Patents

Literature

74 results about "Conventional polyethylene" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Flame retardant polymer compositions

InactiveUS6025422AReduce the amount requiredIncrease resistancePlastic/resin/waxes insulatorsSynthetic resin layered productsPolymer sciencePolyketone

A composition that includes a hydrated inorganic filler and a polymer blend is disclosed. The polymer blend includes a polymerization or copolymerization product of one or more ethylenically unsaturated monomers. In addition, the polymer blend includes an aliphatic polyketone. The incorporation of aliphatic polyketone with polyethylene based polymers or copolymers results in dramatic improvements in both drip resistance and char strength; moreover, the composition of the present invention can use reduced amounts of hydrated inorganic filler relative to conventional polyethylene based compositions. This reduction in the amount of hydrated filler is expected to lead to improvements in physical properties and extrudability not otherwise possible. These properties make the compositions of the present invention particularly useful as an outer layer for electrical wires, optical fibers, or cables containing at least one wire, optical fiber, or both.

Owner:CORNING OPTICAL COMM LLC

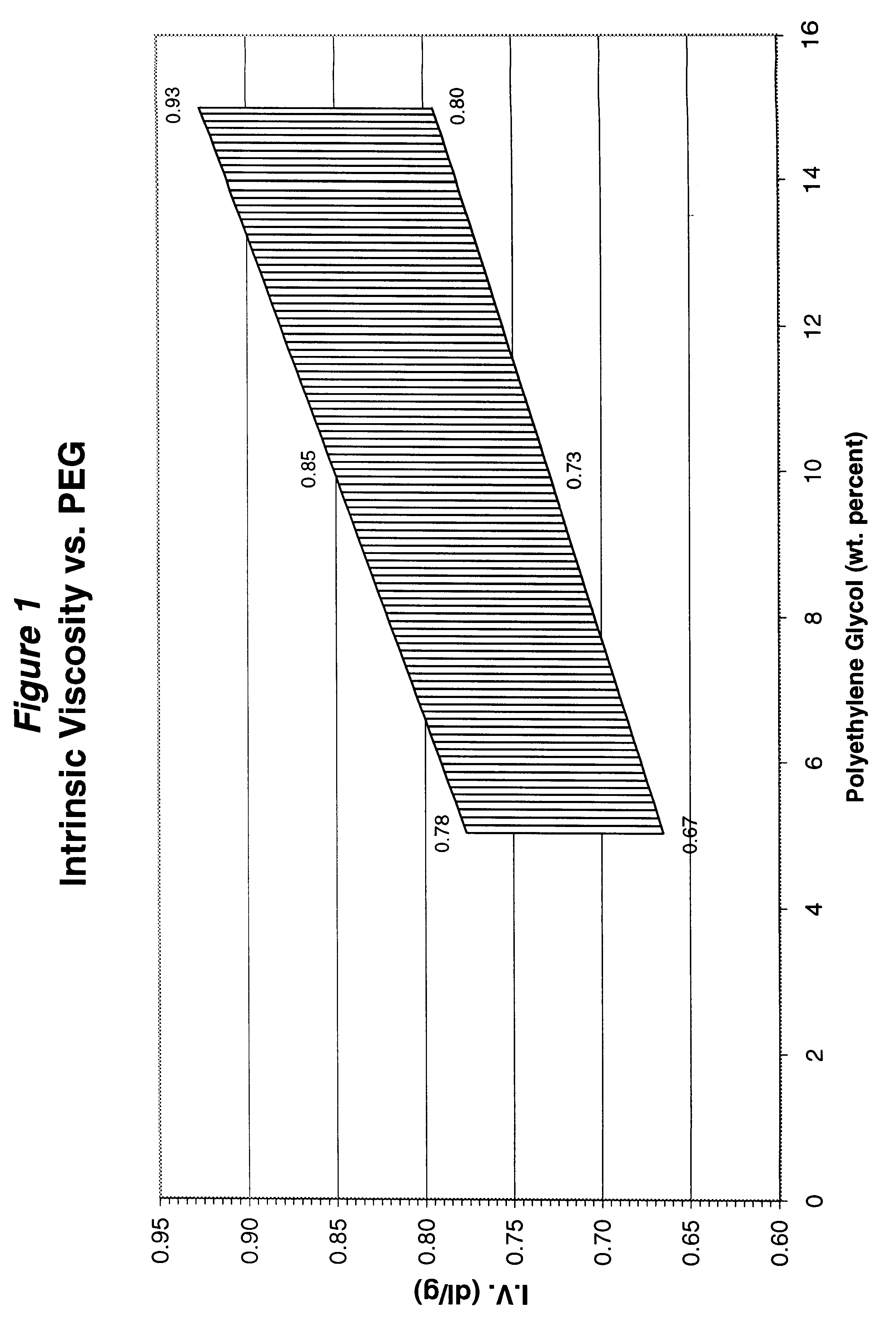

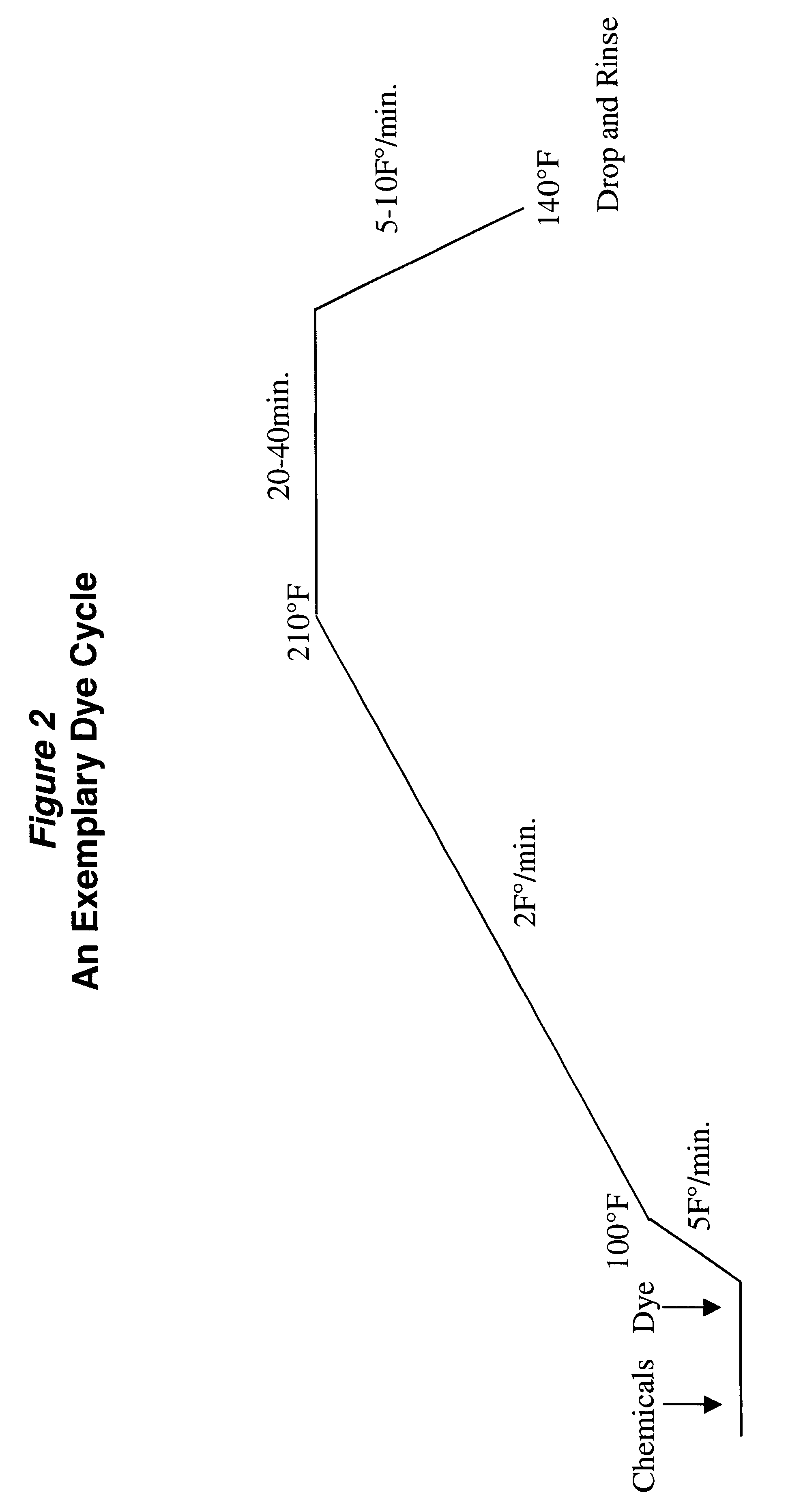

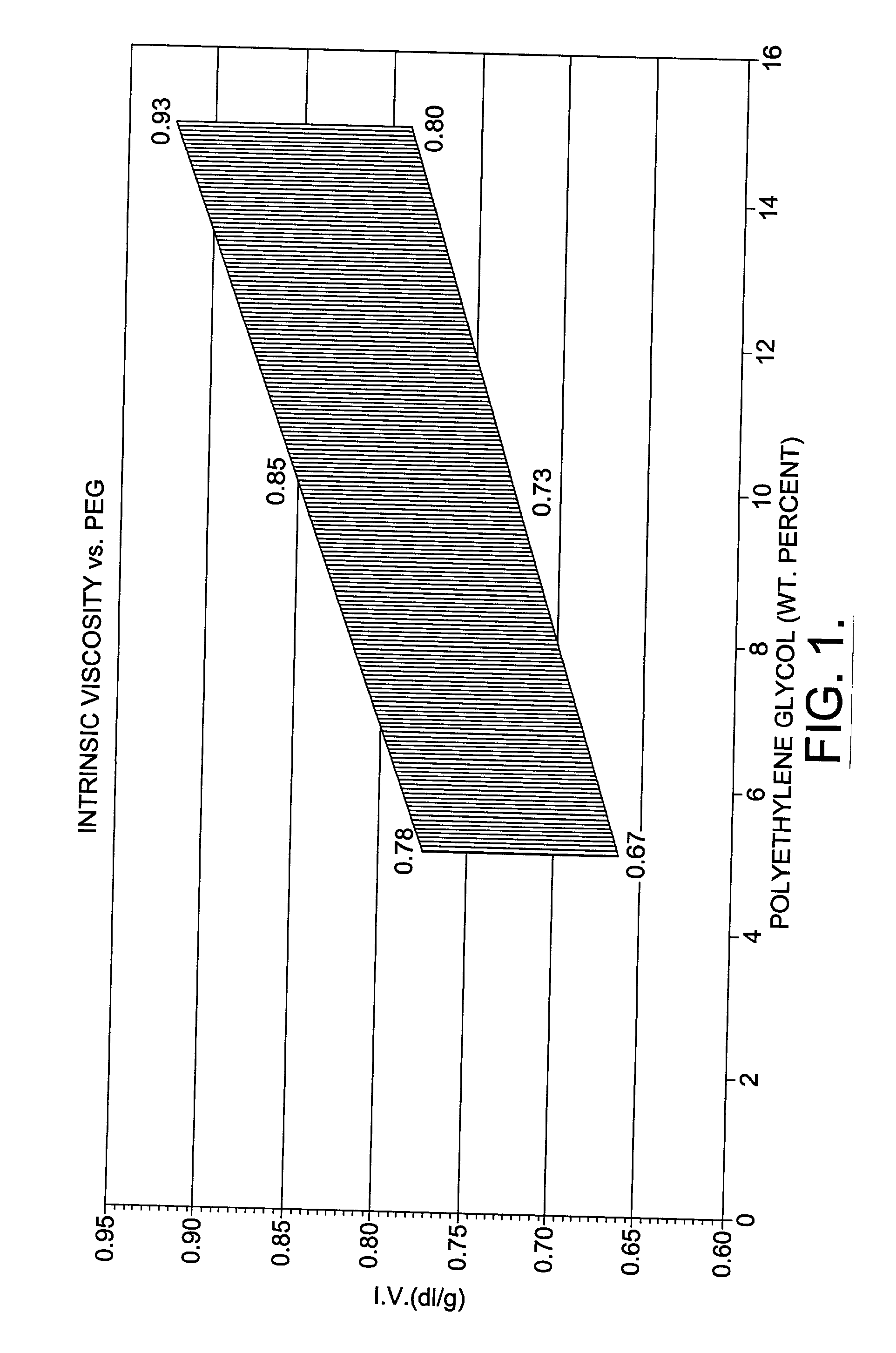

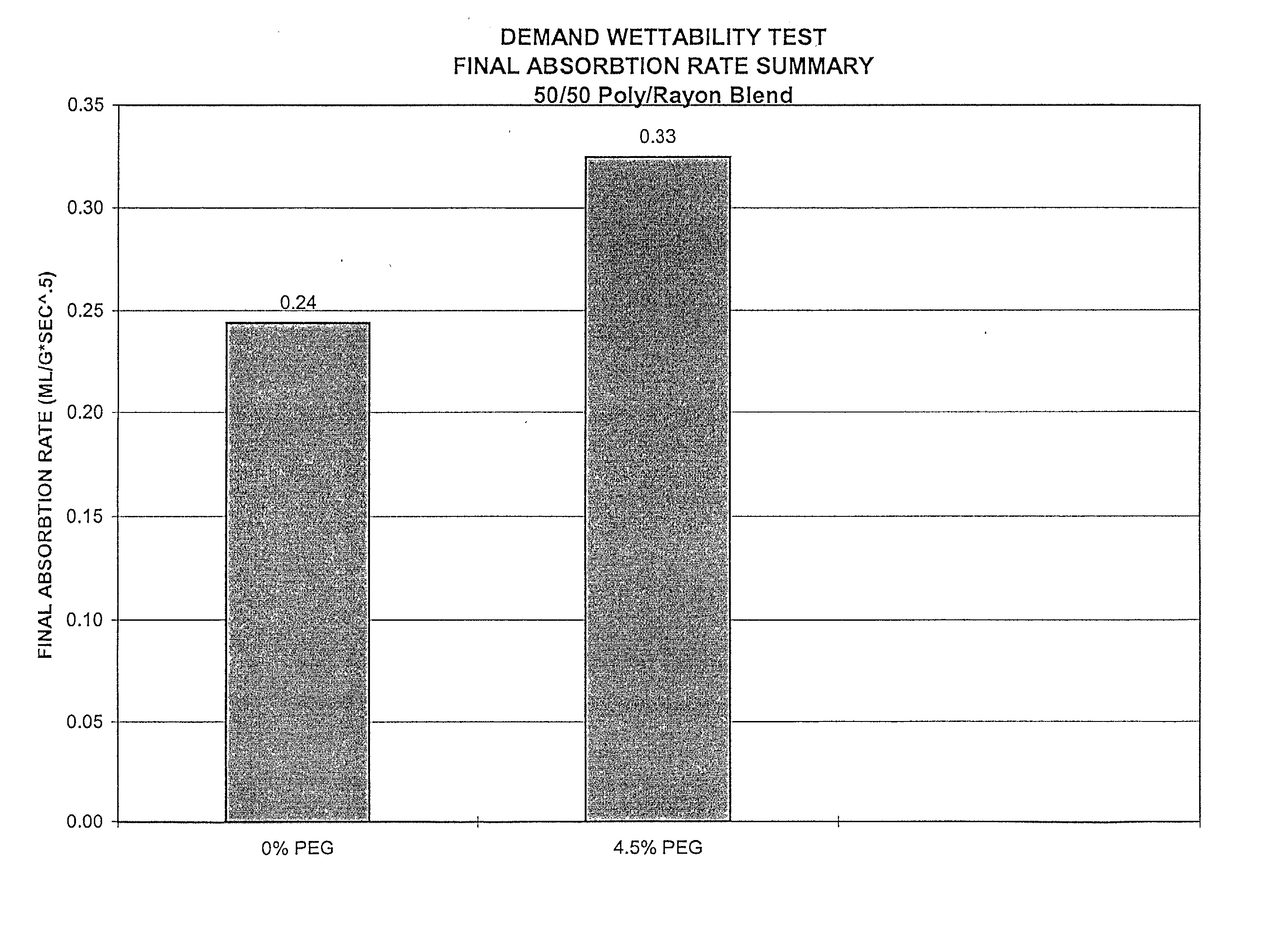

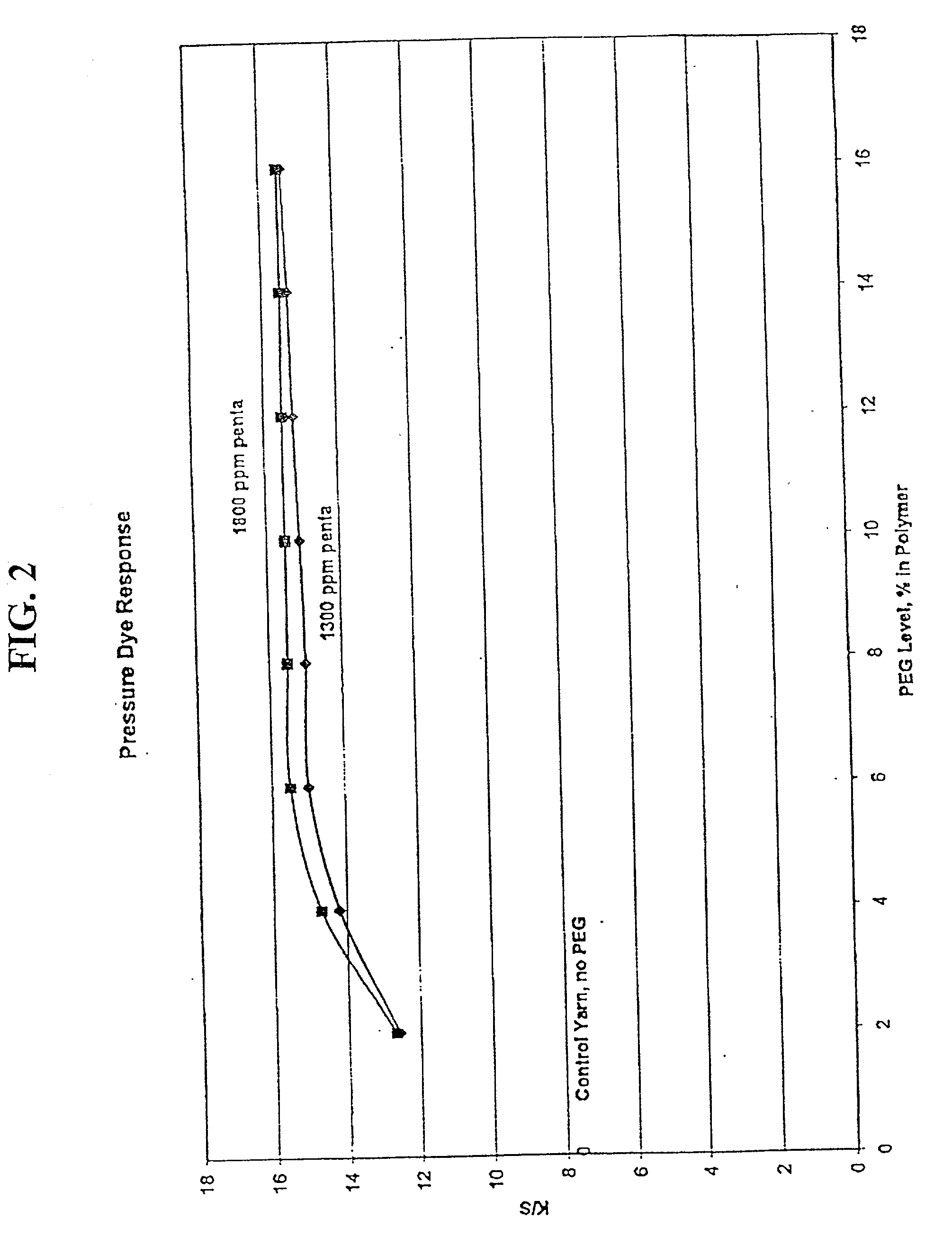

Polyethylene glycol modified polyester fibers and method for making the same

InactiveUS6623853B2Easy to dyeEnhance dye uptakeMonocomponent polyetheresters artificial filamentAnimal housingYarnFiber

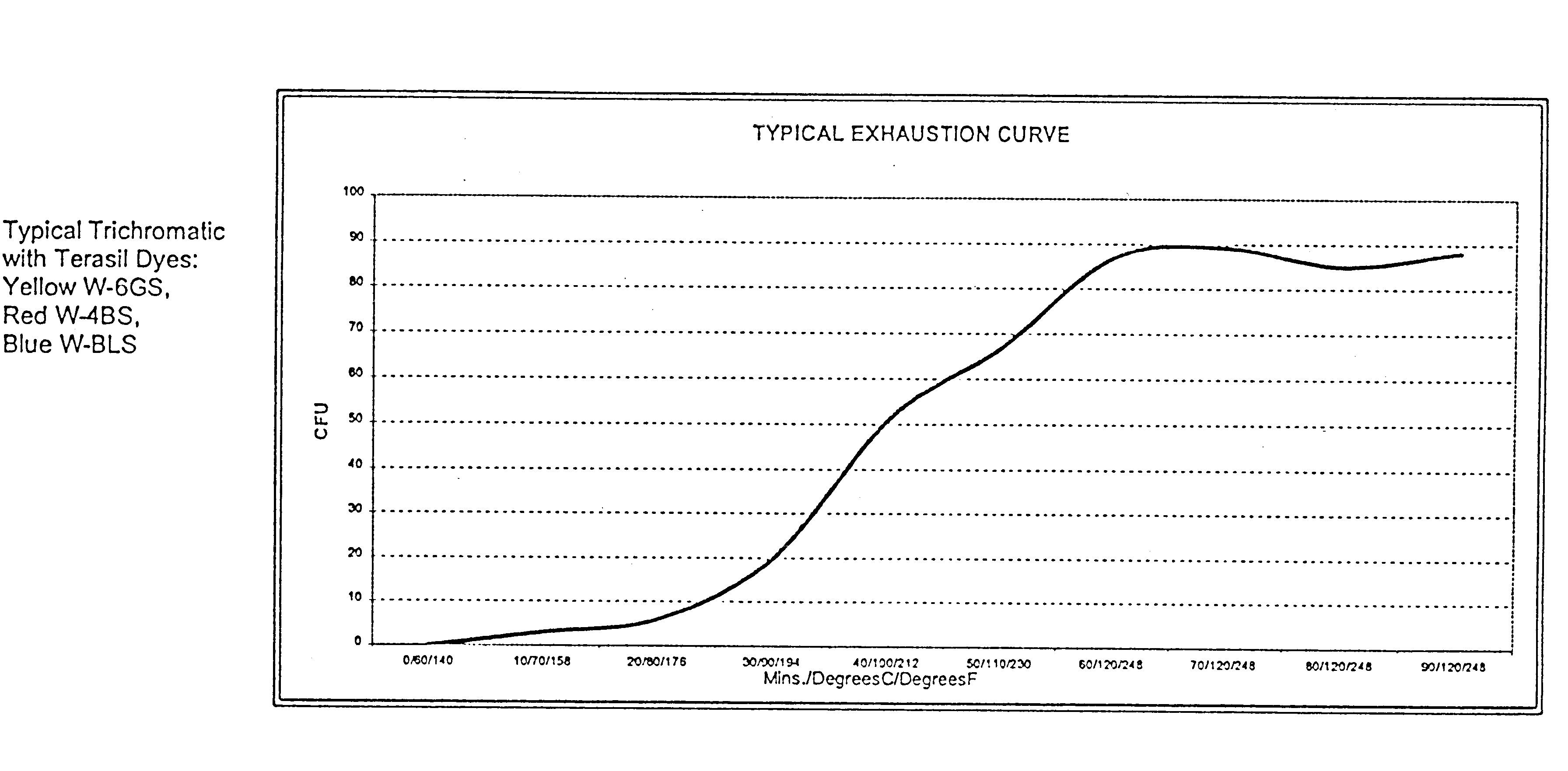

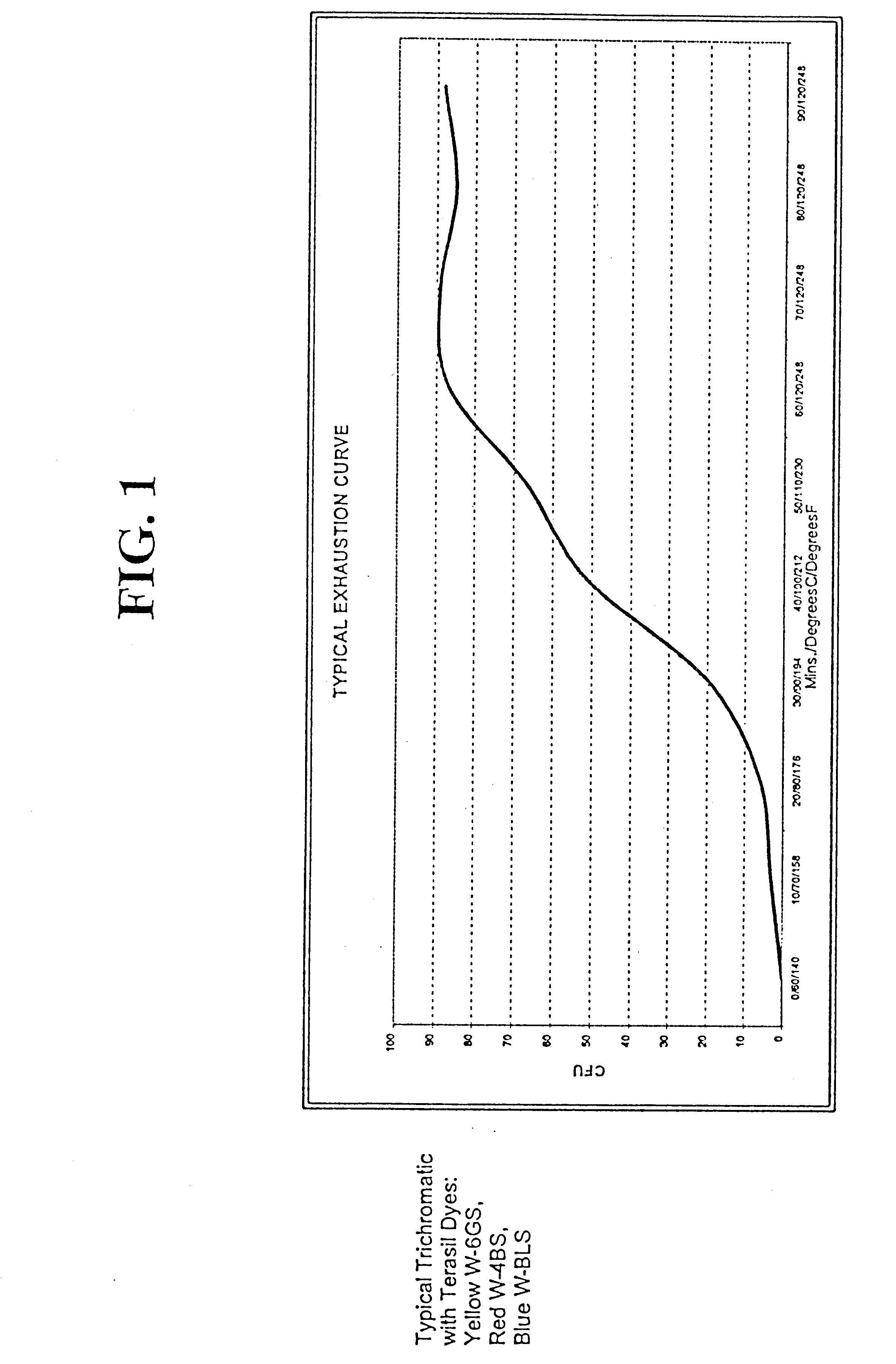

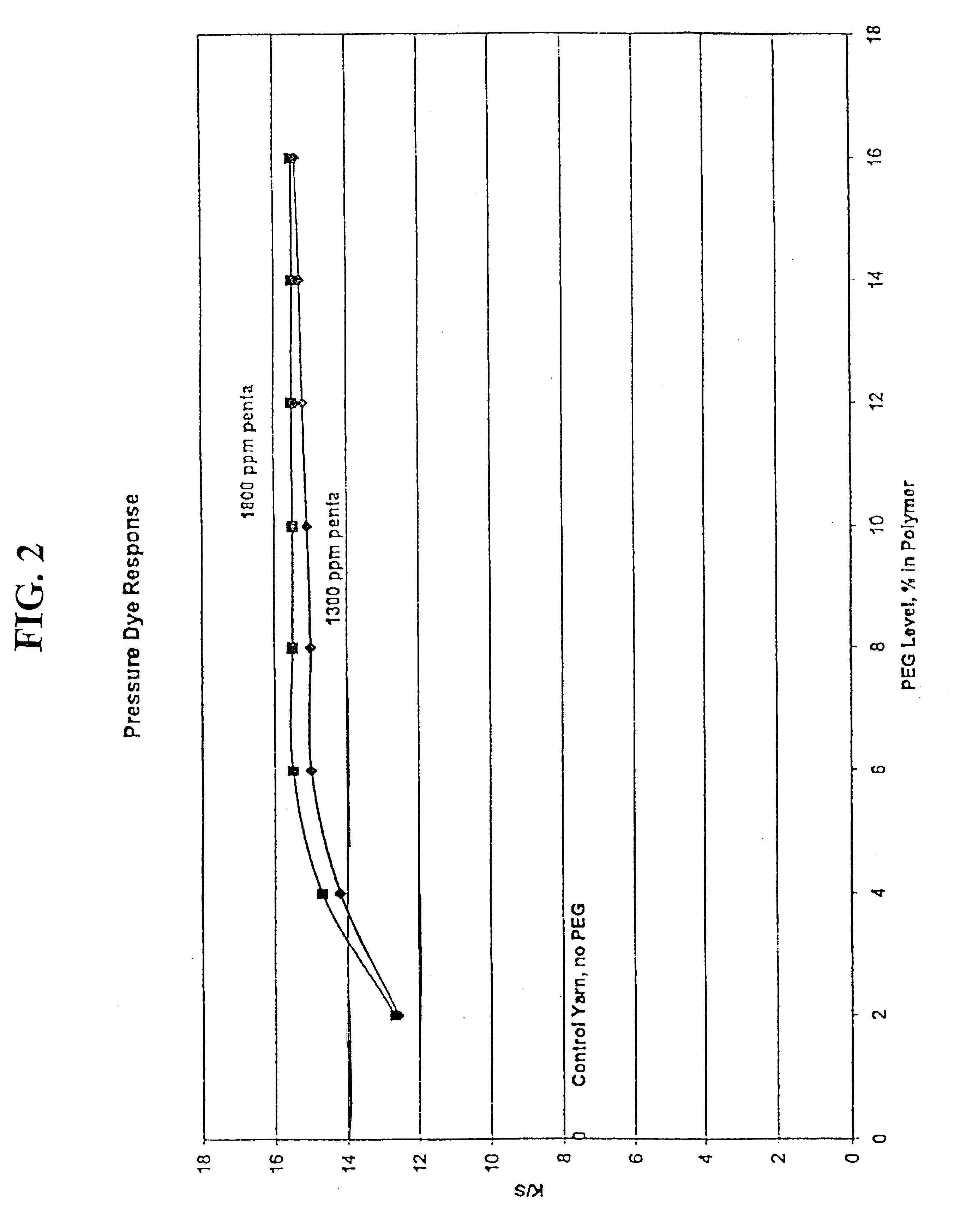

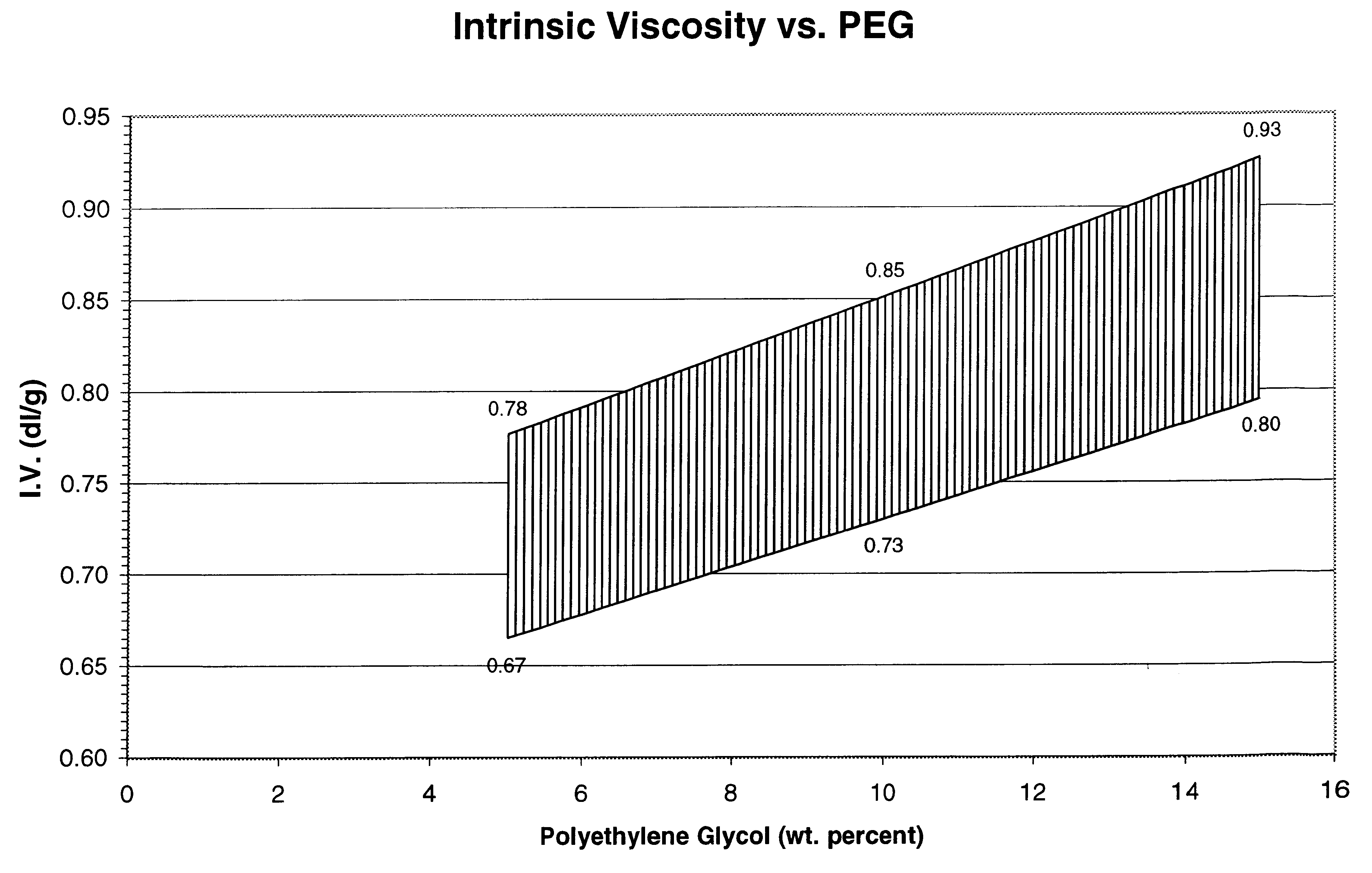

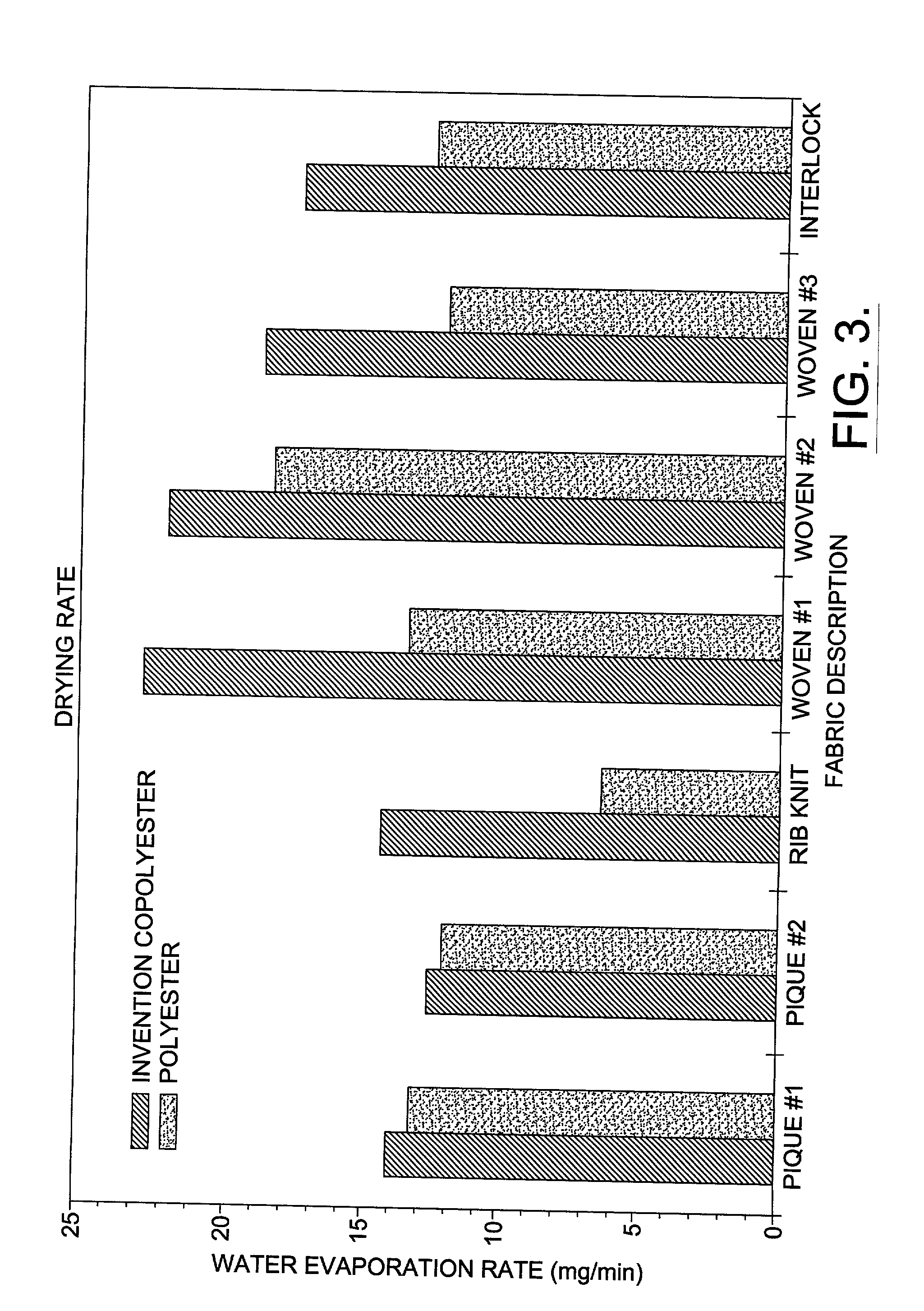

Disclosed is a method of copolymerizing polyethylene glycol (PEG) and branching agent into polyethylene terephthalate (PET) to achieve a polyethylene glycol-modified polyester composition that can be spun into filaments. Fabrics made from fibers formed from the copolyester composition possess wicking, dyeability, and tactility properties that are superior to those of fabrics formed from conventional polyethylene terephthalate fibers of the same yarn and fabric construction. Also disclosed are polyethylene glycol modified copolyester compositions, fibers, yarns, and fabrics.

Owner:FIBER IND INC

Polyethylene glycol modified polyester fibers and method for making the same

InactiveUS6291066B1Easy to dyeImprove dyeing effectProtective fabricsMonocomponent polyetheresters artificial filamentFiberYarn

Disclosed is a method of copolymerizing polyethylene glycol (PEG) and branching agent into polyethylene terephthalate (PET) to achieve a polyethylene glycol-modified polyester composition that can be spun into filaments. Fabrics made from fibers formed from the copolyester composition possess wicking, drying, stretching, abrasion-resistance, flame-retardancy, static-dissipation, dyeability, and tactility properties that are superior to those of fabrics formed from conventional polyethylene terephthalate fibers of the same yarn and fabric construction. Also disclosed are polyethylene glycol modified copolyester compositions, fibers, yarns, and fabrics.

Owner:FIBER IND INC

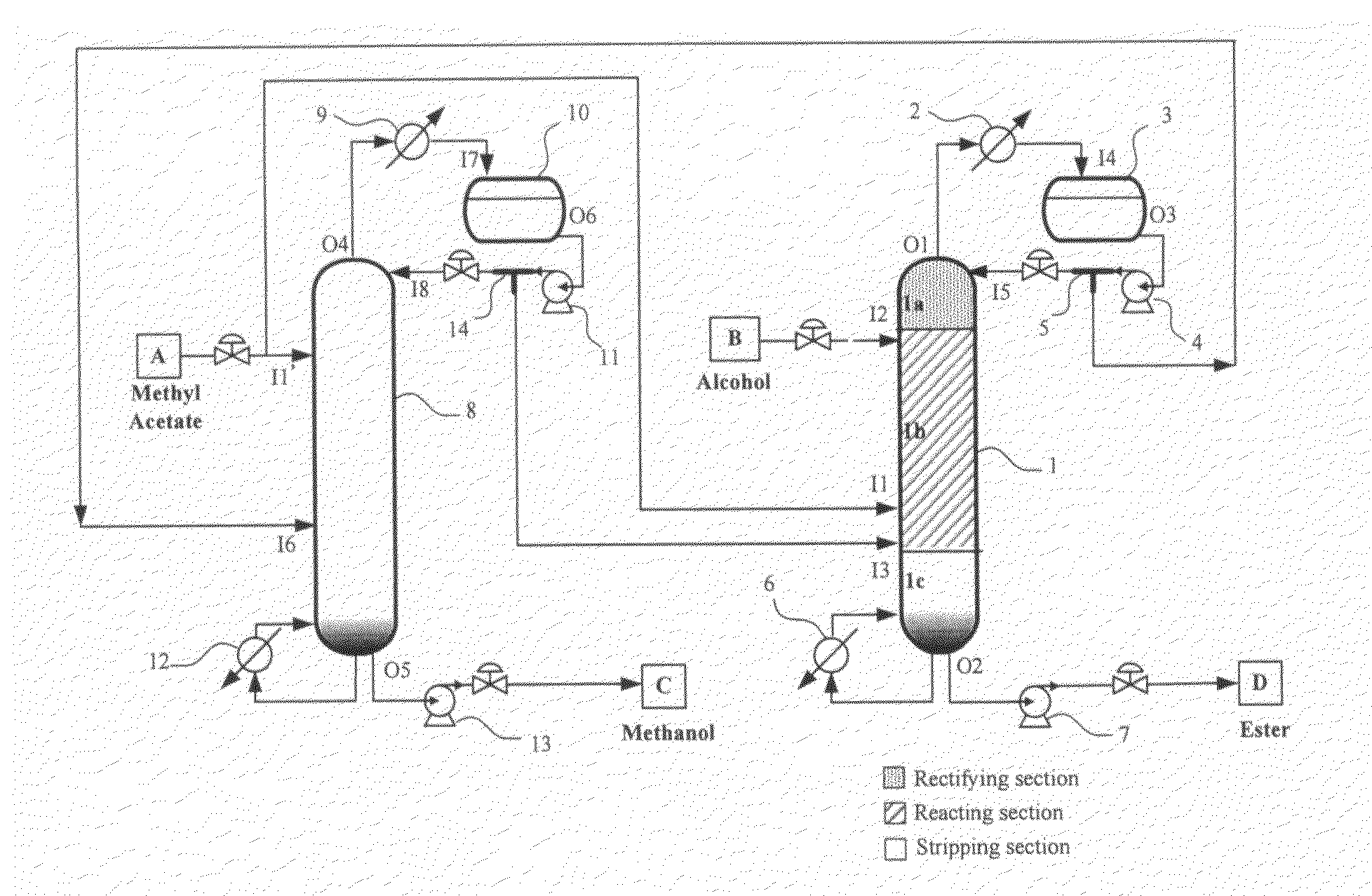

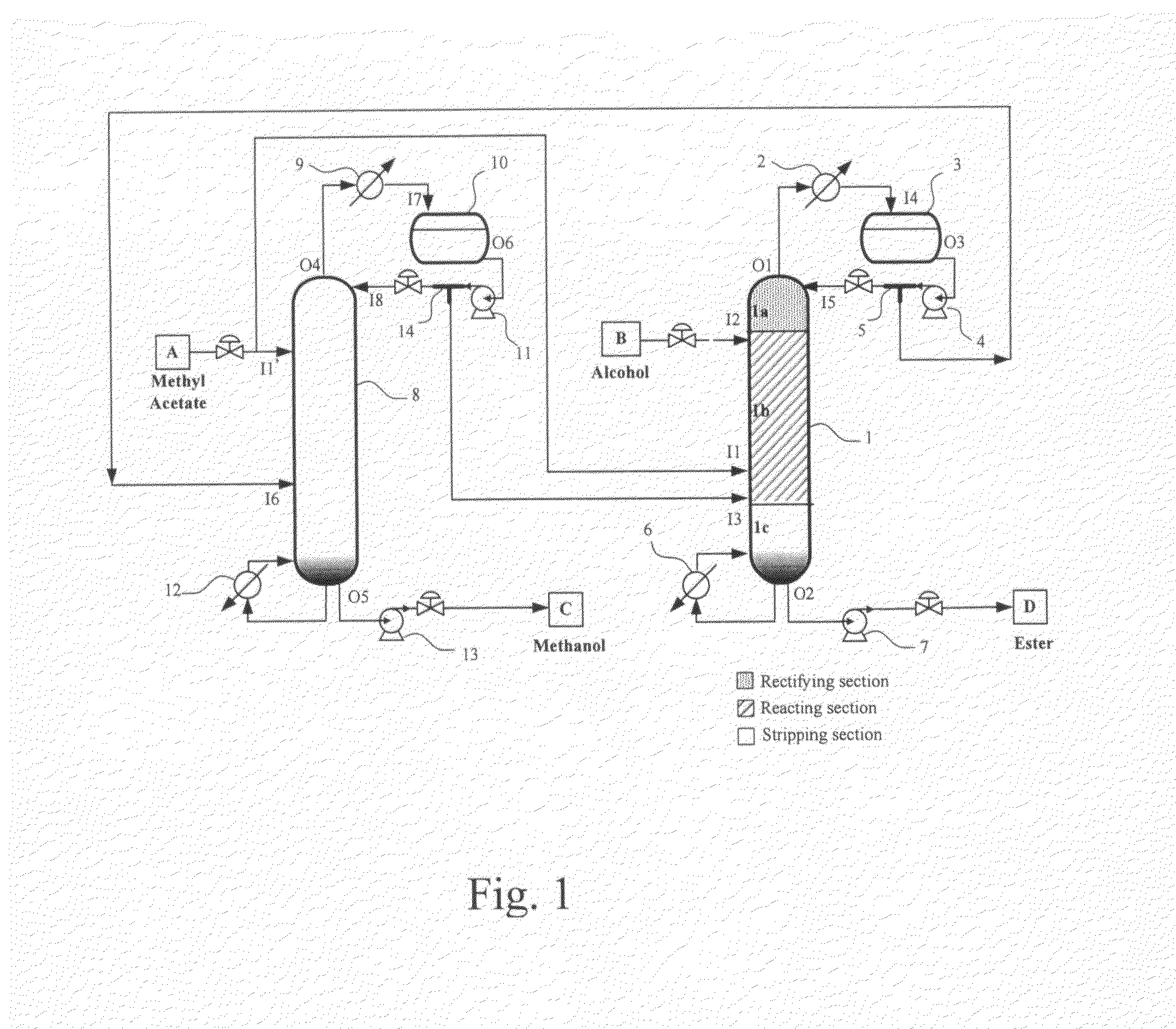

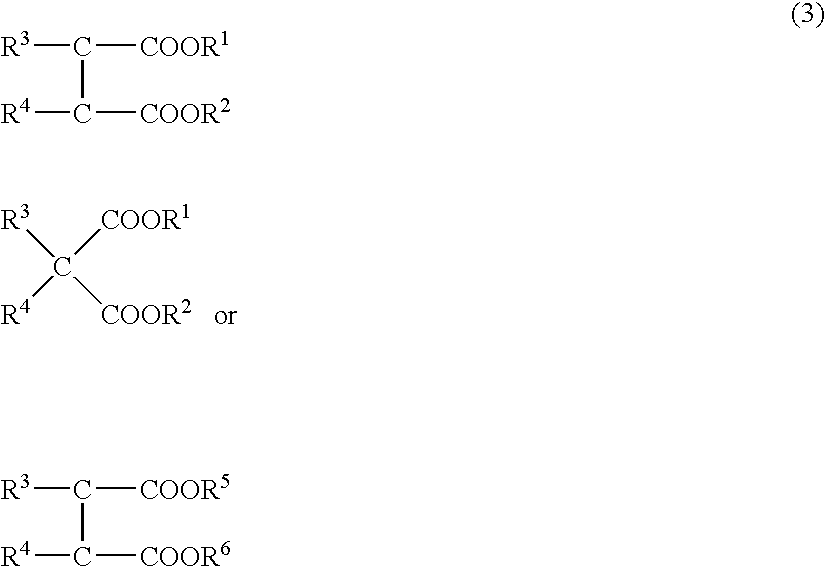

Transesterification process of methyl acetate

ActiveUS20080161595A1Economical and efficient operationOrganic compound preparationPreparation by ester-hydroxy reactionAlcoholTransesterification

A transesterification process of methyl acetate is provided. The process comprises: (a) performing a first reactive distillation of a methyl acetate solution and a first alcohol to generate a first ester and a first mixture; (b) performing a first distillation of a first part of the first mixture to generate a second mixture; and (c) performing a second reactive distillation of a first part of the second mixture and a second alcohol to generate a second ester; wherein the respective one of the first and second alcohols is a limiting reagent. The transesterification process provided in the present invention could highly reduce the investing production cost of the transesterification of the by-product, methyl acetate, in the conventional polyvinyl alcohol plants.

Owner:NAT TAIWAN UNIV

Abrasion-resistant composite material of common polythene and preparation method thereof

The invention discloses an abrasion-resistant composite material of common polythene and a preparation method thereof. The composite material uses the common polythene as a base material, and improves the abrasion resistance of a matrix resin by adding abrasion-resistant stuffing and lubricating components. Simultaneously, the abrasion-resistant composite material retains the good processing property of the general polythene, and overcomes the defect that the polythene with super-high molecular weight is difficult to process. The abrasion-resistant composite material of the common polythene consists of the following components in percentage by mass: 73 to 90 percent of the polythene, 6 to 25 percent of the abrasion-resistant stuffing for surface treatment, and 2 to 4 percent of lubricating agent.

Owner:江苏吉星管业科技有限公司

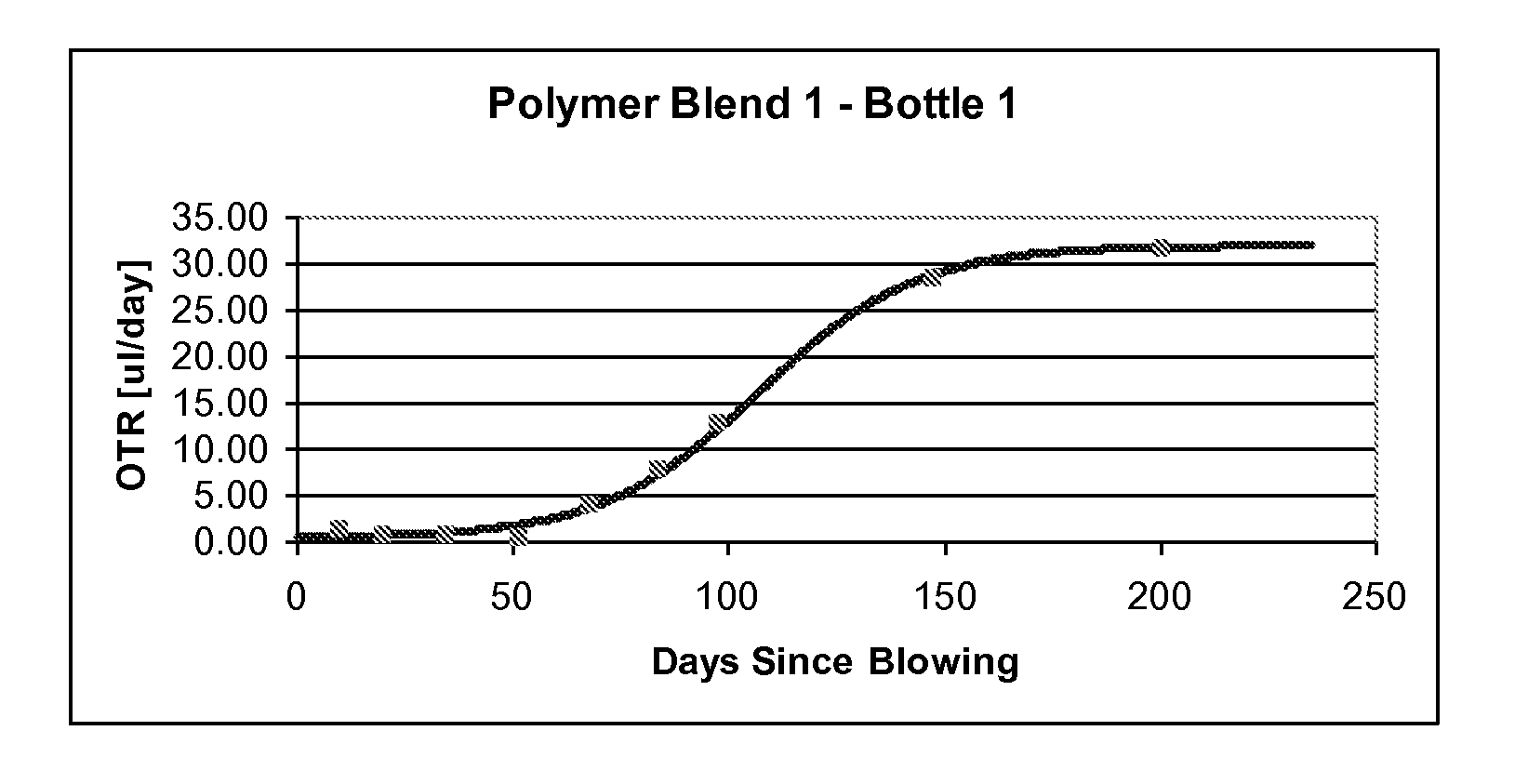

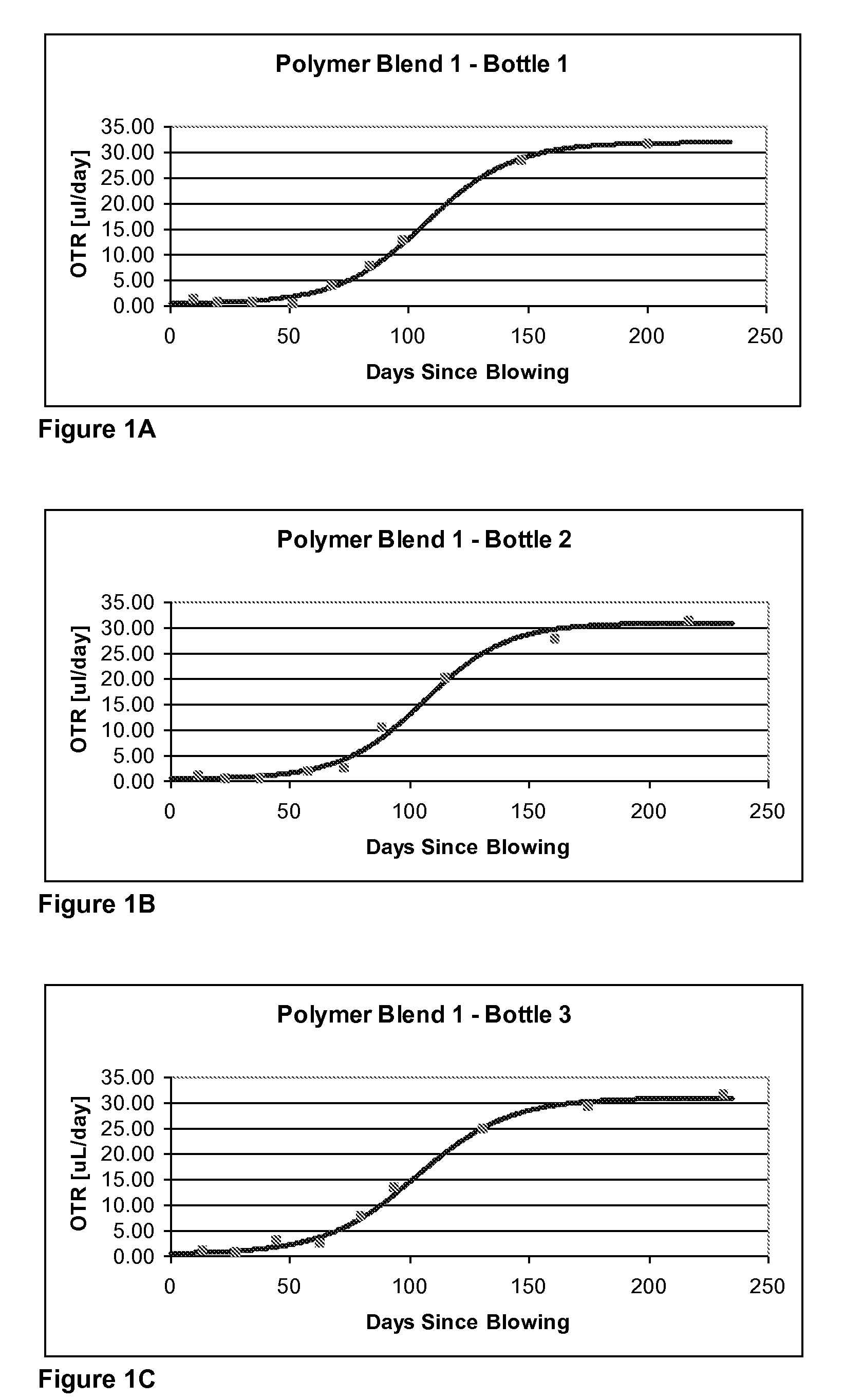

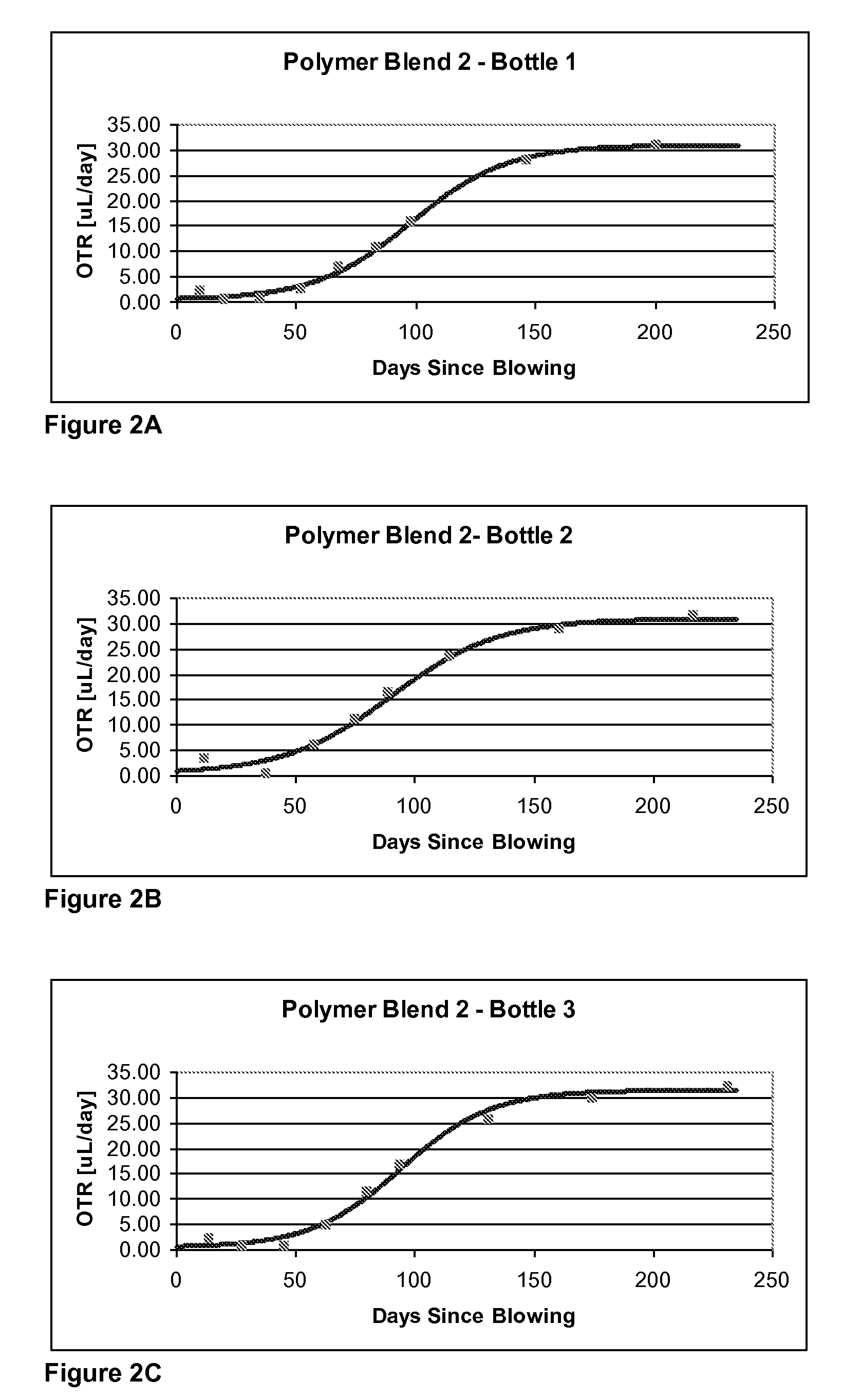

Oxygen-scavenging polymer blends suitable for use in packaging

Polymer blends are disclosed that comprise one or more polybutadiene homopolymers or copolymers having at least one functionality capable of entering into condensation reactions; one or more polyethylene terephthalate homopolymers or copolymers obtained using a catalyst system comprising aluminum atoms and one or more alkaline earth metal atoms, alkali metal atoms, or alkali compound residues, optionally obtained by a melt-phase polymerization process; and one or more transition metal atoms. The blends are useful for packaging, and exhibit improved oxygen-scavenging activity compared with blends made using many conventional polyethylene terephthalate polymers prepared with conventional catalyst systems.

Owner:ALPEK POLYESTER SA DE CV

Adhesive compositions based on blends of grafted substantially linear polyethylenes and non-grafted conventional polyethylenes

InactiveUS20050163996A1Synthetic resin layered productsThin material handlingLow-density polyethylenePolymer science

Laminated films comprising at least one structural layer, at least one adhesive layer and optionally at least one barrier layer made by a high speed or fast quench film process, where the adhesive compositions are blends of acid-grafted substantially linear polyethylenes and conventional-linear polyethylene homopolymer or copolymer or low density polyethylene.

Owner:LEE I HWA +1

Boron nitride-polyethylene space radiation protection composite material and preparation method of composite material

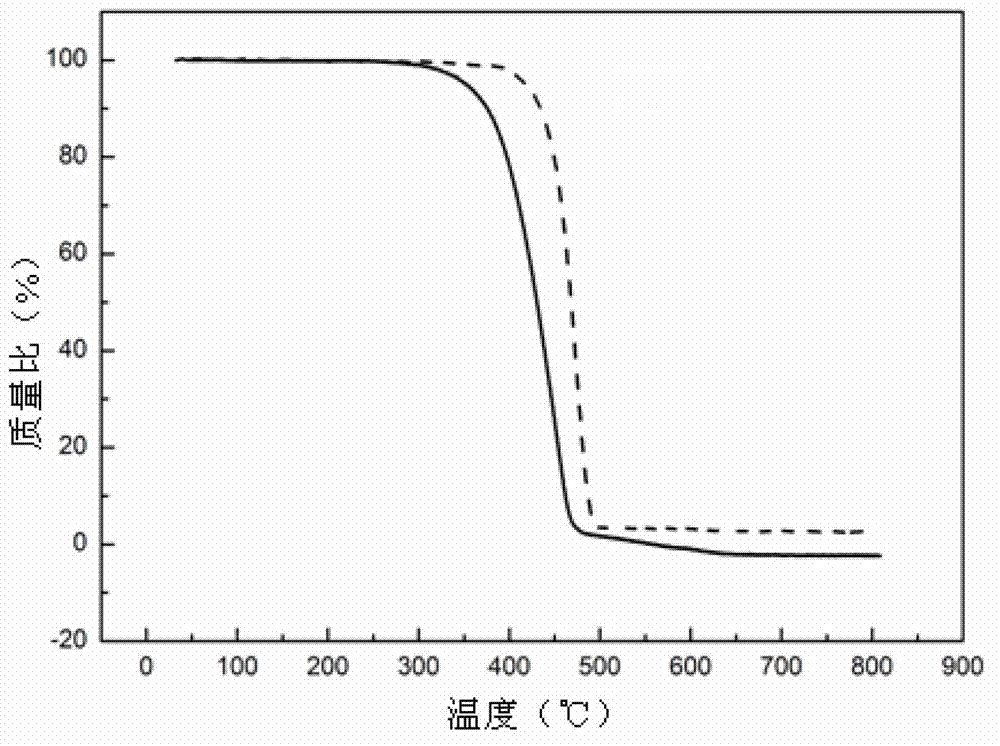

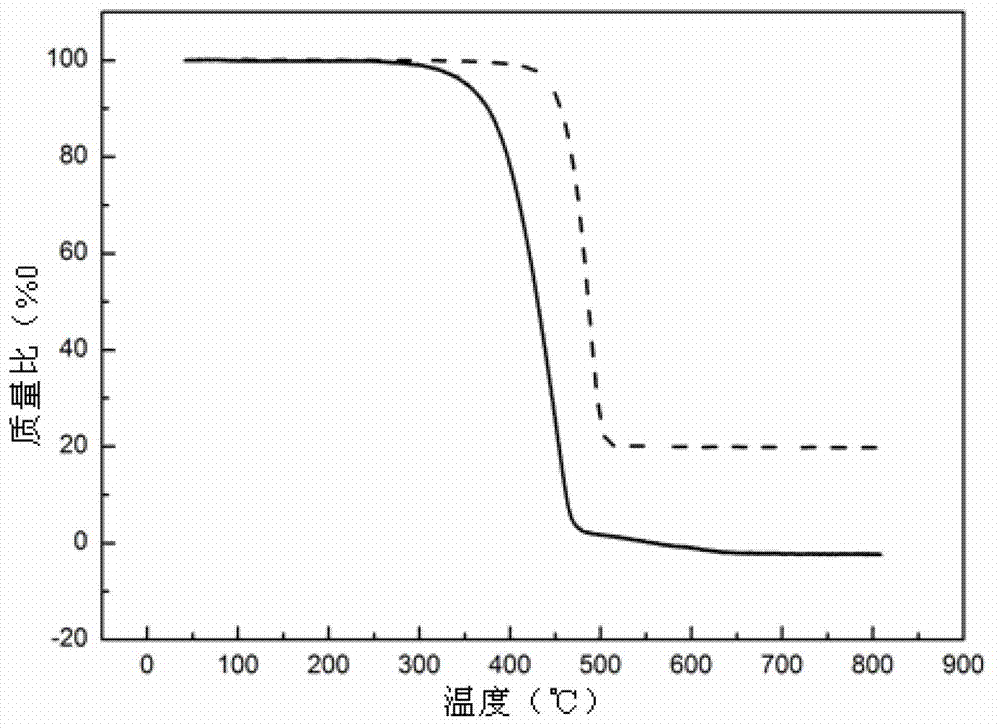

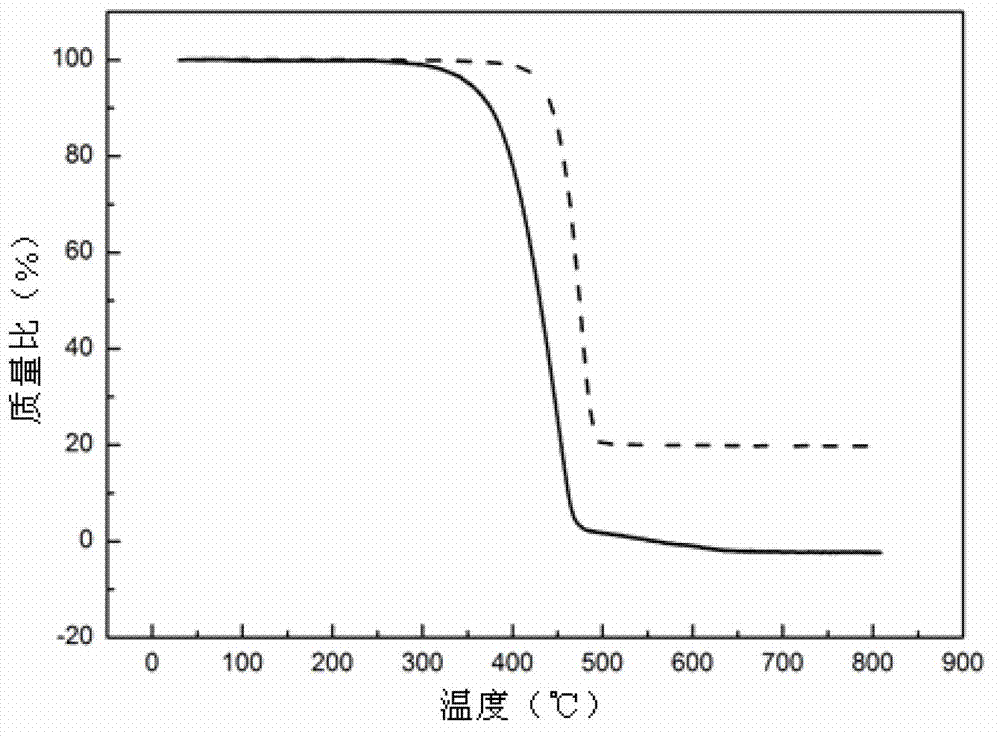

ActiveCN102867557AImproved thermal stability performance indicatorsMeet thermal stability requirementsShieldingProtonBoron nitride

The invention discloses a boron nitride-polyethylene space radiation protection composite material and a preparation method of the boron nitride-polyethylene space radiation protection composite material.The invention relates to a polyethylene space radiation protection composite material and a preparation method of the polyethylene space radiation protection composite material. The invention is used for solving the technical problem that the conventional polyethylene for preparing the space radiation protection material has low thermal stability and low efficiency of filtering protons with pure aluminum in the same mass and thickness. The preparation method disclosed by the invention comprises the following steps of: adding ethanol and boron nitride into a container, then, adding a coupling agent, and reacting in constant temperature water, so as to obtain modified boron nitride, and finally, adding the polyethylene and the boron nitride into a high mixing machine, so as to obtain the boron nitride-polyethylene space radiation protection composite material. The boron nitride-polyethylene composite material prepared with the preparation method disclosed by the invention has a thermal degradation temperature of 430-520 DEG C and high thermal stability, compared with the pure aluminum, efficiency of filtering the protons can be increased for almost 0.4-1 times, an integrated performance is excellent, and the boron nitride-polyethylene space radiation protection composite material has a wide application prospect in radiation protection of spacecrafts.

Owner:HARBIN INST OF TECH

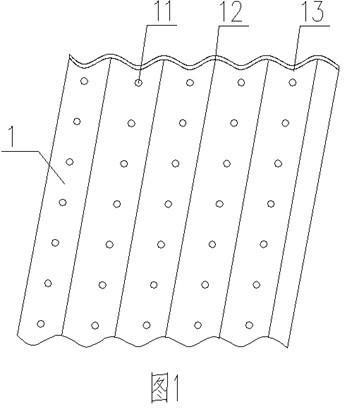

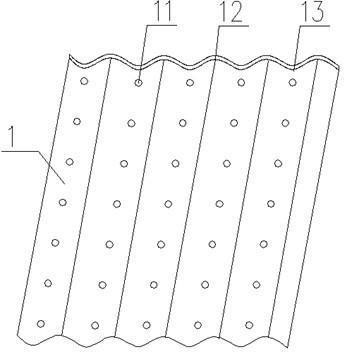

Perforated corrugated plate attachment apparatus for culturing sea cucumbers

InactiveCN102318570AImprove exchange flow effectEvenly distributedClimate change adaptationPisciculture and aquariaPore diameterEngineering

The invention discloses a perforated corrugated plate attachment apparatus for culturing sea cucumbers. The invention is characterized in that: the conventional polyethylene corrugated plate is provided with dense through holes which are in circular, square or rhombic or combined forms; the through holes are positioned at grooves of corrugated plates, and are distributed regularly or irregularly at the intervals 3-8 centimeters; the hole diameters of the through holes are 1.0-5.0 millimeters; the sum of the areas of all through holes is not lower than 5 percent of the surface area of the corrugated plate and not higher than 10 percent of the surface area of the corrugated plate; and the through hole overlapping rate of every two corrugated plate does not surpass 10 percent.

Owner:QINGDAO HENGSHENGYUAN ECOLOGICAL AGRI

Ethylene-based polymer microparticles, functional group-containing ethylene-based polymer microparticles, and catalyst carriers for manufacture thereof

ActiveUS7601423B2Small particle sizeHigh degree of sphericitySynthetic resin layered productsCellulosic plastic layered productsPolymer sciencePtru catalyst

Ethylene-based copolymer microparticles and functional group-containing ethylene-based copolymer microparticles that have particle diameter smaller than that of conventional polyethylene fine-particles, no inter-particle agglomeration, very narrow particle size distribution, and high sphericity are provided, in which requirements (A) to (E): (A) The intrinsic viscosity [η] measured in decalin at 135° C. is in the range of 0.1 to 50 dl / g, (B) at least 95 wt % or more of particles pass through a mesh screen with an opening of 37 μm, (C) the median diameter (d50) measured by laser diffraction scattering is 3 μm≦d50≦25 μm, (D) the circularity coefficient is 0.85 or more, and (E) the variation coefficient of particle diameter (Cv) is 20% or less. Non-agglomerated spherical magnesium-containing microparticles used as magnesium-containing carrier component for olefin-polymerization catalysts that can manufacture the above microparticles are also provided.

Owner:MITSUI CHEM INC

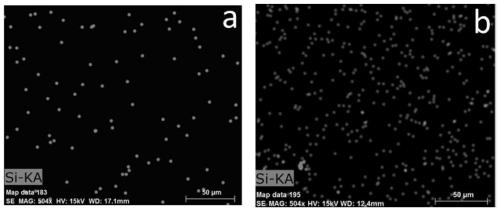

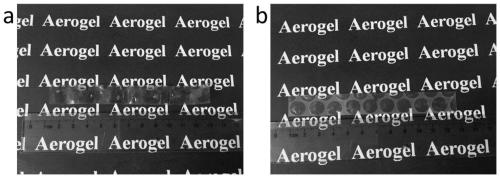

Preparation method of nanoporous high-efficiency heat-insulating polyethylene film

InactiveCN109912874AImprove insulation performanceLow thermal conductivityBulk chemical productionMasterbatchUltimate tensile strength

The invention relates to a preparation method of a nanoporous high-efficiency heat-insulating polyethylene film, by which the nanoporous high-efficiency heat-insulating polyethylene film is prepared from nanometer aerogel powder as an inorganic filler and polyethylene powder as a main raw material. The preparation process comprises the following main steps: performing surface modification on the nanometer aerogel powder, preparing masterbatch, casting the film and the like. Through certain technical characterization, the fact that the nanometer aerogel powder is uniformly dispersed in a polyethylene matrix is proved. Compared with the conventional polyethylene film, the nanoporous high-efficiency heat-insulating polyethylene film provided by the invention has the advantages as follows: theheat conductivity of the nanoporous high-efficiency heat-insulating polyethylene film doped with 3% of the aerogel powder is decreased by 26.1%, and the tensile strength and the elongation at break are not changed too much. Decrease in the heat conductivity indicates increase in heat-preserving and heat-insulating properties of the film, so that the film prepared by the preparation method provided by the invention has a very good application prospect in the field of heat preservation and heat insulation.

Owner:罗瑞尔纳米合成材料(江苏)有限公司

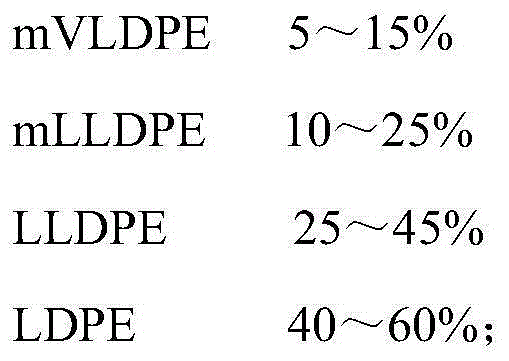

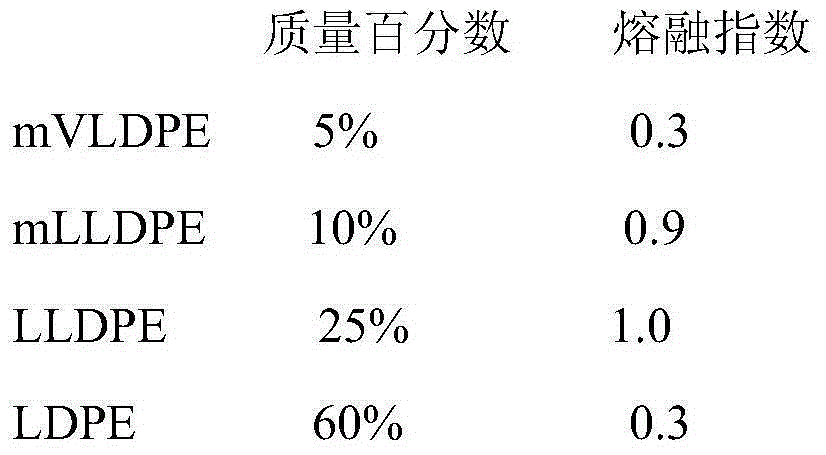

Plastic packaging material for injection powder and preparation process thereof

ActiveCN105175849AImprove puncture strengthHigh tear strengthSynthetic resin layered productsPlastic packagingRoom temperature

The present invention relates to a plastic packaging material for injection powder and a preparation process thereof, and belongs to the field of pharmaceutical packaging materials. The plastic packaging material has a three-layer structure comprising an inner layer, a middle layer and an outer layer. The inner layer and outer layer are made from the following components by weight: 5-15% of mVLDPE, 10-25% of mLLDPE, 25-45% of LLDPE and 40-60% of LDPE; and the middle layer is made from the following components by weight: 5-15% of mLLDPE, 20-40% of LLDPE and 45-75% of LDPE. The plastic packaging material provided by the present invention has good toughness, high transparency, low heat viscosity low heat sealing temperature and small odor, and performances superior to conventional polyethylene products; the plastic packaging material has excellent anti-impact resistance and resistance to environmental stress cracking at room temperature or even at a low temperature of -80 DEG C, excellent barrier properties and tearing strength. The invention provides a better securer choice with higher quality for aseptic pharmaceutical production and packaging.

Owner:ZIBO HUA ZHI LIN PACKING PROD CO LTD

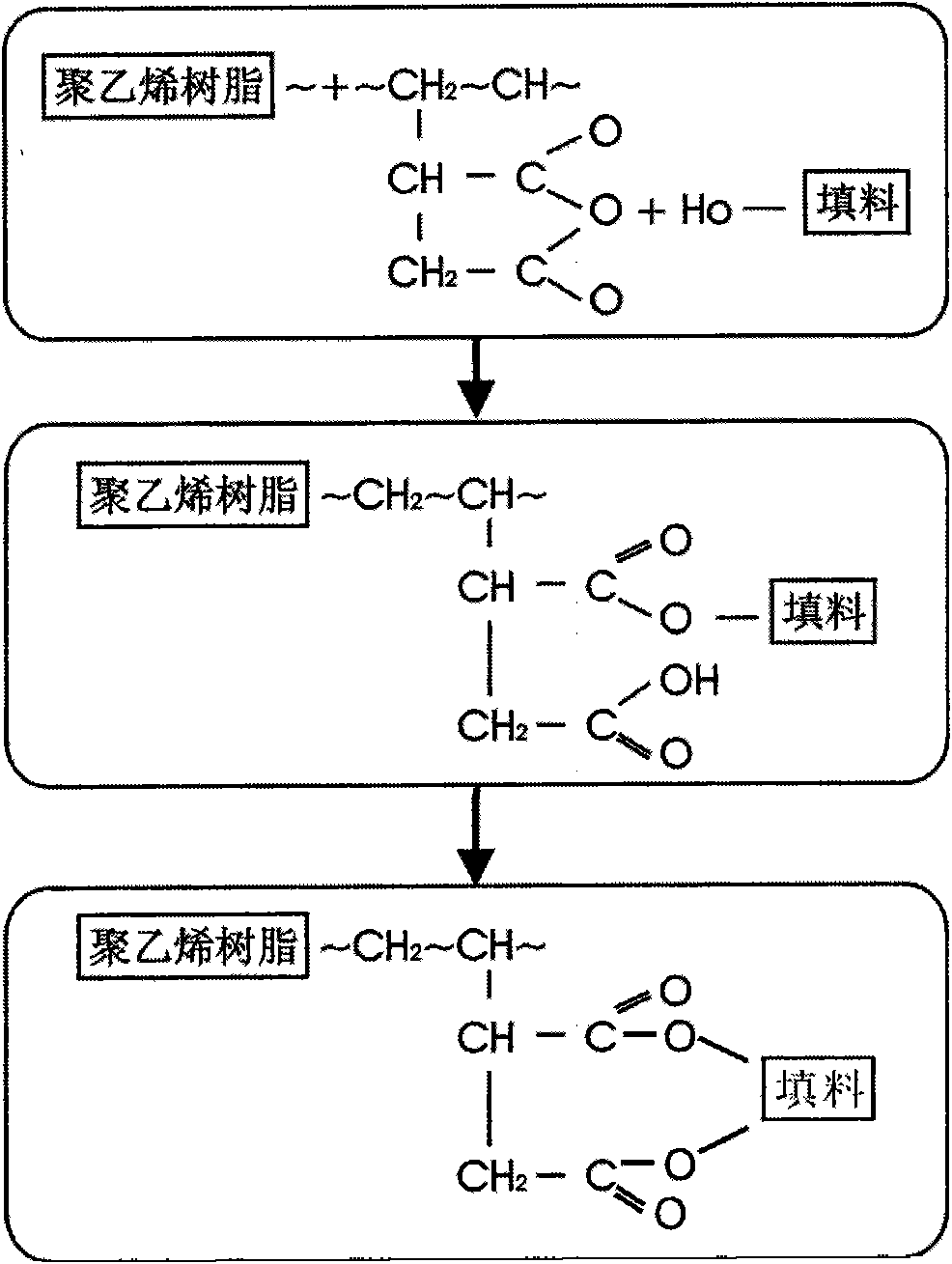

Tea leaf-polyolefin composite material and preparation method thereof

The invention relates to a tea leaf-polyolefin composite material which is prepared from the following raw materials in percentage by weight: 30-35% of tea leaf fine powder treated by a silane coupling agent, 52-58% of polyethylene, 6-10% of maleic anhydride grafted polyethylene, 0.5-0.8% of stearic acid, 1-2% of PE (Poly Ethylene) wax and 0.5-0.8% of antioxidant. The preparation method comprises the following steps: S1, obtaining the tea leaf fine powder treated by the silane coupling agent; S2, preparing treated tea leaf fine powder, polyethylene, maleic anhydride grafted polyethylene, stearic acid, PE wax and antioxidant; S3, adding the treated tea leaf fine powder into a high-speed mixer; S4, adding the maleic anhydride grafted polyethylene; S5, adding polyethylene into the high-speed mixer; S6, adding the stearic acid, PE wax and antioxidant; and S7, obtaining the tea leaf-polyolefin composite material. The material provided by the invention has the beneficial effects that the performance requirements of functional biomass high polymer materials are satisfied; the composite material is a low-cost and green high polymer material which not only has the characteristic of conventional polyethylene, but also is degradable and can be used for improving the mechanical properties of plastic products.

Owner:YINGKOU DONGSHENG IND +1

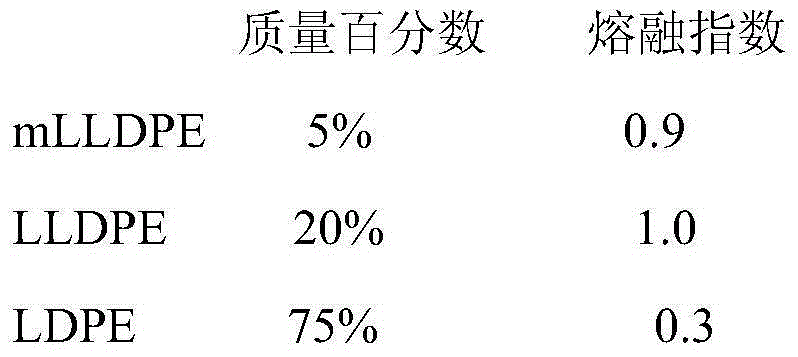

Method of preparing polyethylene glycol modified polyester filaments

InactiveUS20010002737A1Improve featuresImprove certain polyester characteristicsMonocomponent polyetheresters artificial filamentProtective fabricsFiberYarn

Disclosed is a method of copolymerizing polyethylene glycol (PEG) into polyethylene terephthalate (PET) to achieve a polyethylene glycol-modified polyester composition that can be spun into filaments. The method includes the steps of copolymerizing polyethylene glycol into polyethylene terephthalate in the melt phase to form a copolyester composition, then polymerizing the copolyester composition in the solid phase until the copolyester is capable of achieving a melt viscosity that facilitates the spinning of filaments, and thereafter spinning filaments from the copolyester. A copolyester composition comprised of polyethylene glycol and polyethylene terephthalate is also disclosed. Fabrics made from fibers formed from the copolyester composition possess wetting, wicking, drying, flame-retardancy, static-dissipation, and soft hand properties that are superior to those of fabrics formed from conventional polyethylene terephthalate fibers of the same yarn and fabric construction.

Owner:FIBER IND INC

Microfine relatively high molecular weight polyethylene powders

Microfine low density polyethylene powders are provided. The powders are comprised of spherical or substantially spherical particles having an average particle size of 5 microns or less produced by a dispersion process. The powders, by virtue of their relatively high molecular weights compared to conventional polyethylene waxes, have a useful balance of physical properties.

Owner:EQUSR CHEM LP

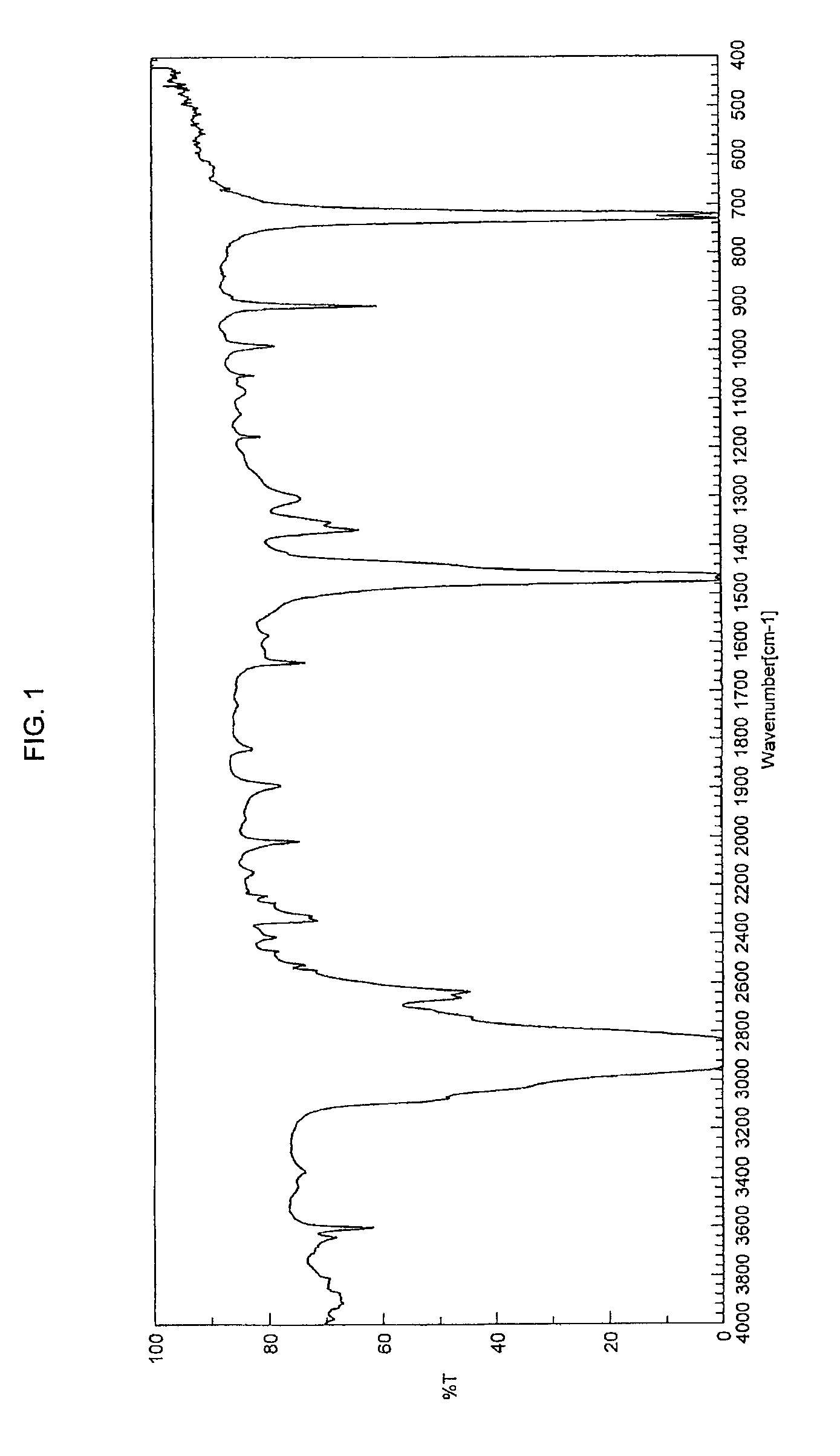

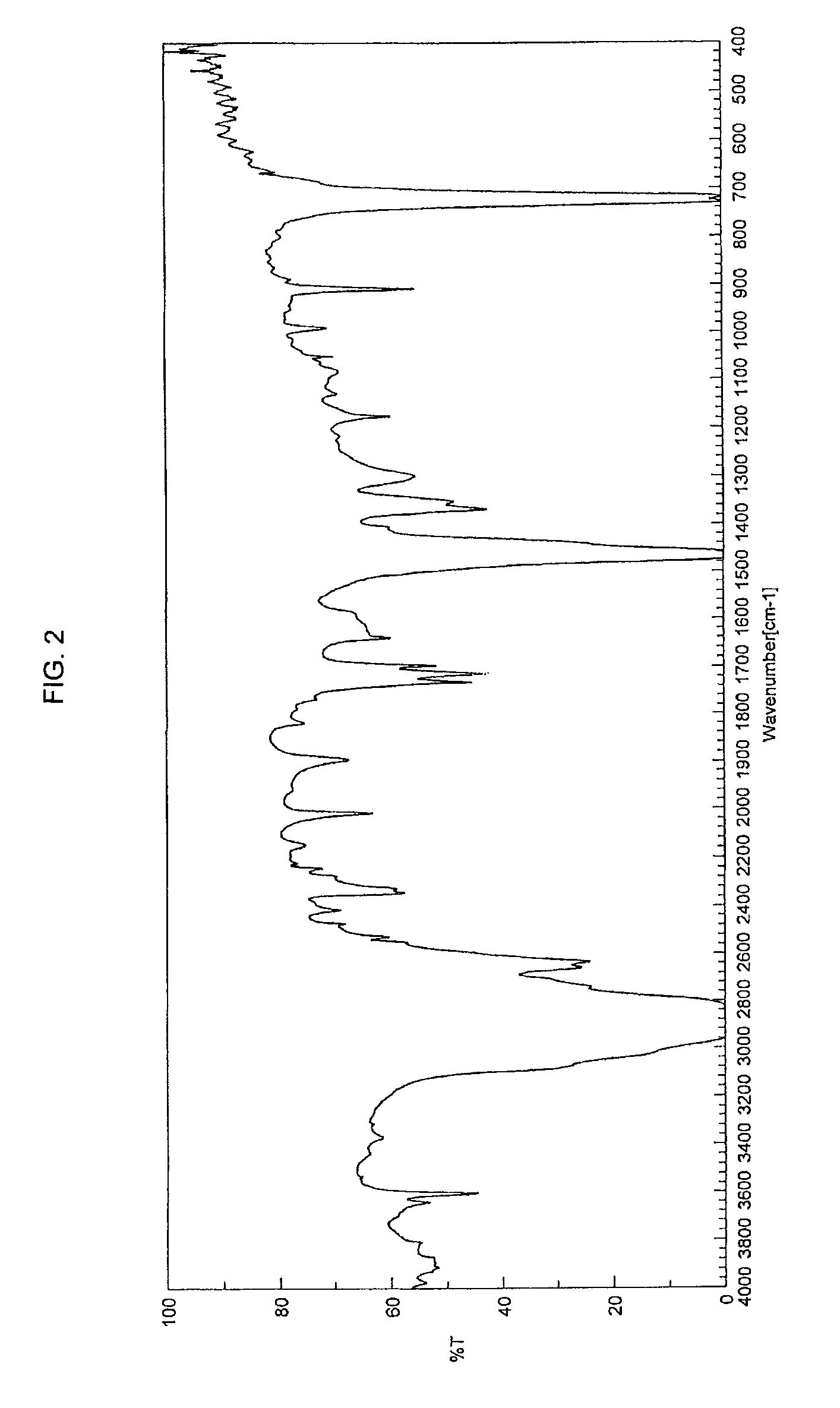

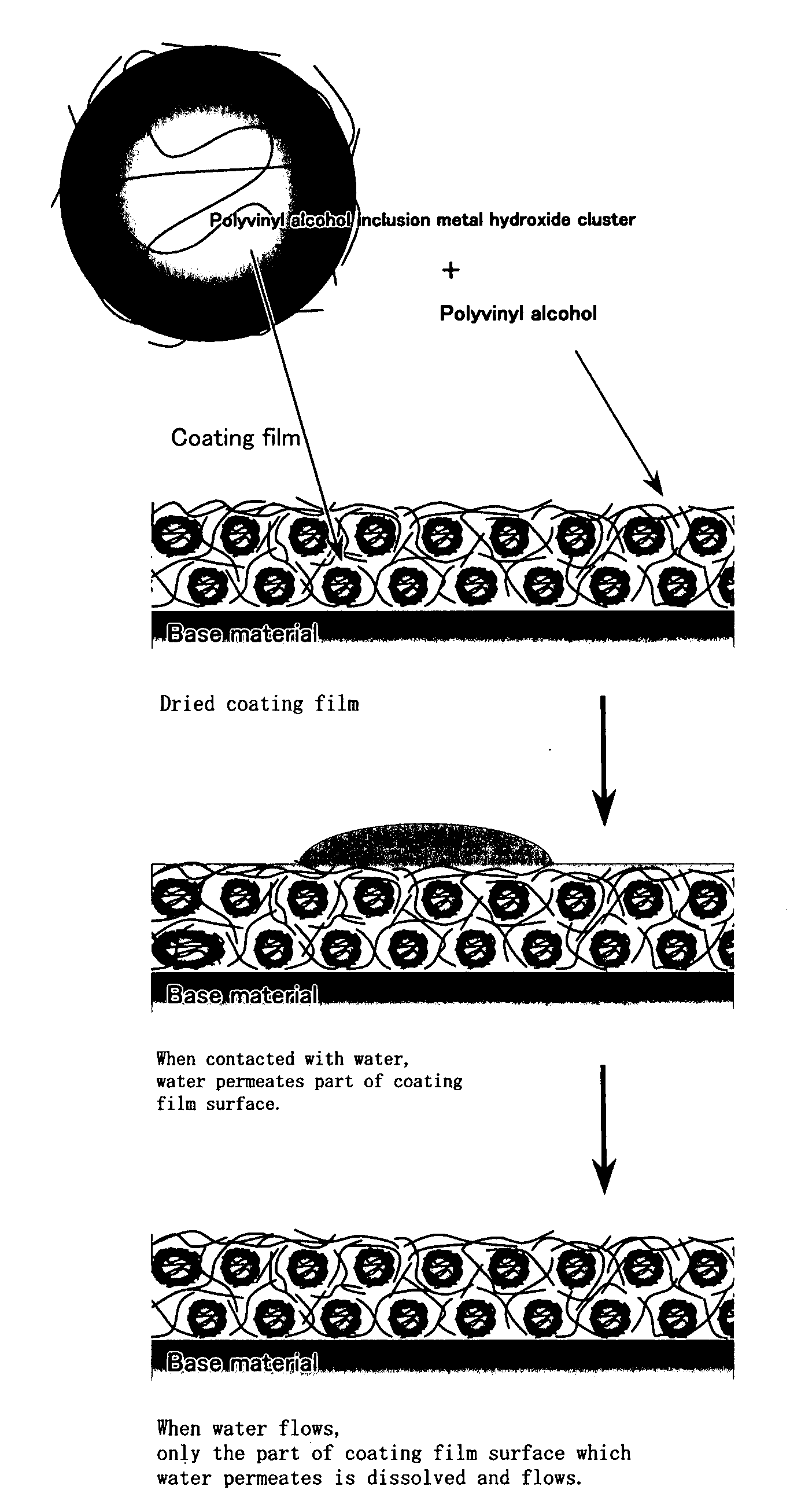

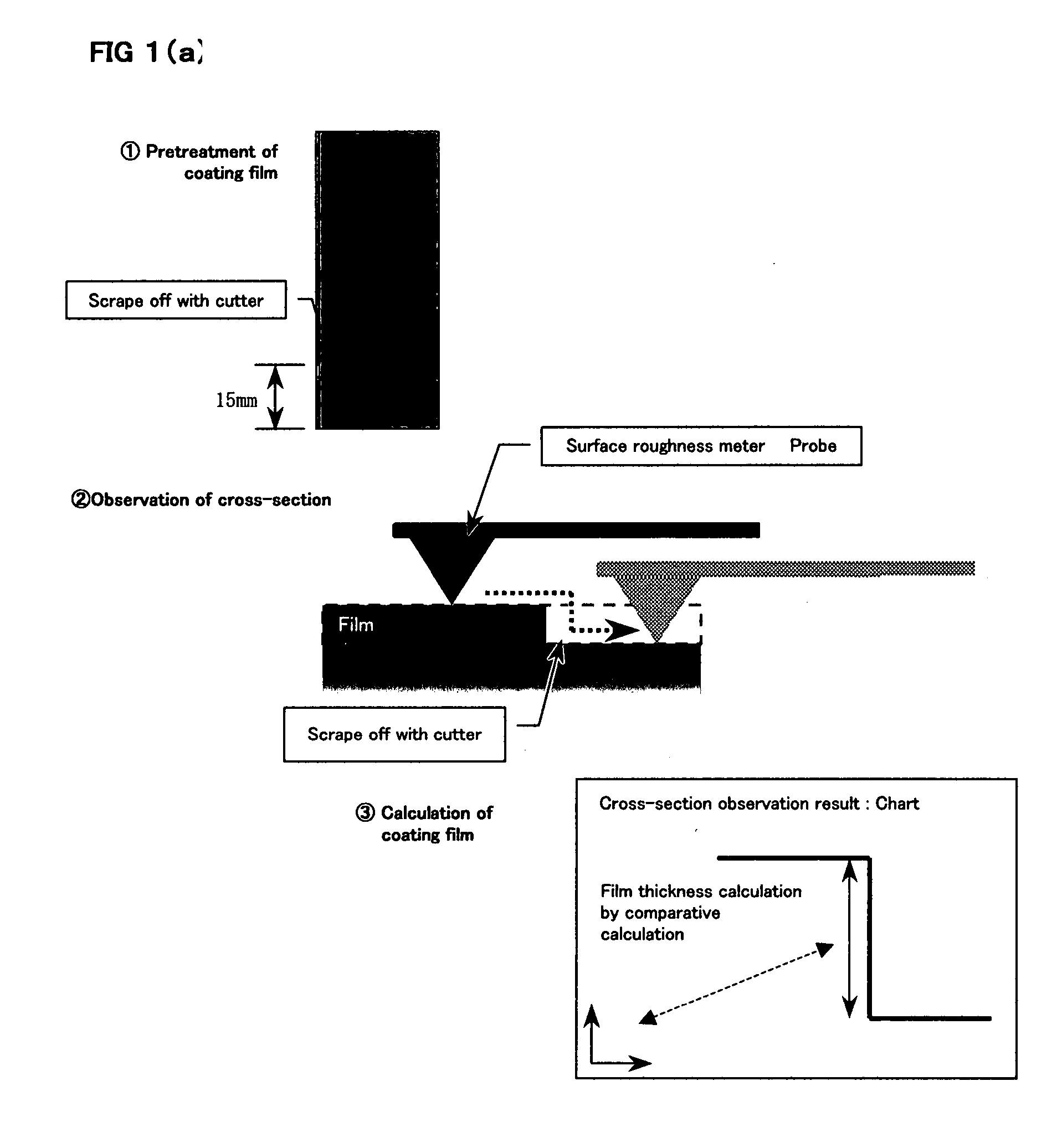

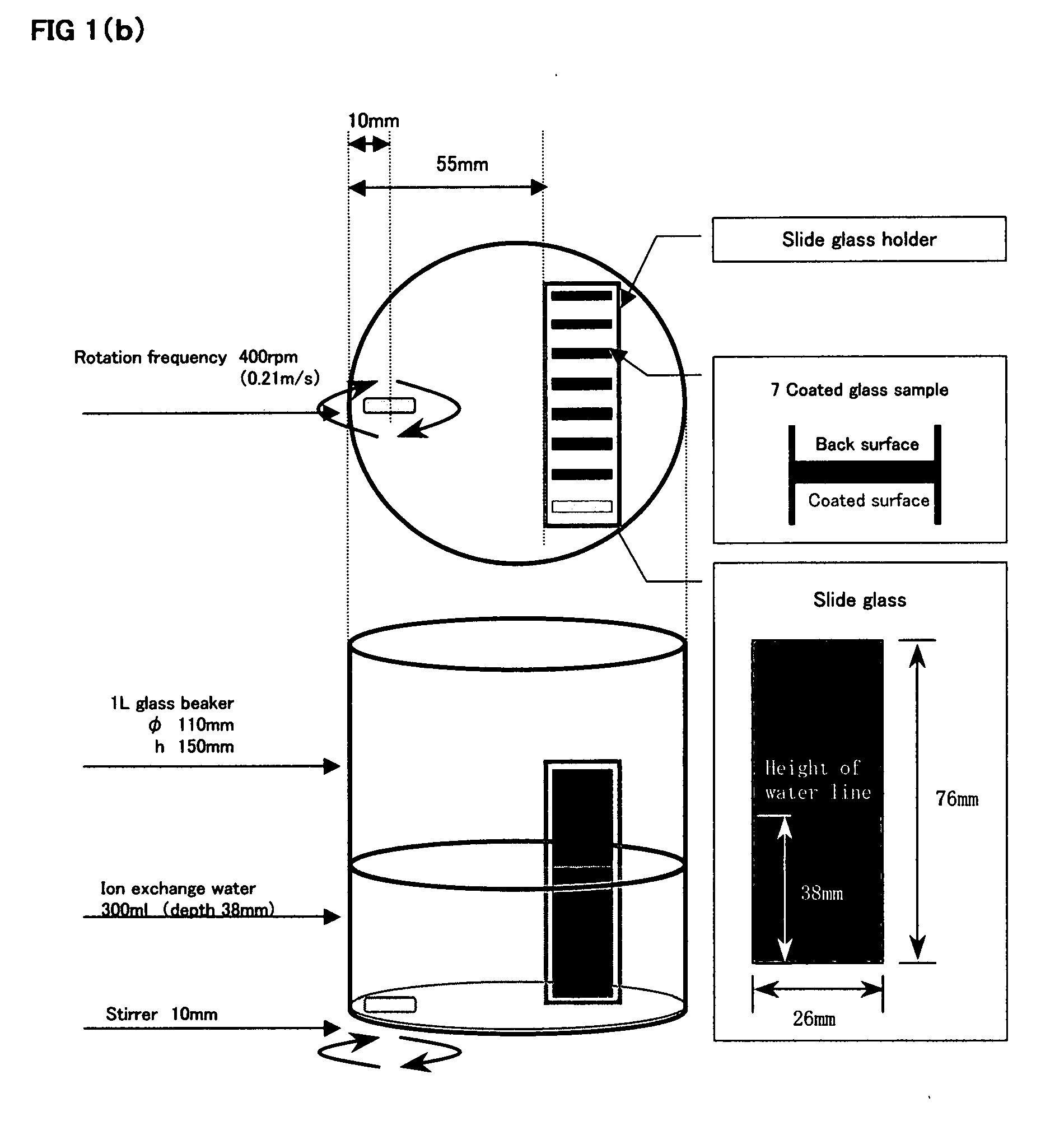

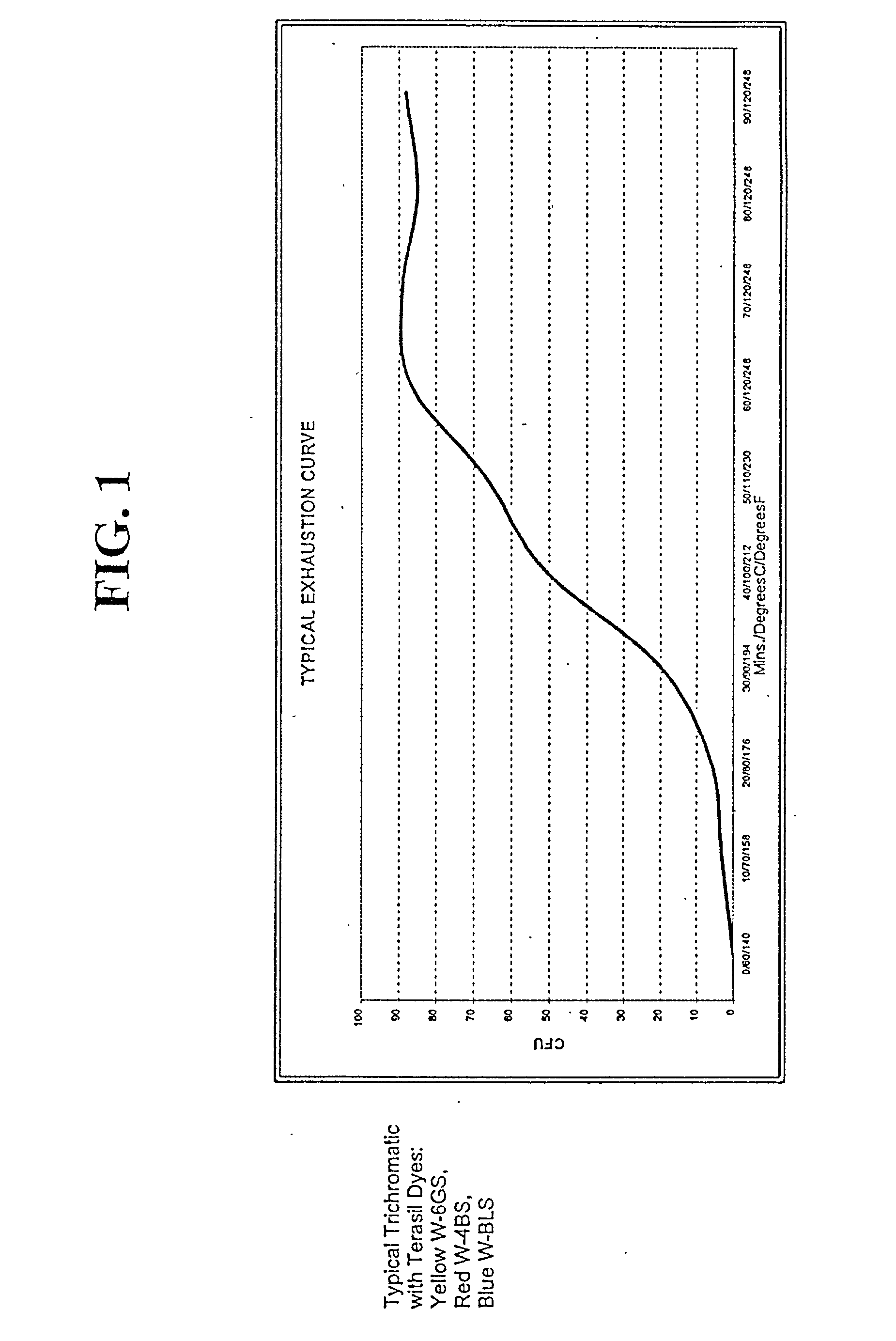

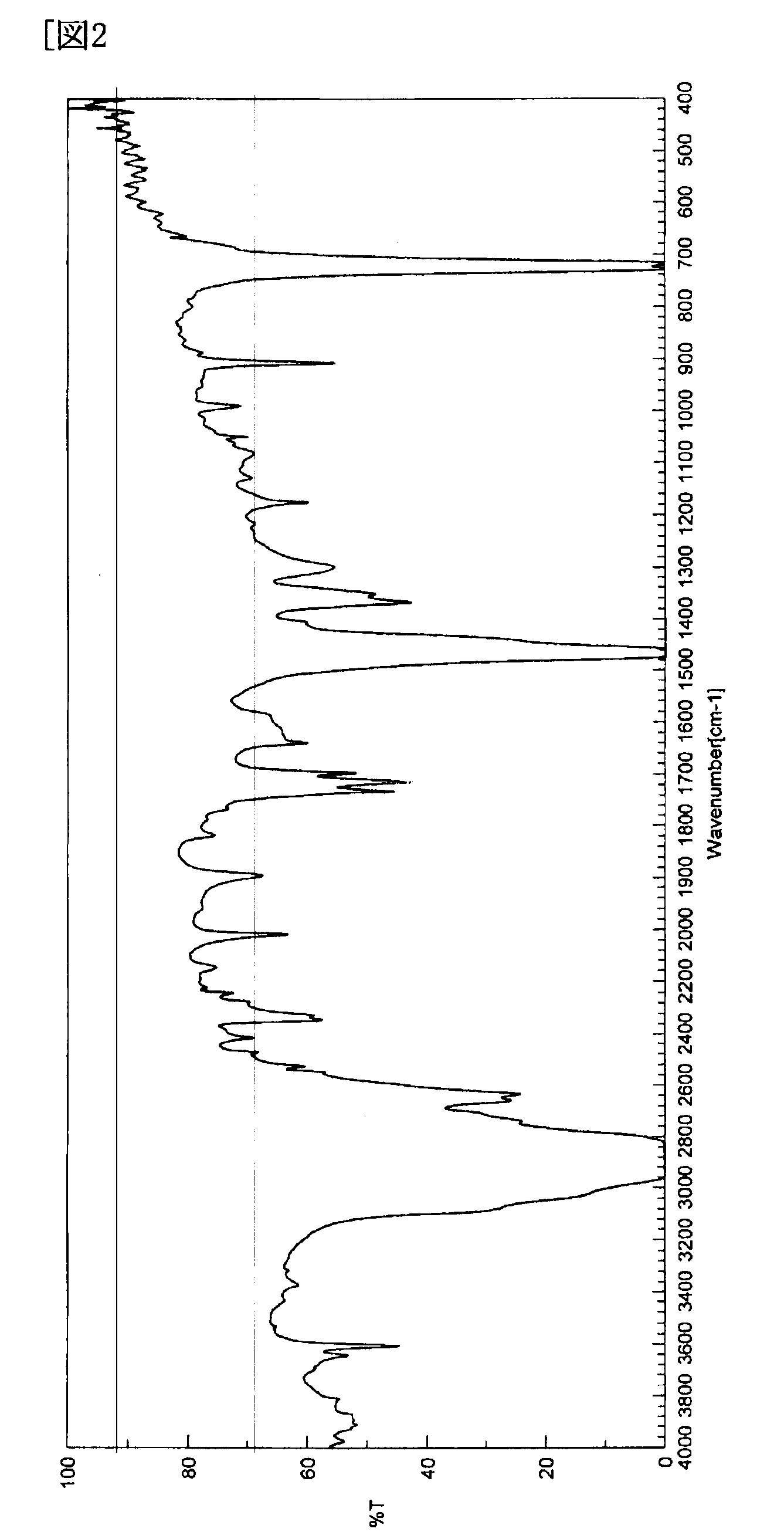

Composite member having gradually soluble coating film, and coating formation material

The present invention provides a gradually soluble coating film to be applied to instruments for waterworks. In a conventional polyvinyl alcohol solution not containing metal salt, there is formed a coating film in which polyvinyl alcohol molecules are piled up as shown in FIG. 2(a). In such coating film, water contacting with a surface thereof penetrates rapidly to the interface between the coating film and a base material, so that when water flows away, the coating film flows out and vanishes completely. On the other hand, in a coating film of the present invention, there are formed polyvinyl alcohol inclusion metal hydroxide clusters derived from the kind of metal in the solution as shown in FIG. 2(b). Although polyvinyl alcohol is dissolved or swollen to allow water to penetrate therein when water contacts with the coating film surface, the penetration speed of water in the direction of film thickness is controlled since the metal hydroxide clusters exist in the film. Therefore, when water flows away, only the film in a water penetrated portion in the vicinity of the coating film surface flows and the entire coating film does not vanish at one time.

Owner:TOTO LTD

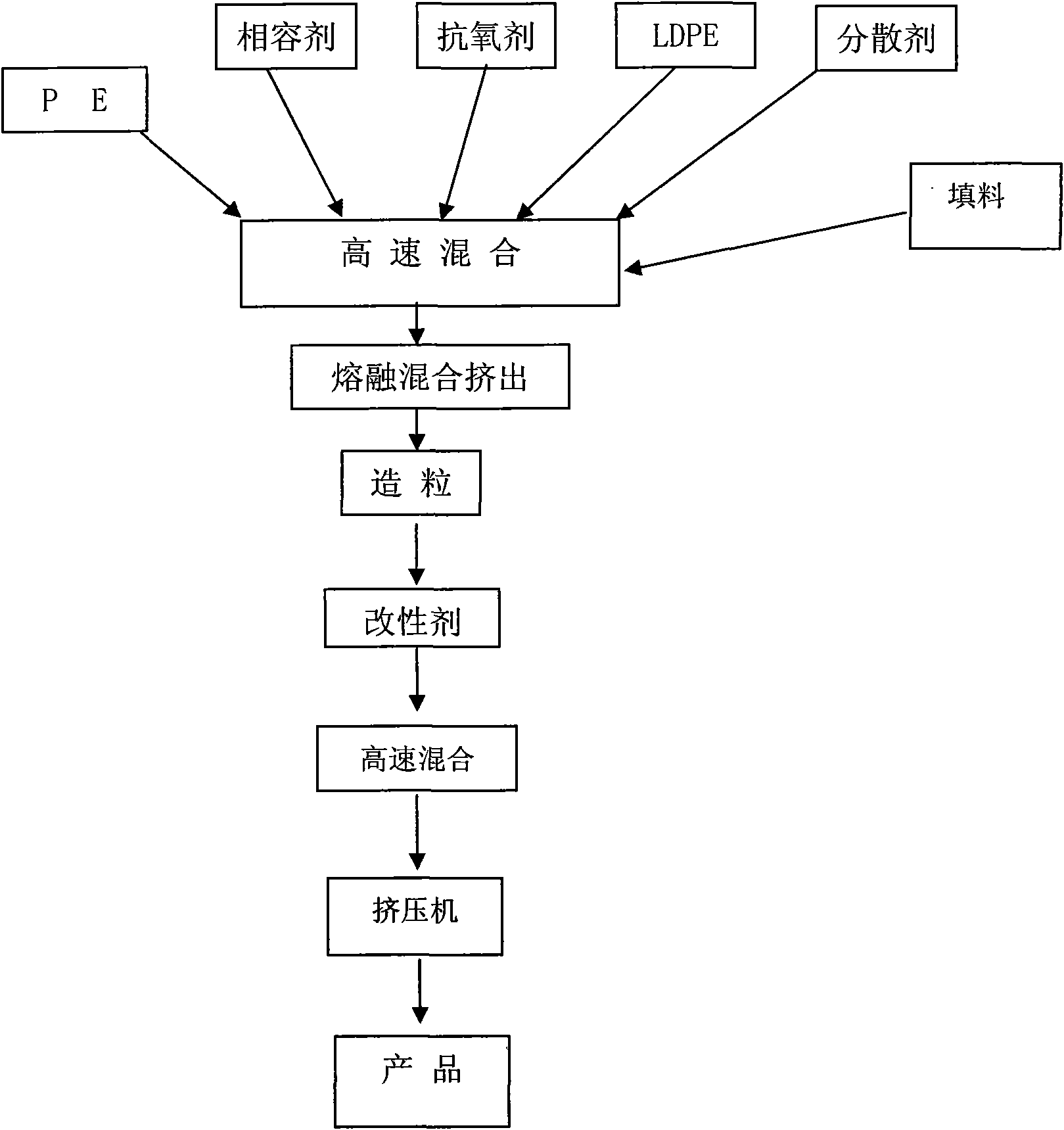

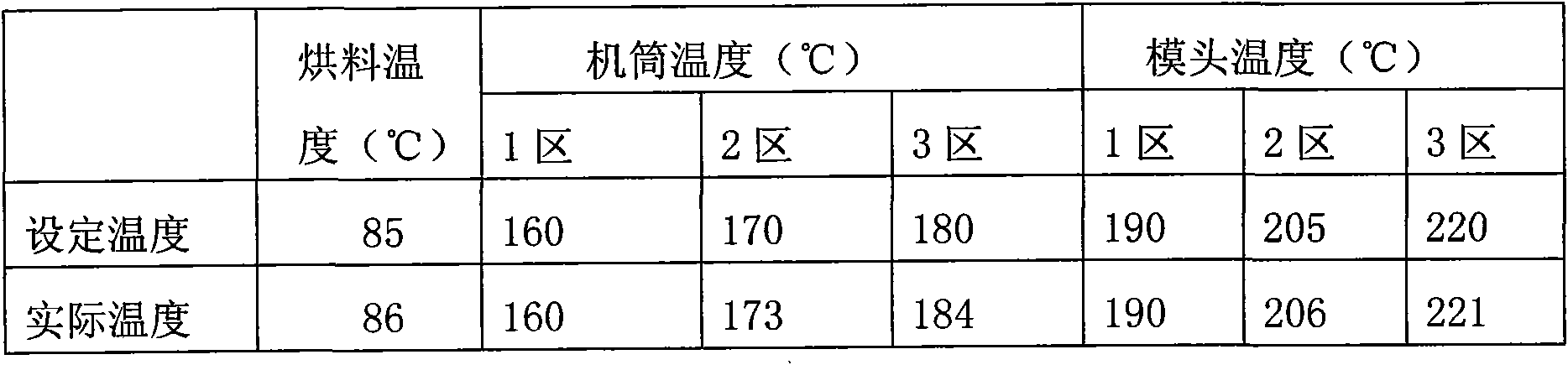

High-density polyethylene alloy pipe and manufacturing method thereof

InactiveCN102040757AOvercoming low tensile strengthImprove barrier propertiesRigid pipesLow-density polyethyleneChemical industry

The invention discloses a high-density polyethylene alloy pipe and a manufacturing method thereof. High-density polyethylene 100 (HDPE 100) is used as base resin, high-density polyethylene-g-maleic anhydride (HDPE-g-MAH) is used as a compatilizer, calcium carbonate (CaCO3) and low-density polyethylene (LDPE) are added into the base resin and the compatilizer, and the mixture is blended with modifier polyamide 6 (PA6) to form a modified polyethylene (PE) alloy product. The method comprises the main operation steps of: (I) preparing HDPE modified granules; and (II) adding the modifier PA6, performing high-speed mixing to form a modified PE mixture, and extruding the modified PE mixture into the product in an extruder. According to the technical scheme, the high-density polyethylene alloy pipe overcomes the defects the defects that the conventional polyethylene resin has low tensile strength, poor rigidity and poor abrasion resistance, chemical resistance, environmental stress cracking resistance and heat resistance, has insufficient blocking property on hydrocarbon solvents and fuel oil, is easily damaged by ultraviolet under the irradiation of sunlight, seriously affects the service life of the product and the like; and the high-density polyethylene alloy pipe is suitable to be used as various heat resistant, abrasion resistant and temperature resistant pipes, and is particularly suitable for pipeline transportation of special industries of drainage, fuel gas and fuel oil delivery, chemistry and chemical industry and the like.

Owner:HUNAN ZHENHUI PIPE IND

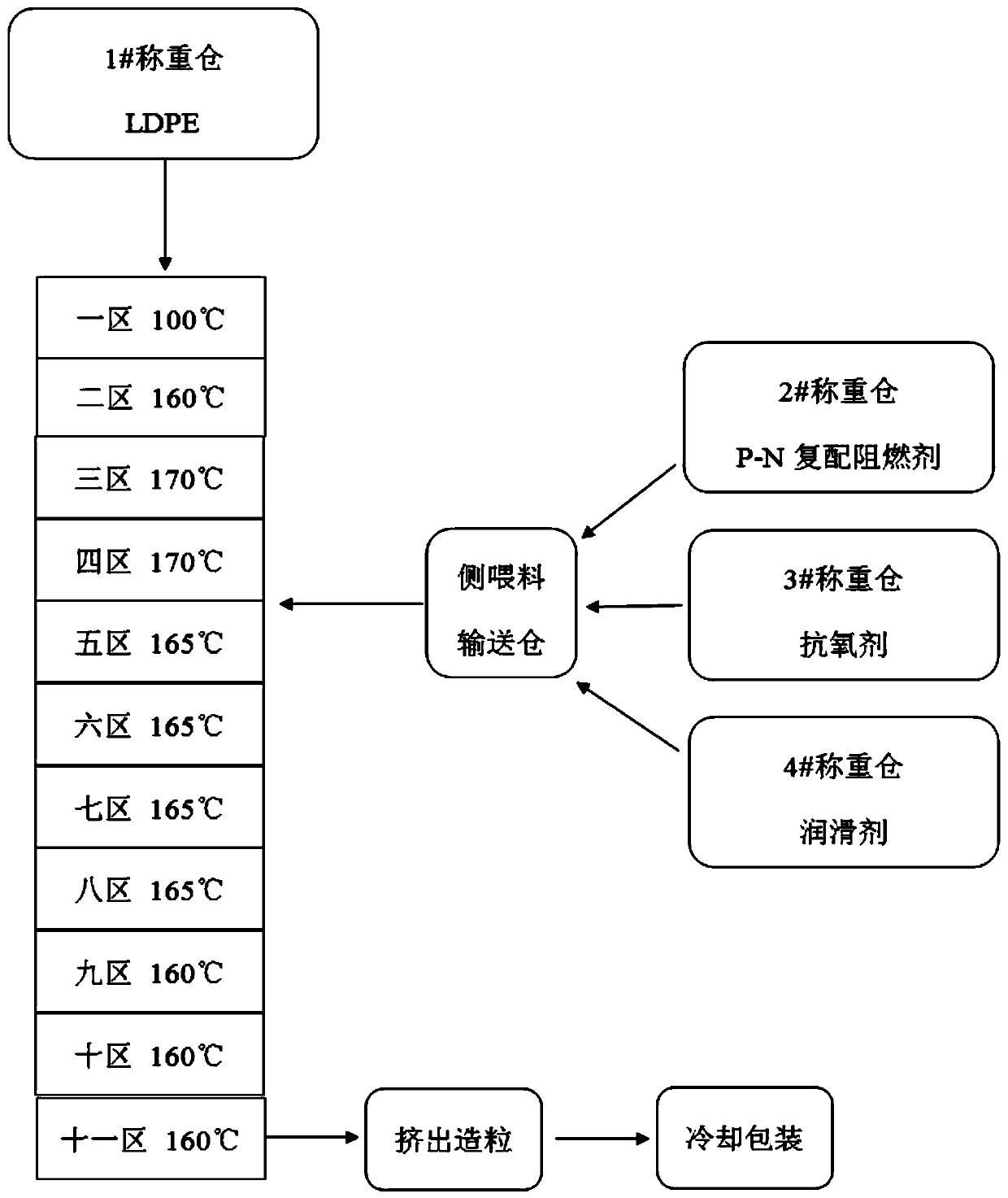

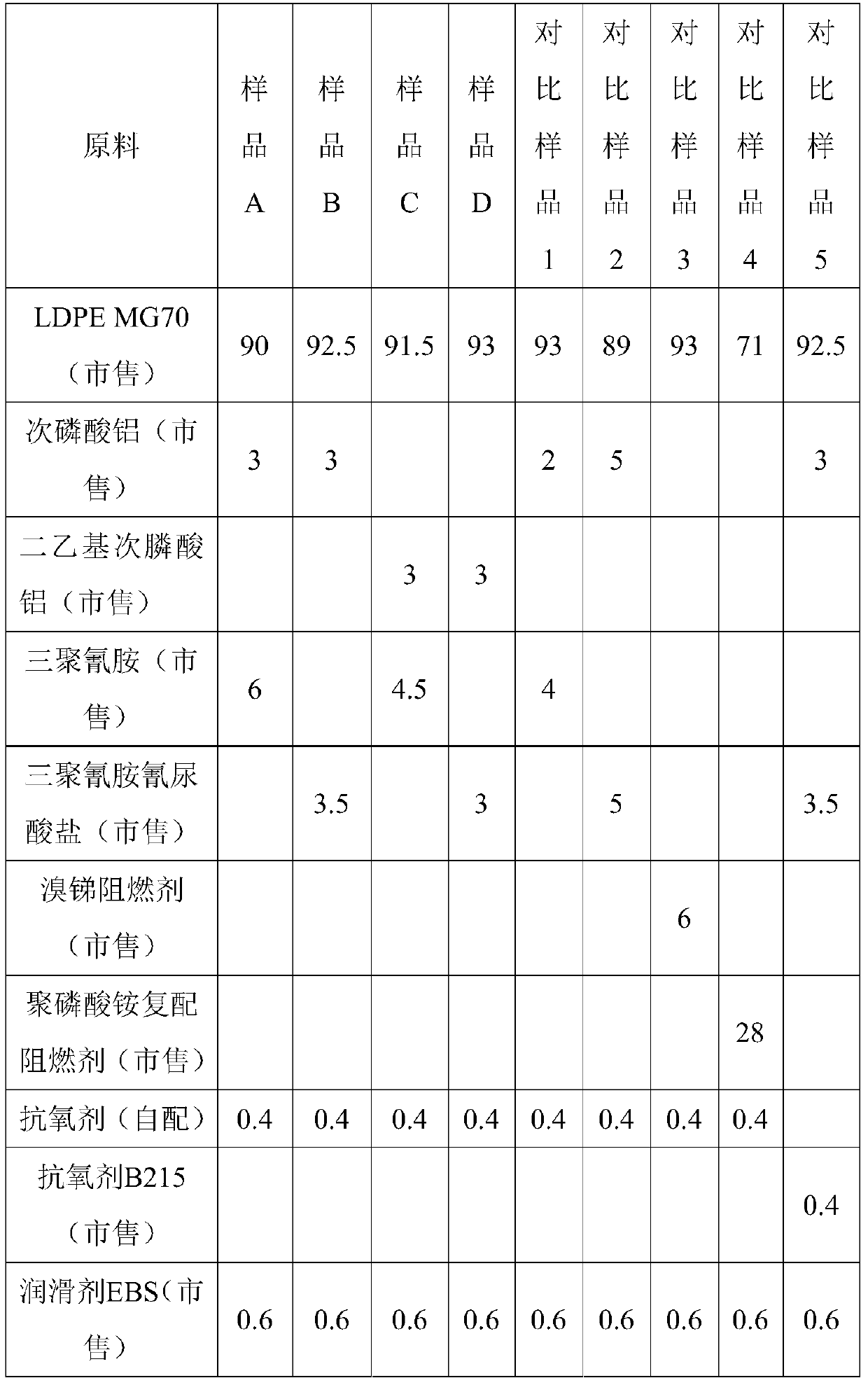

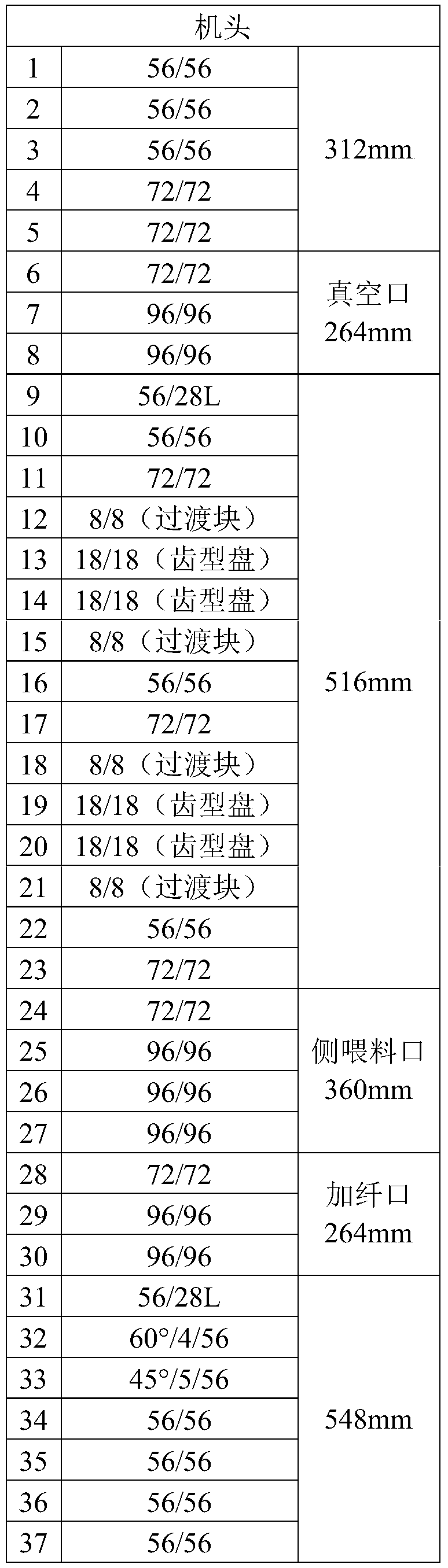

Halogen-free flame-retardant low-density polyethylene material, and preparation method and application thereof

The embodiment of the invention provides a halogen-free flame-retardant low-density polyethylene material, and a preparation method and an application thereof. According to the halogen-free flame-retardant low-density polyethylene material, the flame retardant grade reaches the UL94 V-2 grade; no corrosive gas is generated during combustion; the self-extinguishing property is good, the elongationat break reaches up to 175%, the impact strength reaches 411 J / m, a product is good in flexibility and has no pricking on hands due to touch, favorable resilience, recyclability, environment friendliness and no halogen, and the problem that a conventional polyethylene material cannot satisfy the simulation decoration industry and plug inner film application requirements in the prior art is solved.

Owner:GUANGDONG JUSHI CHEM CO LTD

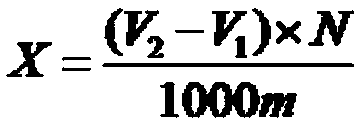

Polyvinyl alcohol water-soluble film and preparation method thereof

The invention relates to a polyvinyl alcohol film which is prepared by a raw material containing modified polyvinyl alcohol. The modified polyvinyl alcohol has a polymerization degree of 1000-3000 andan alcoholysis degree of 80-99.9 (mol) percent; a modified polyvinyl alcohol molecule contains -COONa group, and the content of the -COONa group is 0.01-3.0 (mol) / kg.PVA. The polyvinyl alcohol film prepared by the invention is good in acid and alkali resistance, good in stretchability and capable of resisting a chloride ion environment, has obvious advantages in the application fields such as packaging of weakly-alkaline liquid detergents, packaging of weakly-acidic or weakly alkaline drugs and packaging of pesticides with chloride ions compared with a conventional polyvinyl alcohol film. Thepolyvinyl alcohol film provided by the invention in simple in preparation method and suitable for industrial production.

Owner:SINOPEC SICHUAN VINYLON FACTORY +1

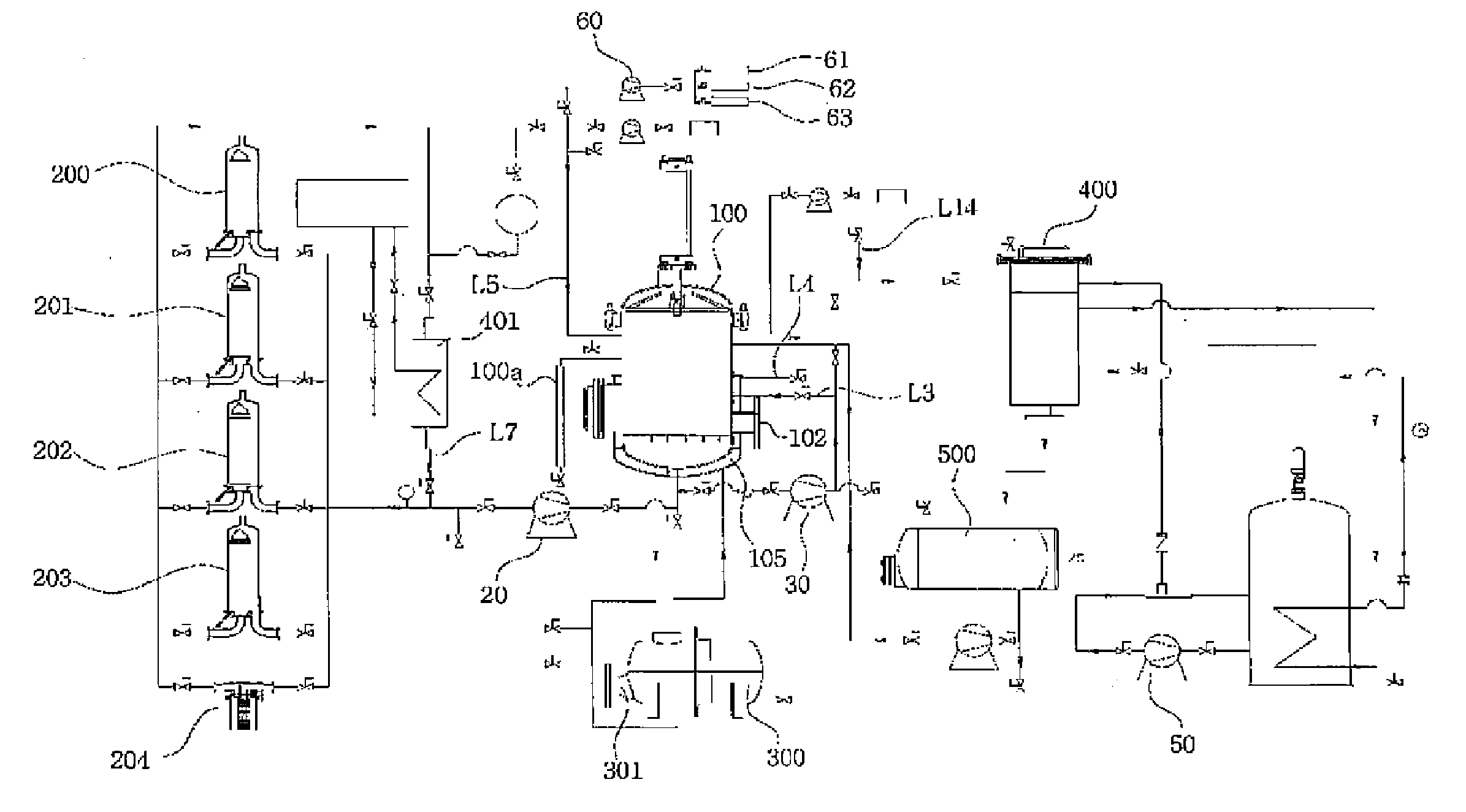

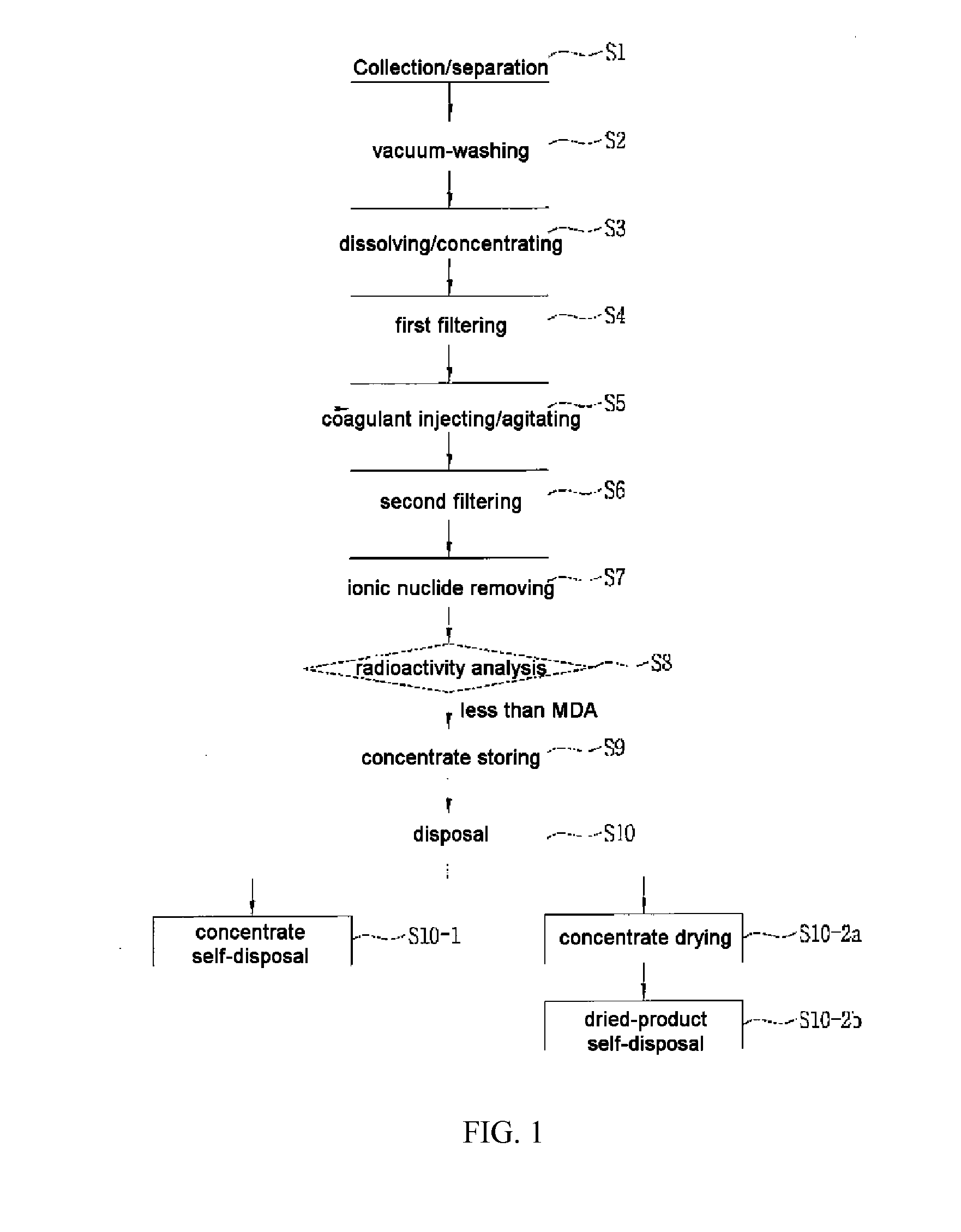

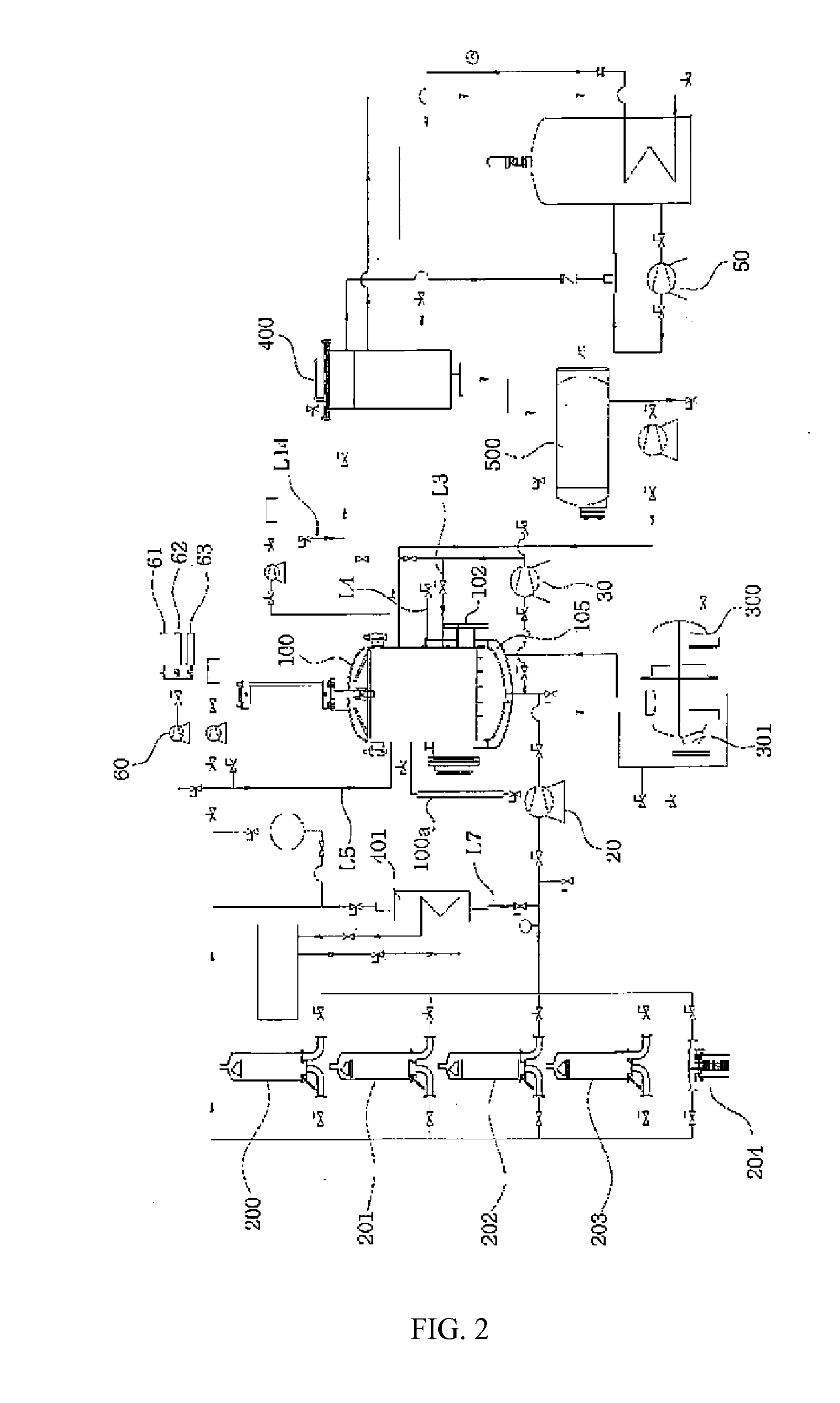

Disposal and Decontamination of Radioactive Polyvinyl Alcohol Products

ActiveUS20120220809A1Easy to useReduce the amount requiredRadioactive contaminantsChemical/physical/physico-chemical processesNuclear powerCatalytic oxidation

Methods and apparatus for decontaminating disposable protective products prepared from polyvinyl alcohol (PVA), used in a nuclear power plant, to less than minimum detectable activity (MDA) are disclosed. In the disclosed methods and apparatus, solid protective products made of PVA, generated from a nuclear power plant, are dissolved into a liquid, and then are decontaminated to less than MDA. The PVA solution decontaminated in this way is concentrated to an appropriate concentration or dried, and finally is subjected to self-disposal. This can fundamentally block the generation amount of combustible waste amounting to 50% or more of low and intermediate level waste of nuclear power plants, thereby considerably contributing to a reduction of the operating expenses of the nuclear power plants. The present invention further relates to methods and apparatus for self-disposing disposable protective products manufactured by conventional polyvinyl alcohol (PVA) through pyrolysis / catalytic oxidation of a PVA solution generated by concentration, and treating the decontaminated PVA solution within a plant. The PVA protective products are dissolved / concentrated / oxidized in water to remove firstly organic matter, and then PVA materials in the PVA solution are completely oxidized into CO2 and H2O by using a small-sized pyrolysis / catalytic oxidation reactor.

Owner:HANA INSPECTION & ENG

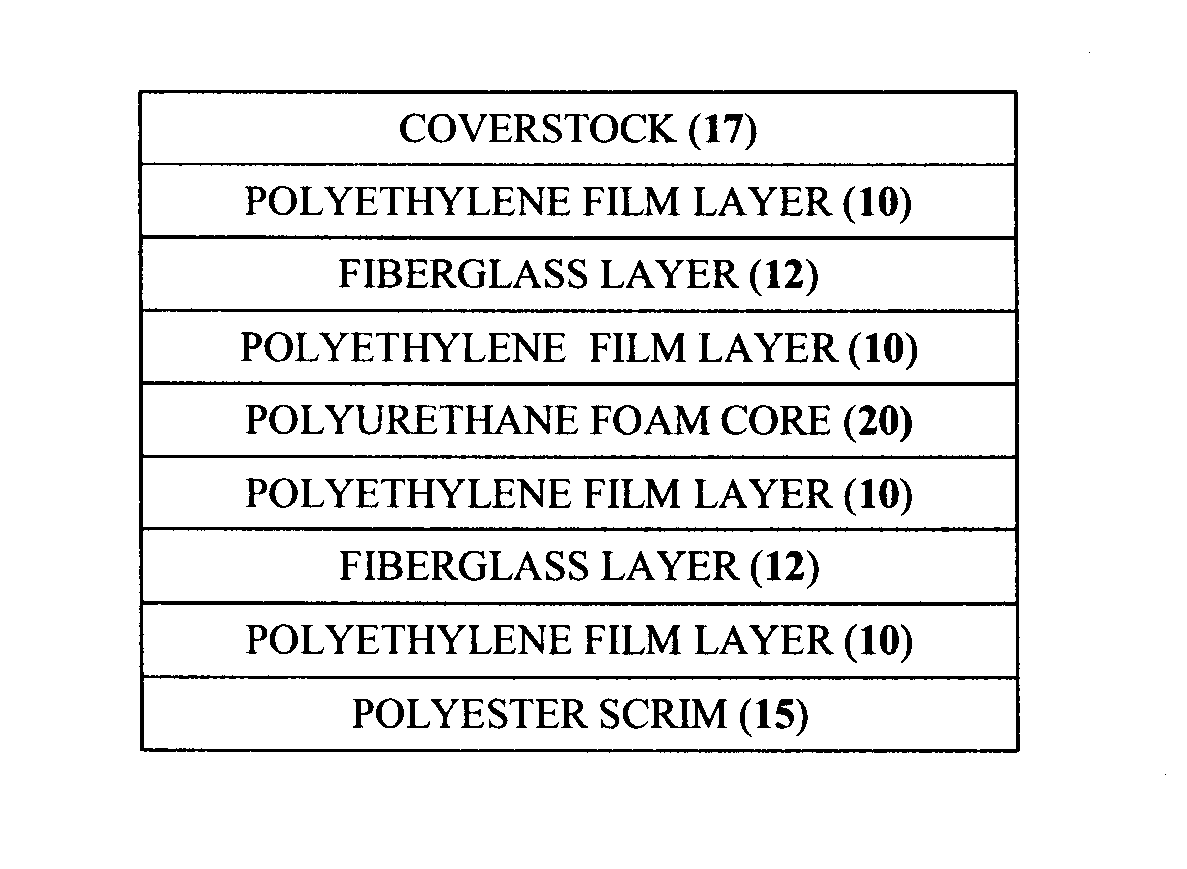

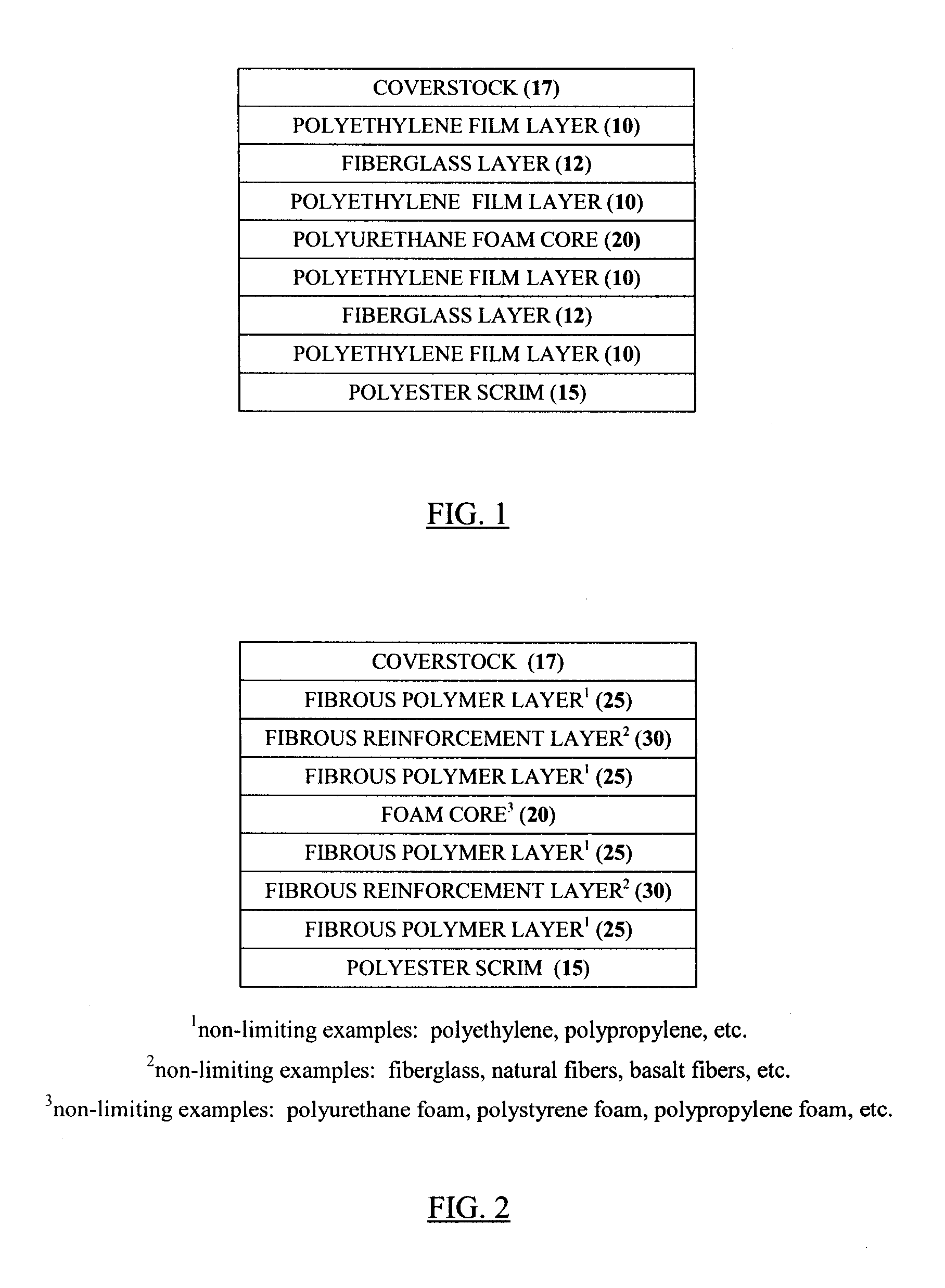

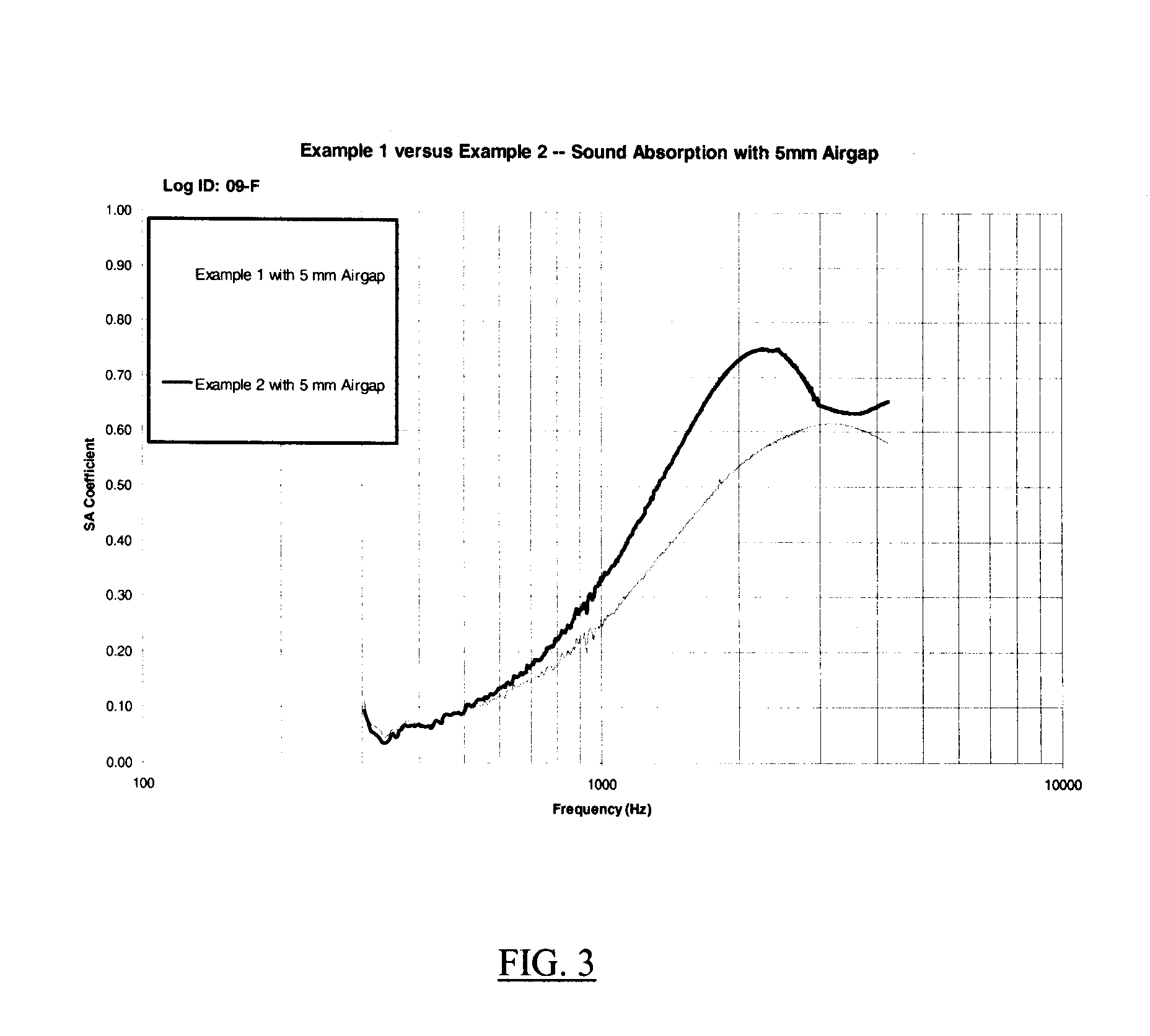

Foam laminate product and process for production thereof

InactiveUS20120052283A1Reduce airflow resistanceImprove sound absorptionSynthetic resin layered productsLaminationEngineeringFoamcore

A laminate product comprising a foam core having a pair of opposed major surfaces and a cover layer secured with respect to each major surface is described. The cover layer contains a fibrous reinforcement layer that is substantially encapsulated by a polymer. It has been found that the use of a fibrous polymer layer (e.g., in place of conventional polyethylene film) results in a laminate product having significantly lower resistance to air flow resistance and significantly improved sound absorption properties.

Owner:PROPRIETECT LP

Polyethylene glycol modified polyester fibers and method for making the same

InactiveUS20030134117A1Easy to dyeEnhance dye uptakeMonocomponent polyetheresters artificial filamentAnimal housingFiberYarn

Disclosed is a method of copolymerizing polyethylene glycol (PEG) and branching agent into polyethylene terephthalate (PET) to achieve a polyethylene glycol-modified polyester composition that can be spun into filaments. Fabrics made from fibers formed from the copolyester composition possess wicking, dyeability, and tactility properties that are superior to those of fabrics formed from conventional polyethylene terephthalate fibers of the same yarn and fabric construction. Also disclosed are polyethylene glycol modified copolyester compositions, fibers, yarns, and fabrics.

Owner:FIBER IND INC

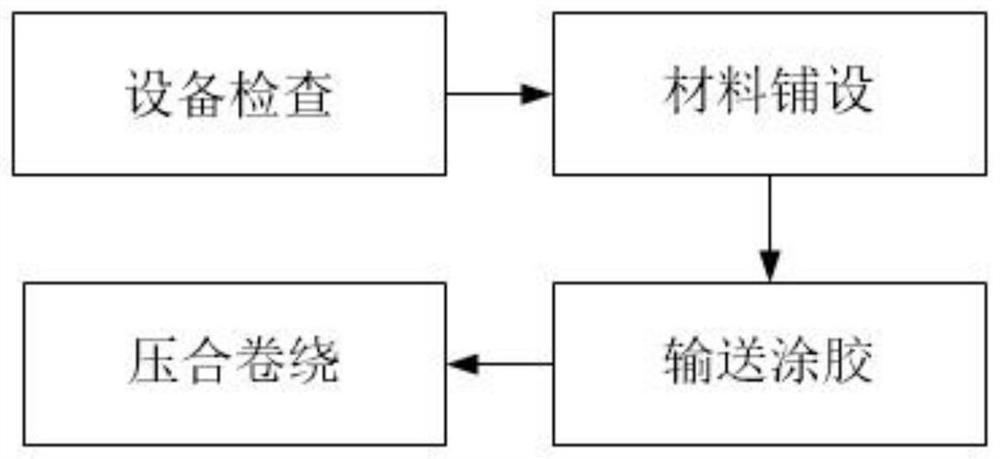

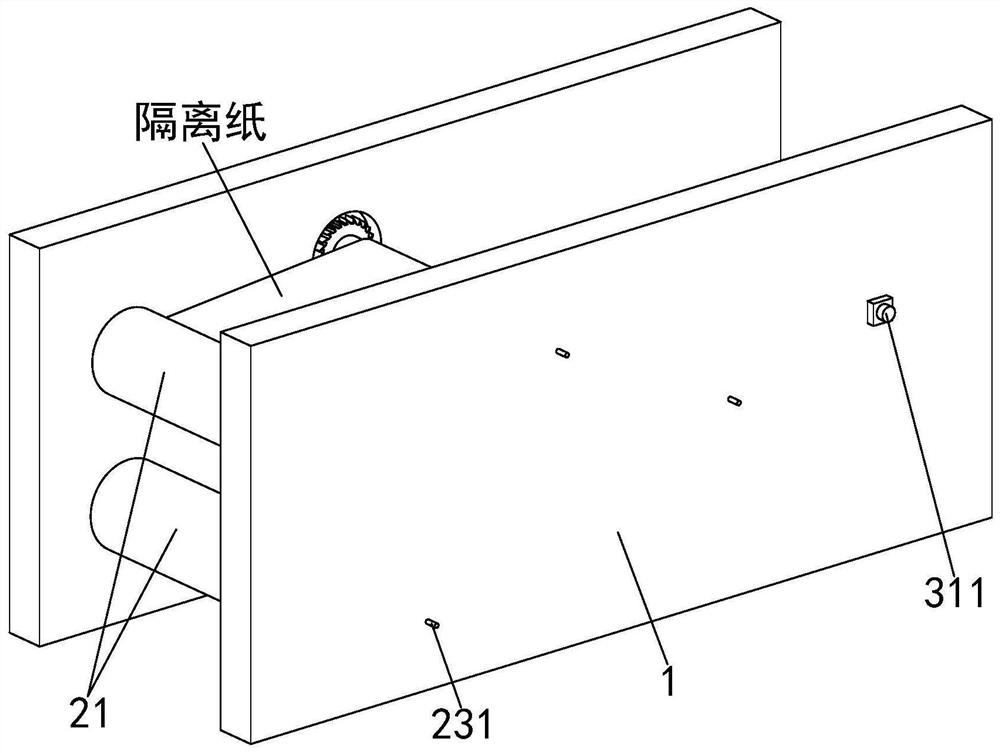

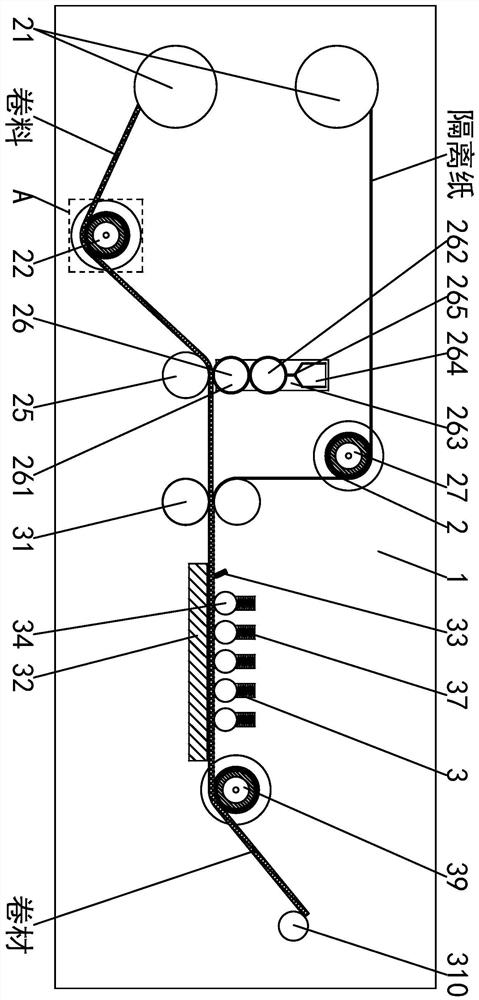

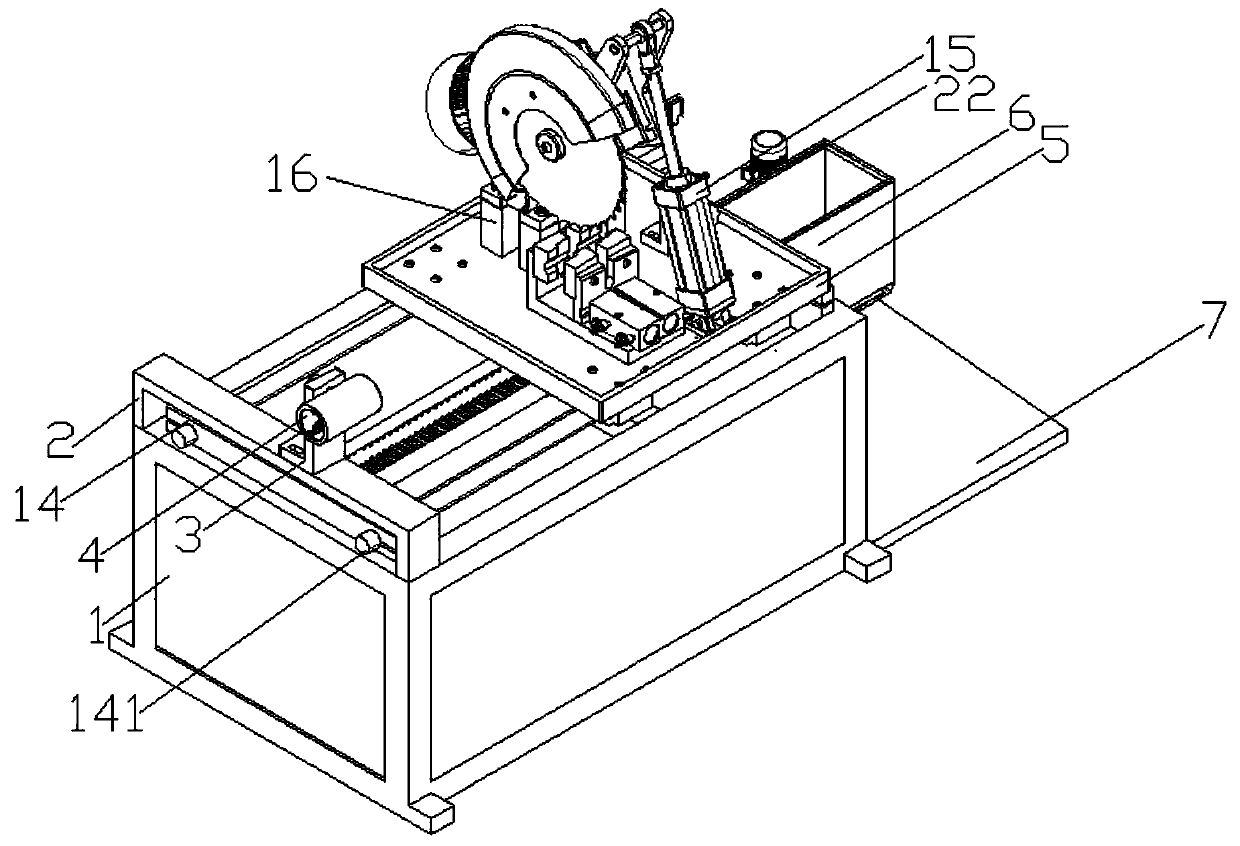

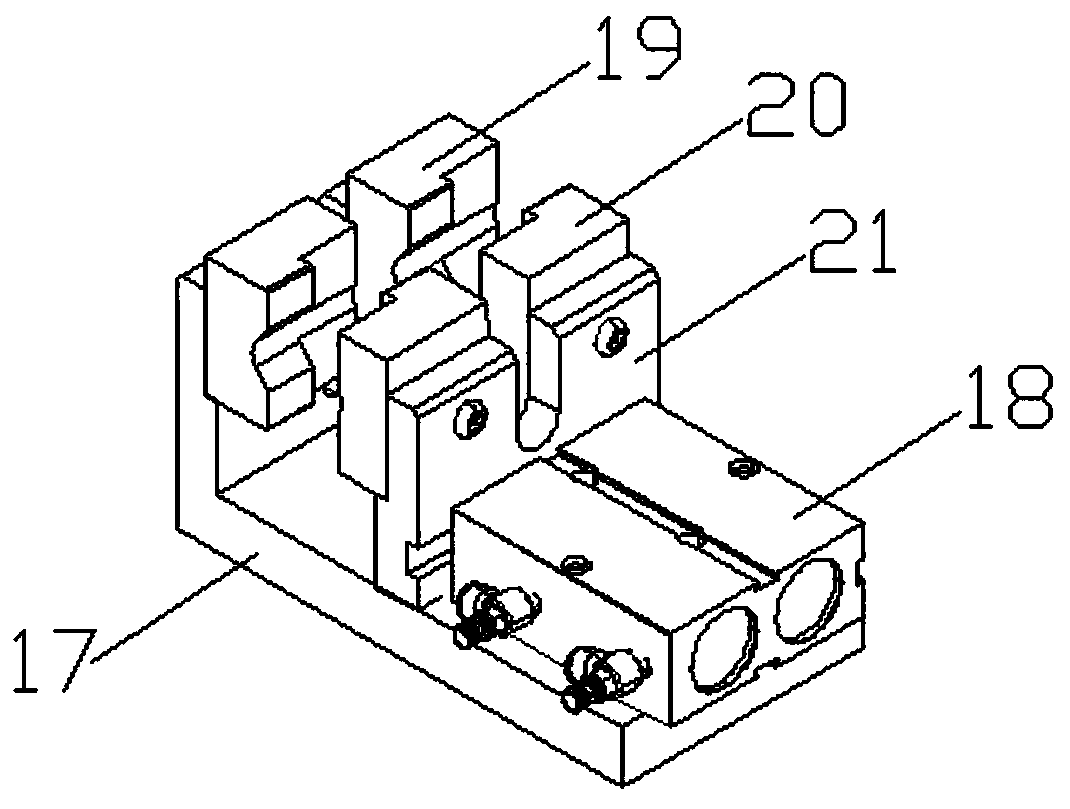

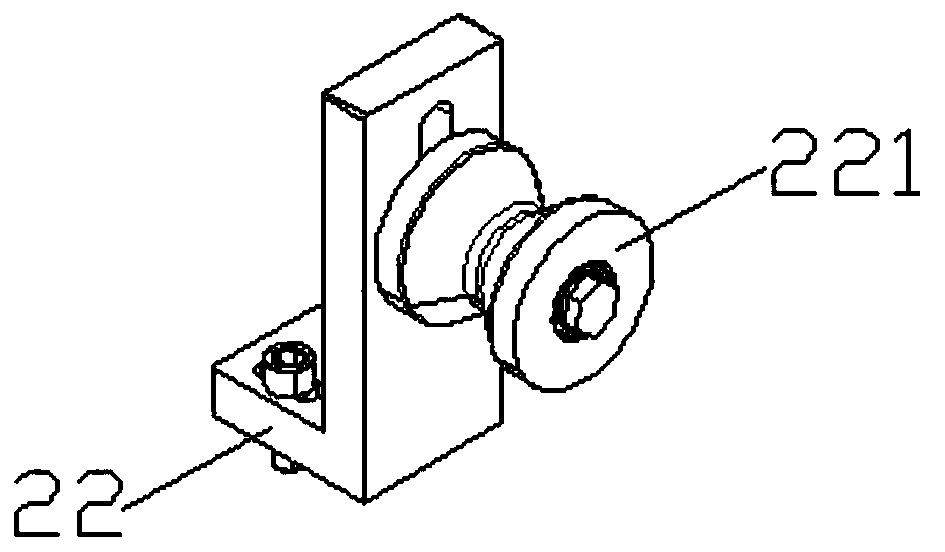

Preparation method of polyethylene polypropylene fiber composite waterproof coiled material

InactiveCN113071191AMany construction stepsIncrease work intensityLamination ancillary operationsLaminationWater leakageAdhesive glue

The invention provides a preparation method of a polyethylene polypropylene fiber composite waterproof coiled material, which uses polyethylene polypropylene fiber composite waterproof coiled material preparation equipment, and the equipment comprises a mounting plate, a conveying and gluing device and a pressing and winding device. The method can solve the following problems in the preparation process of the polyethylene polypropylene fiber composite waterproof coiled material: a, most of the conventional polyethylene polypropylene fiber composite waterproof coiled material is not provided with self-adhesive glue, so that glue needs to be coated on the wall body in actual use, and then the polyethylene polypropylene fiber composite waterproof coiled material is paved on the wall body, the construction steps are multiple, and the working intensity is increased; and b, the surface of the existing traditional polyethylene polypropylene fiber composite waterproof coiled material is coated with self-adhesive glue in advance, so that the self-adhesive glue is not uniformly coated, gaps exist when the coiled material is paved on the wall body, the water leakage phenomenon still exists, and bubbles exist when isolation paper is attached to the surface of the coiled material.

Owner:丁文娟

Oxygen-scavenging polymer blends suitable for use in packaging

Polymer blends are disclosed that comprise one or more polybutadiene homopolymers or copolymers having at least one functionality capable of entering into condensation reactions; one or more polyethylene terephthalate homopolymers or copolymers obtained using a catalyst system comprising aluminum atoms and one or more alkaline earth metal atoms, alkali metal atoms, or alkali compound residues, optionally obtained by a melt-phase polymerization process; and one or more transition metal atoms. The blends are useful for packaging, and exhibit improved oxygen-scavenging activity compared with blends made using many conventional polyethylene terephthalate polymers prepared with conventional catalyst systems.

Owner:ALPEK POLYESTER SA DE CV

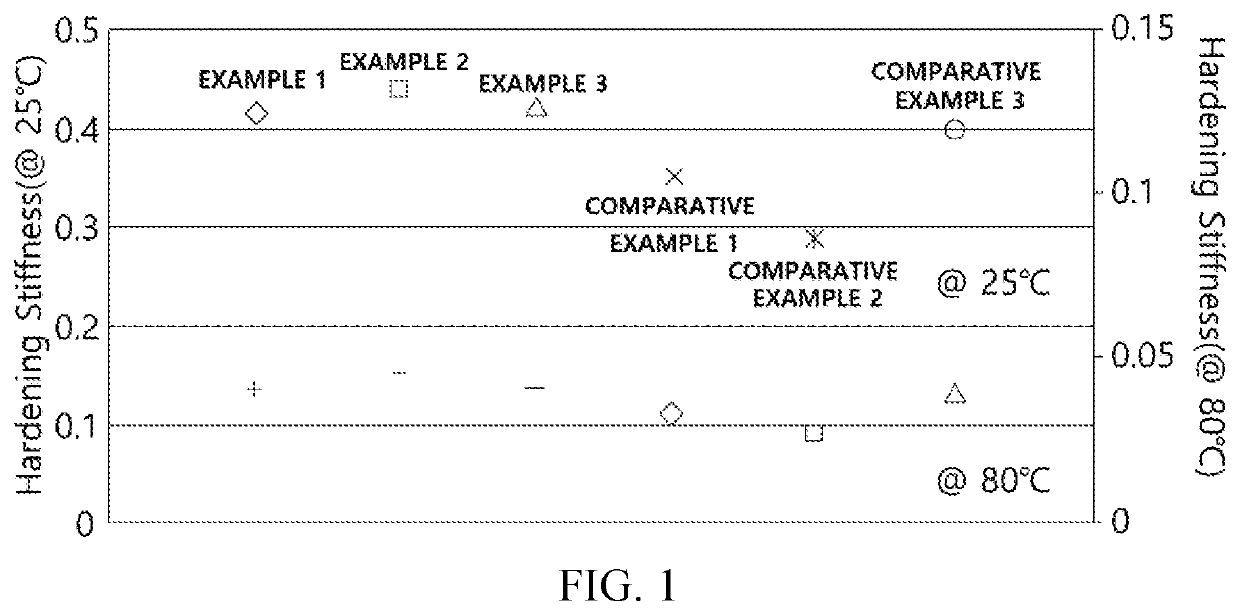

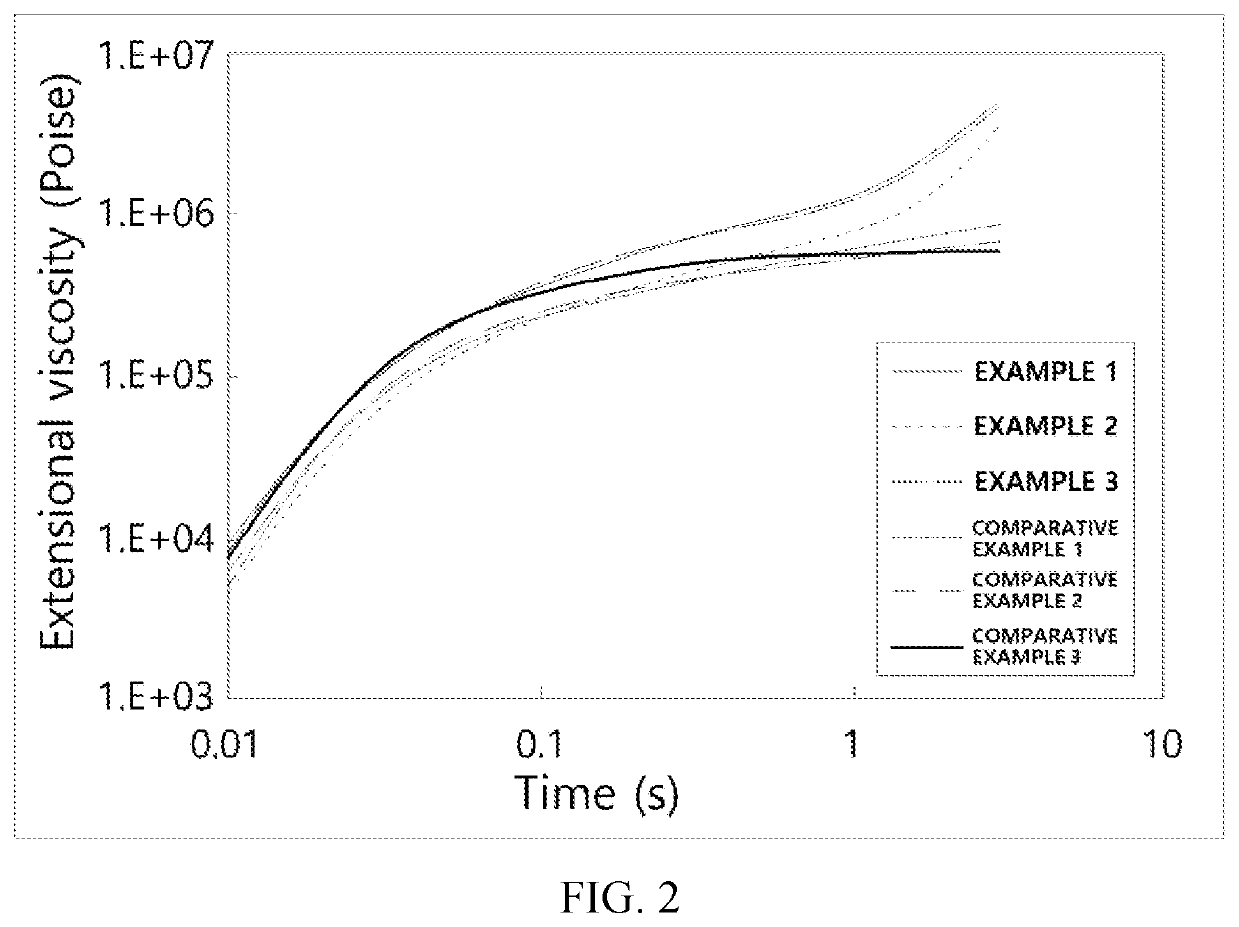

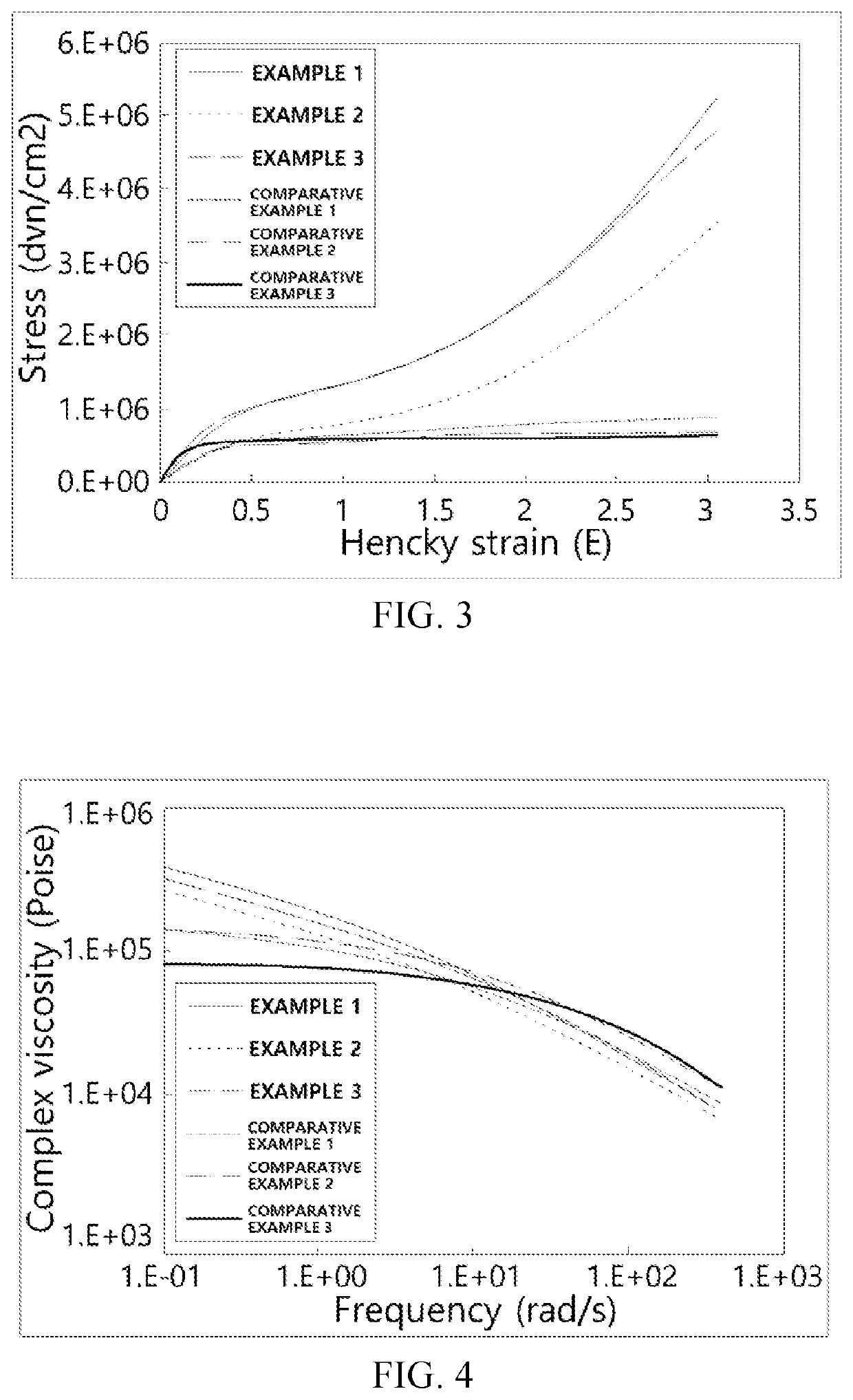

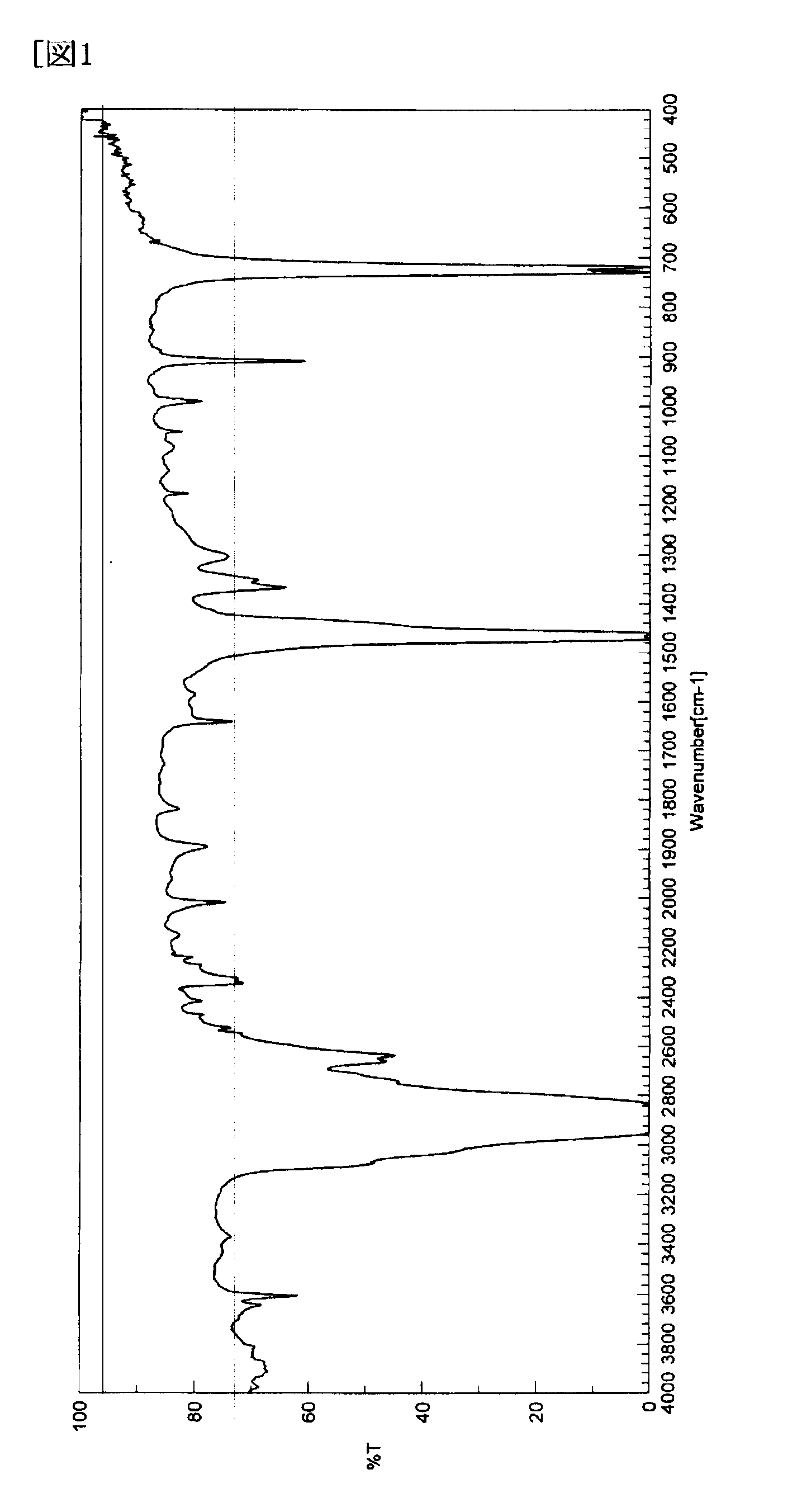

High-density ethylene-based polymer using hybrid supported metallocene catalyst and pipe using same

ActiveUS20200190238A1Excellent long-term pressure resistanceEasy to processMetallocenesPolymer scienceEthylene Homopolymers

The present invention relates to a high-density ethylene-based polymer and a pipe using the same, the high-density ethylene-based polymer including: an ethylene homopolymer; or a copolymer of ethylene and at least one comonomer selected from the group consisting of an α-olefin, a cyclic olefin and linear, branched and cyclic dienes.The pipe using the high-density ethylene-based polymer of the present invention has more superior strain hardening than a conventional polyethylene resin pipe, and thus has excellent long-term pressure resistance characteristics and processability.

Owner:HANWHA CHEMICAL CORPORATION

Preparation method for high-strength cosmetic bottles

The invention provides a preparation method for high-strength cosmetic bottles. According to the method provided by the invention, an inorganic additive is added into conventional polyethylene, so that the high-strength performance of the material is effectively improved, and the preparation process is relatively simple; the preferred inorganic additive is added into a PE plastic, so that a volumeof the plastic product can be increased, the costs can be reduced, the hardness and rigidity can be improved, the shrinkage of the plastic product is reduced, and the dimensional stability is improved; aluminum oxide, silicon tetrafluoride and graphene are added, so that the processing properties of the plastic is improved, and the high strength performance is improved; and the method has obviouseffects in expansion of an application range of the polyethylene.

Owner:余姚市恒邦塑业有限公司

Low gloss ionomer-based capstock

ActiveUS20130317139A1Reduce glossMinimize shineSynthetic resin layered productsConstructions elementsMasterbatchThermoplastic

A low gloss capstock compound is disclosed. The combination of gloss inhibiting agents, metal-based ionomer thermoplastic resins, and acid scavenger added to conventional polyethylene polymer resin achieves a gloss angle at 85° of below 10 GU. Optionally, the compound can also include weathering agents to improve outdoor durability. The compound can be fully formulated or a masterbatch for let-down into polymer to form the fully formulated compound.

Owner:AVIENT CORP

Ethylene-Based Polymer Microparticles, Functional Group-Containing Ethylene-Based Polymer Microparticles,and Catalyst Carriers for Manufacture Thereof

ActiveUS20080044655A1Small particle sizeHigh degree of sphericitySynthetic resin layered productsCellulosic plastic layered productsPolymer scienceMicroparticle

Ethylene-based copolymer microparticles and functional group-containing ethylene-based copolymer microparticles that have particle diameter smaller than that of conventional polyethylene fine-particles, no inter-particle agglomeration, very narrow particle size distribution, and high sphericity are provided, in which requirements (A) to (E): (A) The intrinsic viscosity [η] measured in decalin at 135° C. is in the range of 0.1 to 50 dl / g, (B) at least 95 wt % or more of particles pass through a mesh screen with an opening of 37 μm, (C) the median diameter (d50) measured by laser diffraction scattering is 3 μm≦d50≦25 μm, (D) the circularity coefficient is 0.85 or more, and (E) the variation coefficient of particle diameter (Cv) is 20% or less. Non-agglomerated spherical magnesium-containing microparticles used as magnesium-containing carrier component for olefin-polymerization catalysts that can manufacture the above microparticles are also provided.

Owner:MITSUI CHEM INC

Low gloss capstock

A low gloss capstock compound is disclosed. The combination of gloss inhibiting agents and polyolefin elastomer added to conventional polyethylene polymer resin achieves a gloss angle at 85° of below 10 GU. Optionally, the compound can also include weathering agents to improve outdoor durability. The compound can be fully formulated or a masterbatch for let-down into polymer to form the fully formulated compound.

Owner:AVIENT CORP

High-toughness polyethylene plastic pipe and preparation method thereof

InactiveCN111423648AImprove toughnessGood dispersionMetal working apparatusQuinolinePhysical chemistry

The invention discloses a high-toughness polyethylene plastic pipe and a preparation method thereof. Through dodecylbenzene sulfonic acid, dissolution of 8-hydroxyquinoline can be better promoted, 8-hydroxyquinoline and generated 8-hydroxyquinoline copper can be better dispersed, the agglomeration phenomenon of the 8-hydroxyquinoline copper is reduced, the chemical activity and mildew resistance of the 8-hydroxyquinoline copper are improved, and the toughness of the prepared polyethylene plastic pipe is improved; polyethylene naphthalate has low water vapor transmission rate, and can endow polyethylene with excellent low water vapor transmission performance. According to GB / T 19810-2005, the tensile strength of prepared modified polyethylene particles is 45-50 MPa; and according to GB / T1037-1988, it is determined that a water vapor transmission rate is 0.2-0.5 g / m<2>.24 h.mm, so the technical problems that a conventional polyethylene plastic pipe is not high in both toughness and watervapor transmission rate are solved.

Owner:安徽超星新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com