both ratios are 1: 1;

[0063] The homogeneously mixed materials were heated up to 800°C at a heating rate of 5°C / min under an argon atmosphere, and the holding time was 1h. After the heat treatment, the temperature was naturally lowered.

[0064] The heat-treated material was placed in deionized water at a solid-to-liquid ratio of 1:20, stirred at 60° C. for 1 h, filtered and separated to obtain a lithium-containing filtrate and a purified negative electrode material.

[0065] After testing, the leaching rate of lithium ions in the process of extracting lithium by water leaching reaches 90%, and 1kg of spent negative electrode powder can be recovered to obtain about 25g of l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com