Polyvinyl alcohol water-soluble film and preparation method thereof

A polyvinyl alcohol film and polyvinyl alcohol technology are applied in the field of polyvinyl alcohol water-soluble film and its preparation, and can solve the problems of low production cost, poor weather resistance, low film strength and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

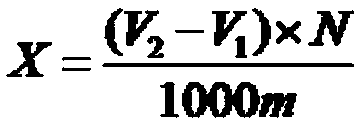

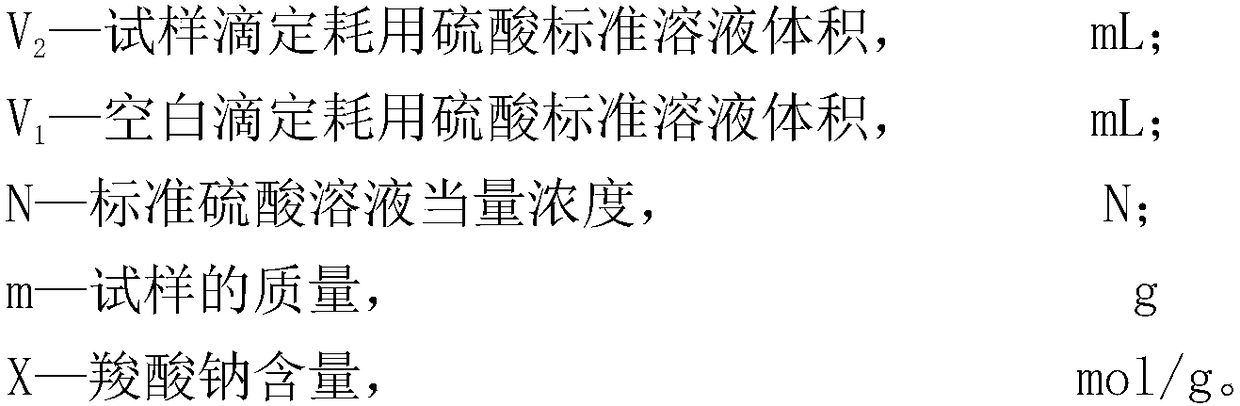

Image

Examples

Embodiment 1

[0032] Preparation of carboxyl modified polyvinyl alcohol:

[0033] (1) Raw material preparation:

[0034] Monomer: Vinyl acetate, 0.7wt% itaconic acid by weight of vinyl acetate to prepare itaconic acid methanol solution with a mass concentration of 10wt%;

[0035] Solvent: methanol accounting for 20wt% of vinyl acetate weight;

[0036] Initiator: Diisopropyl peroxydicarbonate with a mass concentration of 2.0% by weight in methanol solution of diisopropyl peroxydicarbonate accounting for 0.1wt% of vinyl acetate;

[0037] (2) Preparation method:

[0038] Add the above-prepared vinyl acetate monomer, itaconic acid methanol solution and diisopropyl peroxydicarbonate methanol solution into the first polymerizer, where the vinyl acetate and diisopropyl peroxydicarbonate methanol solution are all added, The itaconic acid methanol solution is added to account for 50% of the total weight of the itaconic acid methanol solution, the polymerization temperature is 60±5°C, and the time is 80 minute...

Embodiment 2

[0053] The modified polyvinyl alcohol (polymerization degree of 1800; alcoholysis degree of 98%, containing 1.5 (mol / kg·PVA)-COONa group) prepared in Example 1 was dissolved in water, and the modified polyvinyl alcohol was in an aqueous solution The mass concentration in the medium is 22%, and the modified polyvinyl alcohol aqueous solution is made into a film by a casting method.

Embodiment 3

[0055] Dissolve modified polyvinyl alcohol, ethylene glycol and fumed silica containing 1.0 (mol / kg·PVA)-COONa group with polymerization degree of 1000, alcoholysis degree of 80 (mol)%, and modified polyvinyl alcohol in water. The mass concentration in the aqueous solution is 25%, the mass concentration of ethylene glycol relative to the modified polyvinyl alcohol is about 25%, and the mass concentration of fumed silica relative to the modified polyvinyl alcohol is 0.3%. The polyvinyl alcohol aqueous solution is made into a film by a casting method.

PUM

| Property | Measurement | Unit |

|---|---|---|

| alcoholysis degree | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com