Plastic packaging material for injection powder and preparation process thereof

A technology for injection powder and plastic packaging, which is applied in the field of pharmaceutical packaging materials, can solve the problems of transparency, high heat-sealing temperature, impact resistance and environmental stress cracking resistance, inconvenient operation and transportation, and achieve tear resistance Excellent tensile strength, good impact resistance and environmental stress cracking resistance, excellent processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

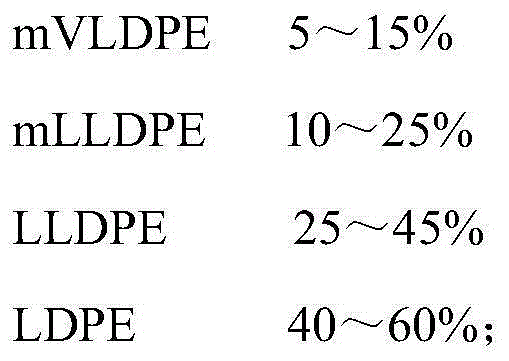

[0040] The formula of embodiment 1 is as follows:

[0041] In terms of mass percentage, both the inner layer and the outer layer are made of the following components:

[0042]

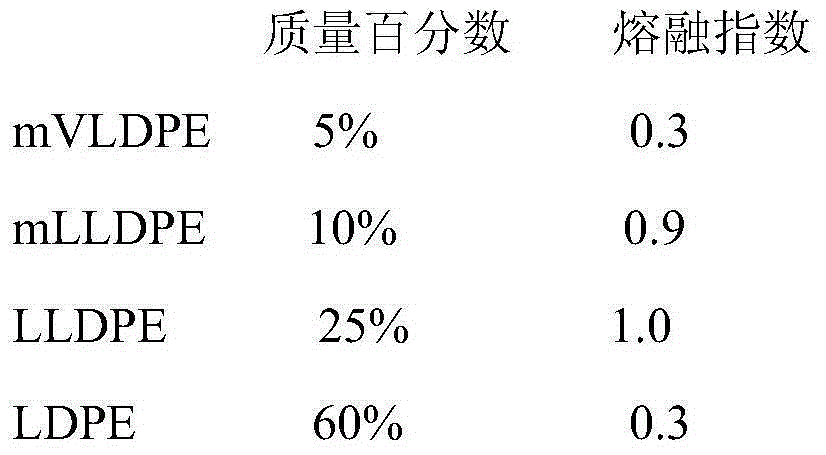

[0043] In terms of mass percentage, the middle layer is made of the following components:

[0044]

[0045] The preparation process of the plastic packaging material for injection powder described in the present embodiment, the steps are as follows:

[0046] (1) Start the air-conditioning unit: make the film blowing area of the production workshop reach B level cleanliness, and the bag making area and inner packaging area reach B+A level.

[0047] (2) Disinfection in clean area: Thorough disinfection is carried out according to GMP requirements.

[0048] (3) Purification of air or nitrogen: the air or nitrogen can reach the A-level standard after being purified.

[0049] (4) Mixing: Mix the above raw materials evenly.

[0050] (5) Film blowing: According to different formulations, the tempe...

Embodiment 2

[0053] The formula of embodiment 2 is as follows:

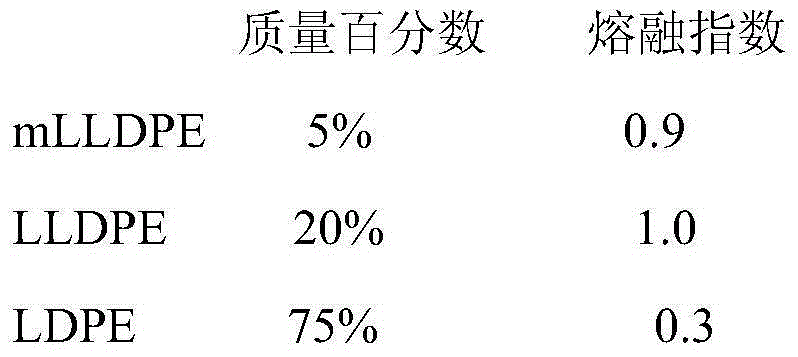

[0054] In terms of mass percentage, both the inner layer and the outer layer are made of the following components:

[0055]

[0056] In terms of mass percentage, the middle layer is made of the following components:

[0057]

[0058] The barrel temperature is 175±3°C, the die head temperature is 165±3°C, the heat sealing temperature is 240±3°C, and the inflation ratio is 1.2. Except for the above parameters, the preparation process of the plastic packaging material for injection powder described in this example is the same as that in Example 1.

Embodiment 3

[0060] The formula of embodiment 3 is as follows:

[0061] In terms of mass percentage, both the inner layer and the outer layer are made of the following components:

[0062]

[0063] In terms of mass percentage, the middle layer is made of the following components:

[0064]

[0065]

[0066] The barrel temperature is 165±3°C, the die head temperature is 165±3°C, the heat sealing temperature is 190±3°C, and the inflation ratio is 1.9. Except for the above parameters, the preparation process of the plastic packaging material for injection powder described in this example is the same as that in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com