High-lithium-content and high-molecular-weight lithium acrylate emulsion as well as preparation method and application thereof

A technology of lithium acrylate and lithium polyacrylate, applied in the field of electrochemistry, can solve the problems of large amount of binder, easy powder drop, poor processing performance, etc. The effect of resistance drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

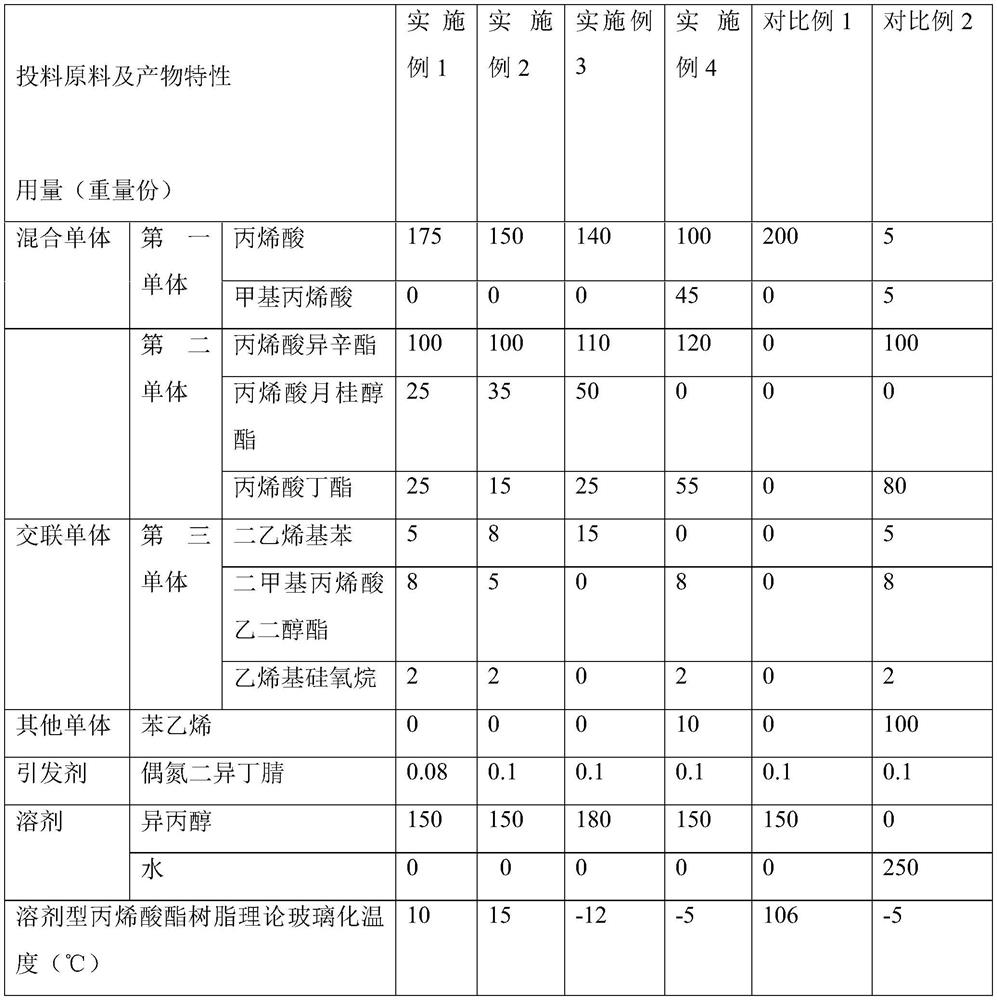

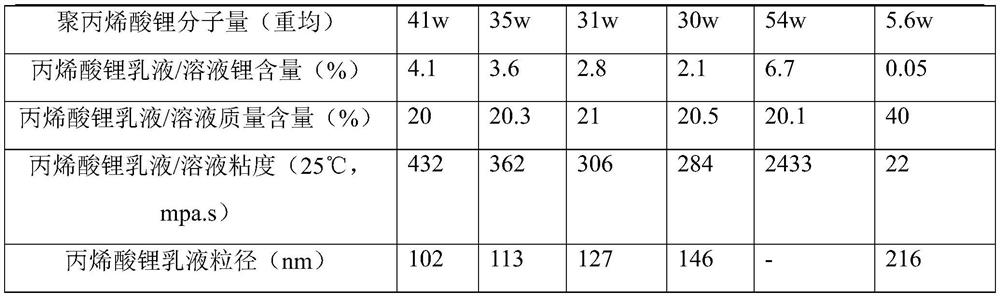

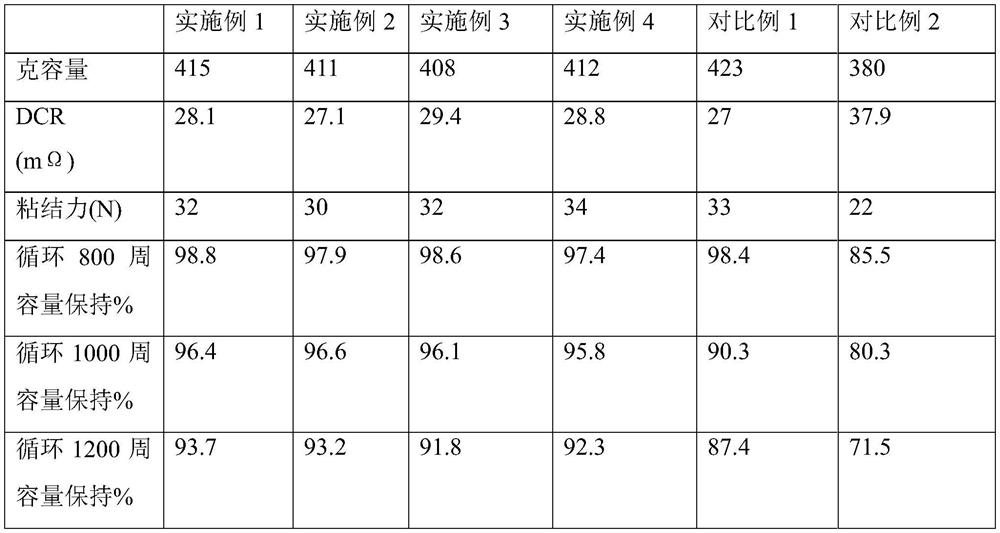

Examples

Embodiment 1

[0038] This example provides a preparation method of lithium acrylate emulsion, comprising the following steps:

[0039] The first step: add 20% of the mixed monomer and 15% of the initiator azobisisobutyronitrile (dissolved in the organic solvent and then added) to the organic solvent at 65°C, react for 3h, and control the temperature at 65-70°C , add the remaining monomers and initiator dropwise, the dropping time is 18-20h; add the cross-linking monomer when the remaining 1 / 8 of the mixed monomer is added dropwise.

[0040] The second step: the isopropanol in the solvent-based acrylate resin is distilled off under reduced pressure, and an aqueous solution of lithium hydroxide (10wt%) is added dropwise to it to make it phase inversion into an oil-in-water emulsion, and the distillation temperature is about 55- 60 degrees Celsius, the total time of the second step is about 3 hours, and the addition amount of the lithium hydroxide aqueous solution is 500 parts by weight.

[0...

Embodiment 2

[0043] This example provides a preparation method of lithium acrylate emulsion, comprising the following steps:

[0044] The first step: add 30% of the mixed monomer and 15% of the initiator azobisisobutyronitrile (dissolved in the organic solvent and then added) to the organic solvent at 65°C, react for 3h, and control the temperature at 65-70°C , add the remaining monomers and initiator dropwise, the dropping time is 10-12h; add the cross-linking monomer when the remaining 1 / 8 mixed monomer is added dropwise.

[0045] The second step: the organic solvent in the solvent-based acrylate resin is distilled off under reduced pressure, and an aqueous solution of lithium hydroxide (10wt%) is added dropwise to it to make it phase inversion into an oil-in-water emulsion, and the distillation temperature is about 55-60 °C. Celsius, the total time of the second step is about 3 hours, and the addition amount of the lithium hydroxide aqueous solution is 500 parts by weight.

[0046] See...

Embodiment 3

[0048] This example provides a preparation method of lithium acrylate emulsion, comprising the following steps:

[0049] The first step: add 10% of the mixed monomer and 15% of the initiator azobisisobutyronitrile (dissolved in the organic solvent and then added) to the organic solvent at 65°C, react for 3h, and control the temperature at 65-70°C , add the remaining monomers and initiator dropwise, the dropping time is 20-22h; add the cross-linking monomer when the remaining 1 / 8 of the mixed monomer is added dropwise.

[0050] The second step: the organic solvent in the solvent-based acrylate resin is distilled off under reduced pressure, and an aqueous solution of lithium hydroxide (10wt%) is added dropwise to it to make it phase inversion into an oil-in-water emulsion, and the distillation temperature is about 55-60 °C. Celsius, the total time of the second step is about 2-5 hours, and the addition amount of the lithium hydroxide aqueous solution is 600 parts by weight.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com