High-density polyethylene alloy pipe and manufacturing method thereof

A technology of high-density polyethylene and low-density polyethylene, which is applied in the field of high-density polyethylene alloy pipes and its manufacturing, can solve poor performances such as wear resistance, chemical resistance, environmental stress cracking resistance and heat resistance. , Insufficient barrier properties of hydrocarbon solvents and fuel oil, affecting the service life of the product, etc., to achieve the effects of easy popularization, enhanced compatibility, and improved barrier properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] ① Formulation: HDPE 75%, LDPE 10%, HDPE-g-MAH 3%, CaCO 3 10%, antioxidant 0.4%, auxiliary antioxidant 0.4%, ultraviolet absorber 0.4%, dispersant 0.4%.

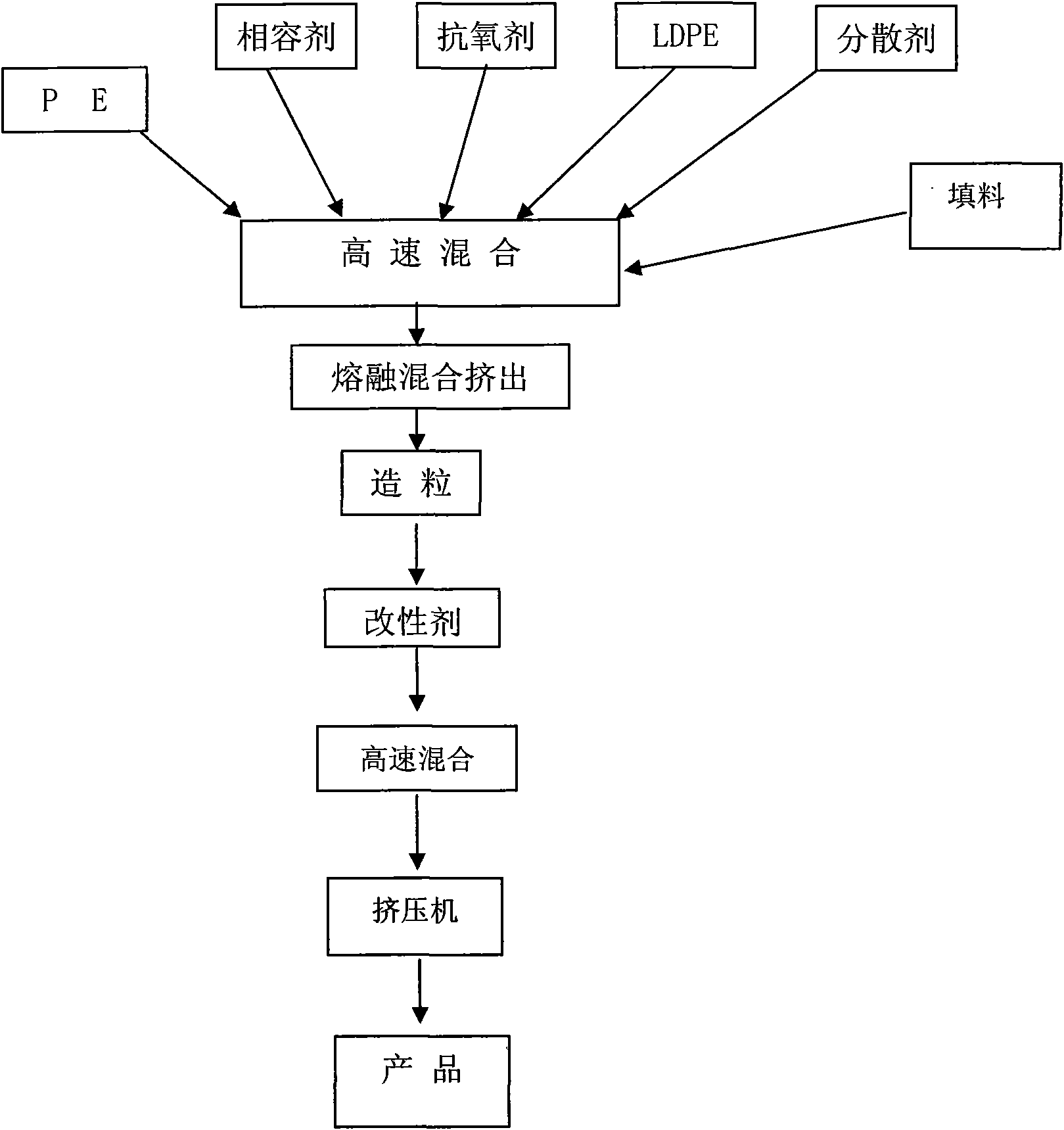

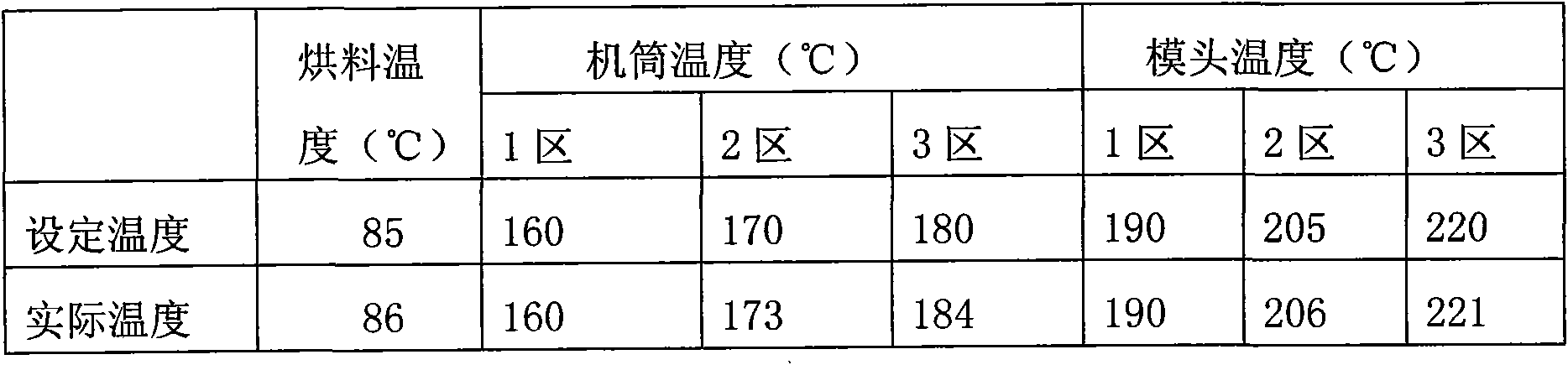

[0072] ②Process: Accurately weigh the weight of various materials according to the above formula, and press image 3 Process parameters for extrusion granulation.

[0073] ③Injection molding performance testing spline

[0074] Injection molding process parameters: baking material temperature: 85°C, injection temperature: 190°C in zone 1, 210°C in zone 2, 220°C in zone 3; injection pressure: 80MPa in zone 1, 40MPa in zone 2, 15MPa in zone 3, injection time 15S, The holding time is 10S, and the cooling time is 15S.

[0075] ④ For performance analysis see Figure 4 .

Embodiment 2

[0077] ① Formulation: HDPE 73%, LDPE 10%, HDPE-g-MAH 5%, CaCO 3 10%, antioxidant 0.4%, auxiliary antioxidant 0.4%, ultraviolet absorber 0.4%, dispersant 0.4%.

[0078] ② Carry out extrusion granulation and injection molding performance testing sample according to the process parameters of Example 1.

[0079] ③For performance test results, see Figure 5 .

Embodiment 3

[0081] ① Formulation: HDPE 71%, LDPE 10%, HDPE-g-MAH 7%, CaCO 3 10%, antioxidant 0.3%, auxiliary antioxidant 0.3%, ultraviolet absorber 0.3%, dispersant 0.3%.

[0082] ②According to the process parameters of Example 1, extrude the material and test the injection molding performance of the sample strip.

[0083] ③For performance test results, see Figure 6 .

[0084] ④ Performance Analysis

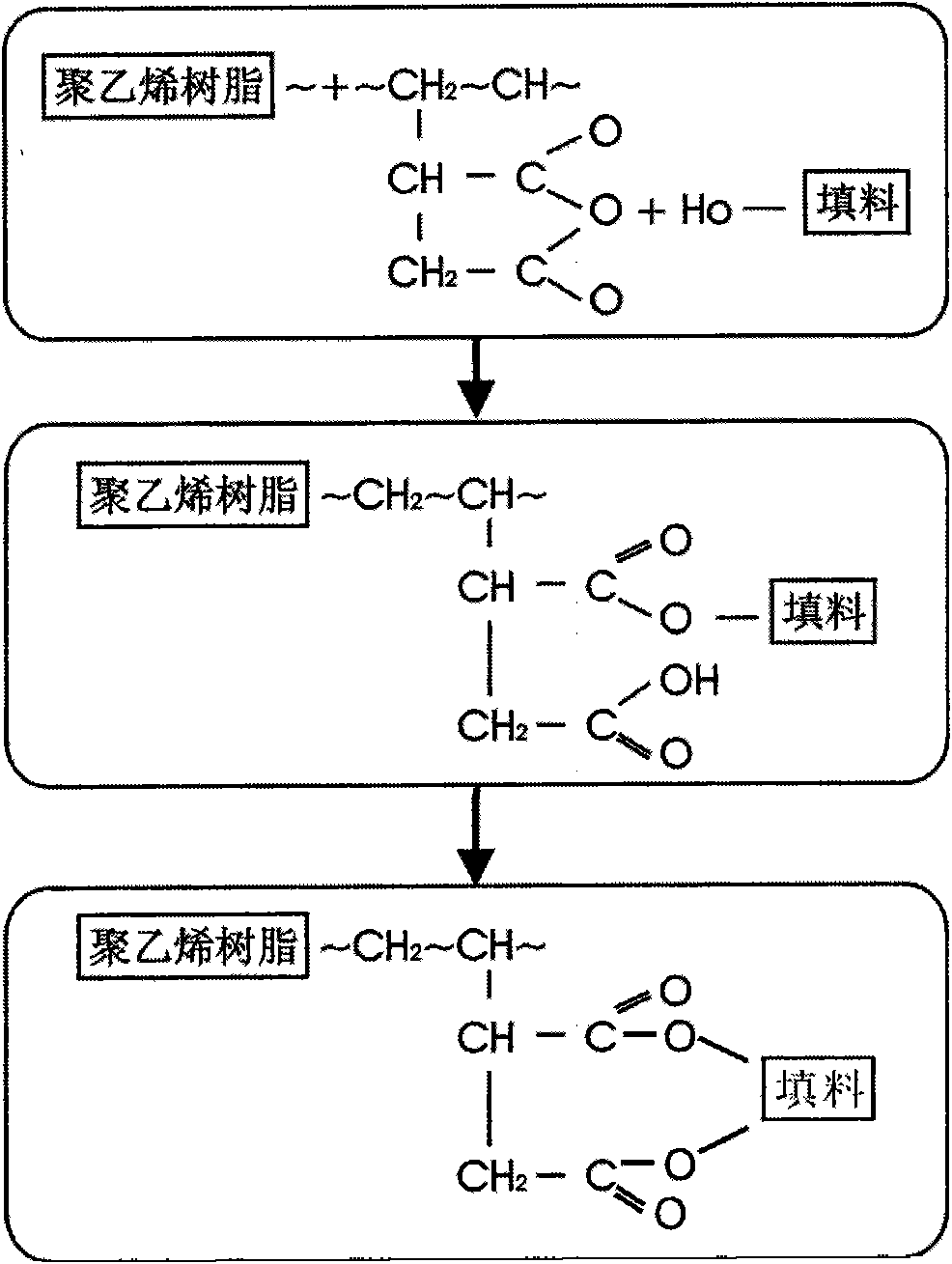

[0085] Using polymer interfacial compatibilizer HDPE-g-MAH for PE / CaCO 3 The filling system has obvious compatibilizing effect. When the interfacial compatibilizer HDPE-g-MAH is added to the system, the impact performance changes greatly. The reason is that the interfacial compatibilizer HDPE-g-MAH plays a central role in it. As an interface modifying substance, it mainly plays three roles in the system: one is the coupling effect, HDPE-g-MAH is a polar polymer material, and its polar groups can interact with the surface of inorganic fillers rich in The "carboxyl terminal group" has a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com