Lithium-based molecular sieve with oxygen generation function and preparation method and production equipment thereof

A production equipment and molecular sieve technology, applied in the field of molecular sieves, can solve the problems of small nitrogen adsorption capacity, low nitrogen and oxygen separation coefficient, affecting the effect of oxygen production, etc., and achieve increased nitrogen adsorption capacity, high nitrogen adsorption capacity, and improved heat resistance stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~7

[0047] As shown in Table 1, the main difference of Examples 1-7 is that the proportioning ratio of raw materials is different.

Embodiment 1

[0049] Embodiment 1 discloses a production equipment of a lithium-based molecular sieve with the function of oxygen production.

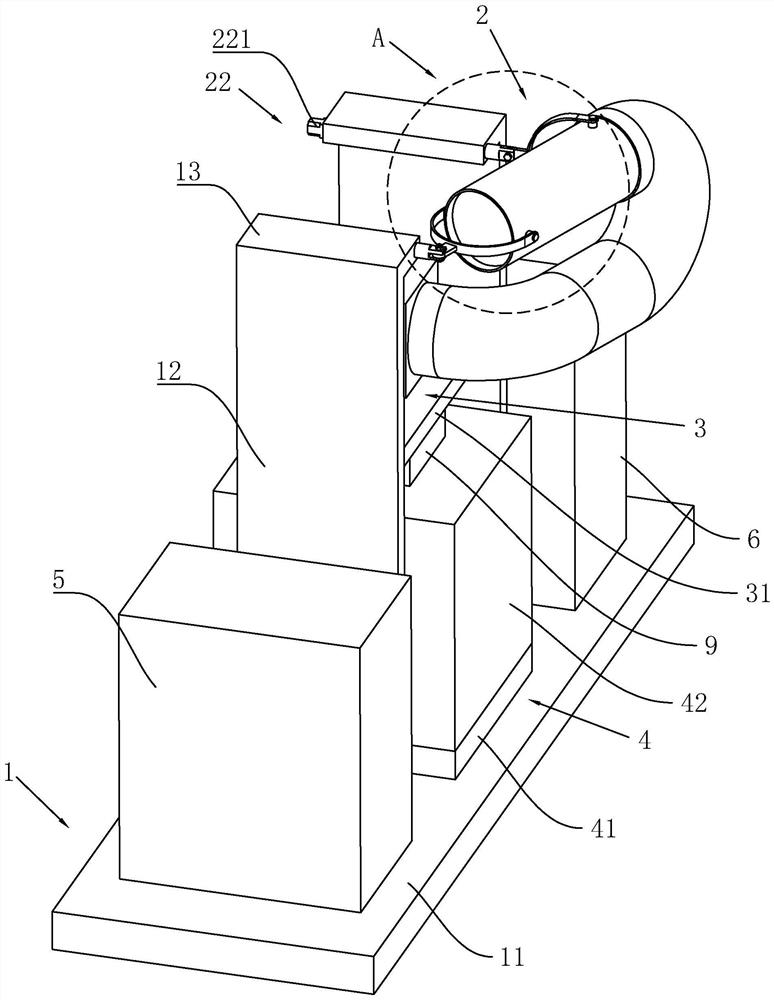

[0050] refer to figure 1 , a kind of production equipment of lithium-based molecular sieve with oxygen production function, comprises frame 1, material mixing device 2, heating device 3, reaction device 4, suction filtration device 5 and roasting device 6, material mixing device 2, heating device 3 , reaction device 4, suction filtration device 5 and roasting device 6 are all arranged on the frame 1.

[0051] refer to figure 1 , the frame 1 includes a base plate 11, two support plates 12 are fixedly connected to the top wall of the base plate 11, the two support plates 12 are all vertically arranged, and a horizontal plate 13 is integrally formed on the side wall at the top of each support plate 12 , the two horizontal plates 13 are located between the two supporting plates 12 .

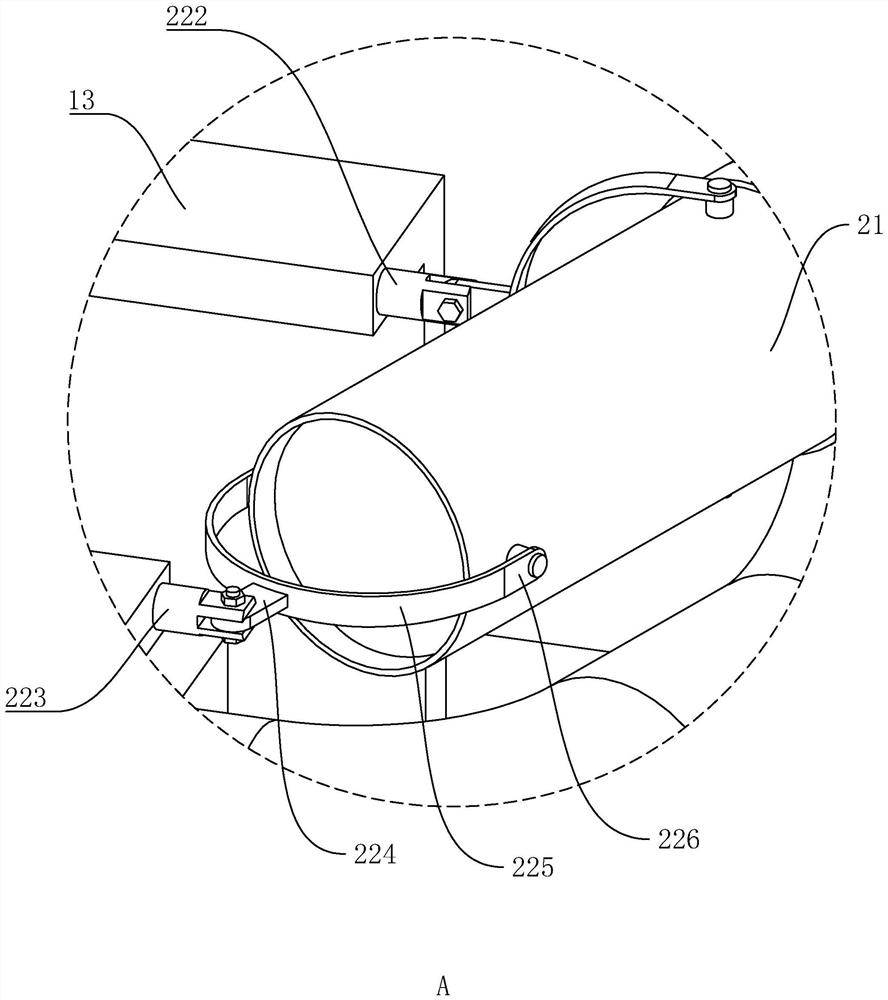

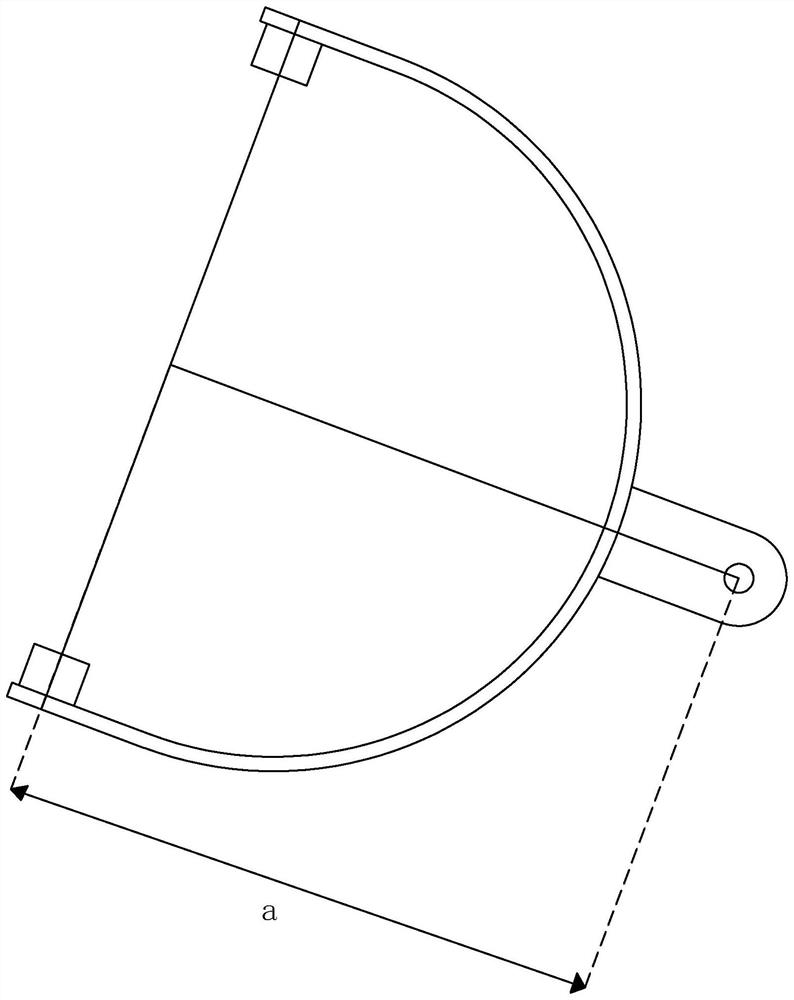

[0052] refer to figure 1 and figure 2 , the mixing device 2 inc...

Embodiment 8

[0067] The difference of embodiment 8 and embodiment 6 is, utilize driving motor 34 to drive seal plate 36 to rotate, open discharge hole 311, make mixture A enter in reactor 42, add the lithium carbonate of 2kg earlier in reactor 42, lithium carbonate After mixing with mixture A evenly, add 16kg of deionized water, 7kg of silica sol, 1.5kg of α-linolenic acid and 1.5kg of γ-aminopropyltriethoxysilane, and react at 160°C for 40 hours to obtain mixture B. Add it to a suction filter for suction filtration, wash the suction filtered product until neutral, and then dry to obtain a mixture C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com