Novel MOF composite material and preparation method and application thereof

A composite material, MOF technology, applied in nanotechnology for materials and surface science, hybrid/electric double-layer capacitor manufacturing, hybrid capacitor electrodes, etc., can solve the problems of low yield, high cost, non-uniform structure, etc., Achieve the effect of high yield, low cost and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

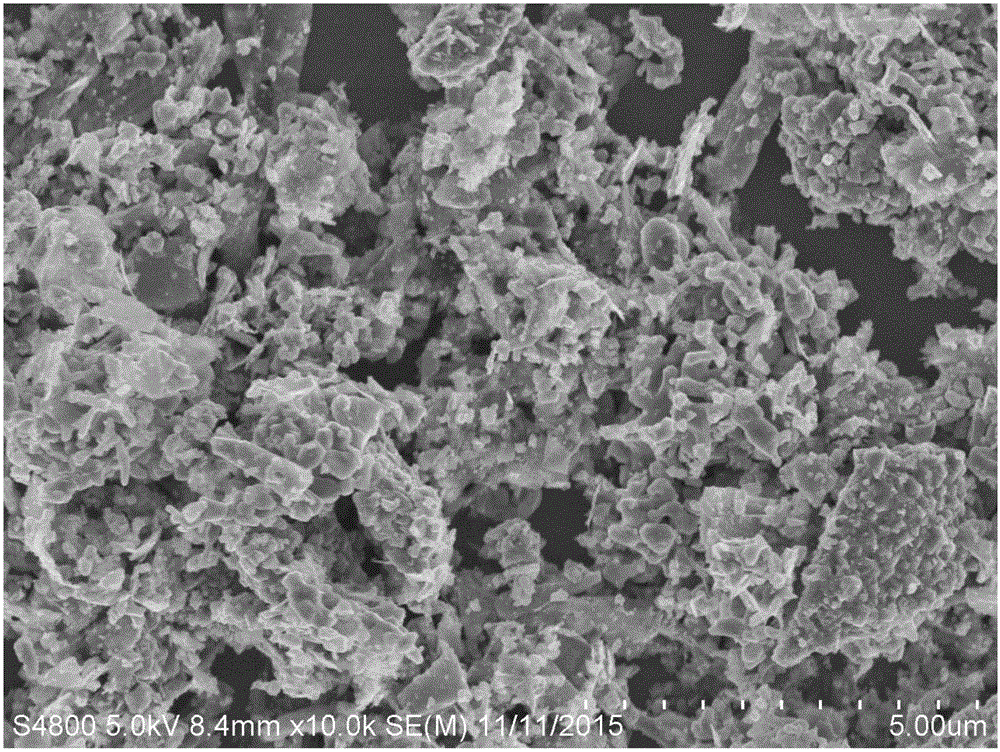

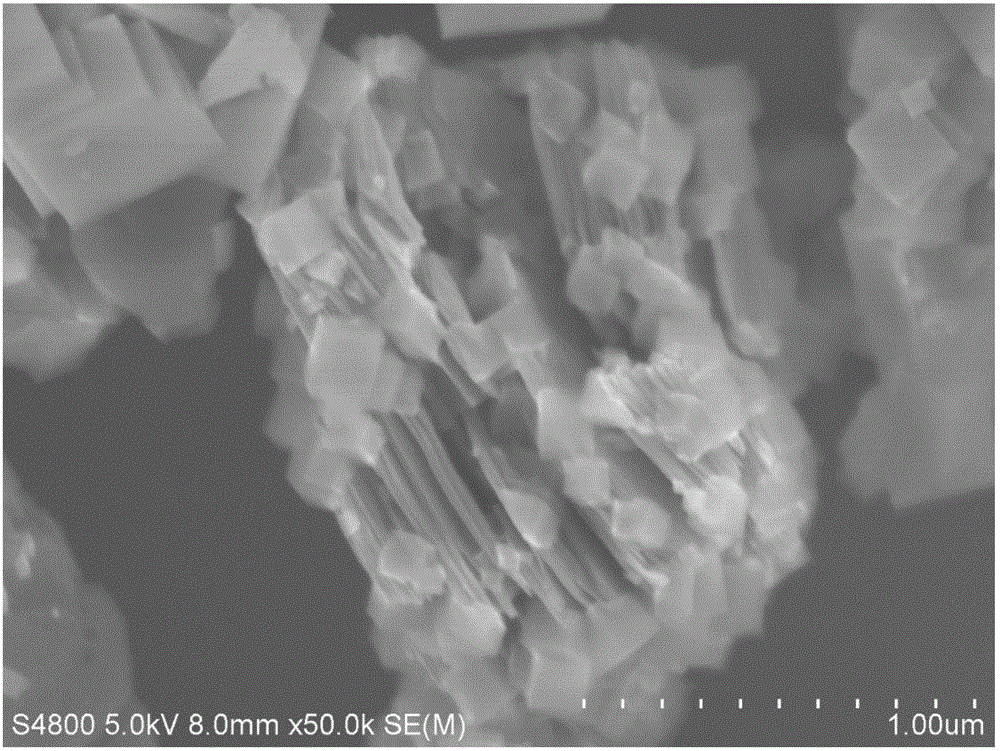

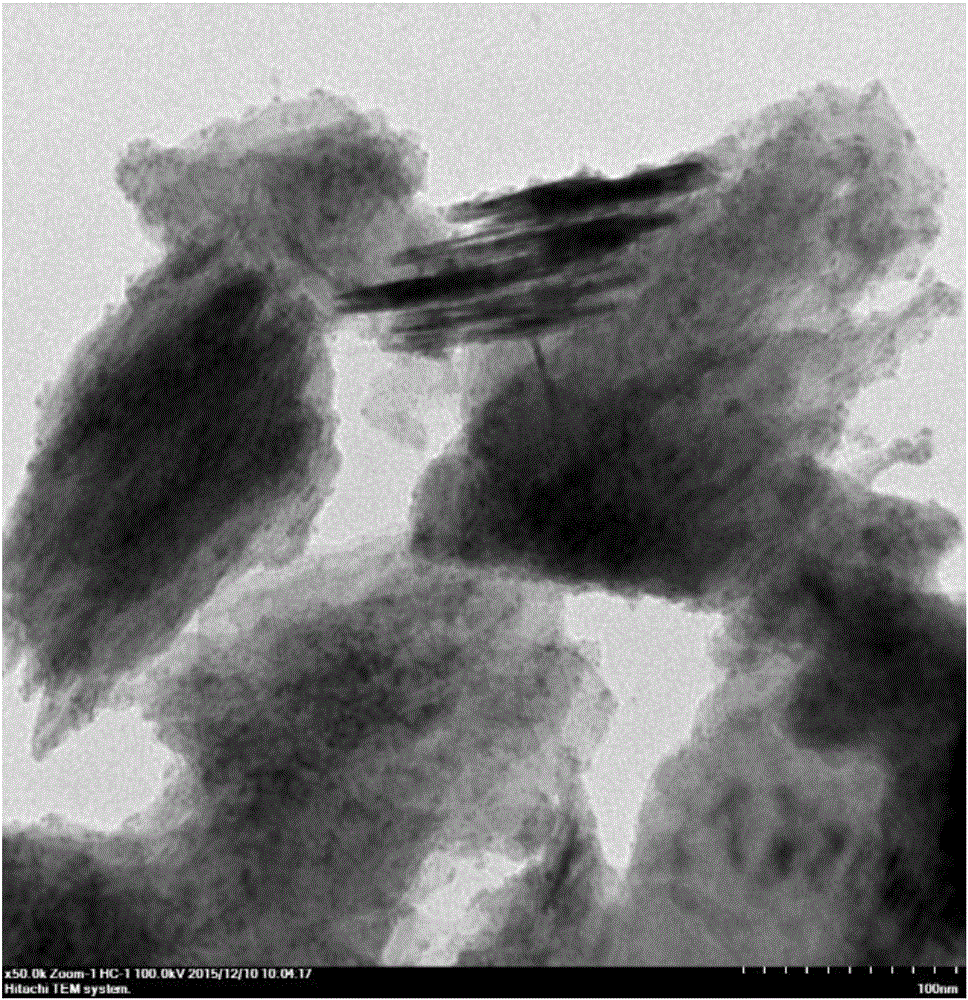

[0034] The MOF / MXene composite material that present embodiment makes, selects Ti 3 AlC 2 and 1,4-naphthalene dicarboxylic acid as MAX materials and organic ligand molecules, including the layered MXene material Ti 3 C 2 , and MOF crystals interspersed in the layered structure and the surface of the material with Al as the node and 1,4-naphthalene dicarboxylic acid as the bridge.

[0035] The specific steps are:

[0036] Step 1, MAX material pretreatment: using a ball mill, Ti 3 AlC 2 Ball milling in ethanol, vacuum drying, ball milling and sieving to obtain submicron Ti 3 AlC 2 powder.

[0037] Step 2, generate MOF / MXene nanocomposites by "one-step method": add water, a small amount of HF, excess naphthalene dicarboxylic acid and treated Ti to the reactor 3 AlC 2 powder, hydrothermal at 180°C for 6 hours, under hydrothermal conditions HF etched away Ti 3 AlC 2 metal atom Al in the structure, giving Ti 3 C 2 , and the obtained Al ions react with naphthalene dicarb...

Embodiment 2

[0043] The MOF / MXene composite material that present embodiment makes, selects Ti 2 AlC and 1,3,5-trimesic acid as MAX materials and organic ligand molecules, including MXene material Ti with layered structure 2 C, and MOF crystals interspersed between layered structures with 1,3,5-trimesic acid as nodes and Al as bridges, Figure 5 It is the scanning electron micrograph of the MOF composite material in this example. .

[0044] The specific steps are: Step 1, MAX material pretreatment: using a ball mill, Ti 2 AlC is ball milled in ethanol, vacuum dried and sieved to obtain submicron Ti 2 AlC powder.

[0045] Step 2, generate MOF / MXene nanocomposites by "one-step method": add water, HF, excess 1,3,5-trimesic acid and treated Ti to the reactor 2 AlC powder, hydrothermal at 120°C for 8 hours, HF etched away Ti under hydrothermal conditions 2 Metal atom Al in AlC structure, to get Ti 2 C nanosheet structure, and the obtained Al ions react with 1,3,5-trimesic acid to obtain ...

Embodiment 3

[0048] The MOF / MXene composite material that present embodiment makes, selects Ti 3 AlC 2 and 1,4-naphthalene dicarboxylic acid as MAX materials and organic ligand molecules, including the layered MXene material Ti 3 C 2 , and MOF crystals interspersed in the layered structure and the surface of the material with Al as the node and 1,4-naphthalene dicarboxylic acid as the bridge.

[0049] The specific steps are:

[0050] Step 1, MAX material pretreatment: using a ball mill, Ti 3 AlC 2 Ball milling in ethanol, vacuum drying, ball milling and sieving to obtain submicron Ti 3 AlC 2 powder.

[0051] Step 2, generate MOF / MXene nanocomposites by "one-step method": add water, a small amount of HF, excess naphthalene dicarboxylic acid and treated Ti to the reactor 3 AlC 2 powder, hydrothermal at 200°C for 1 hour, under hydrothermal conditions HF etched away Ti 3 AlC 2 metal atom Al in the structure, giving Ti 3 C 2 , and the obtained Al ions react with naphthalene dicarbo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com