Method of preparing polyethylene glycol modified polyester filaments

a technology of polyethylene glycol and polyester, which is applied in the field of polyethylene glycol modified polyester filaments, can solve the problems of slow melt-phase polymerization kinetics, adverse effects on others, and render the processing of such peg-modified polyesters somewhat impractical in commercial polyester spinning operations, and achieve similar favorable characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

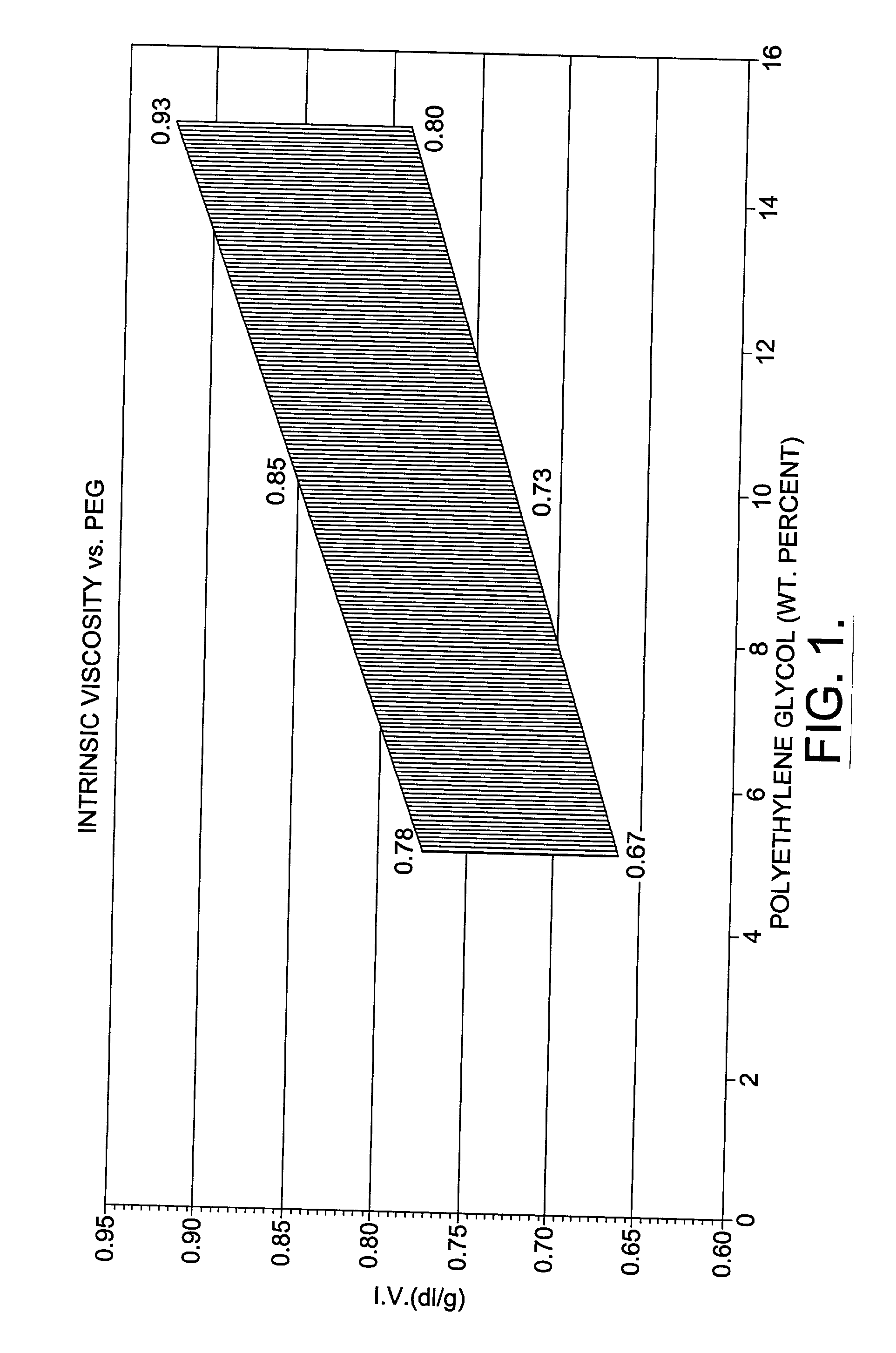

[0089] Melt Polymerization--The copolyester composition was polymerized like standard polyethylene terephthalate, except that the polymerization temperature was 10.degree. C. lower than normal. Polyethylene glycol, having an average molecular weight of 400 g / mole, was injected into the process before the initiation of the polymerization at a rate sufficient to yield 10 weight percent polyethylene glycol in the copolyester composition. Likewise, pentaerthyritol was added before polymerization at a rate that would yield 500 ppm in the copolyester composition. The copolyester was then extruded, quenched, and cut. The quench water was 10.degree. C. colder than normal. The copolyester was crystallized 10.degree. C. lower than normal. The copolyester was melt polymerized to an intrinsic viscosity of 0.62 dl / g.

[0090] Solid State Polymerization--The copolyester chip was solid state polymerized like a normal polyethylene terephthalate bottle resin chip except that the chip was maintained at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| weight fraction | aaaaa | aaaaa |

| weight fraction | aaaaa | aaaaa |

| weight fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com