Transesterification process of methyl acetate

a technology of methyl acetate and esterification process, which is applied in the preparation of ester-hydroxy reactions, chemical apparatus and processes, and organic chemistry, etc., can solve the problems of reducing methyl acetate is a less valuable solvent, and the overall economic efficiency of the conventional polyvinyl alcohol plant is reduced. , to achieve the effect of economic and efficient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiments

[0053]

ItemsEmbodiment IEmbodiment IIMol. Composition of methyl60% methyl60% methylacetate solutionacetate +acetate + 40%40% methanolmethanolMol. Composition of100% n-butanol100% n-butanoln-butanol solutionThe reactive distillation device (1)No. of the reactive trays3548No. of the rectifying trays 5 5No. of the stripping trays 8 7No. of trays that n-butanol43th55thfeedsNo. of trays that methylX12thacetate feedsNo. of trays that a zeotrope feeds12th12thThe distillation device (8)No. of total trays1419No. of trays that methyl12thXacetate feedsNo. of trays that reflux feeds5th8thThe amount of reflux112.45 (kmol / hr)109.64 (kmol / hr)The purity of butyl acetate99 mol %99 mol %The purity of methanol99 mol %99 mol %

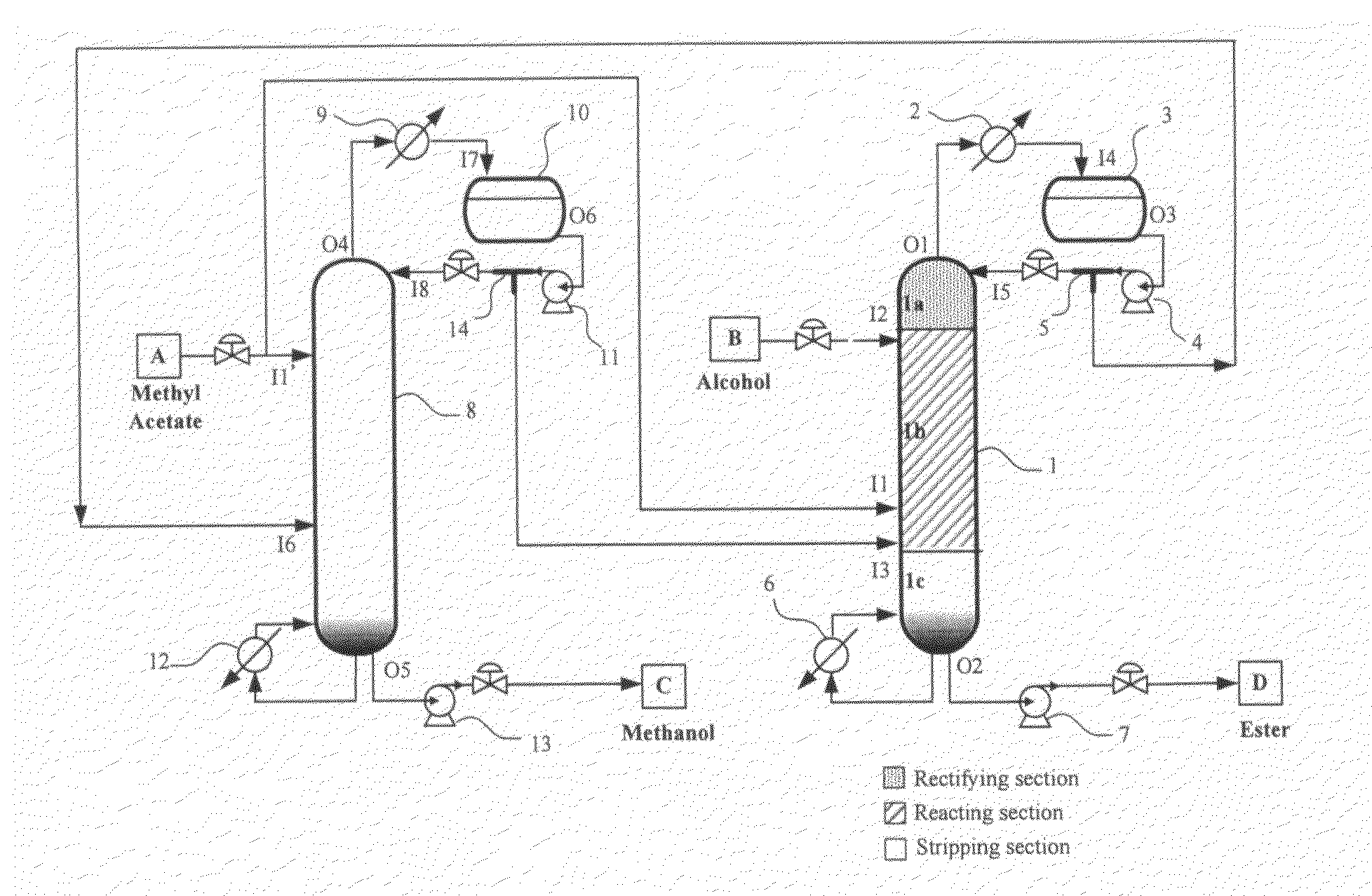

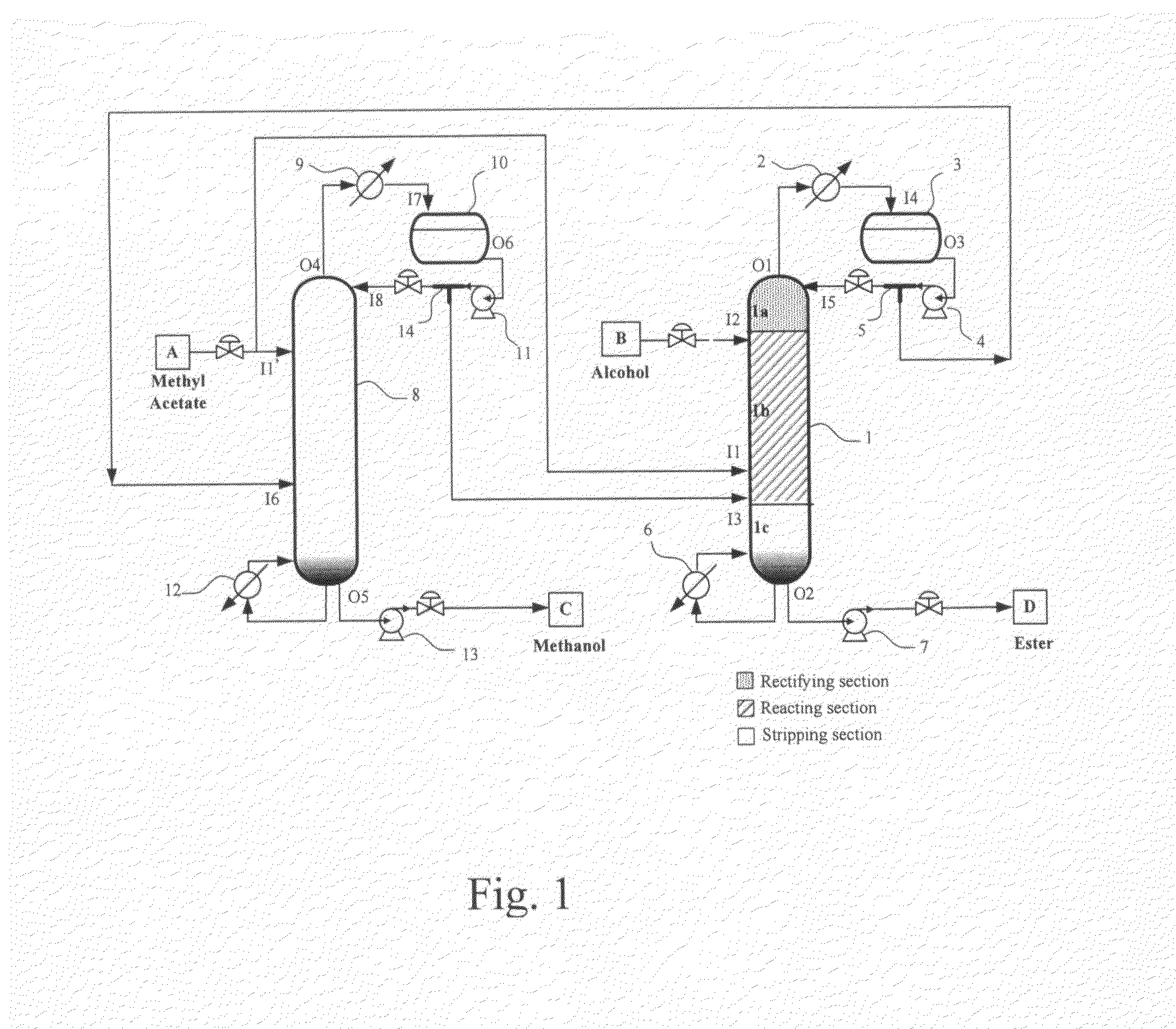

[0054]In the Embodiment I, the methyl acetate solution is fed to the distillation device (8); in the embodiment II, the methyl acetate solution is fed to the reactive distillation device (1).

[0055]In conclusion, although the reactive distillation system depends upon the plurality o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com