Device and method for atomization cleaning of 3D printing photosensitive resin

A 3D printing and photosensitive resin technology, applied in metal processing equipment, 3D object support structure, additive manufacturing, etc., can solve the problems of high viscosity of photosensitive resin materials, difficult to clean, waste of alcohol, etc., to achieve high industrial production value, standardized cleaning Process, the effect of ensuring product accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

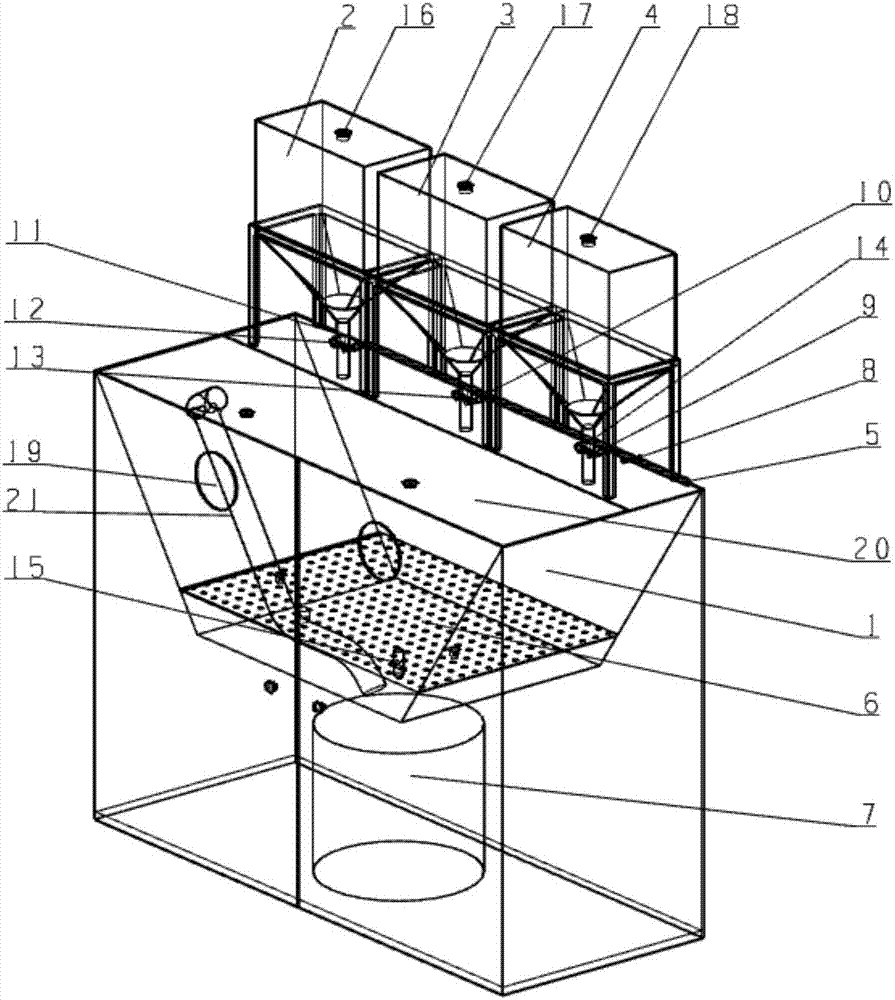

[0026] Such as figure 1 As shown, a gas atomization cleaning 3D printing photosensitive resin equipment includes a cleaning tank, an alcohol container, a high gas system, and a waste liquid collection device. A filter screen baffle 6 is placed inside the cleaning tank 1, and a transparent The glass cover 20 has an operation port 19 in the front, and an exhaust pipe 21 in the left side. The cleaning tank 1 is equipped with three alcohol containers for cleaning liquids with different recycling times, which are respectively the first alcohol container 2 and the second alcohol container. Two alcohol container 3, the 3rd alcohol container 4, have first port cover 16, the second port cover 17, the 3rd port cover 18 respectively on it, leave stomata respectively on the three port covers, guarantee that alcohol is under the condition of gravitational field Flow out smoothly; the first alcohol container 2, the second alcohol container 3, and the third alcohol container 4 are respective...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com