Glass material and preparation method and product thereof

A technology of glass material and integral material, applied in the field of glass-ceramic and its preparation, can solve the problems of single color of high-strength cover plate, difficult to obtain the depth of stress layer, low hardness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] The first step, component weighing, mixing

[0073] According to each component and its mass fraction listed in Table 1, Example 1, select the corresponding raw materials, mix the raw materials evenly, and put the uniform mixture into a platinum or alumina crucible;

[0074] The second step, the preparation of the basic glass plate

[0075] According to the ease of melting of the glass composition, the temperature of 1450° C. was kept in an electric furnace for 20 hours to make it melt uniformly, and a basic glass plate with a thickness of 1.0 mm was formed by the ingot cutting method.

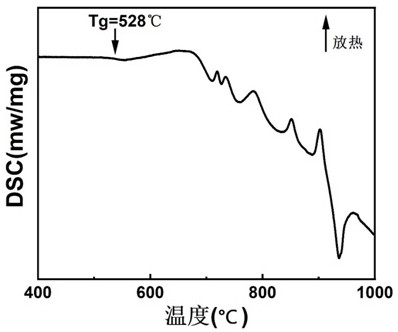

[0076] The third step, crystallization heat treatment

[0077] Carry out crystallization heat treatment on the obtained basic glass plate. The specific method is to nucleate by holding at 650°C for 2 hours, and carry out crystal growth at 760°C for 8 hours, and then cool with the furnace to produce glass-ceramics. The process system of glass crystallization heat treatment of other exa...

Embodiment 2

[0084] The first step, component weighing, mixing

[0085] According to each component listed in Table 1 Example 2 and their mass fraction ratios, select corresponding raw materials, mix the raw materials uniformly, and put the uniform mixture into a platinum crucible;

[0086] The second step, the preparation of the basic glass plate

[0087] According to the ease of melting of the glass composition, it was kept in an electric furnace at a temperature of 1420° C. for 20 hours to make it melt uniformly, and a basic glass plate with a thickness of 2.0 mm was formed by the ingot cutting method.

[0088] The third step, crystallization heat treatment

[0089] Carry out crystallization heat treatment on the obtained basic glass plate. The specific method is to nucleate by holding at 630°C for 4 hours, and carry out crystal growth at 730°C for 3 hours, and then cool with the furnace to produce glass ceramics.

[0090] The fourth step, mechanical processing of glass-ceramics

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com