Halogen-free flame-retardant low-density polyethylene material, and preparation method and application thereof

A low-density polyethylene and flame retardant technology, applied in the field of flame retardant materials, can solve the problems of inability to meet the needs of the simulation decoration industry and the application of the inner film of the plug, and achieve the effects of low cost, good simulation effect and good resilience.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

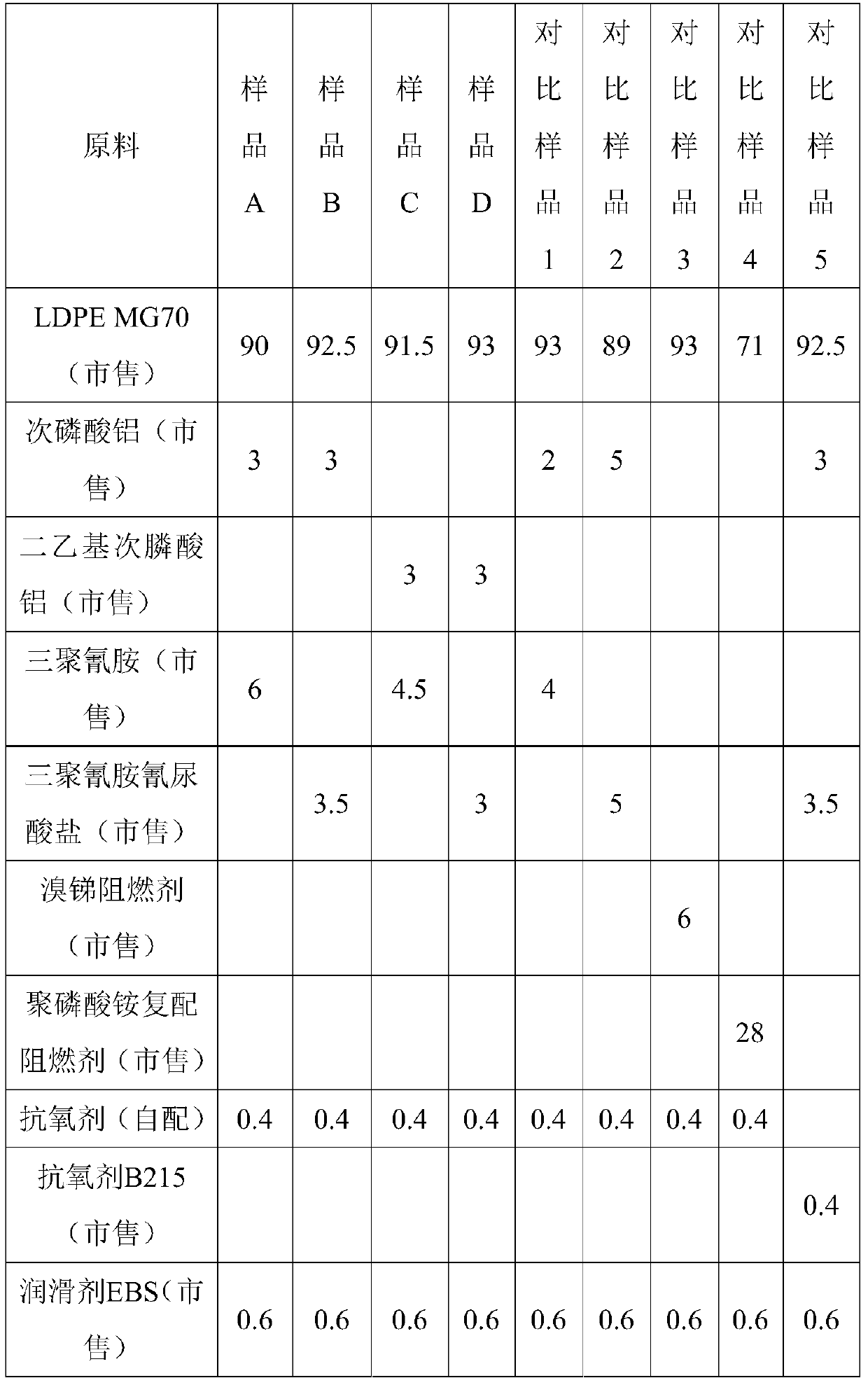

[0064] This example provides a halogen-free flame-retardant low-density polyethylene material, including the following raw materials in parts by weight:

[0065] LDPE: 80-95 parts, halogen-free compound flame retardant: 5-15 parts, antioxidant: 0.2-0.8 parts, lubricant: 0.3-0.7 parts.

[0066] Among the above-mentioned halogen-free flame-retardant low-density polyethylene materials, the preferred mass parts of LDPE are 88-93 parts. The preferred mass parts of the halogen-free compound flame retardant is 6-9 parts. The preferred amount of antioxidant is 0.4 parts. The preferred amount of lubricant is 0.6 parts.

[0067] The flexural modulus of LDPE is 90-120 MPa. The elongation at break of LDPE is greater than 150%. The melt index of LDPE under the test conditions of 190°C and 2.16kg is 20g / 10min~50g / 10min.

[0068] The halogen-free compound flame retardant is a P-N compound flame retardant, and the mass ratio of the P-based flame retardant to the N-based flame retardant i...

Embodiment 2

[0072] This example provides a preparation method for a halogen-free flame-retardant low-density polyethylene material, and the steps include:

[0073] S1: Weigh the LDPE, halogen-free compound flame retardant, antioxidant and lubricant according to the proportion and mix them;

[0074] S2: After kneading by a twin-screw extruder, extrude and granulate to obtain the halogen-free flame-retardant low-density polyethylene material.

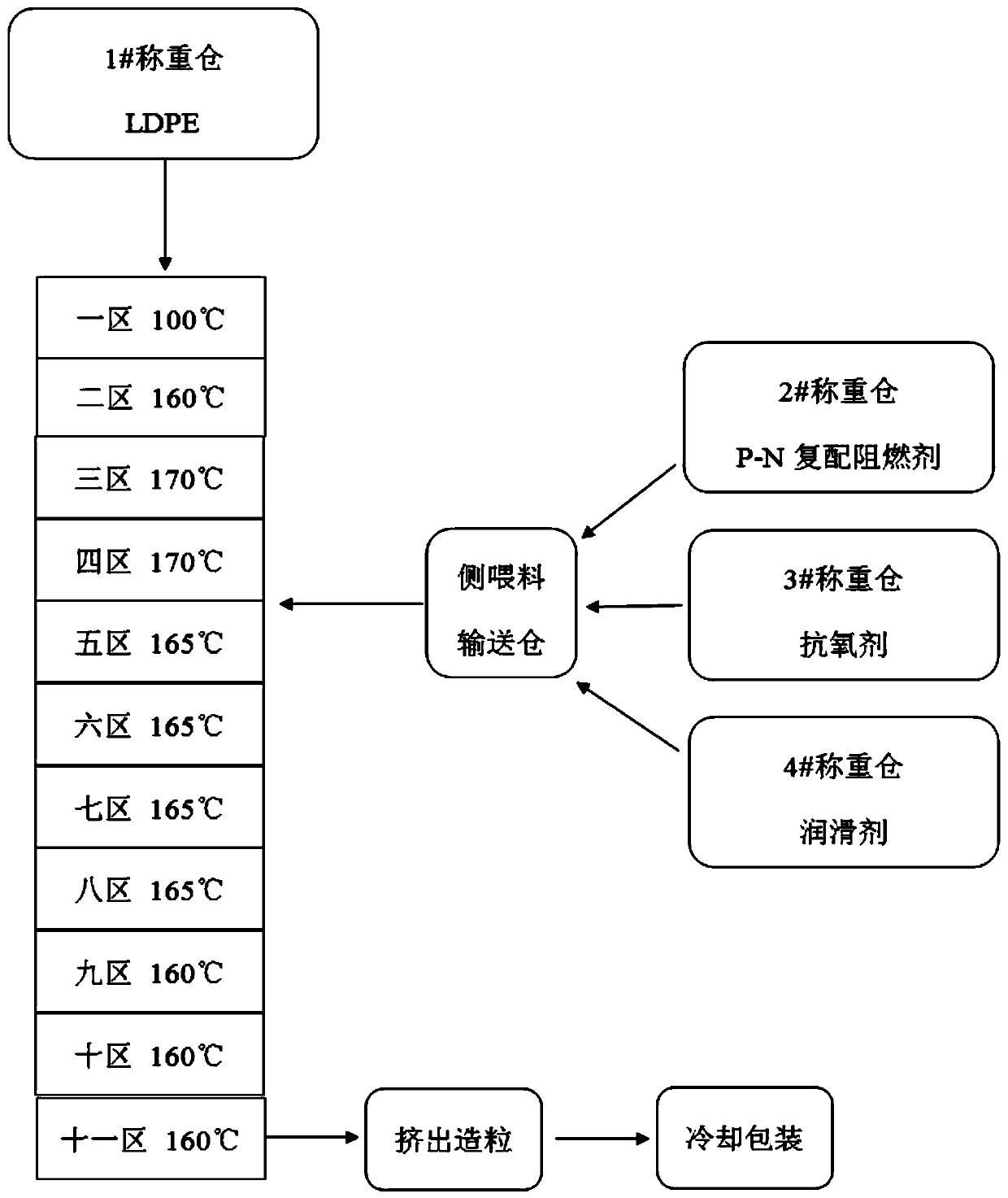

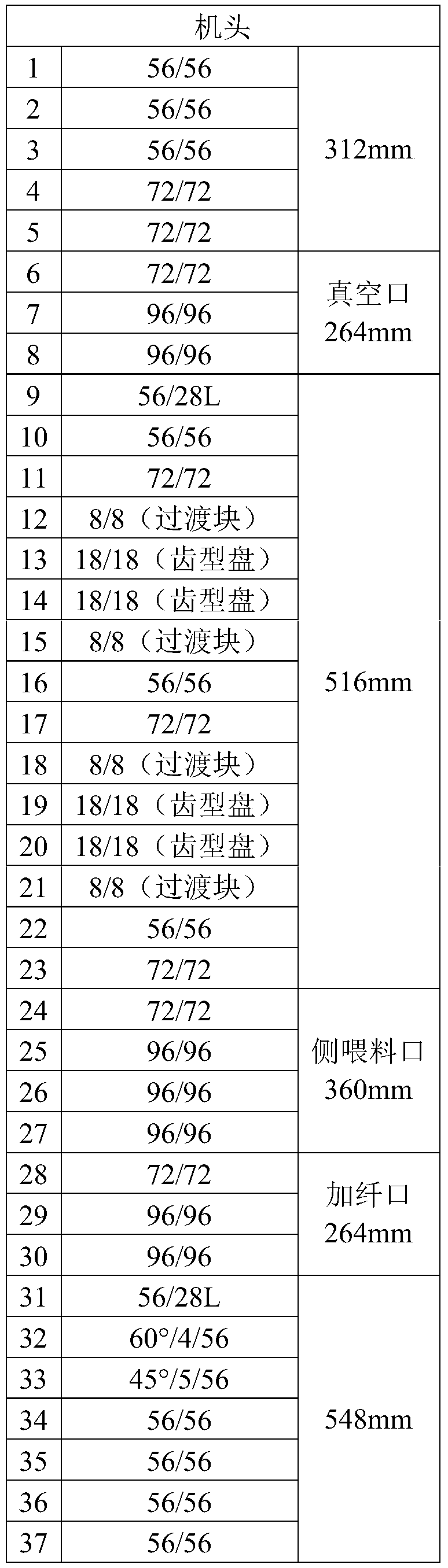

[0075] Specifically, the preparation method of the above-mentioned halogen-free flame-retardant low-density polyethylene material, the process is as follows figure 1 As shown, the steps include:

[0076] 1) Feed LDPE into the twin-screw extruder through the 1# loss-in-weight weighing bin from the main feeding port;

[0077] 2) Mix the P-N compound flame retardant according to the proportion and add it to the 2# loss-in-weight weighing chamber, add the antioxidant to the 3# loss-in-weight weighing chamber, and add the lubricant to the 4# loss-in-wei...

Embodiment 3

[0086] This example provides the application of the halogen-free flame-retardant low-density polyethylene material or the halogen-free flame-retardant low-density polyethylene material prepared by the above-mentioned preparation method in simulated decorations and / or plug inner films.

[0087] In applications, simulated decorations include but are not limited to simulated green lawns, simulated Christmas trees, simulated branches and other seasonal simulated products.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flexural modulus | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

| Screw diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com