Method for producing ultrahigh molecular weight polyethylene

A technology of ultra-high molecular weight and production method, which is applied in the production field of ultra-high molecular weight polyethylene, can solve the problems of difficult molecular weight operation, etc., and achieve the effect of simple and easy process, high industrial production value and improved performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

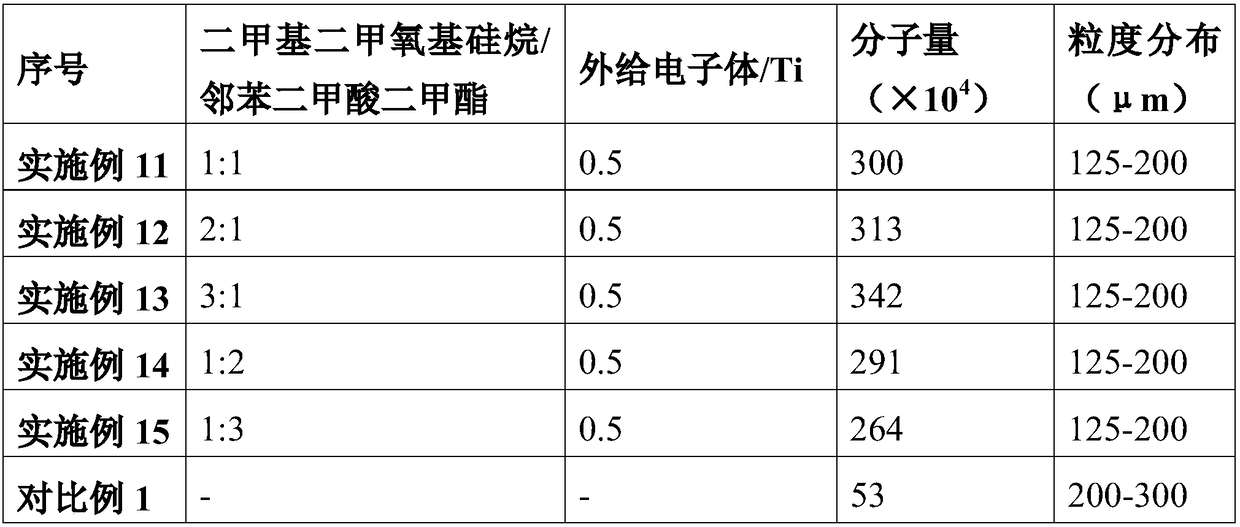

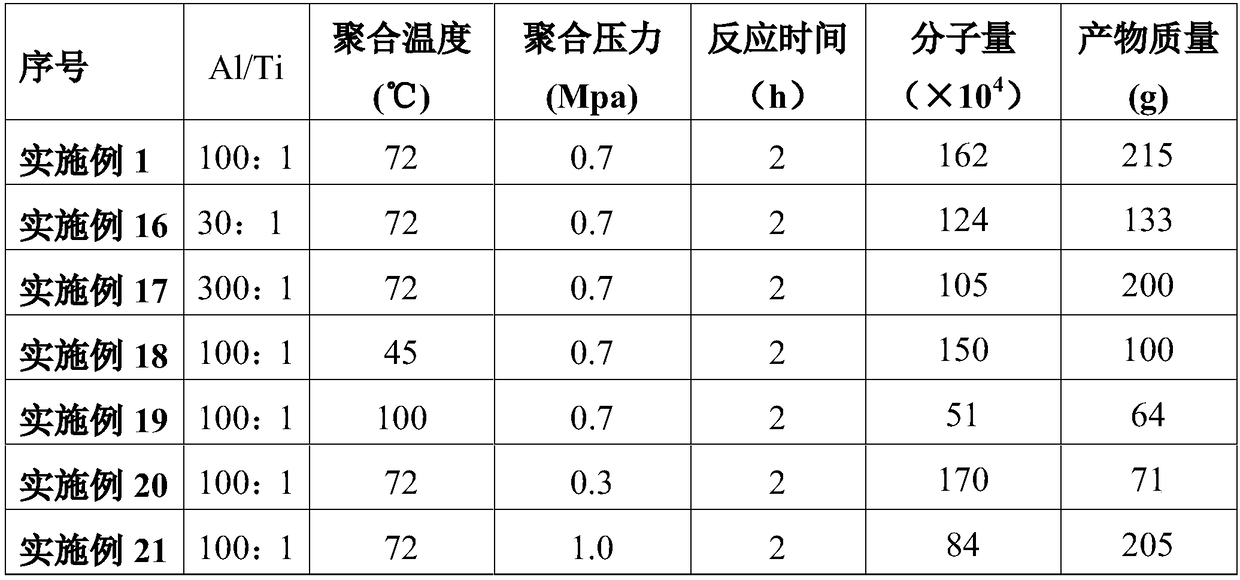

Examples

Embodiment 1

[0039] Using a 2L reactor, carry out at least 3 times N 2 Purging to remove water and deoxygenation treatment, add 600ml of hexane, and add 8mg of main catalyst with hexane, appropriate amount of co-catalyst, Al / Ti in co-catalyst / main catalyst is 100:1, appropriate amount of external electron donor dimethyl dimethyl Oxysilane, dimethyldimethoxysilane / Ti=0.2 (molar ratio), the total amount of hexane added is 1L, the temperature of the reaction system is raised, when the temperature rises to 65°C, ethylene gas is added, and the reaction is carried out at a constant pressure of 0.7Mpa , control the reaction temperature at 72°C until the end of the polymerization, lower the temperature and exhaust, separate the solid and liquid phases, and dry to obtain ultra-high molecular weight polyethylene. The experimental results are shown in Table 1.

Embodiment 2

[0041] Adjust the amount of external electron donor added, dimethyldimethoxysilane / Ti=0.1 (molar ratio), other conditions are the same as in Example 1, and the experimental results are shown in Table 1.

Embodiment 3

[0043] Adjust the amount of external electron donor, dimethyldimethoxysilane / Ti=0.5 (molar ratio), other conditions are the same as in Example 1, and the experimental results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com