Robot rotational joint driving device and method

A technology for rotating joints and driving devices, which is applied to fluid pressure actuating devices, mechanical equipment, servo motors, etc., can solve the problems of small inertia, high cost, complex structure of DC motors, etc., and achieves high output power, high reliability, and high reliability. Guaranteed accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

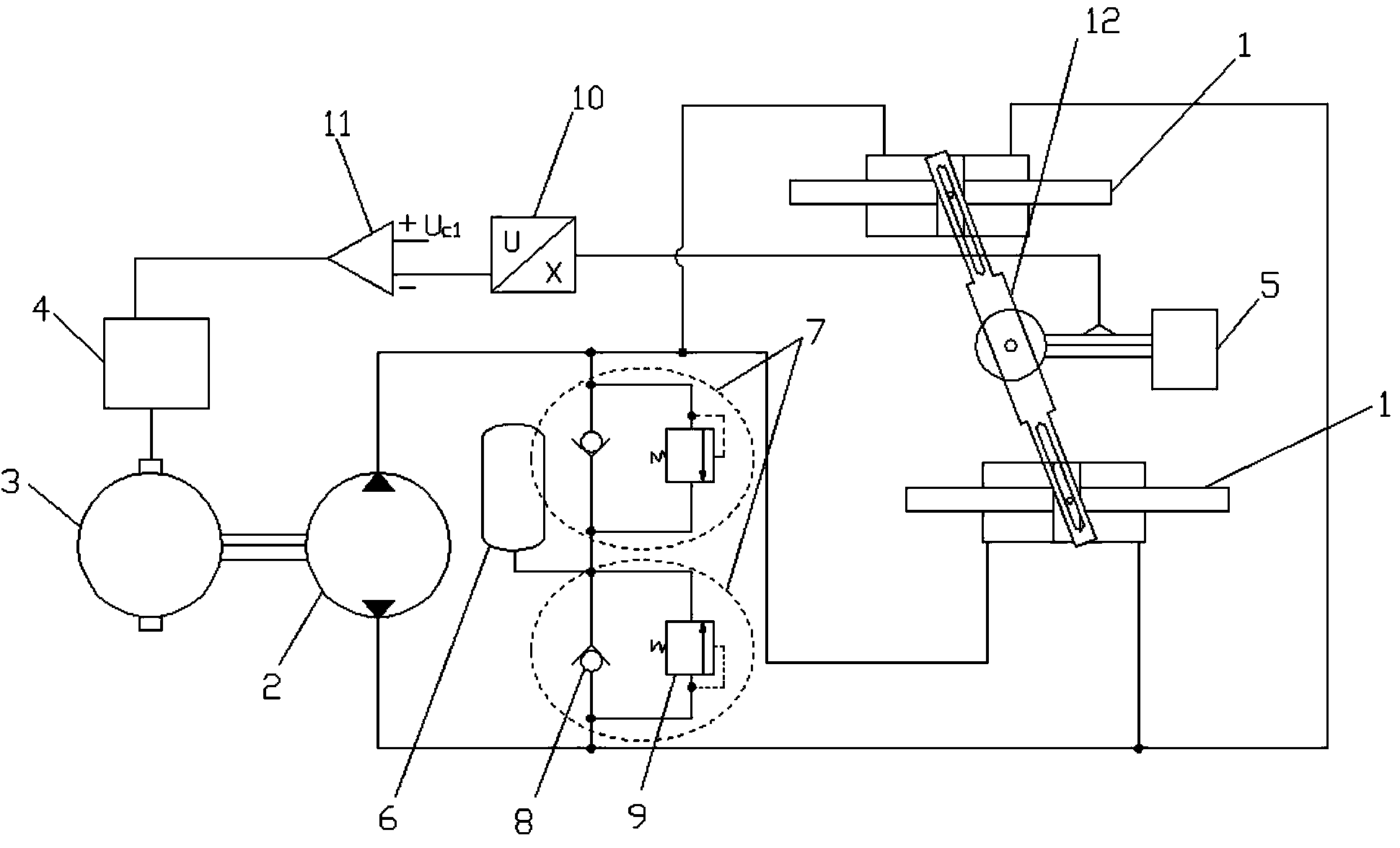

[0035] At present, the joint drive of the rotary robot is mainly realized by the mechanical transmission actuator with the DC servo motor as the driving source, but the structure of the DC motor is complex and the cost is high. Some special-purpose rotating robots require high output power and compact structure of the drive device, that is, actuators with high power density to deal with the mass distribution of the robot. The current robot joint drive technology cannot solve this problem well.

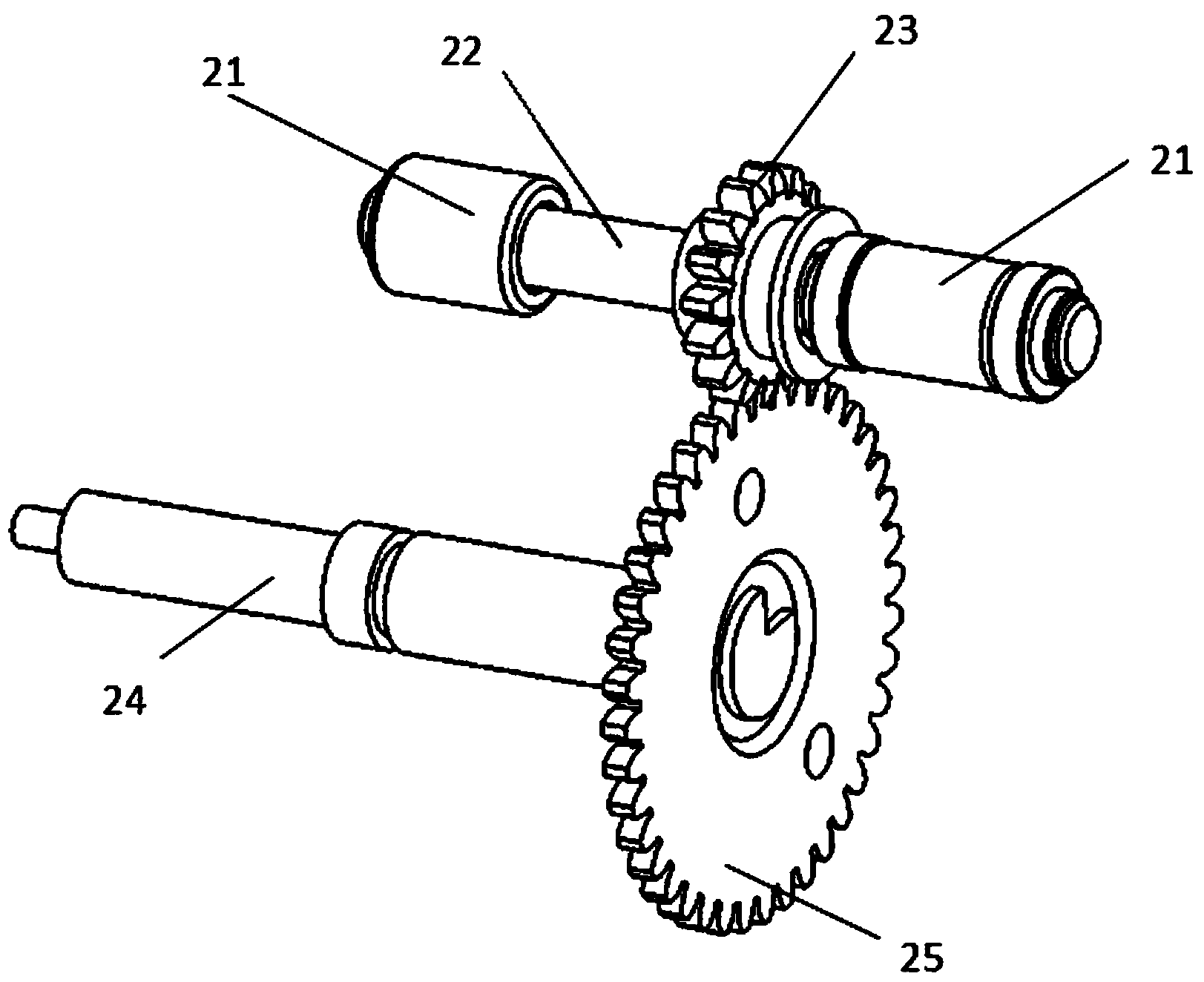

[0036] Aiming at the deficiencies in the prior art, the present invention provides a robot rotary joint driving device and a driving method. The driving device uses a servo motor to drive a hydraulic actuator for output, and the output power is large, which can effectively solve the problem of high power, high power, and The compact structure of the rotary joint is required, and the driving device has a simple structure, is easy to implement, and has high reliability.

[0037] The tech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com