Patents

Literature

43results about How to "High value of industrial production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Recovery method of waste lithium iron phosphate positive electrode material

ActiveCN112441572AImprove leaching rateRealize full recyclingAluminium oxide/hydroxide preparationWaste accumulators reclaimingPregnant leach solutionO-Phosphoric Acid

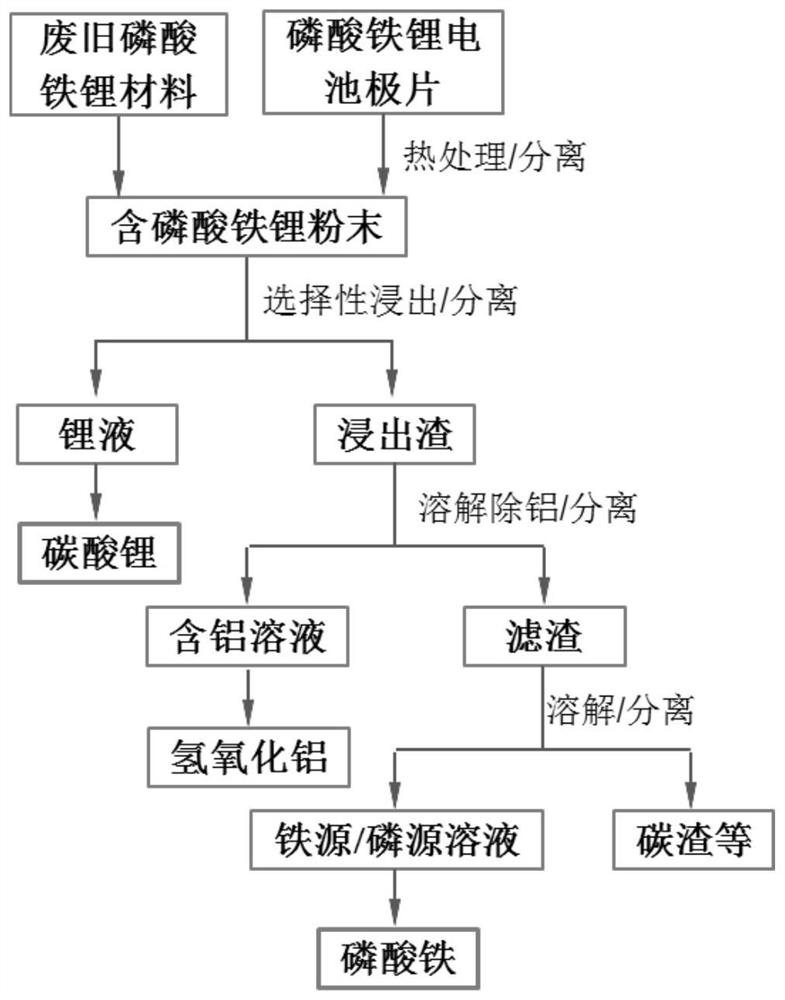

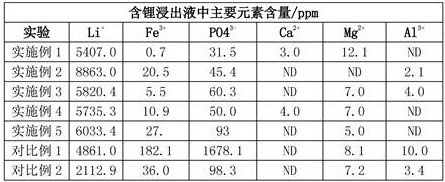

The invention provides a recovery method of a waste lithium iron phosphate positive electrode material. The method comprises the following steps: S1, adding waste lithium iron phosphate powder to a leaching agent A, slowly adding a leaching agent B, adjusting the pH value to be more than or equal to 2, and carrying out solid-liquid separation to obtain a lithium-containing leaching agent and a leaching residue; S2, adding a precipitator into the lithium-containing leachate to obtain lithium carbonate; S3, adding a first alkaline solution into the leaching residues, and filtering to obtain an aluminum-containing solution and filter residues; S4, adjusting the pH value of the aluminum-containing solution to obtain an aluminum hydroxide precipitate; S5, adding the filter residue into a firstacidic solution, performing filtering, adding a second alkaline solution into the obtained filtrate, adjusting the pH value to 2.0-2.7 to obtain basic iron phosphate, and adding phosphoric acid to obtain iron phosphate. The leaching agent A comprises a mixed solution of at least one of a weak base solution or a weak acid solution and a first oxidizing agent; and the leaching agent B comprises a mixed solution of a second acidic solution and a second oxidant. By the adoption of the method, the leaching rate of lithium is high, impurities are few, the purification and wastewater treatment cost during lithium carbonate preparation is reduced, and meanwhile iron phosphate can be efficiently recycled.

Owner:BYD CO LTD +1

Method for compositing iron oxide and graphene by virtue of hydrothermal process

InactiveCN103560228AGood dispersionIncrease profitWater/sewage treatment by irradiationCell electrodesPhotocatalytic degradationIon

The invention discloses a method for compositing iron oxide and graphene by virtue of a hydrothermal process. The method comprises the following steps: 1) dissolving hexahydrate ferric trichloride and oxidized graphene, (ammonium dihydrogen phosphate and sodium hydroxide) in a certain amount of deionized water to obtain a solution; 2) ultrasonically treating the solution for 1 hour; 3) putting magnetons in the solution and magnetically stirring the solution for 2 hours; 4) pouring the stirred solution into a high-pressure reaction kettle, putting the high-pressure reaction kettle into an electrothermal constant-temperature drying oven and reacting the solution for a period of time at preset temperature; and 5) performing centrifugal washing and vacuum drying to obtain a composite of iron oxide and graphene. The composite precipitate prepared by virtue of the hydrothermal process has controllable particle size, good dispersibility, high utilization rate of sunlight, excellent electronic transmission performance, as well as excellent properties in the application aspects of photo-catalytically degrading organic pollutants and serving as a negative material of a novel lithium battery, thereby having a high industrial production value.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

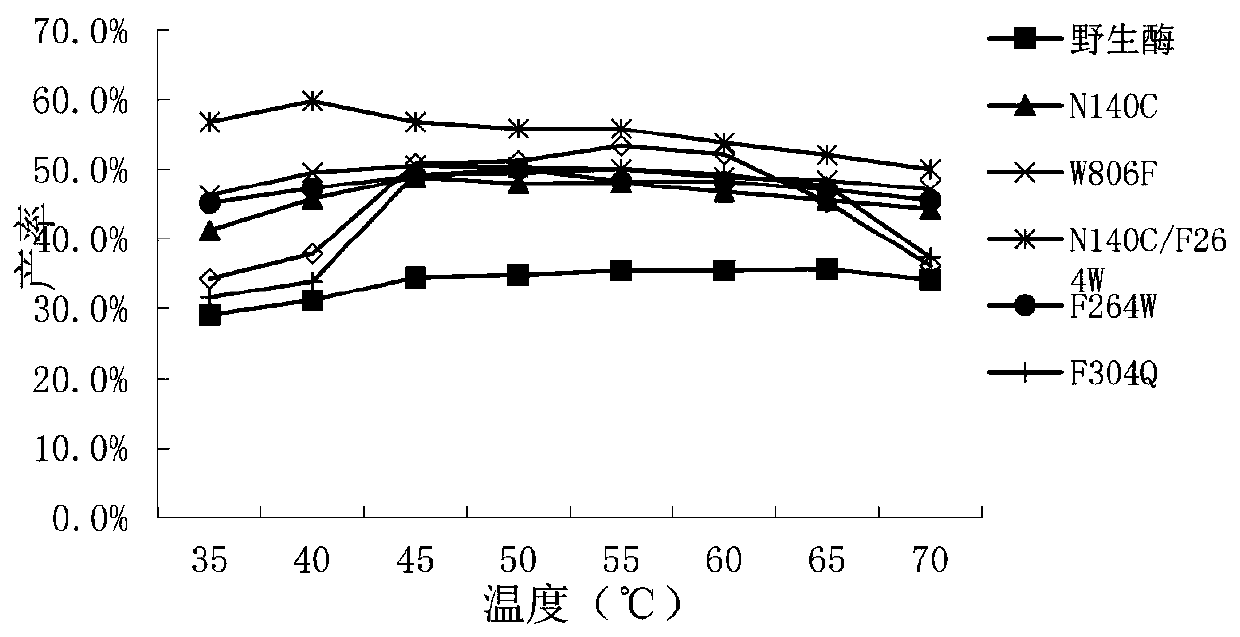

Mutant of Beta-galactosidase as well as preparation method and application thereof

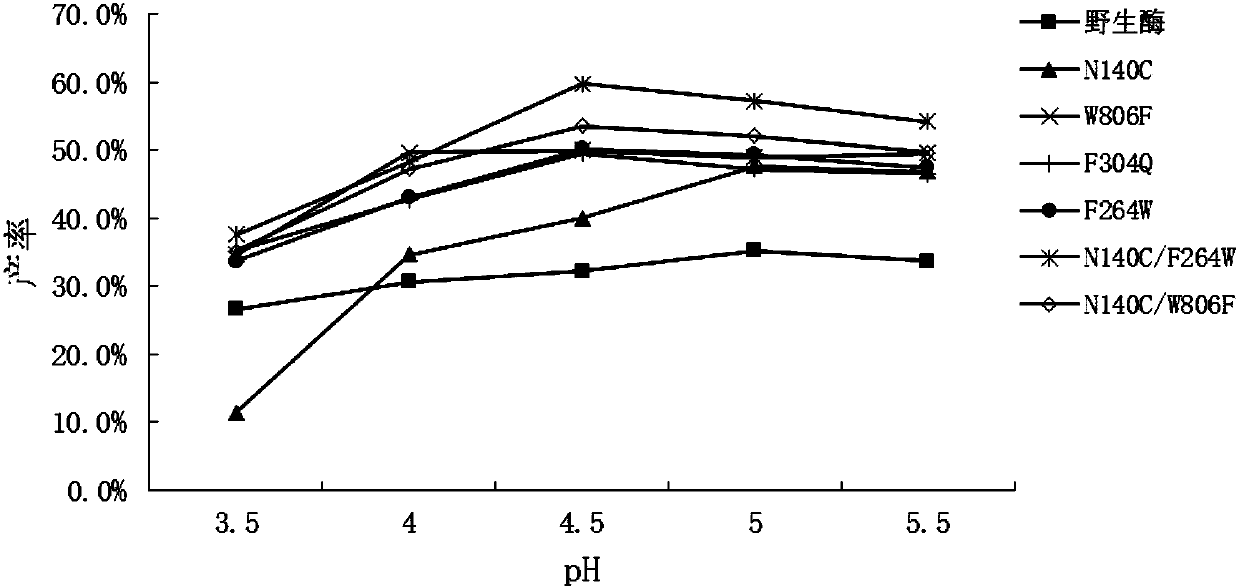

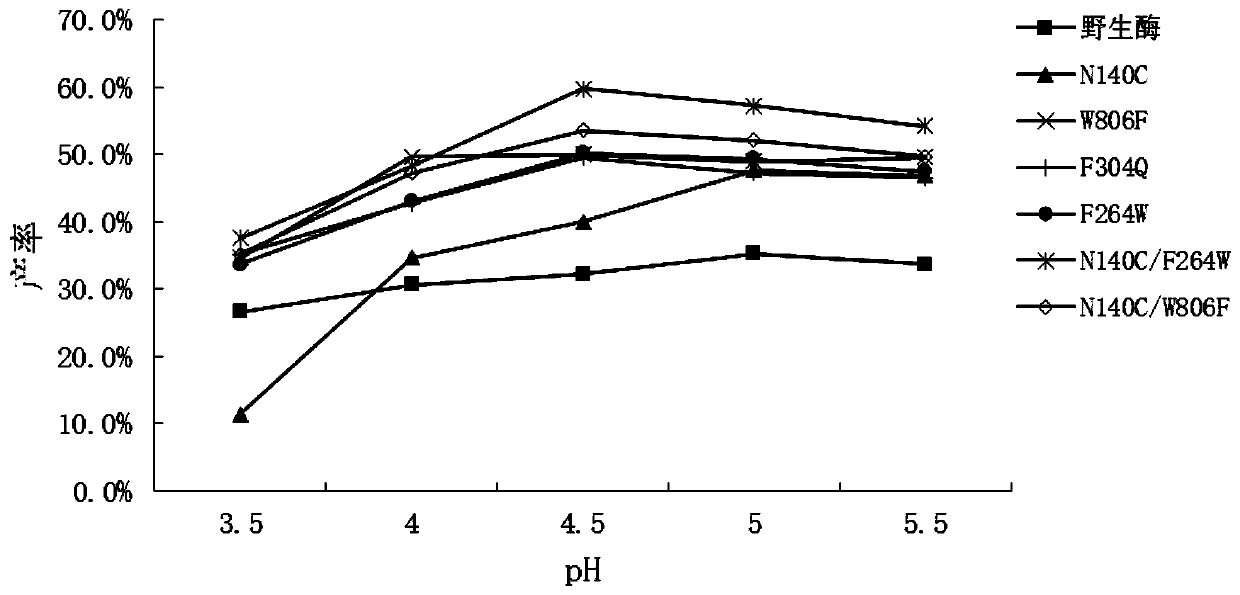

ActiveCN107937365ASolve the problem of low industrial production yieldStrong transglycoside activityMilk preparationFermentationGalactooligosaccharideMutant

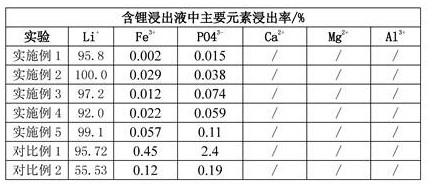

The invention discloses a mutant of Beta-galactosidase as well as a preparation method and application thereof, and belongs to the fields of gene engineering and enzyme engineering. Through mutating an amino acid at a specific locus in the Beta-galactosidase, transferring into a recombinant bacterium and then carrying out enzymatic conversion in an optimized condition, a yield of galactooligosaccharide generated by the mutant reaches 59.8 percent, and is increased by approximately 70 percent compared with that of a wild enzyme; the improvement of the yield of the galactooligosaccharide is realized, and the mutant has extremely high industrialized application.

Owner:JIANGNAN UNIV

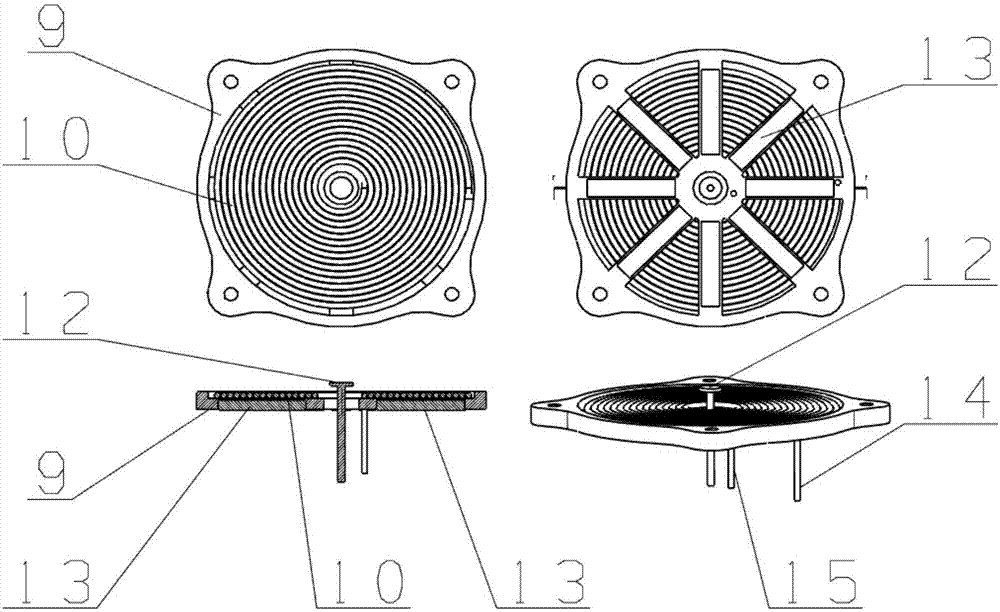

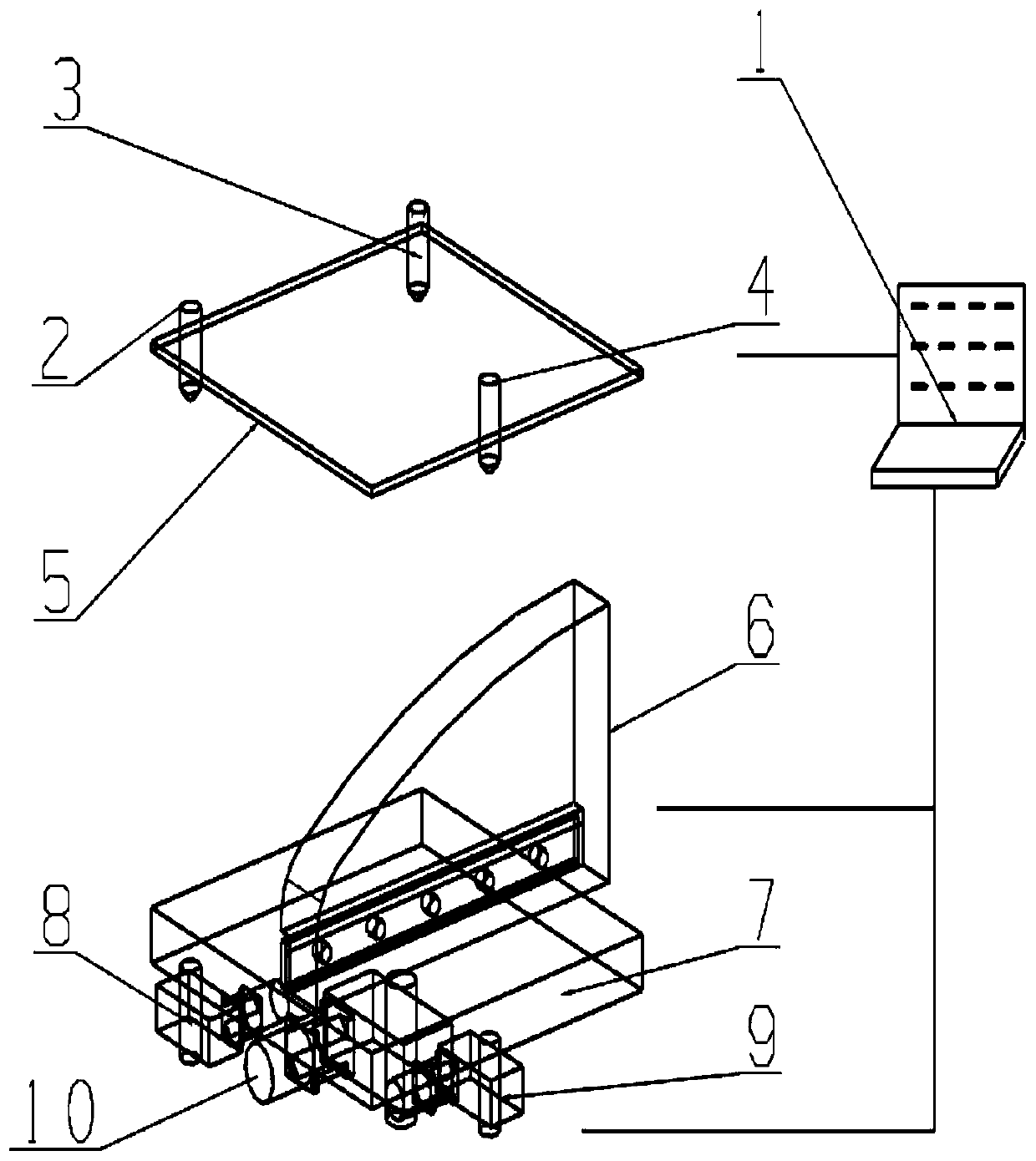

Electromagnetic induction heating 3D printing and forming system

InactiveCN108012358AImprove heating efficiencyAvoid heating inefficienciesAdditive manufacturing apparatusCoil arrangementsElectromagnetic inductionHigh energy

The invention relates to an electromagnetic induction heating 3D printing and forming system, and relates to the technical field of 3D printing equipment. By adopting an electromagnetic induction heating technology, the electromagnetic induction heating can realize high heating efficiency, energy conservation and environmental protection, so that the defects of low efficiency, high energy consumption and the like of resistance wire heating can be avoided. In addition, the electromagnetic induction heating is high in temperature and uniform in heating, controllable in heating speed and heatingtemperature, and relatively high in control sensitivity; next, by adopting an electromagnetic heating disk mode, an electromagnetic induction coil is wound into a disk shape, so that the overall structural size is small, and too much space of the forming system is not occupied; the invention provides circular, square, rectangular and fan-shaped electromagnetic induction coil winding modes, so thata thought is provided for the electromagnetic induction heating coil winding modes; and specific to different equipment structural characteristics, different winding modes can be selected, so that space can be utilized effectively, and heating uniformity is ensured.

Owner:BEIJING XINGHANG MECHANICAL ELECTRICAL EQUIP

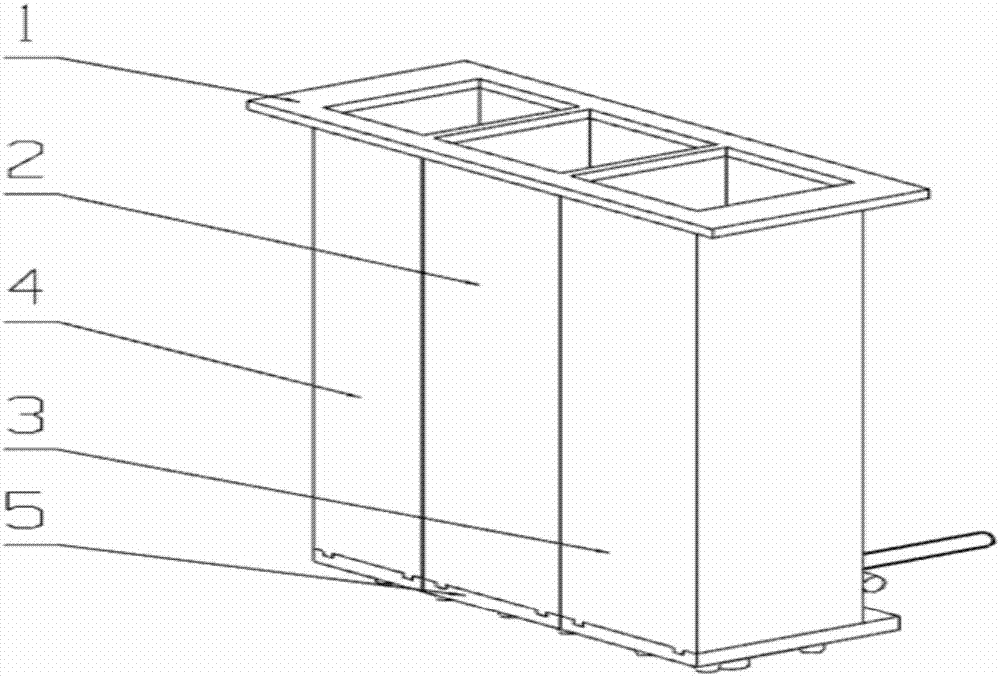

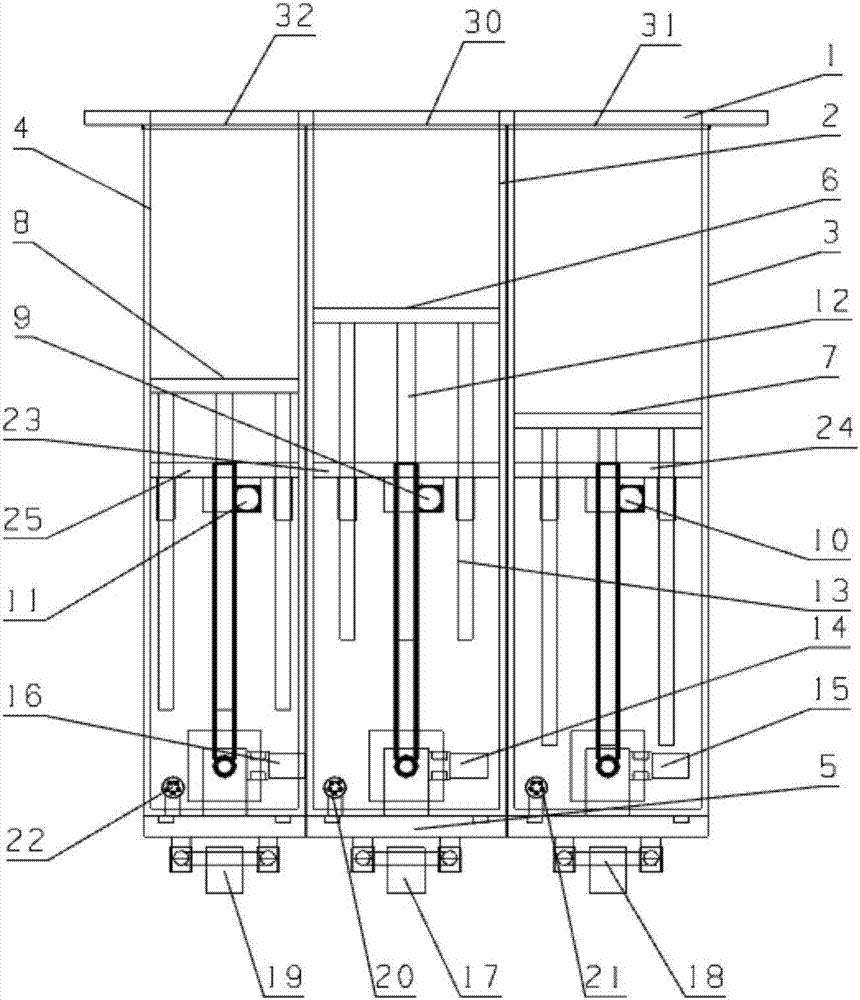

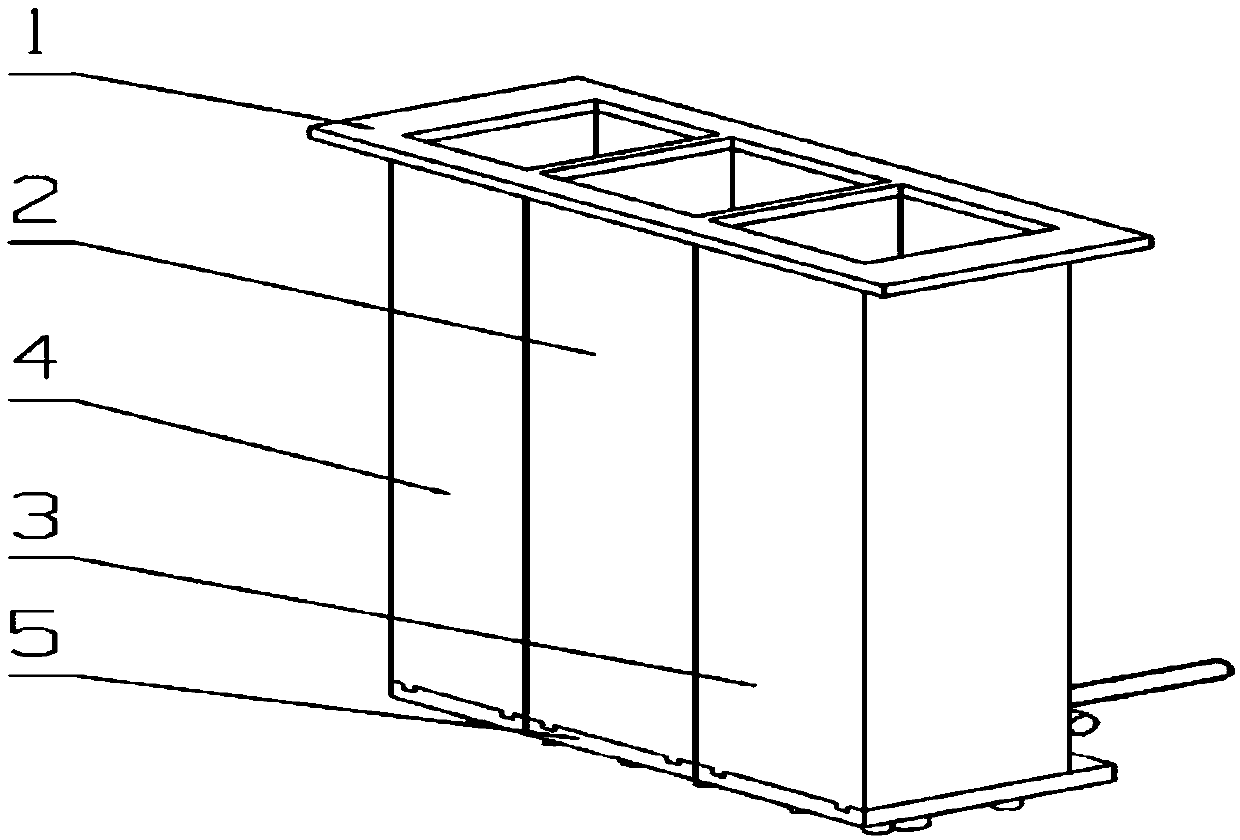

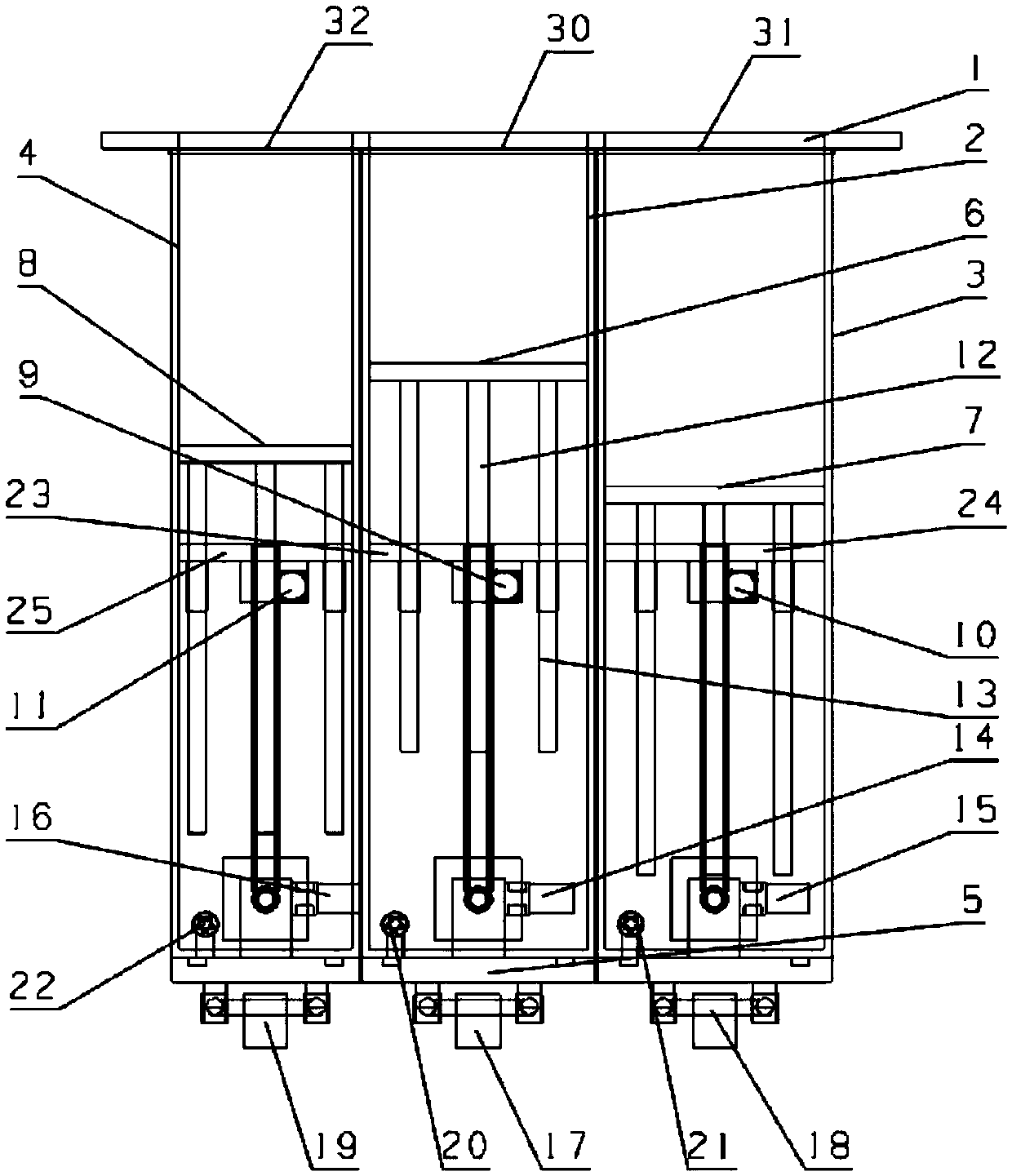

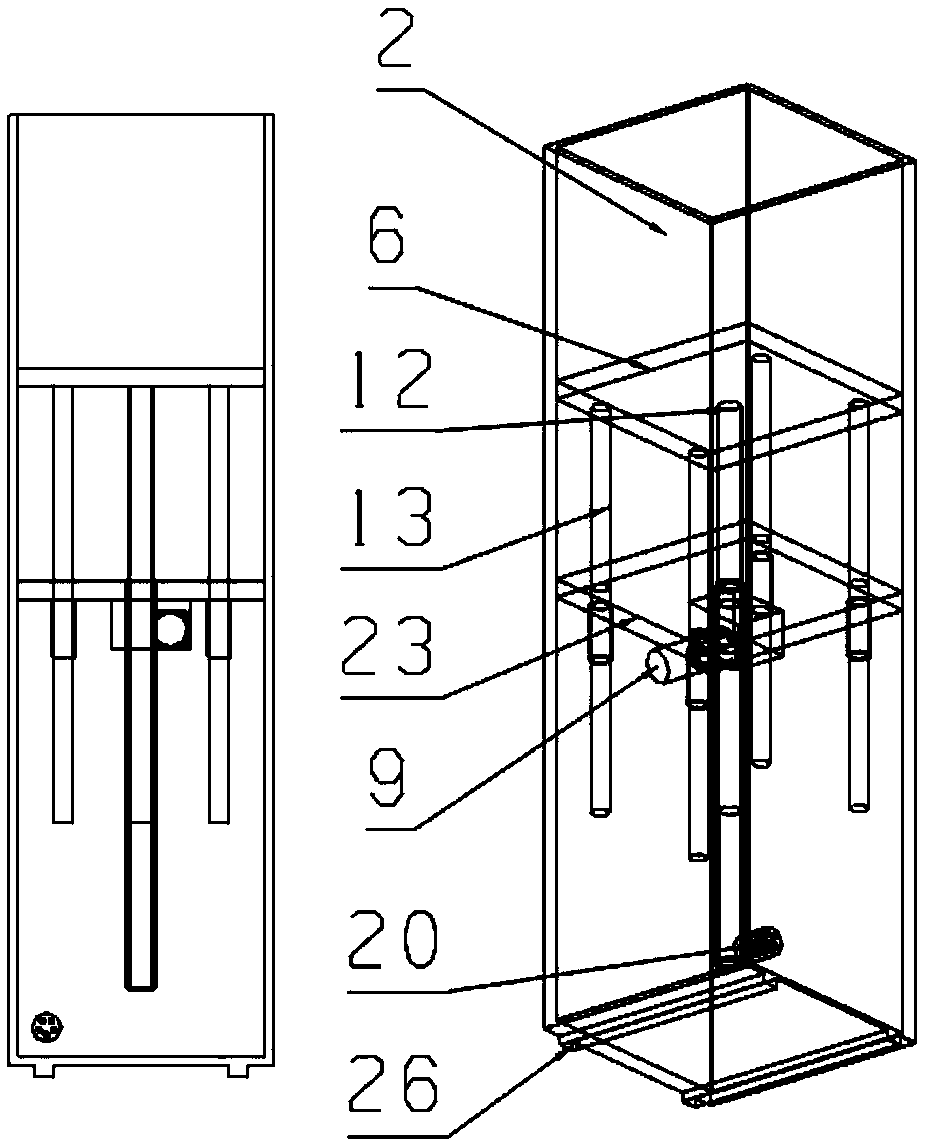

3D printing molding modular system suitable for automatic production line and using method of 3D printing molding modular system

ActiveCN107470621AAchieve installationSolve the key problems of continuous large-scale productionAdditive manufacturing apparatusIncreasing energy efficiencyProduction lineComputer module

The invention belongs to the field of 3D printing equipment, and particularly relates to a 3D printing molding modular system suitable for an automatic production line and a using method of the 3D printing molding modular system. A working cabin frame, a molding cylinder module, a feeding cylinder module, a collecting cylinder module and a lower base module are included. A collecting cylinder internal structure comprises a working table face base plate, a lifting motor, parallel guide rods, a power source connector and other components; a lower base mainly comprises a base plate, a lifting motor, a horizontal pushing motor, a power source connector and other components, the base plate can bear the molding cylinder module, the feeding cylinder module and the collecting cylinder module on the upper portion, the cylinder modules are lifted through the lifting motor and are taken out through the horizontal pushing motor, the lower base descends, the cylinder modules are pushed out, and therefore the replacement function and the like are achieved. According to the 3D printing molding modular system, modularization of work including 3D printing preparation work, the printing process, cleaning after completion and the like is achieved, streamlined operation is achieved, function combination and convenience are achieved, and the production line mode manufacturing is achieved.

Owner:BEIJING XINGHANG MECHANICAL ELECTRICAL EQUIP

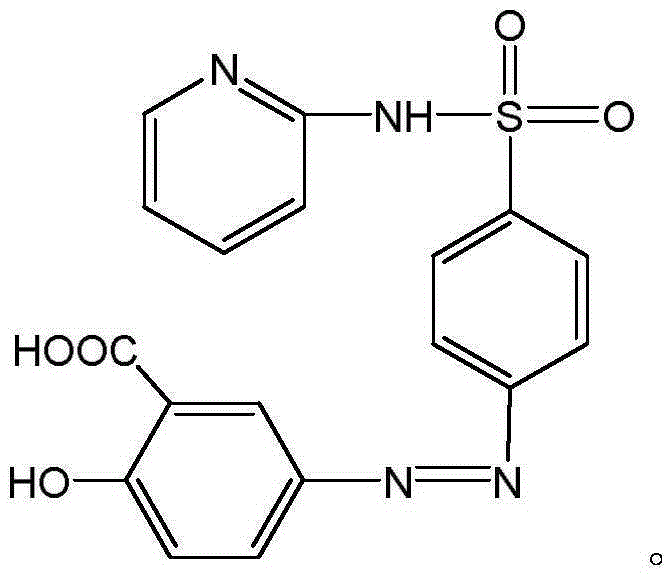

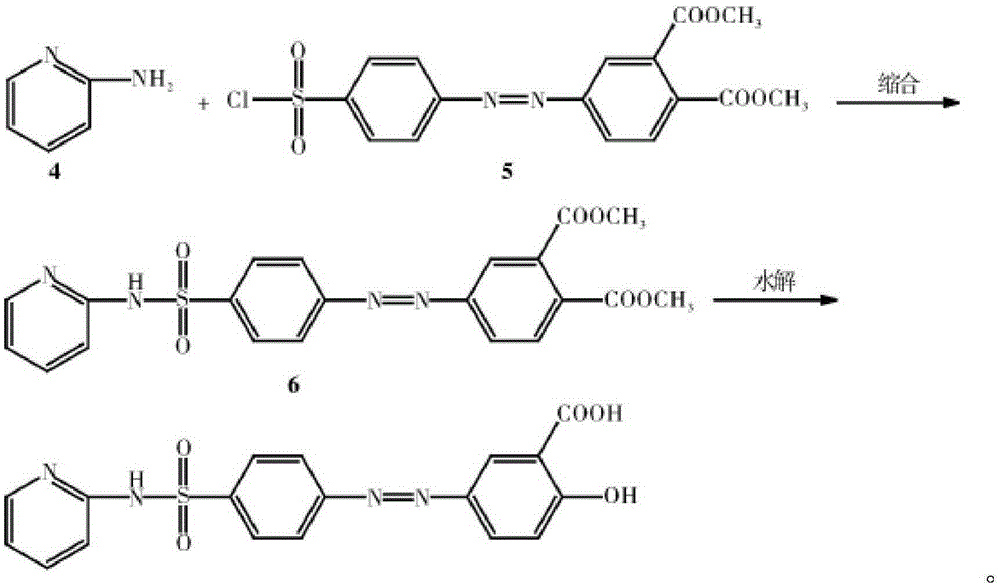

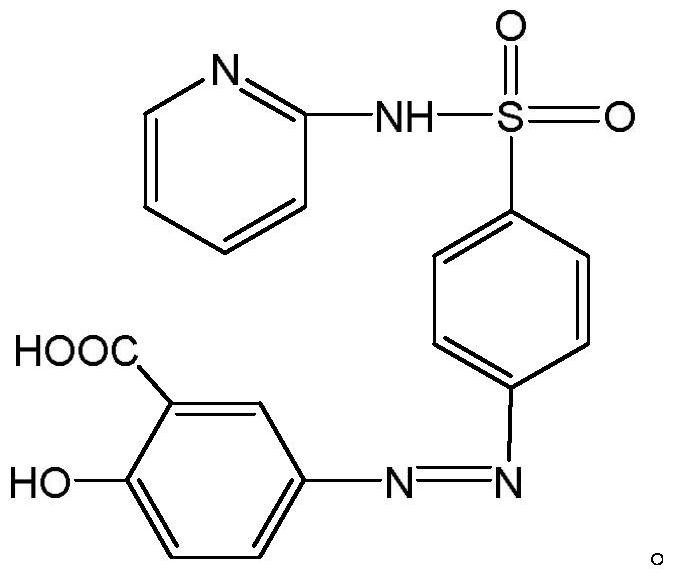

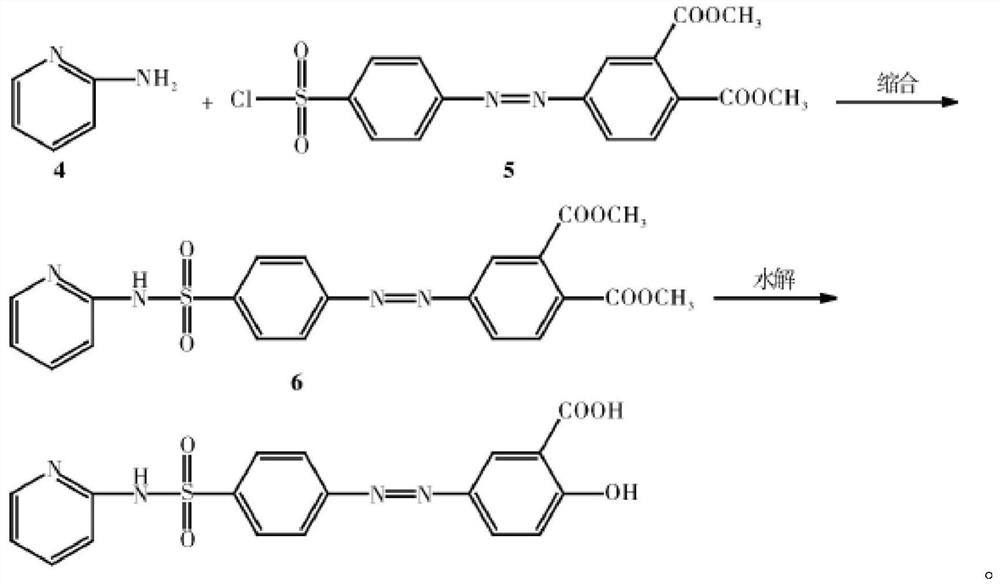

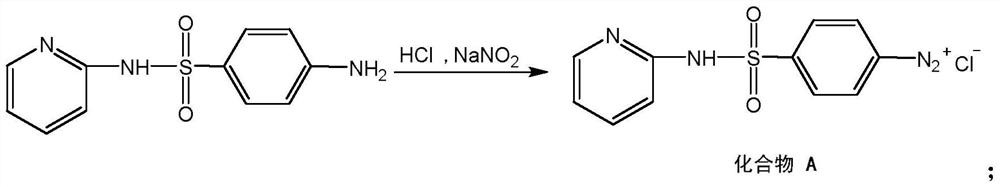

Preparation method for sulfasalazine

ActiveCN105348184AConvenient sourceImprove conversion rateOrganic chemistryAqueous sodium hydroxideSalicylic acid

The invention discloses a preparation method for sulfasalazine. The preparation method comprises the steps of: S1, carrying out a diazotization reaction on sulfapyridine in an aqueous solution dissolved with hydrochloric acid and sodium nitrite to obtain diazonium salt; S2, carrying out a coupling reaction on the diazonium salt and salicylic acid in a sodium hydroxide aqueous solution to obtain a sulfasalazine crude product; and S3, purifying the sulfasalazine crude product. According to the preparation method disclosed by the invention, by taking sulfapyridine as an initial raw material, the diazotization reaction, the coupling reaction and purification are successively carried out to obtain the sulfasalazine. The diazotization reaction and the coupling reaction have a relatively high conversation rate and relatively few side reactions, so that the purity of the product is improved, and the yield is ensured. In addition, the sulfapyridine is easily available in source, so that the production cost is lowered, and the preparation method has relatively great industrial production value.

Owner:SUZHOU HUANGHE PHARMA CO LTD

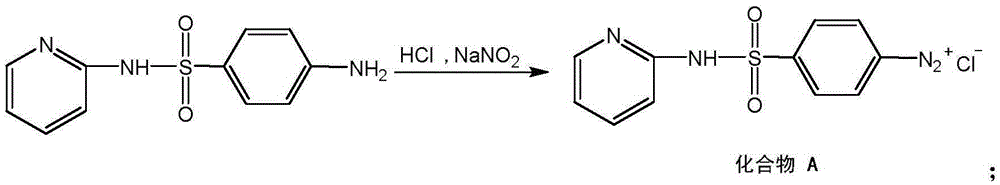

Carbon-supported metal catalyst and preparation method and application thereof

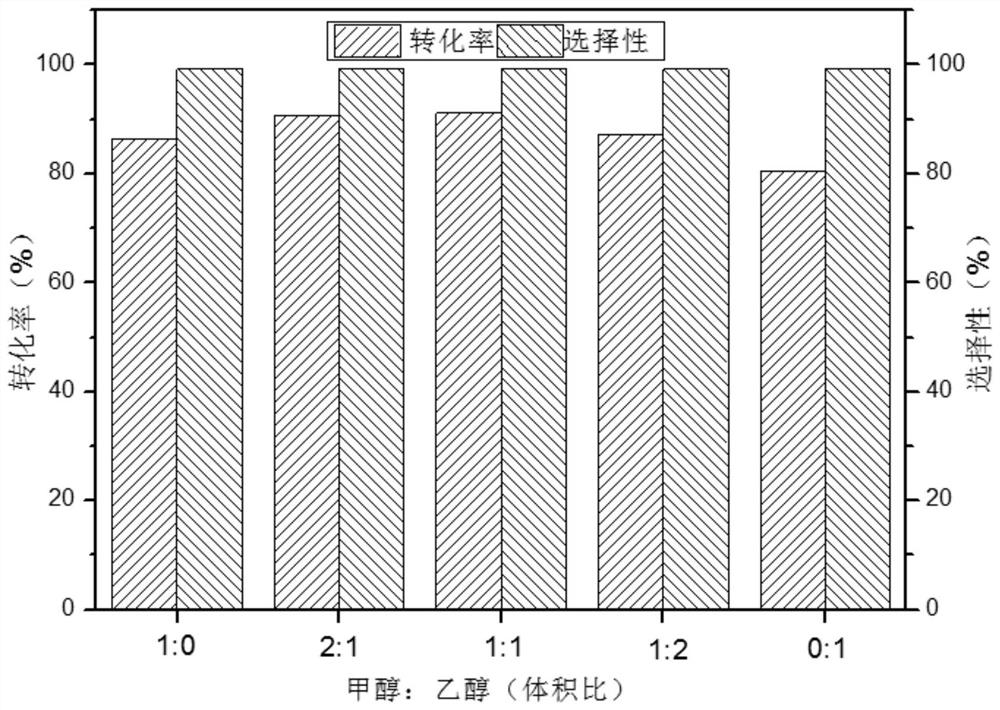

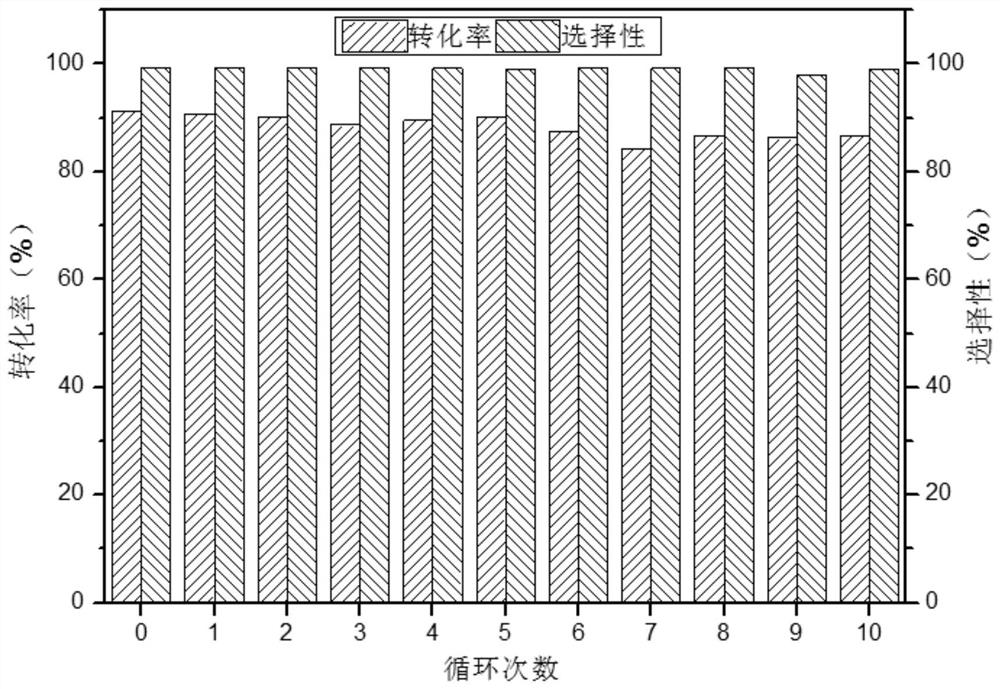

ActiveCN112536043ALow costHigh value of industrial productionOrganic chemistryOrganic compound preparationPlatinumPtru catalyst

The invention relates to a carbon-loaded metal catalyst as well as a preparation method and application thereof. The carbon-loaded metal catalyst comprises a carbon carrier and high-entropy alloy particles loaded on the surface of the carbon carrier, and the high-entropy alloy particles comprise ruthenium, iron, cobalt, nickel and platinum. Experiments prove that under the condition of the same metal loading capacity, the catalytic performance of the carbon-loaded metal catalyst provided by the technical scheme of the invention is not greatly different from that of a ruthenium-platinum-carbondouble-noble-metal catalyst, and compared with iron-platinum, nickel-platinum, cobalt-platinum and other double-metal carbon-based catalysts, the carbon-loaded metal catalyst provided by the inventionis better in catalytic performance and more stable in recycling performance. Meanwhile, the cost of metal elements such as iron, cobalt and nickel in the high-entropy alloy particles is relatively low, so that the cost of the carbon-loaded metal catalyst is greatly reduced.

Owner:ZHEJIANG NHU CO LTD +2

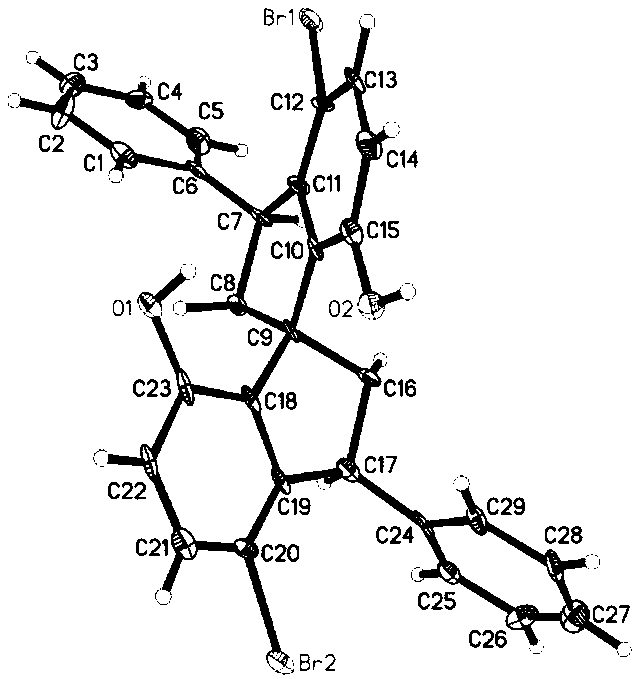

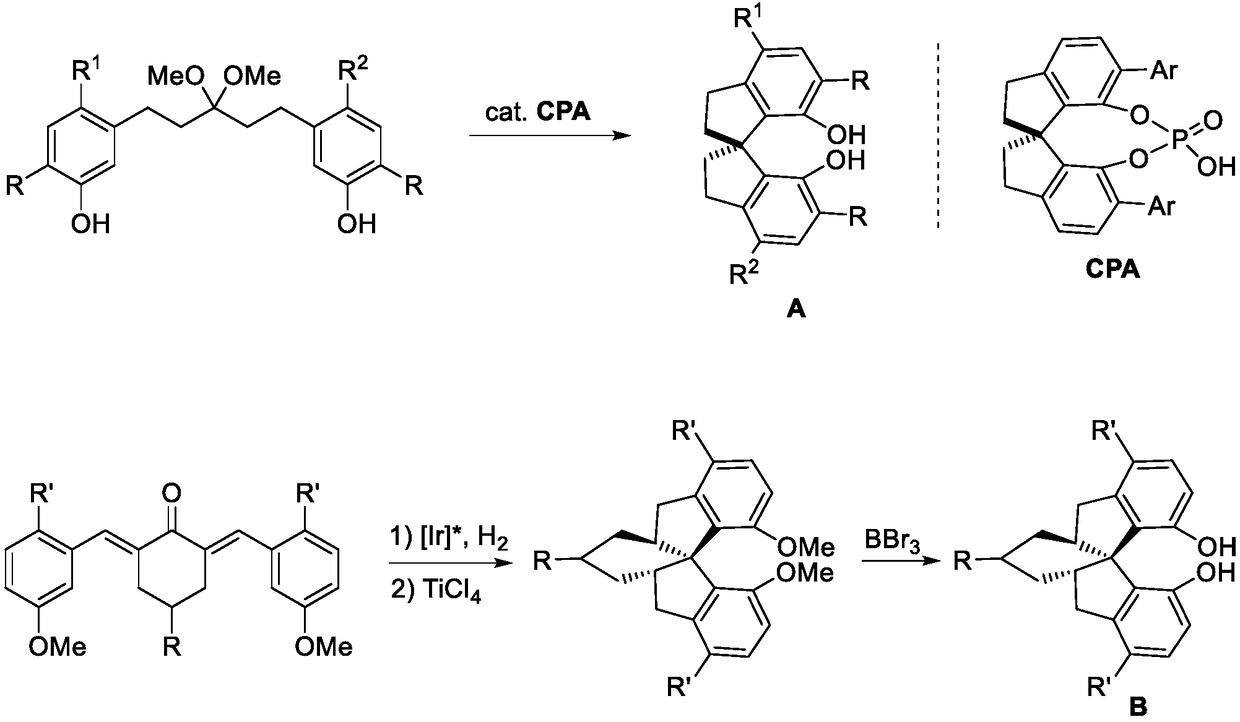

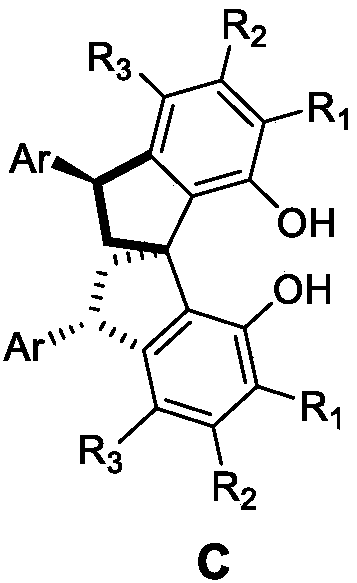

Asymmetric synthesis method for 3,3'-diaryl substituted chiral spiro bisphenol compound

ActiveCN109400445AHigh yieldHigh enantioselectivityOrganic compound preparationOrganic chemistry methodsBenzaldehydeSynthesis methods

The invention discloses an asymmetric synthesis method for a 3,3'-diaryl substituted chiral spiro bisphenol compound. The method comprises the steps that acetone serves as a raw material and is subjected to condensation reaction with substituted benzaldehyde so as to obtain I; under the action of a chiral rhodium catalyst, the compound I and an aryl boron reagent are subjected to enantioselectivesynthesis so as to obtain II; and under the catalysis of Bronsted acid or Lewis acid, the compound II is subjected to intramolecular Friedel-Crafts reaction so as to prepare a compound III. The synthesis method has the advantages that chiral raw materials are not needed, splitting is not needed, the yield is high, the enantioselectivity is good and the like; in an amplified synthesis process, theamount of the chiral rhodium catalyst can be as low as 0.5 mol%, and industrial production application values are achieved.

Owner:CHINA PHARM UNIV

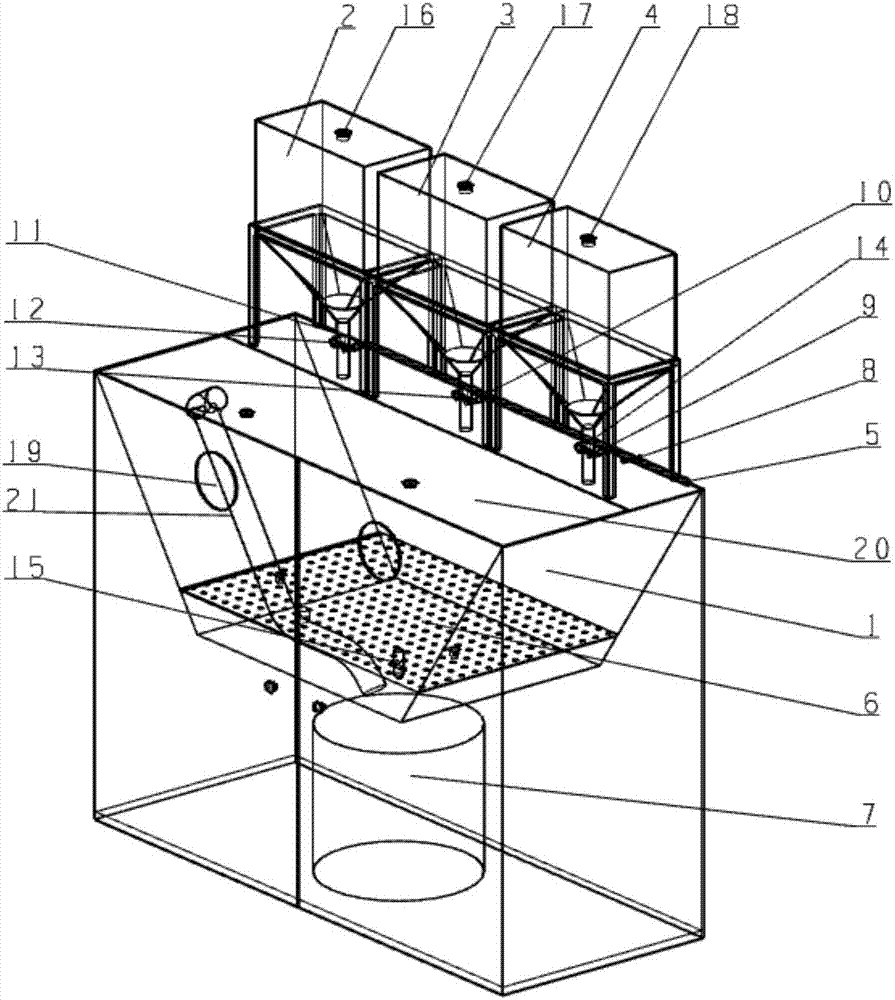

Device and method for atomization cleaning of 3D printing photosensitive resin

InactiveCN107310158AFast cleaningStandardize the cleaning processAdditive manufacturing apparatusManufacturing recyclingGlass coverAlcohol

The invention belongs to the field of resin product treatment, and concretely relates to a device and a method for atomization cleaning of 3D printing photosensitive resin. The device comprises a cleaning tank, alcohol containers, a high gas system and a waste liquid collector. A filter screen baffle plate is arranged in the cleaning tank to prevent the above product from directly immersing in alcohol; the cleaning tank adopts a glass cover plate, so the cleaning tank is visible; the front side of the cleaning tank is provided with a glove operating opening, so the cleaning tank is convenient to clean; three alcohol containers are arranged above the cleaning tank, and are respectively used for containing cleaning liquids recovered at different recovery times, the rear side of the cleaning tank is provided with a high pressure gas pipeline to realize alcohol atomization, and valve switches are arranged below the alcohol containers and on pipelines to control the flow; and a valve arranged below the cleaning tank, and a waste liquid collecting container is arranged below the valve. Grading multi-time recovery, one-time recovery and new alcohol cleaning are adopted, so the cost is greatly reduced, the cleaning flow of the 3D printing photosensitive resin is standardized, the flow and the pressure are controllable, and rapid cleaning of the surface of the product is realized.

Owner:BEIJING XINGHANG MECHANICAL ELECTRICAL EQUIP

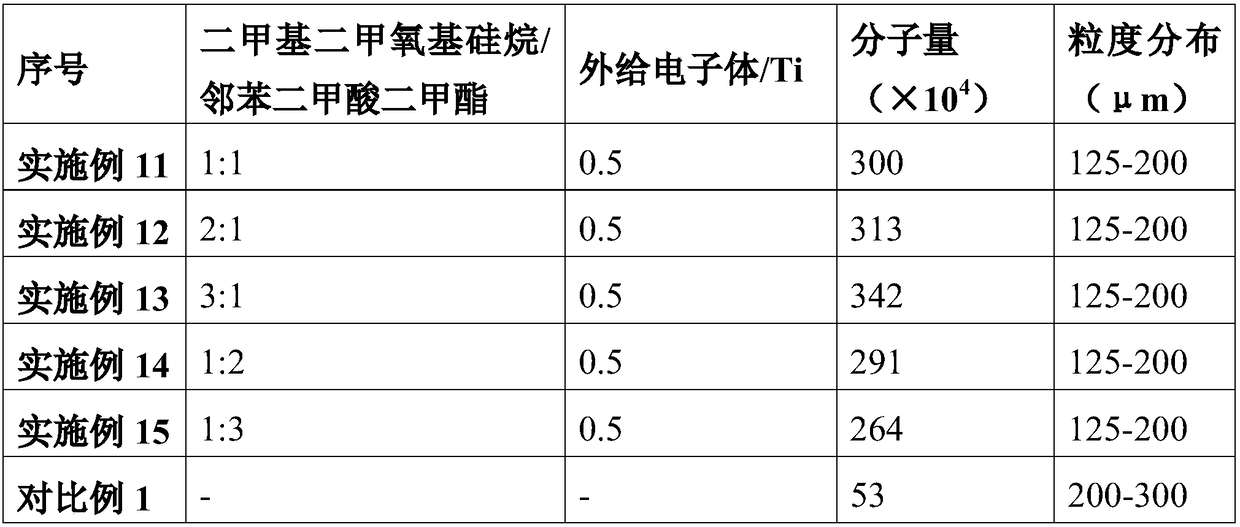

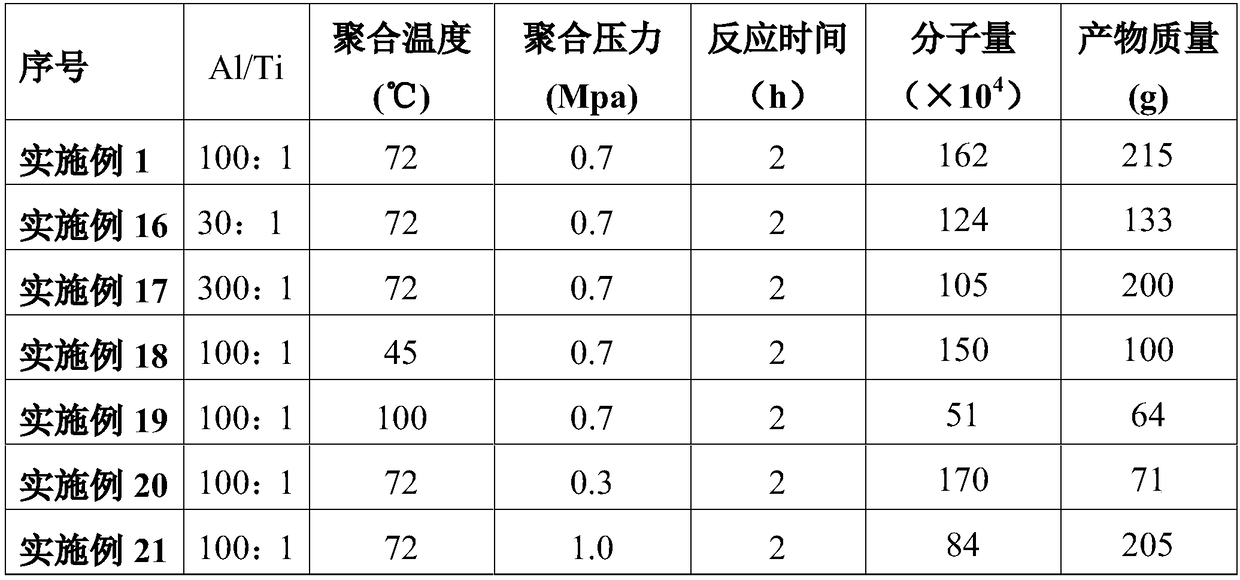

Method for producing ultrahigh molecular weight polyethylene

The invention discloses a method for producing ultrahigh molecular weight polyethylene with M miu of 1.5-8 million. The method comprises that an external electron donor is added into a reaction systemin the presence of a main catalyst and a cocatalyst and then the system undergoes homopolymerization of ethylene. Through the use amount of the silane external electron donor, the molecular weight ofthe ultrahigh molecular weight polyethylene is adjusted without change of catalyst conditions and through use of the ester external electron donor, the particle size and distribution of the ultrahighmolecular weight polyethylene powder are improved. The method has the advantages of control of technical conditions and temperature, simple operation and remarkable industrial value.

Owner:PETROCHINA CO LTD

Composite ceramics

The invention discloses composite ceramics prepared from the following components by weight: 97%+ / -0.1% of alumina, 3%+ / -0.2% of talc, 3.5%+ / -0.1% of zirconium dioxide and 1%+ / -0.1% of vanadium zirconium yellow. The hardness, wear resistance and toughness of alumina are changed by using high-weight-ratio alumina proportioning and supplement of zirconia, talc and vanadium zirconium yellow, the hardness higher than that of other alumina ceramics is achieved, the toughness better than that of other alumina ceramics is achieved, the hardness reaches 1100-1150 Vickers hardness, and the wear resistance also reaches 30 million times. Therefore, the composite ceramics have wide application prospects in new energy vehicle industry, and especially are applied in automotive seal parts and valves.

Owner:湖南福美来电子陶瓷有限公司

Method for preparing 7-dehydrocholesterol

The invention relates to a method for preparing 7-dehydrocholesterol, which comprises the following steps: 1) protecting hydroxyl on the 3-site of cholesterol; 2) oxidizing carbon on the 7-site of the product obtained in step 1) into carbonyl; 3) carrying out a hydrazone reaction on the product obtained in step 2) and a hydrazine derivative; 4) reacting the product obtained in step 3) with a strongly alkaline reagent; and 5) reacting the product obtained in step 4) with water or an acid. The method has the advantages of simple operation process, less secondary reaction, high yield and less corrosion to equipment, thereby having high industrial production values.

Owner:ANHUI BBCA FERMENTATION TECH ENG RES

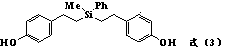

Silicon-containing diphenol and preparation method thereof

InactiveCN104817581AEasy to manufactureRaw materials are easy to getSilicon organic compoundsPolymer scienceSilanes

The invention provides a silicon-containing diphenol and a preparation method thereof, wherein a structure of the silicon-containing diphenol is represented as the formula (I). The preparation method includes following steps: (A) with di-substituted divinyl silane as a raw material, performing a catalytic olefin double-decomposition reaction with vinylphenol to obtain an intermediate, di-substituted bis(hydroxylstyryl)silane; (B) performing catalytic hydrogenation and catalytic transfer hydrogenation to obtain di-substituted bis(hydroxylphenethyl)silane, which is the silicon-containing diphenol in the invention. The silicon-containing diphenol represented in the formula (I) is excellent in toughness, flame resistance and heat resistance. The preparation method is simple in operation, is mild in conditions, is high in product yield, is low in cost, is green and environment-friendly, and is high in industrialization value.

Owner:QUZHOU UNIV

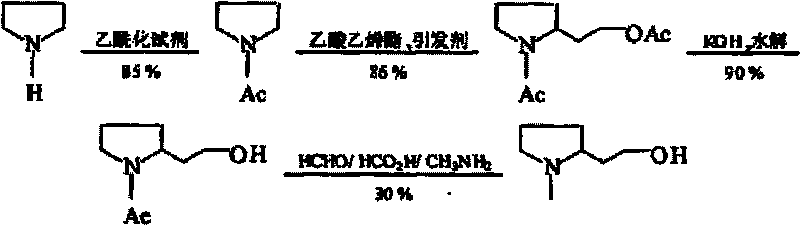

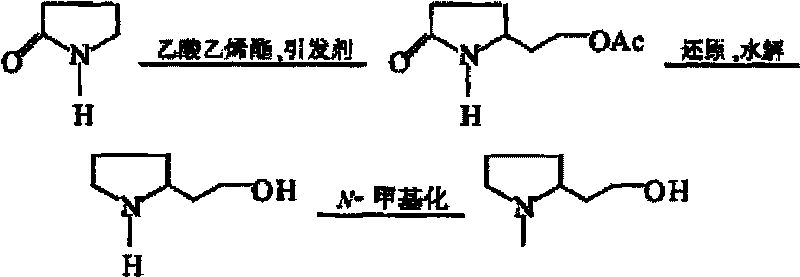

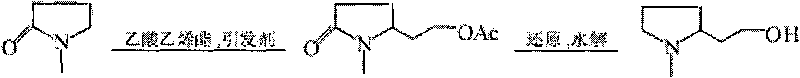

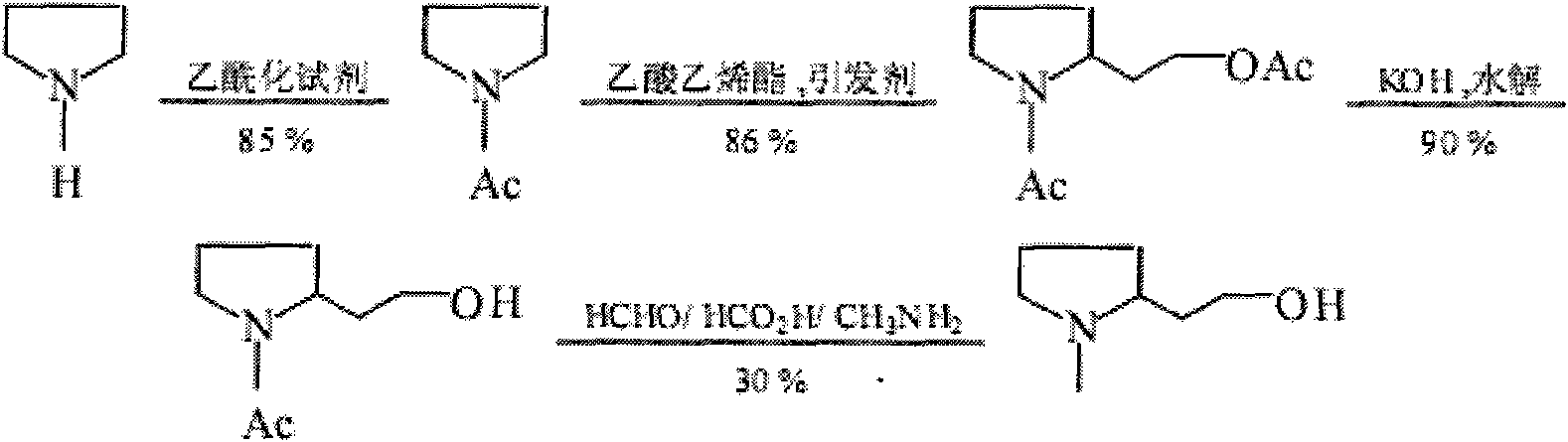

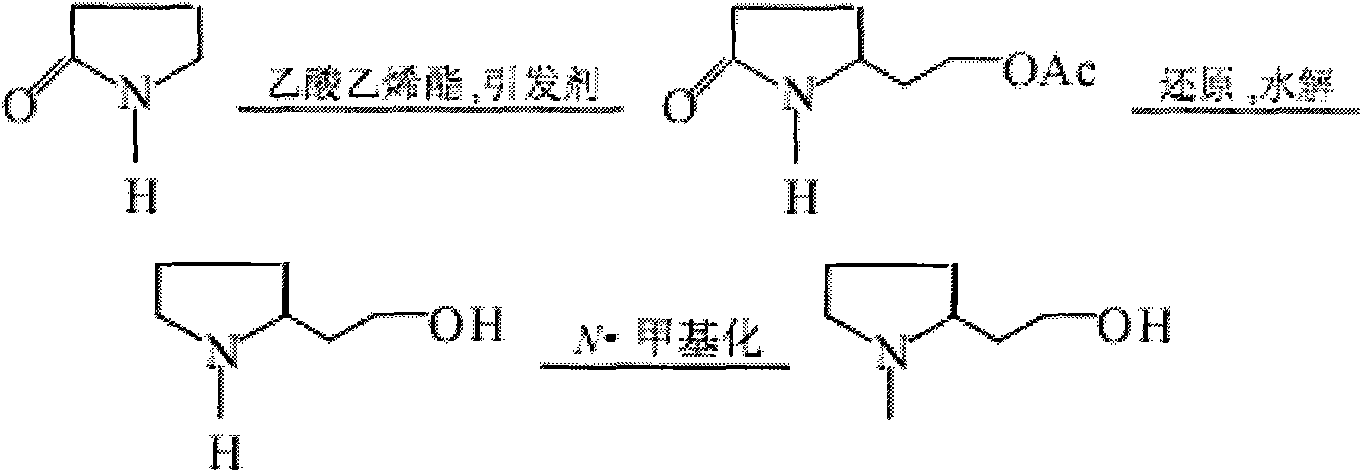

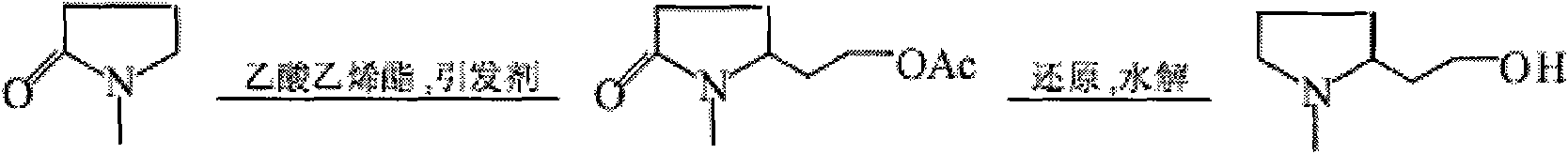

Synthesis method of N-methyl-2-hydroxyethyl hydroxyethyl

ActiveCN101735132ARaw materials are cheap and easy to getShort synthetic routeOrganic chemistrySynthesis methodsNitrogen gas

The invention discloses a synthesis method of N-methyl-2-hydroxyethyl hydroxyethyl, which comprises the following steps of: (1) adding dimethyl sulfate and N-methyl pyrrolidone into a reaction kettle for reaction; (2) cooling and dropwise adding an ethanol solution of sodium ethylate, continuously dropwise adding ethyl cyanoacetate, reacting and filtering to obtain an intermediate (I); (3) adding the intermediate (I) and a catalyst as well as a high-boiling point organic solvent to the reaction kettle, heating, fractionating, reacting, filtering, recovering propylene glycol, and carrying vacuum rectification to obtain a intermediate (II); and (4) adding the intermediate (II) and the catalyst as well as a solvent into the reaction kettle, replacing by using nitrogen and hydrogen sequentially, introducing hydrogen, reacting, cooling, evacuating, filtering, evaporating out moisture content, and carrying out vacuum rectification to obtain the N-methyl-2-hydroxyethyl hydroxyethyl. The synthesis method has the advantages of cheap and easily obtained raw materials, short synthesis route, mild reaction conditions, relatively low production cost and higher overall yield.

Owner:江苏恒祥化学股份有限公司

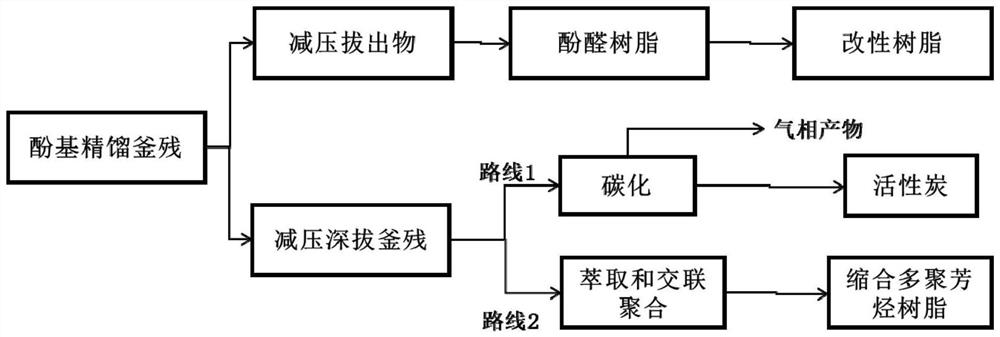

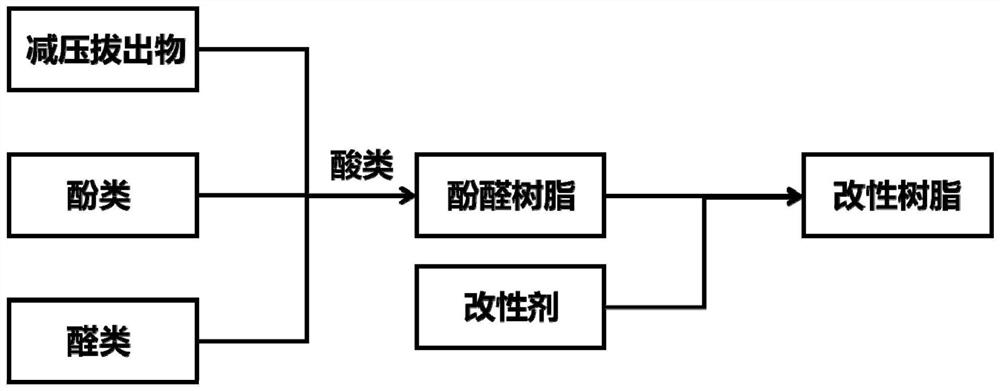

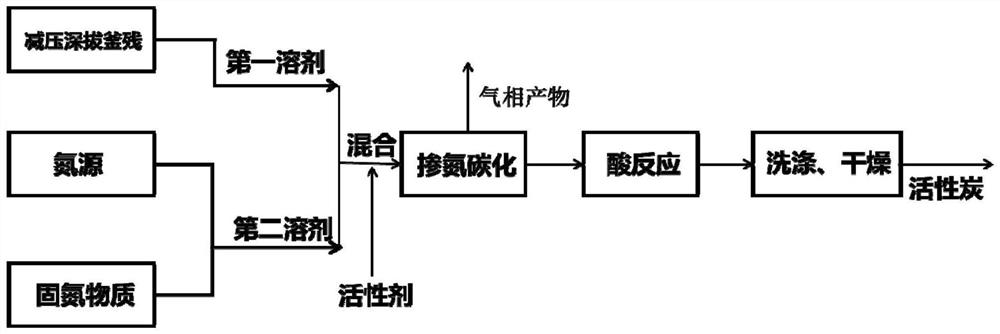

Method for treating phenol-based residues of rectifying still

ActiveCN112194766ARealize resource utilizationImprove performanceGas treatmentCarbon compoundsActivated carbonCarbonization

The invention provides a treatment method of phenol-based residues of a rectifying still. The treatment method comprises the following steps: carrying out reduced-pressure deep drawing on the phenol-based residues of the rectifying still to obtain a reduced-pressure pull-out substance and reduced-pressure deep drawing still residues; and subjecting the reduced-pressure deep drawing still residuesto carbonization to obtain a gas-phase product and activated carbon, or to extraction and cross-linking polymerization to obtain condensed polyaromatic hydrocarbon resin. Thus, phenol-based residual solid waste of the rectifying still can be effectively converted into an industrial product with excellent performance, environmental pressure is relieved, good economic benefit is obtained, wide application prospects are realized.

Owner:TIANJIN UNIV

Comprehensive water-saving process for producing stevioside

ActiveCN107383127AImprove qualityLow ashSugar derivativesGeneral water supply conservationChemistryOzone

The invention discloses a comprehensive water-saving process for producing stevioside. Down-column water generated in a resin adsorption step is subjected to purification treatment and a waste acid, a waste alkali and waste water, which are generated in an adsorption resin and desalting and decolorizing resin regeneration step are subjected to treatment, in the production procedure of the stevioside. According to the comprehensive water-saving process, a water extracting solution of a stevia leaf is subjected to resin adsorption; down-column waste water is subjected to rough filtration, primary filtration, ceramic film filtration, resin adsorption treatment, ozone treatment, adsorption filtration and reverse osmosis treatment in sequence to obtain purifier water which is directly used for the water extraction of the stevia leaf; abundant waste acid, waste alkali and waste water, which are produced in a resin regeneration procedure, are recycled; a water consumption is decreased by 70 percent or above; an acid consumption and an alkali consumption are decreased by 60 percent or above; meanwhile, by-products flavone and chlorogenic acid are obtained. According to the comprehensive water-saving process, a new pollutant does not be generated; no new chemical reagents are put; the quality of treated water is high; part of indexes are superior to those of underground water and municipal water; the ash content of a stevioside product can be decreased; the improvement of the purity and the yield of the product is facilitated; the industrial production value of the stevioside is improved.

Owner:CHENGUANG BIOTECH GRP CO LTD

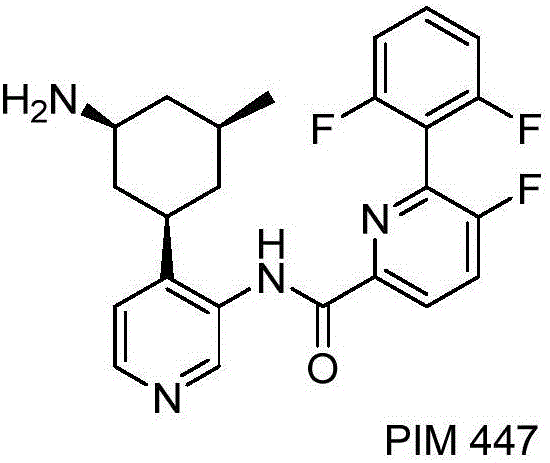

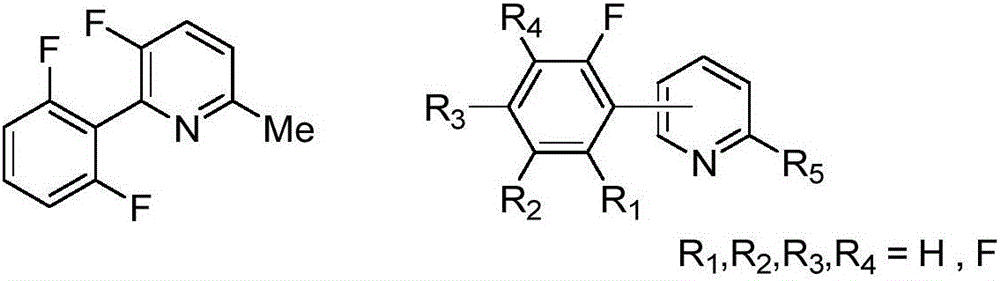

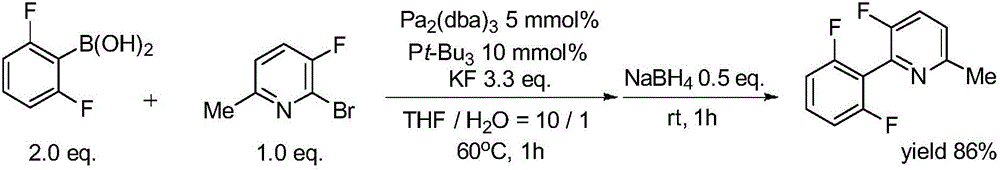

Synthesis method of (poly)fluorophenylpyridine compounds

InactiveCN106243018AReduce manufacturing costLower reaction costOrganic chemistryGrignard reagentSynthesis methods

The invention discloses a synthesis method of (poly)fluorophenylpyridine compounds. The method is characterized by under anhydrous and oxygen-free conditions, using tetrahydrofuran as a solvent, an alkyl Grignard reagent or lithium alkylide as an activating agent and equivalent zinc halide as an assistant agent and adopting a compound formed by a nickel source and a diphosphine ligand as a catalyst to achieve cross-coupling of polyfluorobenzene and halogenated pyridine, thus synthesizing a series of (poly)fluorophenylpyridine compounds with yield of about 90% and purify not less than 99%. The synthesis method has the beneficial effects that use of expensive (poly)fluorophenylboronic acid and palladium catalysts is avoided by adopting cheaper (poly)fluorophenyl and nickel compound as the raw material and the catalyst, so the synthesis method has obvious economic advantages; the synthesis method has the advantages of simple reaction system, mild conditions, simplicity in operation, easiness in aftertreatment, low pollution, easiness in industrialization, and the like and shows higher social value and industrial popularization prospect.

Owner:SHAANXI NORMAL UNIV

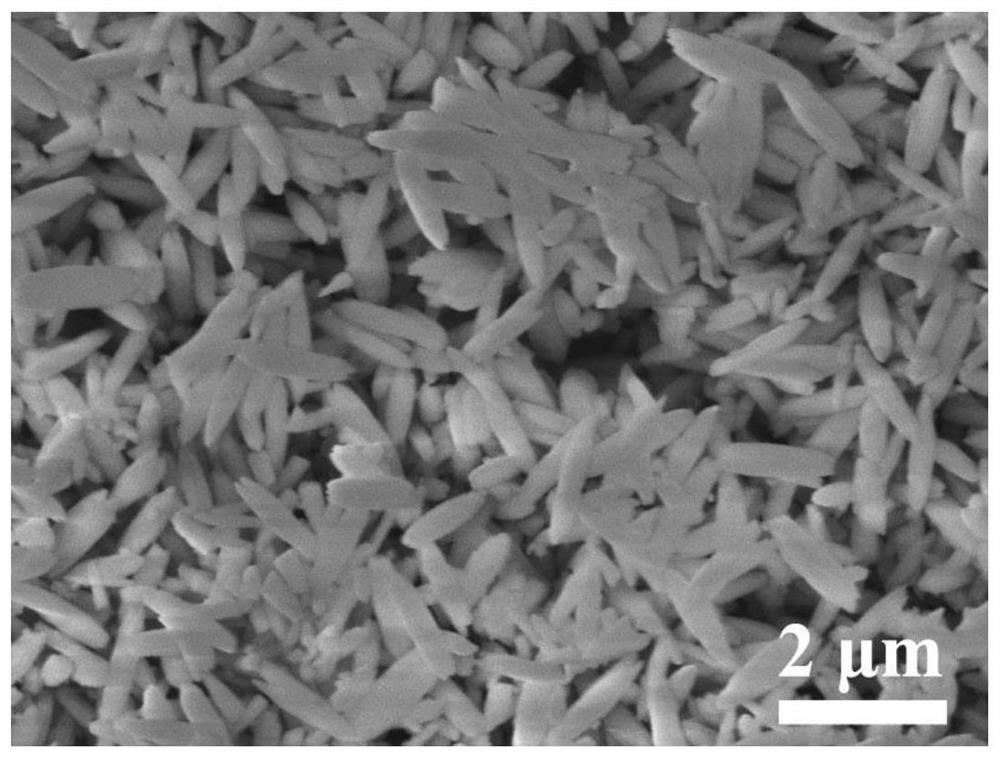

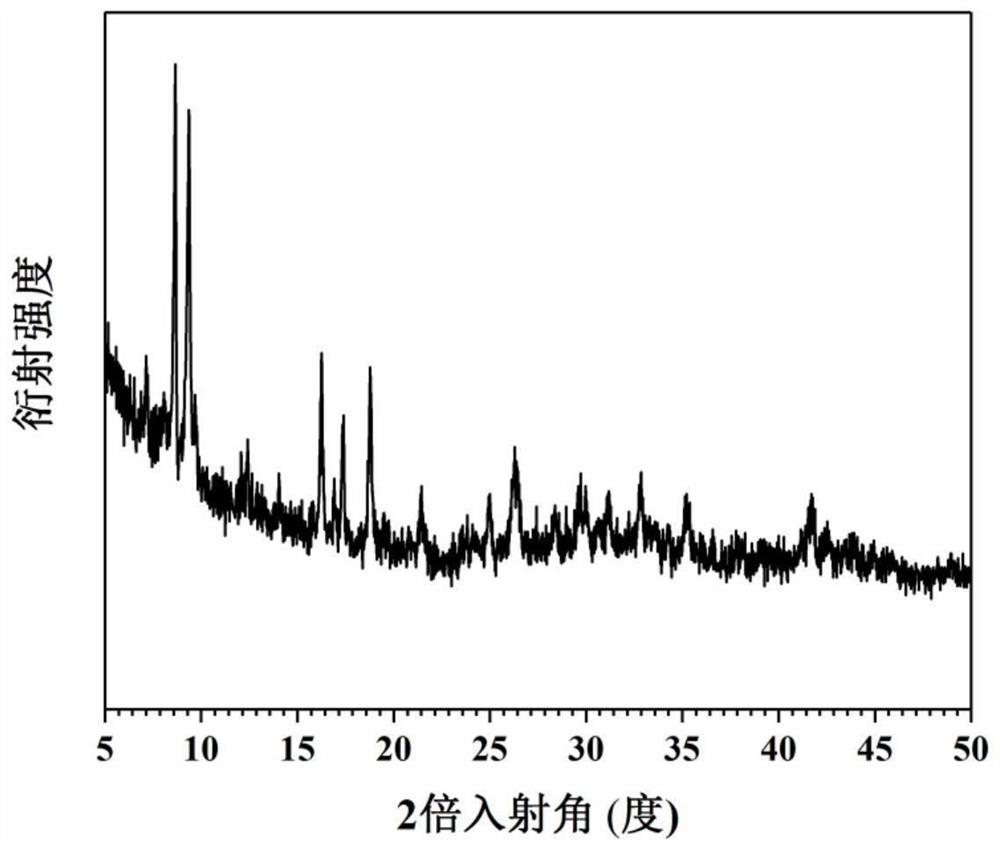

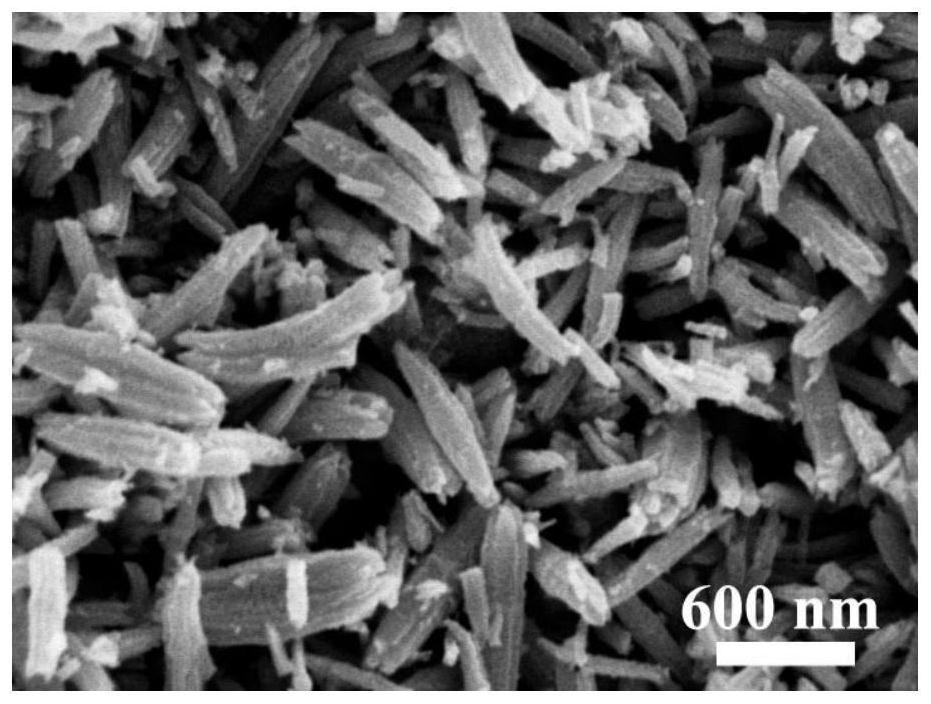

CdZnS superfine nanoparticle loaded In2O3 fusiform nanorod composite material, and preparation method and application thereof

PendingCN113385193ABroaden the range of light absorptionThe pros and cons of photocatalytic performanceCatalyst activation/preparationHydrogen productionNanoparticlePhoto catalysis

The invention belongs to the technical field of preparation of photocatalyst materials, and relates to a CdZnS superfine nanoparticle loaded In2O3 fusiform nanorod composite material, and a preparation method and application thereof. The heterogeneous optical composite material for catalyzing hydrogen production, which is prepared by loading CdZnS superfine nanoparticles on fusiform mesoporous In2O3 nanorods, can be stably applied to hydrogen production by photocatalytic decomposition of water, solves the instability caused by photocorrosion of CdZnS in a photocatalytic process, not only widens the light absorption range of a photocatalytic material, but also greatly enhances the catalytic hydrogen production efficiency. And the whole preparation process is simple, the reaction is easy to control, the repeatability is very good, and the industrial production value is very high.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

A mutant of β-galactosidase and its preparation method and application

ActiveCN107937365BSolve the problem of low industrial production yieldStrong transglycoside activityMilk preparationFermentationMicrobiologyGalactooligosaccharide

The invention discloses a mutant of β-galactosidase and its preparation method and application, belonging to the fields of genetic engineering and enzyme engineering. By mutating the amino acid at a specific site in β-galactosidase, transferring it into the recombinant bacteria, and performing enzyme transformation under optimized conditions, the yield of galactooligosaccharides produced by the mutant reached 59.8%, which was higher than that of the wild The enzyme is increased by about 70%, and the yield of galactooligosaccharides is increased, which has extremely high industrial application.

Owner:JIANGNAN UNIV

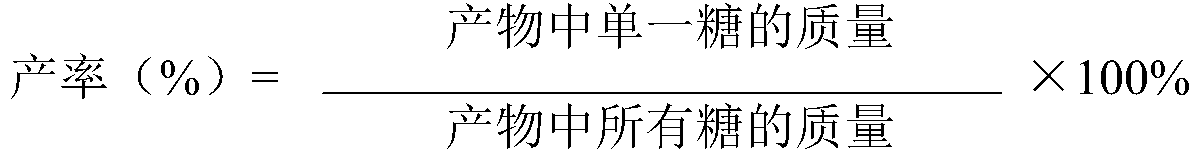

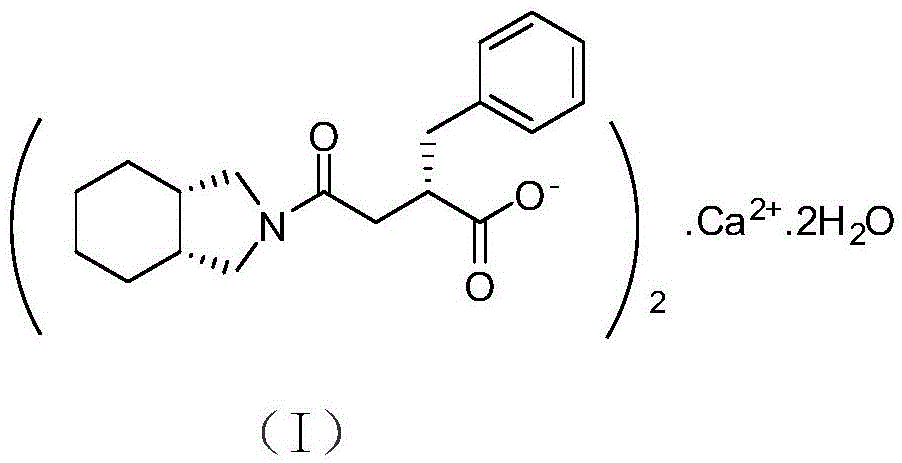

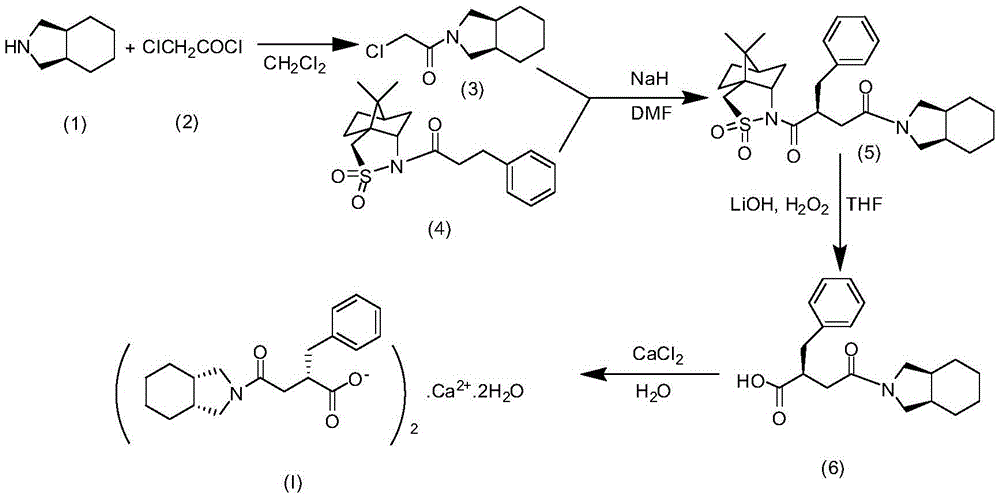

A kind of preparation method of mitiglinide calcium

InactiveCN103724253BRaw materials are easy to getMild reaction conditionsOrganic chemistryHydrolysisMITIGLINIDE CALCIUM

The invention provides a novel preparation method for Mitiglinide calcium hydrate. The method comprises the following steps: adopting cis-hexahydroisoindole as a raw material, conducting acylation reaction, hydrocarbonylation reaction, hydrolysis reaction, and salt forming reaction on the raw material, and obtaining the Mitiglinide calcium hydrate; a one-port process method is adopted for conducting the hydrocarbonylation reaction and the hydrolysis reaction, and the product purity can reach over 99.8%, and the yield can reach over 36%. The preparation method for Mitiglinide calcium hydrate has the advantages of the easy-to-get raw material, mild reaction condition, simple and practicable operation, and relatively high yield, therefore, the method has relatively higher industrial production value, and industrialization has been realized at present.

Owner:中国人民解放军联勤保障部队第九六六医院

A comprehensive water-saving process for stevioside production

ActiveCN107383127BEliminate odorHas a decolorizing effectSugar derivativesGeneral water supply conservationChlorogenic acidFiltration

The invention discloses a comprehensive water-saving process for producing stevioside. Down-column water generated in a resin adsorption step is subjected to purification treatment and a waste acid, a waste alkali and waste water, which are generated in an adsorption resin and desalting and decolorizing resin regeneration step are subjected to treatment, in the production procedure of the stevioside. According to the comprehensive water-saving process, a water extracting solution of a stevia leaf is subjected to resin adsorption; down-column waste water is subjected to rough filtration, primary filtration, ceramic film filtration, resin adsorption treatment, ozone treatment, adsorption filtration and reverse osmosis treatment in sequence to obtain purifier water which is directly used for the water extraction of the stevia leaf; abundant waste acid, waste alkali and waste water, which are produced in a resin regeneration procedure, are recycled; a water consumption is decreased by 70 percent or above; an acid consumption and an alkali consumption are decreased by 60 percent or above; meanwhile, by-products flavone and chlorogenic acid are obtained. According to the comprehensive water-saving process, a new pollutant does not be generated; no new chemical reagents are put; the quality of treated water is high; part of indexes are superior to those of underground water and municipal water; the ash content of a stevioside product can be decreased; the improvement of the purity and the yield of the product is facilitated; the industrial production value of the stevioside is improved.

Owner:CHENGUANG BIOTECH GRP CO LTD

Synthesis method of N-methyl-2-hydroxyethyl hydroxyethyl

ActiveCN101735132BRaw materials are cheap and easy to getShort synthetic routeOrganic chemistrySynthesis methodsNitrogen gas

The invention discloses a synthesis method of N-methyl-2-hydroxyethyl hydroxyethyl, which comprises the following steps of: (1) adding dimethyl sulfate and N-methyl pyrrolidone into a reaction kettle for reaction; (2) cooling and dropwise adding an ethanol solution of sodium ethylate, continuously dropwise adding ethyl cyanoacetate, reacting and filtering to obtain an intermediate (I); (3) addingthe intermediate (I) and a catalyst as well as a high-boiling point organic solvent to the reaction kettle, heating, fractionating, reacting, filtering, recovering propylene glycol, and carrying vacuum rectification to obtain a intermediate (II); and (4) adding the intermediate (II) and the catalyst as well as a solvent into the reaction kettle, replacing by using nitrogen and hydrogen sequentially, introducing hydrogen, reacting, cooling, evacuating, filtering, evaporating out moisture content, and carrying out vacuum rectification to obtain the N-methyl-2-hydroxyethyl hydroxyethyl. The synthesis method has the advantages of cheap and easily obtained raw materials, short synthesis route, mild reaction conditions, relatively low production cost and higher overall yield.

Owner:江苏恒祥化学股份有限公司

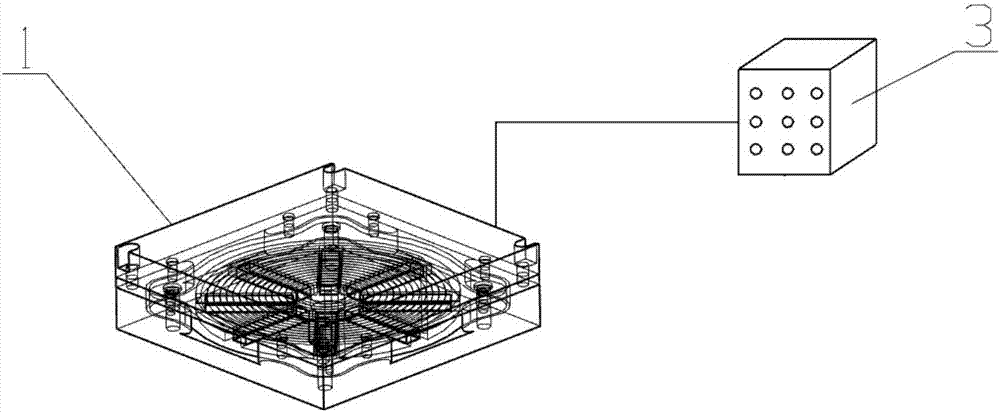

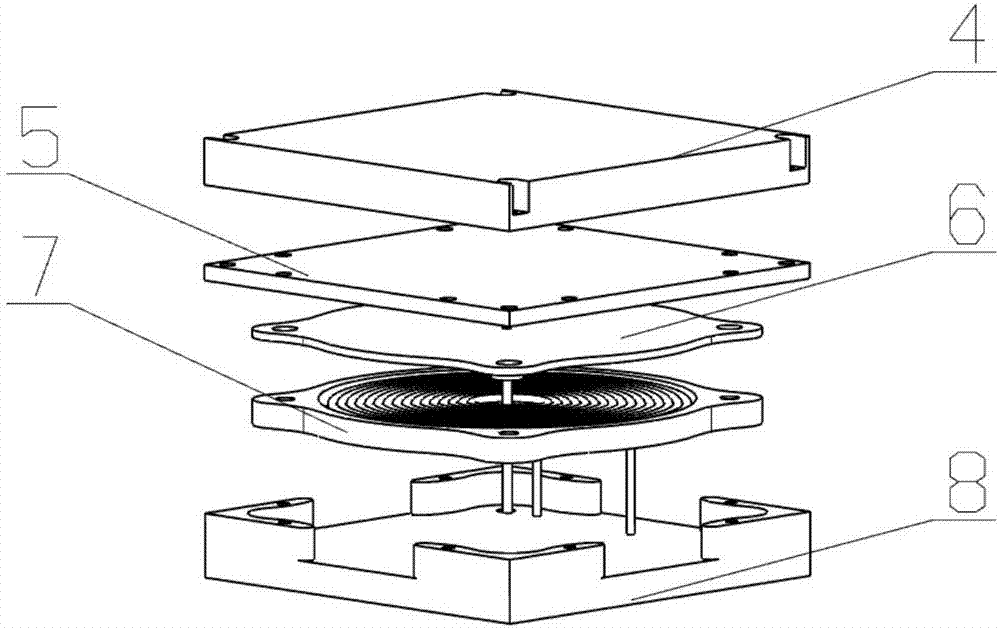

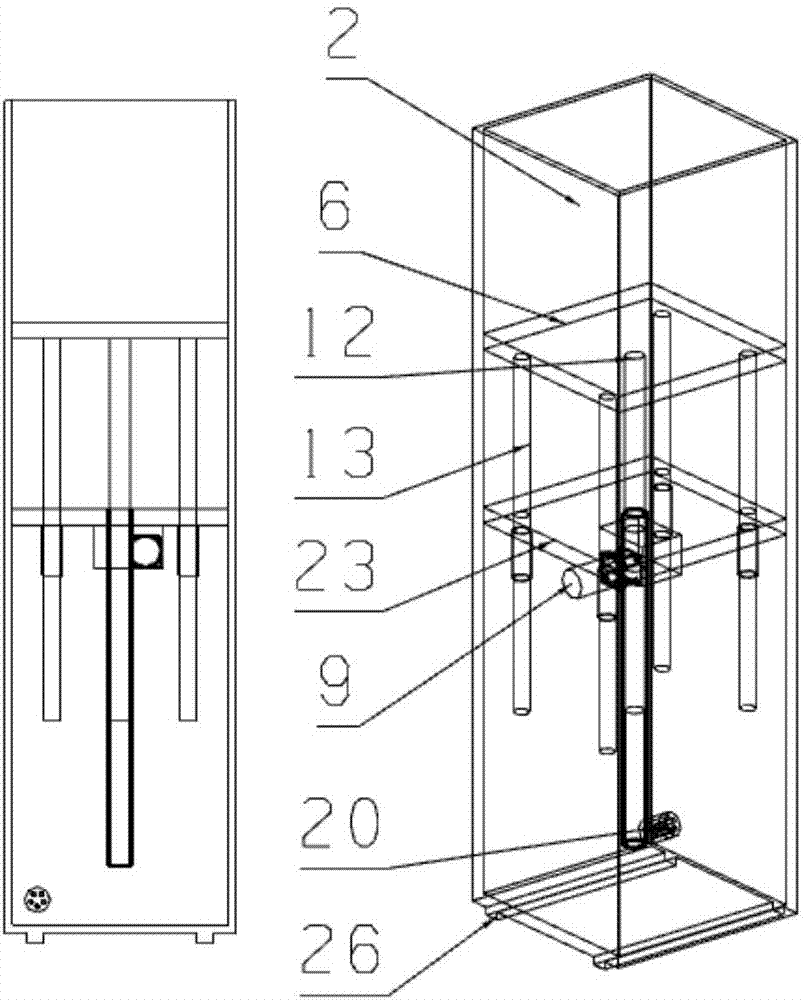

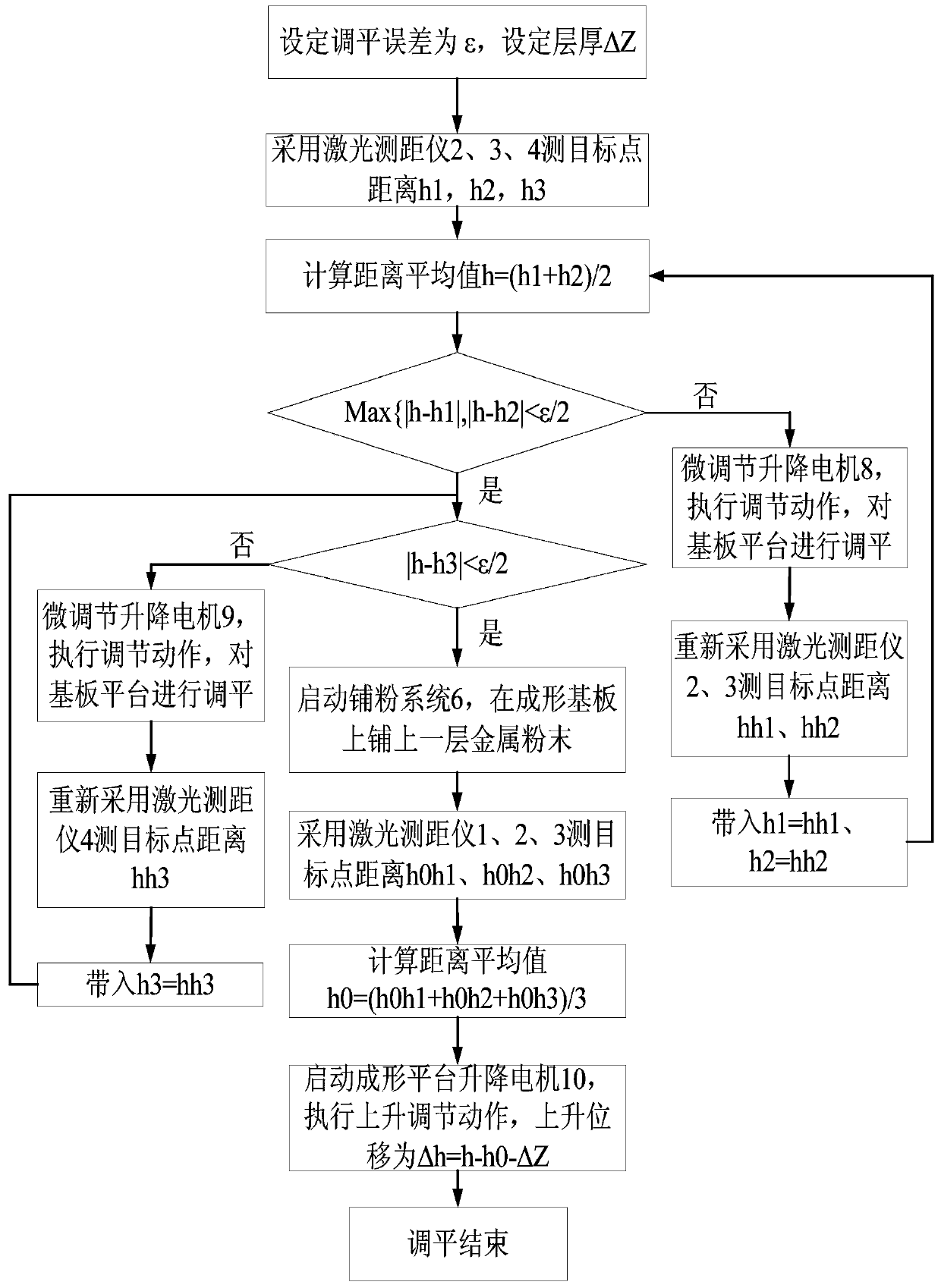

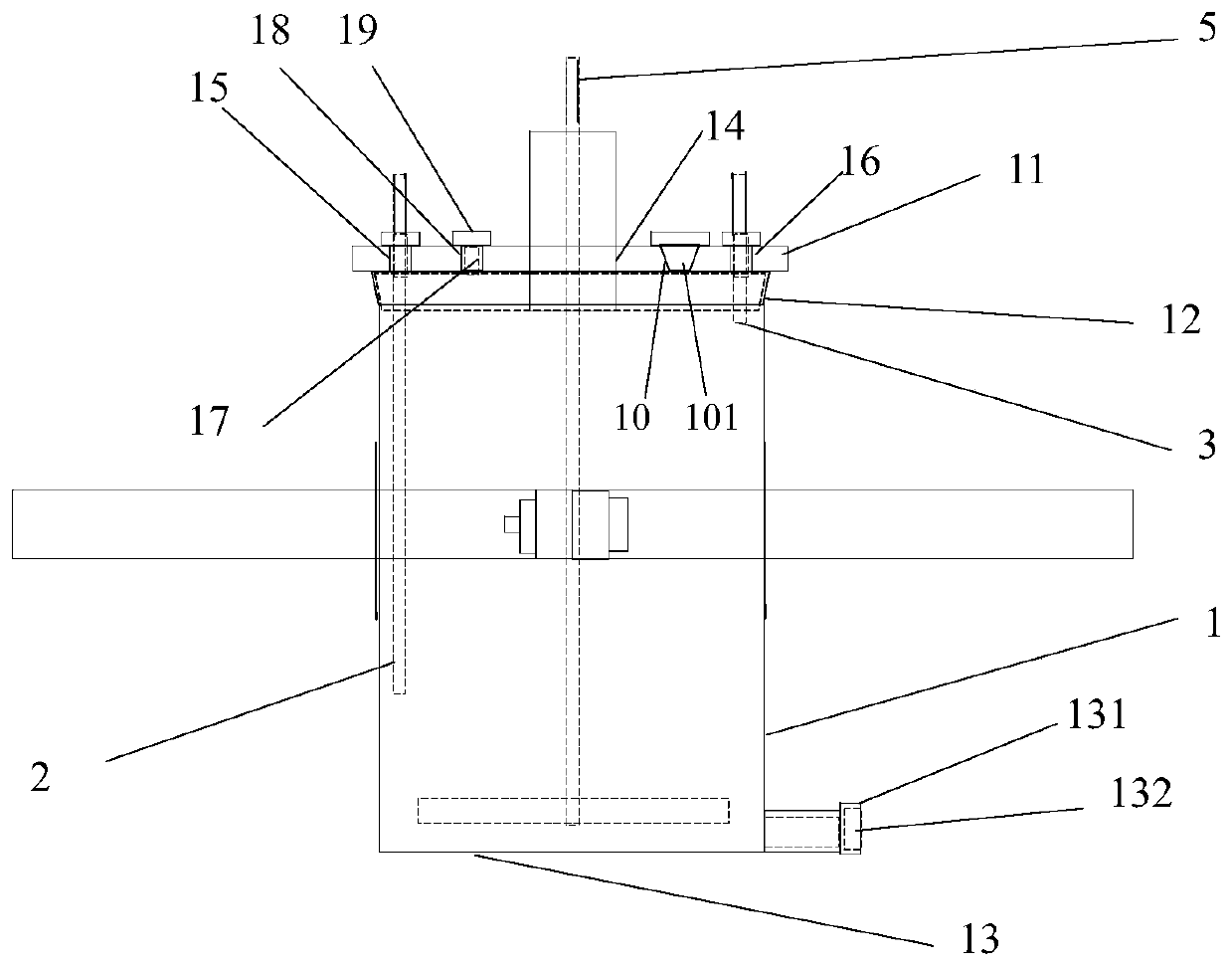

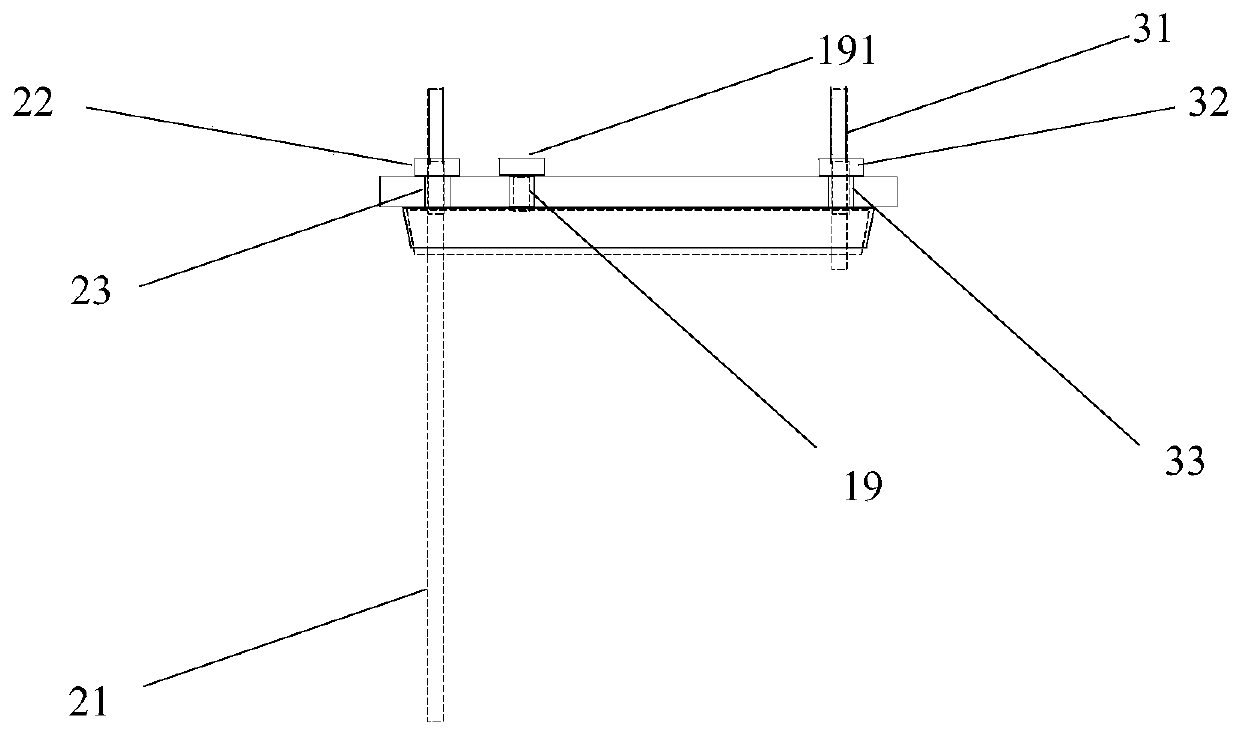

An automatic leveling system and leveling method for substrates of laser selective melting forming equipment

ActiveCN107457405BIncrease productivityHigh value of industrial productionAdditive manufacturing apparatusIncreasing energy efficiencyProduction lineSelective laser melting

The invention belongs to the technical field of 3D printing, and in particular relates to an automatic leveling system and a leveling method for a forming platform of laser selective melting forming equipment. It adopts the concept of fully automated control modular design, rebuilds the leveling system of the manufacturing equipment platform, realizes the convenience of 3D printing substrate leveling preparation, removes manual, automation, improves production efficiency, and ensures product quality. It is suitable for the leveling of industrial-grade 3D printing platforms, especially in the area of metal selective melting and forming technology. It is oriented to the future automatic production line mode, and the automatic leveling system and method have extremely high industrial production value in the field of future equipment manufacturing.

Owner:BEIJING XINGHANG MECHANICAL ELECTRICAL EQUIP

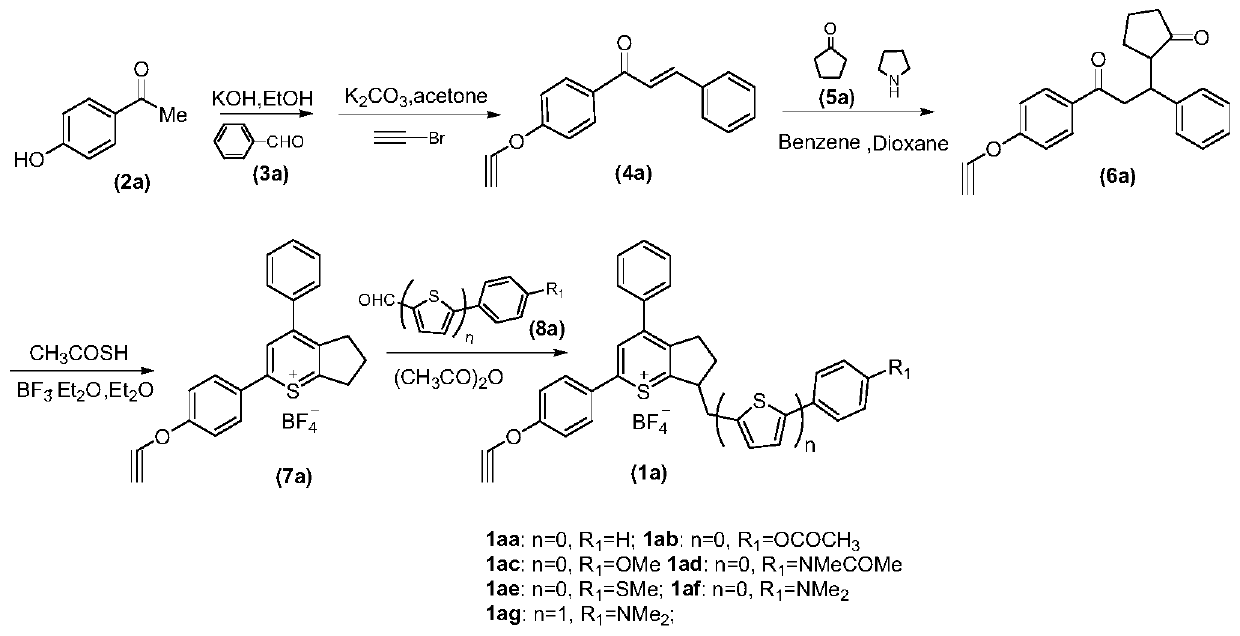

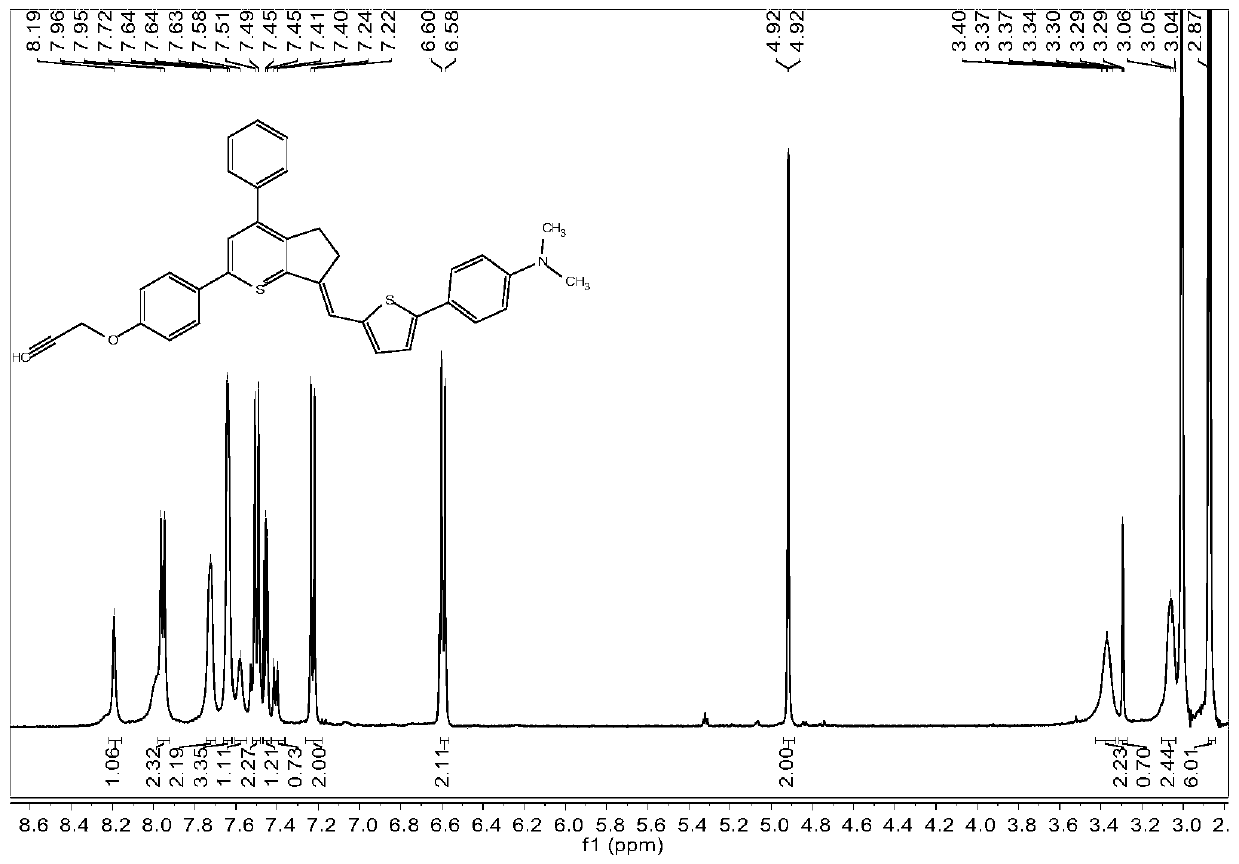

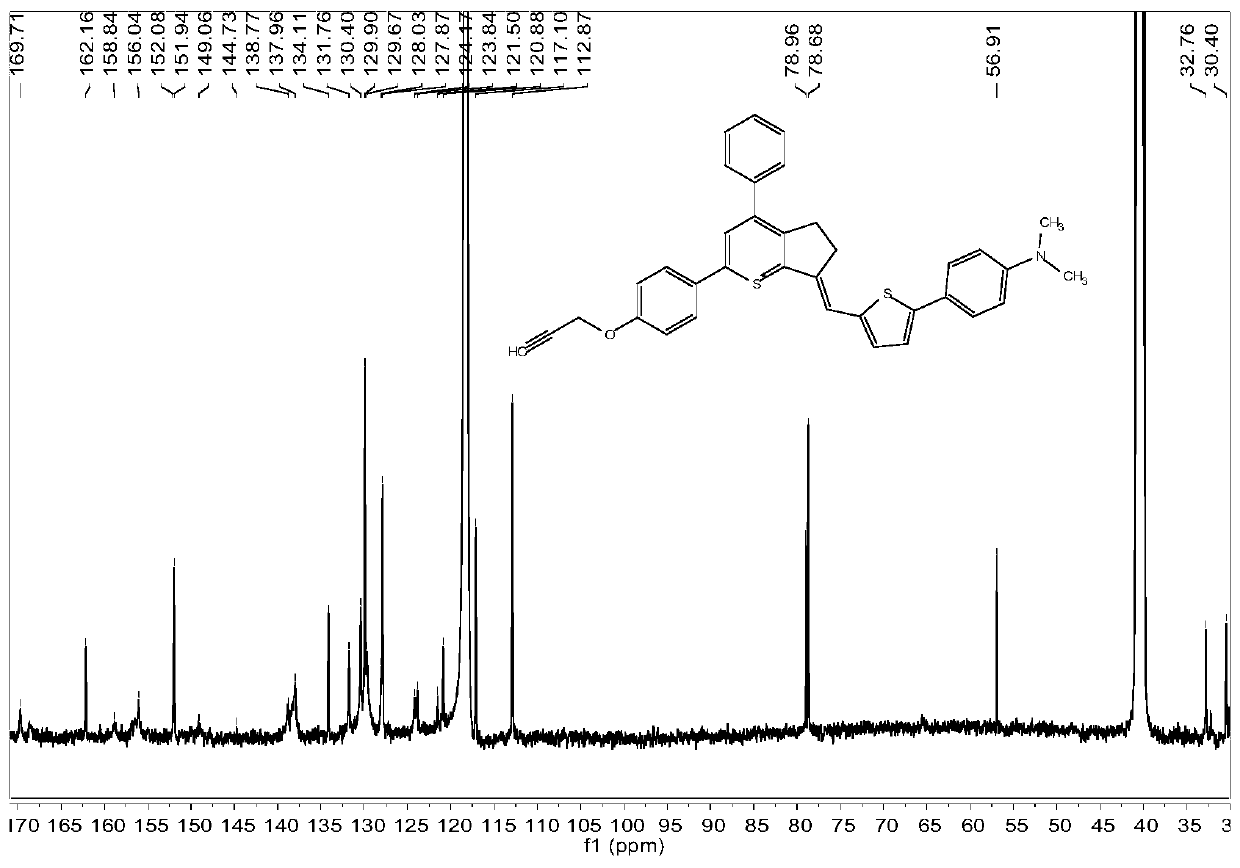

A near-infrared second region fluorescent compound capable of targeting mitochondria, its preparation method and application

ActiveCN109369633BThe synthetic route is simpleSimple post-processingOrganic chemistryLuminescent compositionsBiocompatibilityBiomedicine

The invention discloses a near-infrared second-region fluorescent compound capable of targeting mitochondria as well as a preparation method and application thereof. According to the compound, the emission wavelength ranges from 600 nm to 1200 nm and can reach the near-infrared second-region (900-1200 nm) after the compound is modified by different functional groups. The compound can be used for the biological fields of mitochondrion imaging, photo-thermal therapy and osteosarcoma and whole-body bone imaging; and added modified sites can be used for connecting different bioactive groups, so that the water solubility, the biocompatibility and the targeting property are improved, and the compound can also be used for in-vitro detection of various disease markers and in-vivo early diagnosis of breast cancer, brain glioma, colon cancer, liver cancer and the like. The fluorescent compound has the advantages of being novel in structure, simple in synthesis steps, resistant to photobleaching,non-toxic, good in biocompatibility and excellent in industrial production value and biomedical application prospect.

Owner:WUHAN UNIV

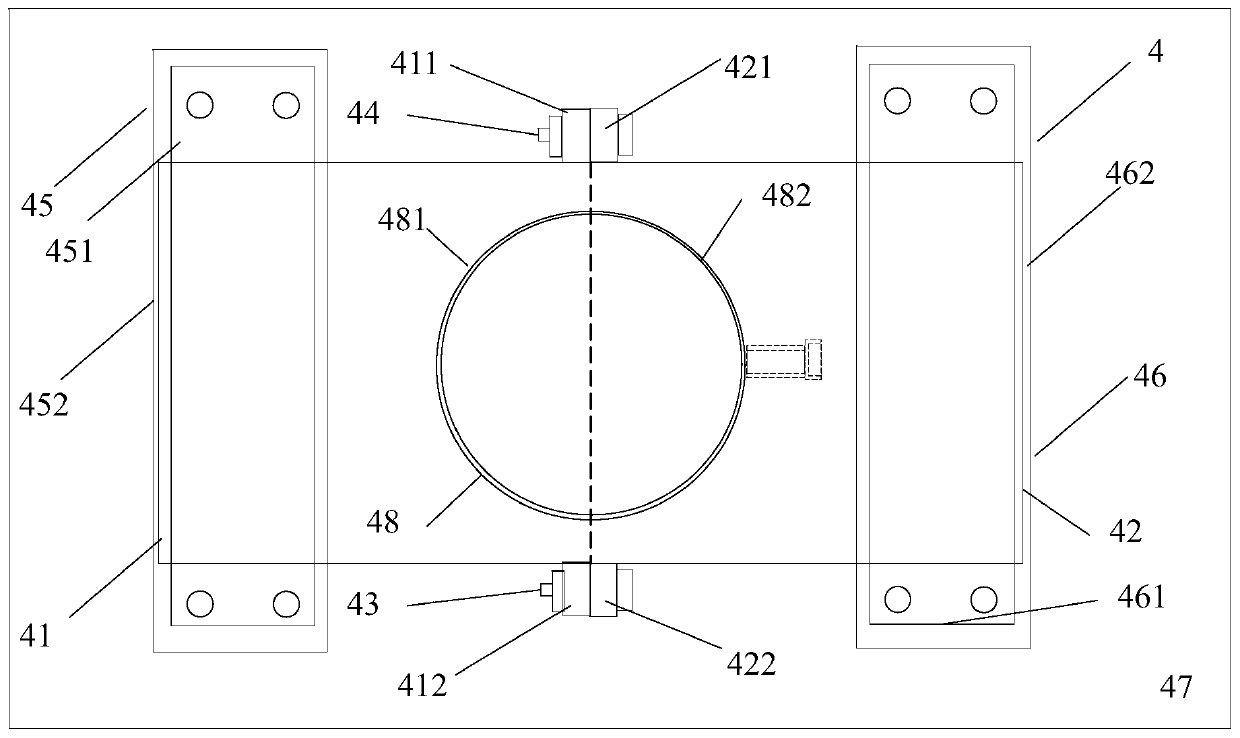

Preparation method of amino-substituted quinoline nitrogen heterocyclic ring

ActiveCN110270295AImprove performanceImprove protectionOrganic chemistryChemical/physical/physico-chemical stationary reactorsBromineFormate Esters

The invention relates to a preparation method of an amino-substituted quinoline nitrogen heterocyclic ring. The amino-substituted quinoline nitrogen heterocyclic ring is prepared through a specifically-made reaction kettle, the reaction kettle is provided with a kettle body (1) made of glass, and the kettle body is provided with a kettle cover (11), a lower flange (12) and a cylinder (13); the reaction kettle further comprises an air inlet combination (2), an air outlet combination (3), a fixing device (4) and a stirring part (5). The method comprises the steps that 8-bromoquinoline is dissolved in N,N-dimethylformamide for preparing 8-quinolinecarbonitrile, then the 8-quinolinecarbonitrile reacts with a sulfuric acid aqueous solution to obtain 2quinoline-8-formic acid, the 2quinoline-8-formic acid is dissolved in methyl alcohol, and thionyl chloride is dropwise added to obtain quinoline-8-methyl formate; the quinoline-8-methyl formate is dissolved in carbon tetrachloride, pyridine is added, and bromine is dropwise added to obtain 3-bromoquinoline-8-methyl formate; the 3-bromoquinoline-8-methyl formate reacts with lithium hydroxide to prepare 3-bromoquinoline-8-formic acid; through transition of 3-bromine-8-Boc-aminoquinoline, a product 3-bromine-8-aminoquinoline is obtained.

Owner:北京六合宁远医药科技股份有限公司

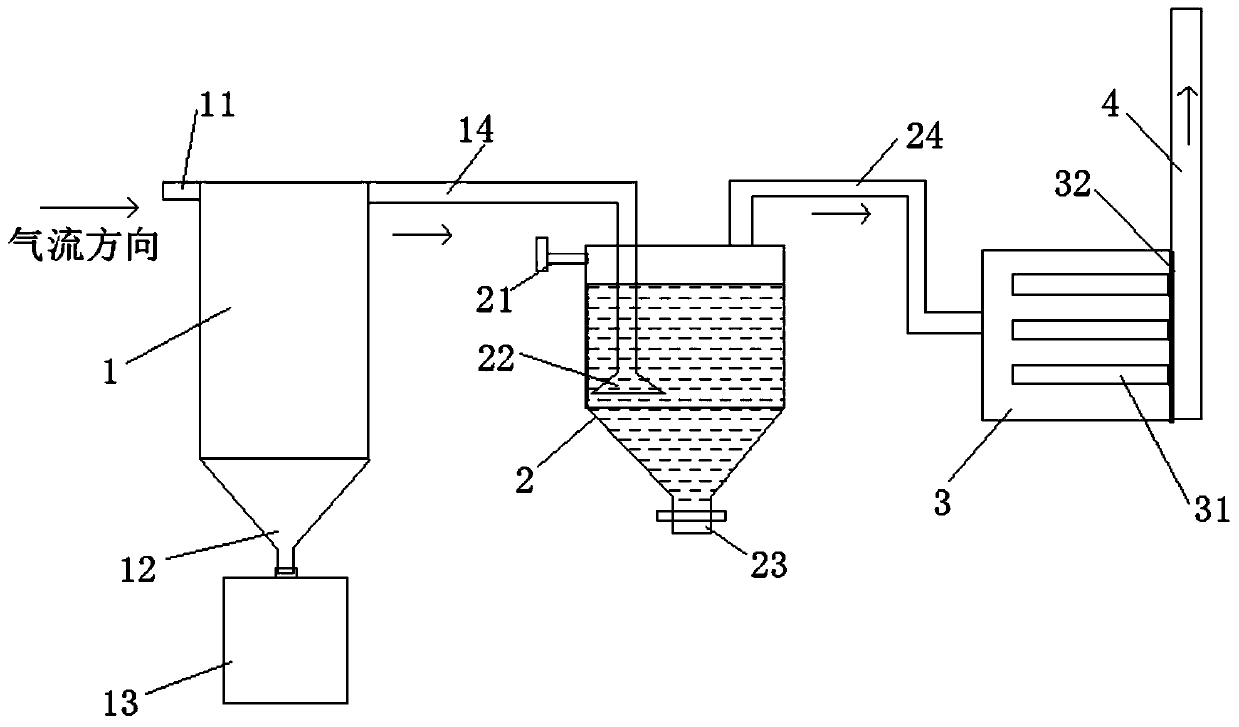

An energy-saving and environment-friendly flue gas filtration system

ActiveCN108554148BGood dust removalImprove adsorption capacityGas treatmentOther chemical processesFlue gasSorbent

The invention discloses an energy-saving and environment-friendly type flue gas filtering system. The energy-saving and environment-friendly type flue gas filtering system comprises a dust filter, a gas absorption tank, an adsorption pot and an exhausting pipe; dust solid particles in flue gas are removed through the dust filter; the gas absorption tank is used for absorbing and removing acidic gas including carbon dioxide, sulfur dioxide and the like in the flue gas; an adsorbent in the adsorption pot is used for adsorbing and removing carbon monoxide in the flue gas; preparation of the adsorbent in the adsorption pot comprises the following steps: firstly, enabling ruthenium trichloride and sodium periodate to react in an acidic environment, and oxidizing ruthenium trichloride into a high-valence ruthenium compound; then loading the high-valence ruthenium compound into modified chlorite and sufficiently dispersing the high-valence ruthenium compound in the surface and pore channels of the modified chlorite, wherein high-valence ruthenium can be complexed with 4 carbon monoxide at the same time, and the adsorption amount of the chlorite adsorbent on carbon monoxide is 130ml / g or above and is much higher than the loading amount of an existing transition metal loaded adsorbent on the carbon monoxide, so that the adsorbent has relatively high industrial production value.

Owner:山东新兴业环保科技股份有限公司

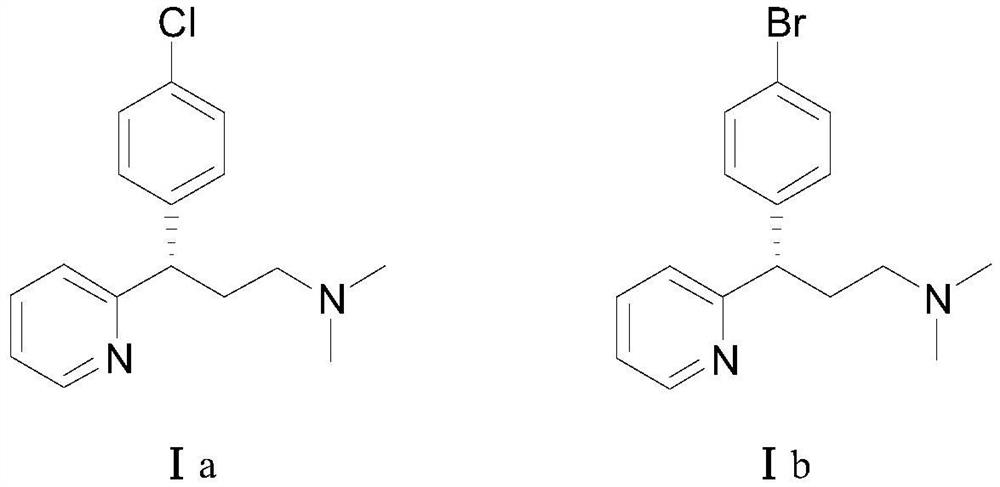

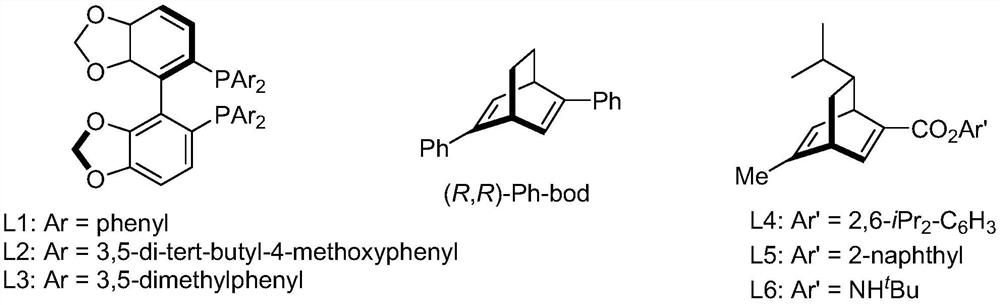

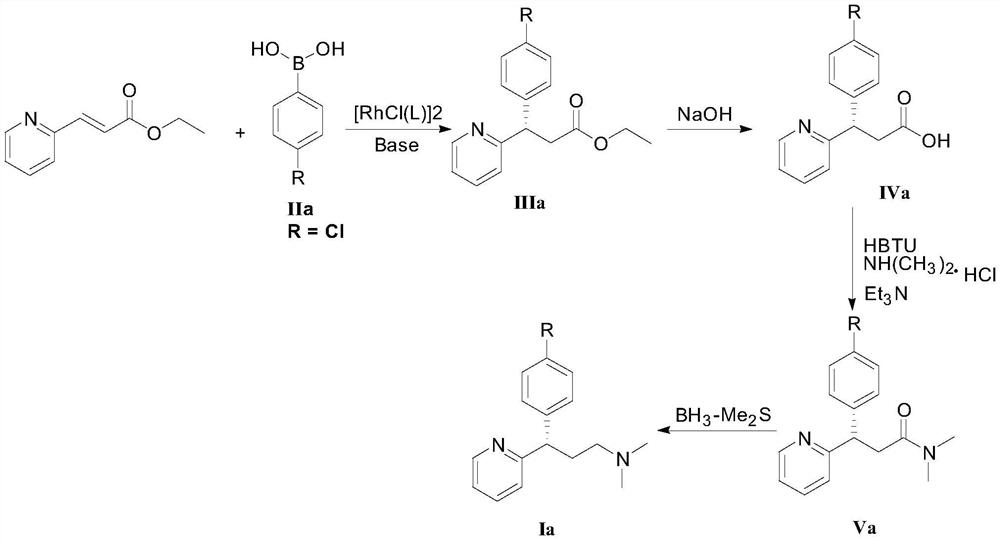

A kind of asymmetric synthesis method of dexchlorpheniramine and dexbrompheniramine

The invention belongs to the field of chemical synthesis, and discloses an asymmetric synthesis method of D-halopheniramine, which comprises: under the condition of the presence of alkali, 3-(2-pyridyl) ethyl acrylate acts on a chiral rhodium catalyst The asymmetric addition product can be obtained by reacting with 4-chlorophenylboronic acid or 4-bromophenylboronic acid, and the single-step yield can reach up to 96%, and the ee value can reach 96%; the asymmetric addition product can be hydrolyzed to obtain the corresponding acid, acid Condensation with dimethylamine hydrochloride gives the corresponding amide; reduction of the amide gives the desired final product. The raw material of this route is cheap and easy to obtain, the route is short, the enantioselectivity of the product is high, the total yield is about 75%, and it has high industrial production value.

Owner:成都泰和伟业生物科技有限公司

A kind of preparation method of sulfasalazine

ActiveCN105348184BConvenient sourceImprove conversion rateOrganic chemistryAqueous sodium hydroxideSalicylic acid

The invention discloses a preparation method for sulfasalazine. The preparation method comprises the steps of: S1, carrying out a diazotization reaction on sulfapyridine in an aqueous solution dissolved with hydrochloric acid and sodium nitrite to obtain diazonium salt; S2, carrying out a coupling reaction on the diazonium salt and salicylic acid in a sodium hydroxide aqueous solution to obtain a sulfasalazine crude product; and S3, purifying the sulfasalazine crude product. According to the preparation method disclosed by the invention, by taking sulfapyridine as an initial raw material, the diazotization reaction, the coupling reaction and purification are successively carried out to obtain the sulfasalazine. The diazotization reaction and the coupling reaction have a relatively high conversation rate and relatively few side reactions, so that the purity of the product is improved, and the yield is ensured. In addition, the sulfapyridine is easily available in source, so that the production cost is lowered, and the preparation method has relatively great industrial production value.

Owner:SUZHOU HUANGHE PHARMA CO LTD

A 3D printing forming modular system suitable for automated production lines and its application method

ActiveCN107470621BAchieve installationSolve the key problems of continuous large-scale productionAdditive manufacturing apparatusIncreasing energy efficiencyProduction lineElectric machinery

The invention belongs to the field of 3D printing equipment, and in particular relates to a modular forming system suitable for automatic production line 3D printing equipment and a use method thereof. It includes working cabin frame, forming cylinder module, material supply cylinder module, collection cylinder module and lower base module. The internal structure of the collecting cylinder includes the worktable base plate, lifting motor, parallel guide rod, power connector and other components; the lower base mainly includes the base plate, lifting motor, horizontal push-out motor, power connector and other components, and the base plate can carry the above forming cylinder, material supply Cylinder, collection cylinder module, when lifting the motor, the cylinder module is raised, the motor is pushed out horizontally to take out the cylinder module, the lower base is lowered, and then the cylinder module is pushed out, so that functions such as replacement can be realized. The invention realizes the modularization of 3D printing preparation work, printing process, and cleaning after completion, realizes streamlining of operations, combination of functions, and convenience, and realizes production line mode manufacturing.

Owner:BEIJING XINGHANG MECHANICAL ELECTRICAL EQUIP

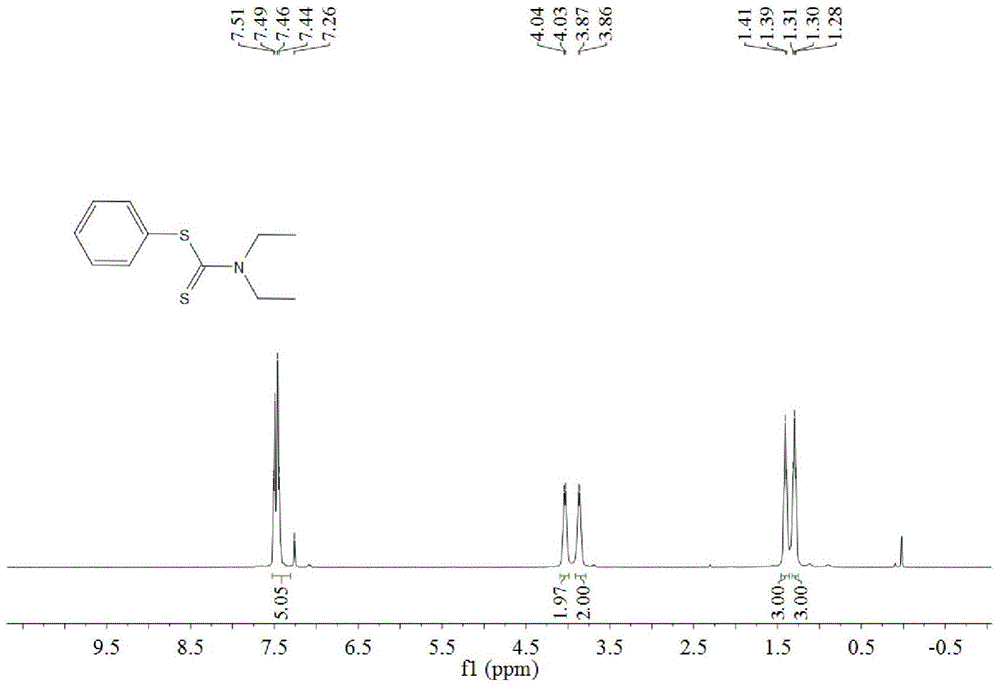

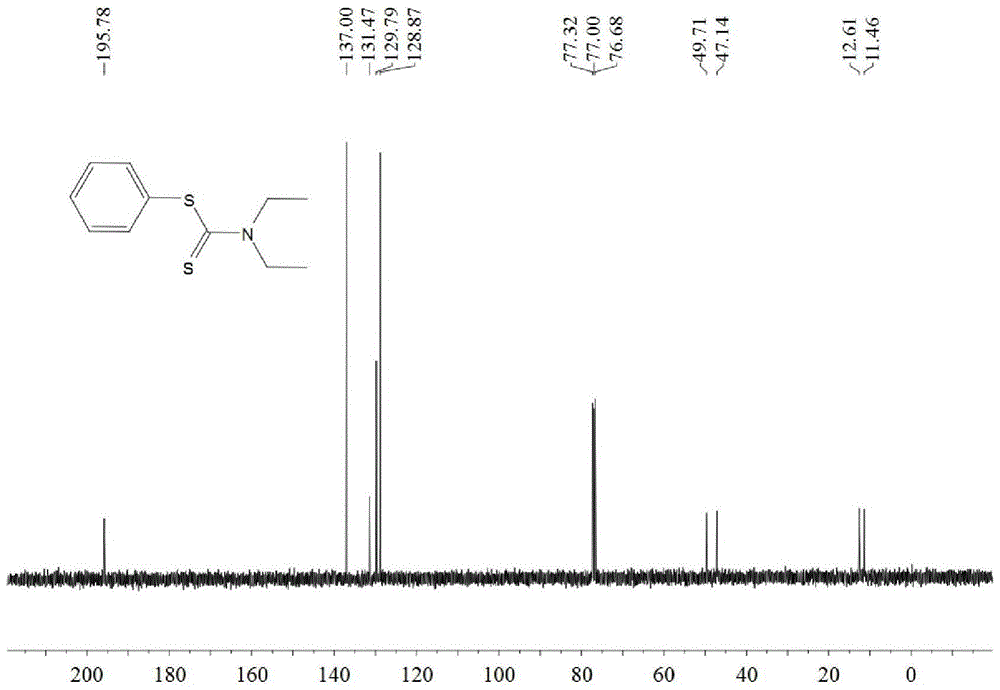

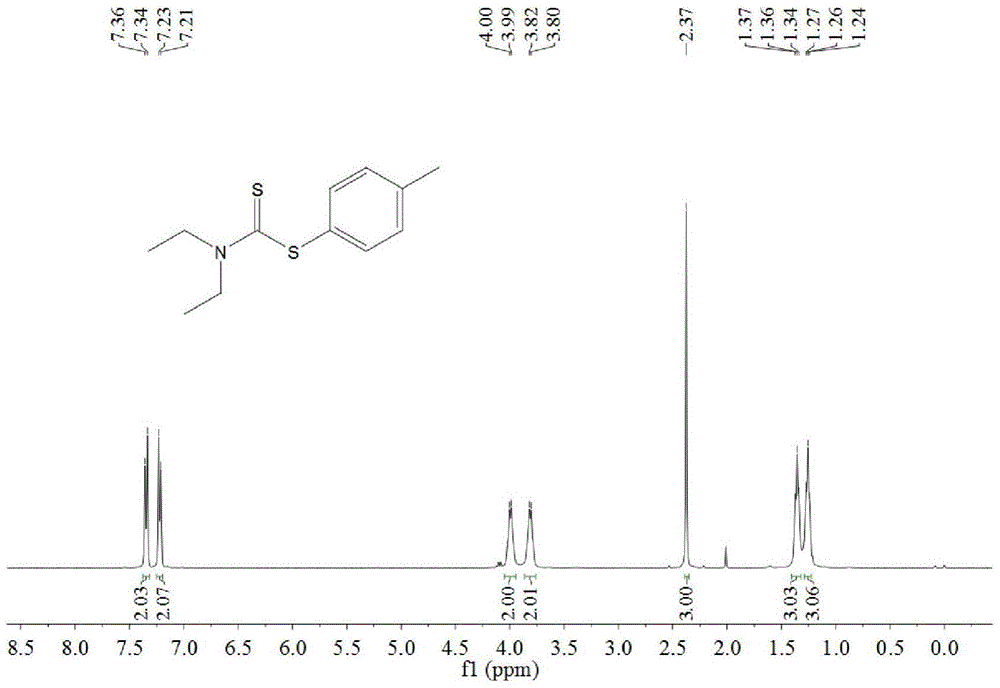

A kind of synthetic method of dithiocarbamate

The invention belongs to the technical field of chemical synthesis and discloses a dithiocarbamate synthesis method. The dithiocarbamate synthesis method comprises that in an organic solvent, Ar-B(OH)2, NHR1R2 and carbon disulfide as raw materials and a copper salt and alkali as promoters undergo a reaction at a temperature of 60-120 DEG C for 10-24h with stirring, after the reaction, the reaction product is cooled to a room temperature, then is filtered and then is subjected to reduced pressure distillation for solvent removal so that a crude product is obtained, and the crude product is purified by column chromatography so that dithiocarbamate is obtained. The dithiocarbamate synthesis method realizes dithiocarbamate synthesis by one step, has simple and easy processes and a high product yield, utilizes cheap and easily available raw materials, has a low synthesis cost and has great industrial production values.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com