Preparation method of nanoporous high-efficiency heat-insulating polyethylene film

A polyethylene film and nano-porous technology, which is applied in the production of bulk chemicals, insulation improvement, climate change adaptation, etc., can solve the problems of difficult and uniform dispersion of nano-airgel powder, and achieve high chemical stability and compatibility The effect of high stability and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] A preparation method of nano-porous high-efficiency heat-insulating polyethylene film, adding nano-airgel powder into a coupling agent solution (coupling agent and solvent volume ratio 1: (50-150)), stirring at room temperature for 0.5h-1h After aging 2d. After aging, put it into a 60°C-80°C drying oven to dry for 2h-4h to obtain the modified airgel powder. Mix the modified nano-airgel powder and polyethylene powder evenly in a certain proportion, add a certain proportion of polyethylene wax and functional additives, and put them into the internal mixer at 120°C-150°C, and banbury for 30min- After 50 minutes, put it into a twin-screw granulator for granulation, and obtain the thermal insulation masterbatch. Finally, the masterbatch or the masterbatch and the base material are mixed and stretched through a casting machine at 120°C-150°C to obtain a nanoporous high-efficiency heat-insulating polyethylene film.

[0026] Preferably, the aerogel is silica aerogel.

[0027...

Embodiment 1

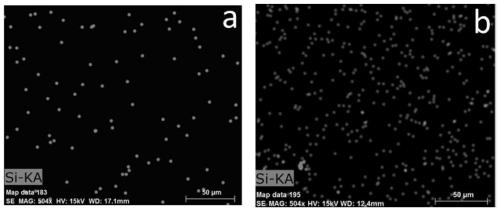

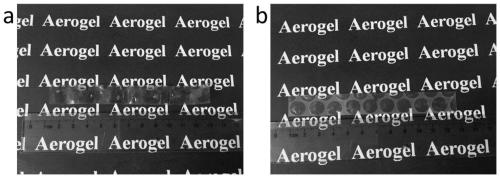

[0031] Example 1: Preparation of nanoporous high-efficiency thermal insulation polyethylene film under solid phase

[0032] The preparation of nanoporous high-efficiency thermal insulation polyethylene film under solid phase is mainly divided into three parts: first, the modification of silica airgel powder. Put a certain amount of silica airgel powder into a container containing a silane coupling agent solution, and stir at room temperature for 30min-60min; The coupling agent solution is prepared by 1mL silane coupling agent corresponding to 50mL-150mL ethanol. Second, mix the modified silica airgel powder, polyethylene powder, polyethylene wax and additives evenly and put them into a mixer at 120°C-150°C, mix for 30min-50min, and put them into twin-screw granulation In-machine granulation to obtain nanoporous high-efficiency heat-insulating polyethylene masterbatch; the mass ratio of airgel powder, polyethylene powder, polyethylene wax and additives is 3:100:5:(0.1-0.3). T...

Embodiment 2

[0033] Example 2: Preparation of nanoporous high-efficiency thermal insulation polyethylene film in liquid phase

[0034] The preparation of nanoporous high-efficiency thermal insulation polyethylene film in liquid phase is mainly divided into three parts: first, the modification of silica airgel powder. Put a certain amount of silica airgel powder into a container containing a silane coupling agent solution, and stir at room temperature for 30min-60min; The coupling agent solution is prepared by 1mL silane coupling agent corresponding to 50mL-150mL ethanol. Second, mix the modified silica airgel powder, polyethylene powder, polyethylene wax and additives evenly into a container filled with ethanol, stir at room temperature for 30min-60min, and send it to 70℃-80℃ Dry in an oven for 4-8 hours; after that, put it into a granulator to granulate to obtain nanoporous high-efficiency heat-insulating polyethylene masterbatch; the mass ratio of airgel powder, polyethylene powder, pol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com