Surface deliquescence-resistant aluminum-lithium-based ternary alloy powder and preparation method thereof

A ternary alloy, anti-deliquescent technology, used in metal processing equipment, explosives, transportation and packaging, etc., can solve problems such as increased difficulty in use, reduced storage activity and stability, and poor stability, and achieves improved stability. The effect of maintaining activity and stability, preventing deliquescence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

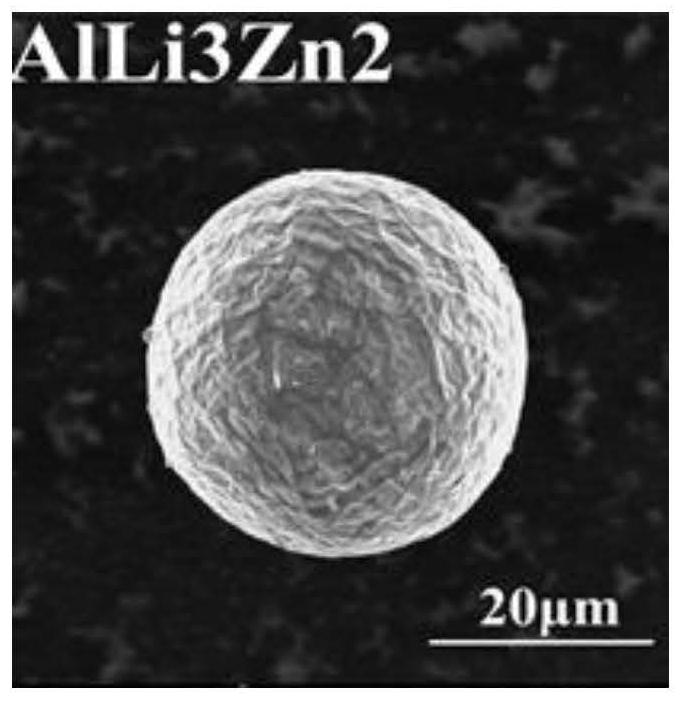

[0127] Preparation of AlLi3Zn2 ternary alloy powder:

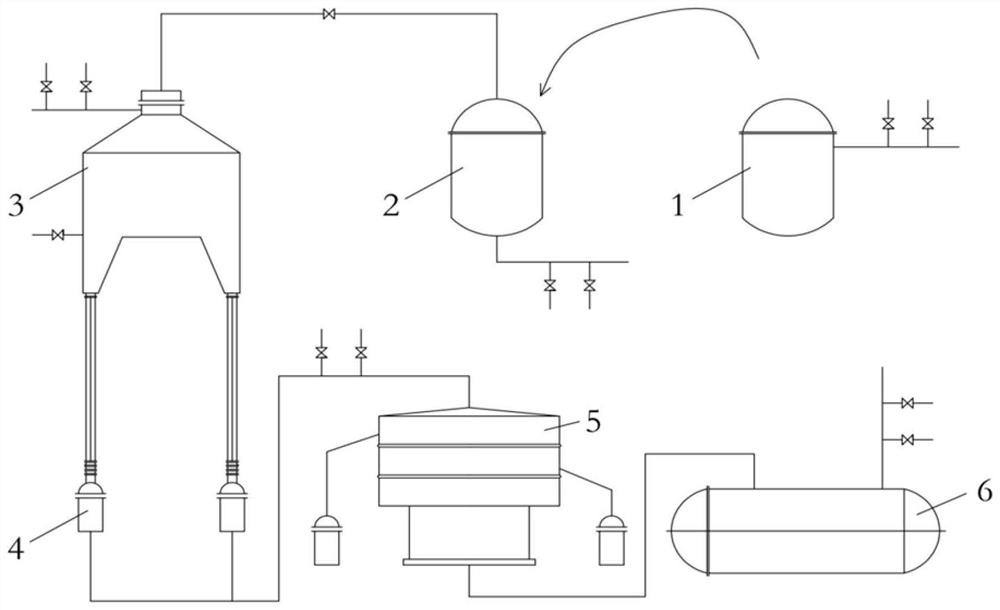

[0128] Use system devices such as figure 1 shown.

[0130] Under the condition of positive argon pressure of 105kPa, the oxygen volume content in the silicon carbide crucible melting furnace is not more than 0.01% by vacuuming and filling with argon gas, the melting temperature is 750 ° C, and 100 kg of aluminum-lithium binary alloy ingot (AlLi20) is melted. Store for later use.

[0131] 2. Alloy melting

[0132] Take the aluminum-lithium binary basic alloy ingot (AlLi20), remove the scale and weigh 6.0kg. According to formula (5) and formula (6), it can be seen that 33.2kg of aluminum and 0.8kg of zinc should be added. 40 kg of raw material were placed in melting furnace 2 . The first time to evacuate to 0.1kPa, fill with argon to 101.3kPa and stir; the second time to evacuate to 10kPa, fill with argon to 101.3kPa and stir, the detection value of oxygen content in the furnace is 0.009%. H...

Embodiment 2

[0144] Preparation of AlLi5Zn4 ternary alloy powder:

[0145] Use system devices such as figure 1 shown.

[0146] 1. Alloy smelting

[0147] Under the condition of argon positive pressure of 103kPa, the oxygen volume content in the silicon carbide crucible melting furnace is not more than 0.01% by vacuuming and filling with argon twice, and the melting temperature is 800 ℃, and the aluminum-lithium binary alloy ingot (AlLi20) is melted. 100kg, ready for storage after preparation.

[0148] 2. Alloy melting

[0149] Take the aluminum-lithium binary basic alloy ingot (AlLi20), remove the oxide scale and weigh 10.0kg. According to formula (5) and formula (6), it can be seen that 28.4kg of aluminum and 1.6kg of zinc should be added. 40 kg of raw material were placed in melting furnace 2 . The first time to evacuate to 0.1kPa, fill with argon to 101.3kPa and stir; the second time to evacuate to 10kPa, fill with argon to 101.3kPa and stir, the detection value of oxygen content ...

Embodiment 3

[0160] Preparation of AlLi8Zn5 ternary alloy powder:

[0161] Use system devices such as figure 1 shown.

[0162] 1. Alloy smelting

[0163] Under the condition of positive argon pressure of 103kPa, the oxygen volume content in the silicon carbide crucible melting furnace is not more than 0.01% by vacuuming and filling with argon twice, and the melting temperature is 850 ℃, and the aluminum-lithium binary alloy ingot (AlLi20) is melted. 100kg, ready for storage after preparation.

[0164] 2. Alloy melting

[0165]Take the aluminum-lithium binary basic alloy ingot (AlLi20), remove the oxide scale and weigh 16.0kg. According to formula (5) and formula (6), it can be seen that 22.0kg of aluminum and 2.0kg of zinc should be added. 40 kg of raw material were placed in melting furnace 2 . The first time to evacuate to 0.1kPa, fill with argon to 101.3kPa and stir; the second time to evacuate to 10kPa, fill with argon to 101.3kPa and stir, the detection value of oxygen content i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com