Method for preparing lithium ionic sieve adsorbent

A lithium ion and adsorbent technology, which is applied in the field of preparing lithium ion sieve adsorbents, can solve problems such as poor adsorption performance, poor product controllability, and long process, and achieve stable structure, low time and energy consumption, and controllability high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

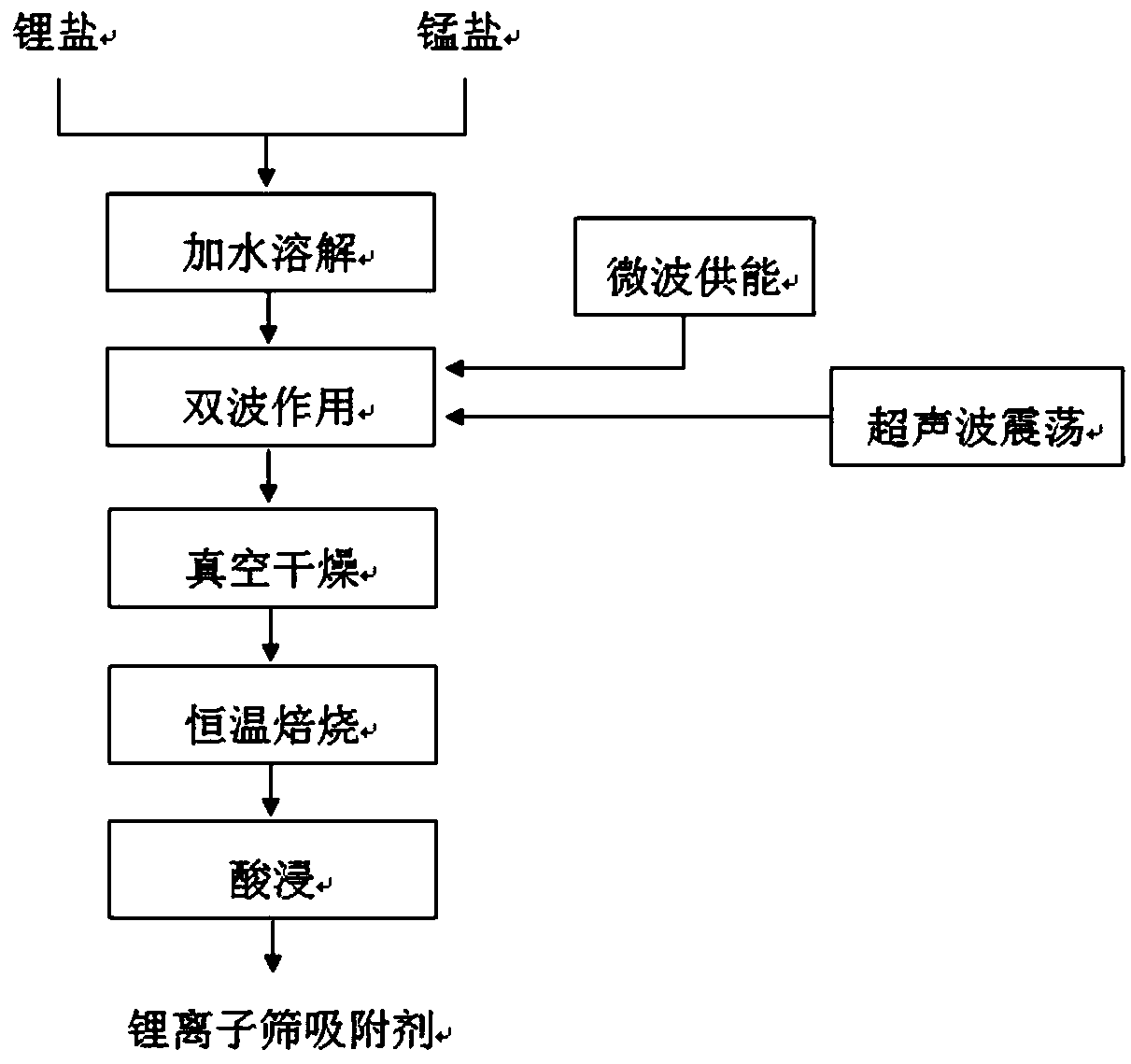

[0032] The present embodiment provides a kind of method for preparing lithium ion sieve adsorbent (its flow chart is as follows figure 1 shown), including the following steps:

[0033] (1) Take by weighing 2.82g lithium citrate, 7.90g manganese acetate (lithium manganese molar ratio 1:1.075), take pure water as solvent, fully mix;

[0034] (2) Place the mixed solution in a computerized microwave, ultrasonic, ultraviolet combined catalytic synthesizer, and heat it under the joint action of microwave and ultrasonic wave. First, heat it in a closed environment for 0.5h, and then adjust it to an open system and heat it for 1h to obtain co-precipitation The product, wherein the microwave parameters are: frequency 2450MHz, power 800W, ultrasonic parameters are: frequency 25KHz, power 800W;

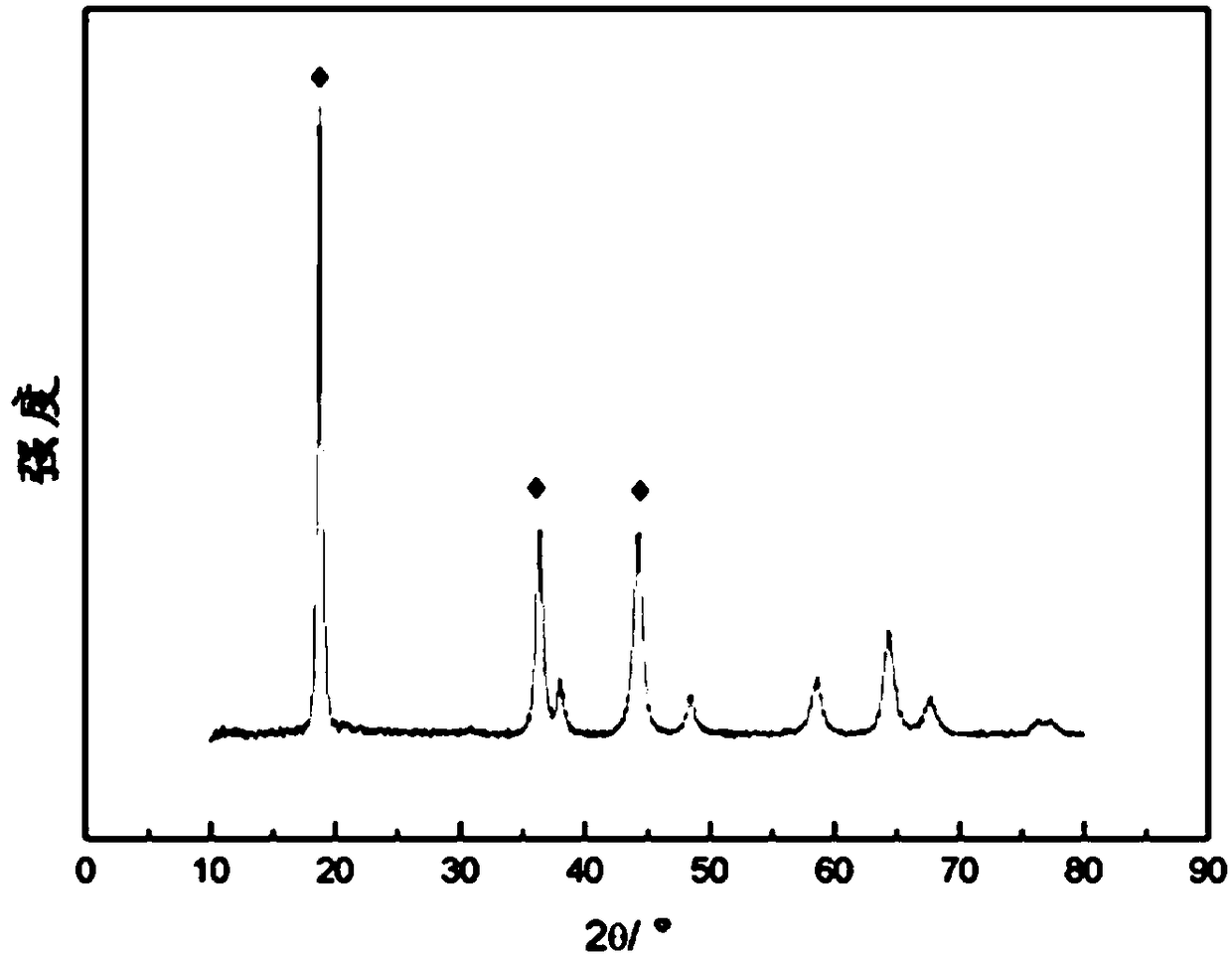

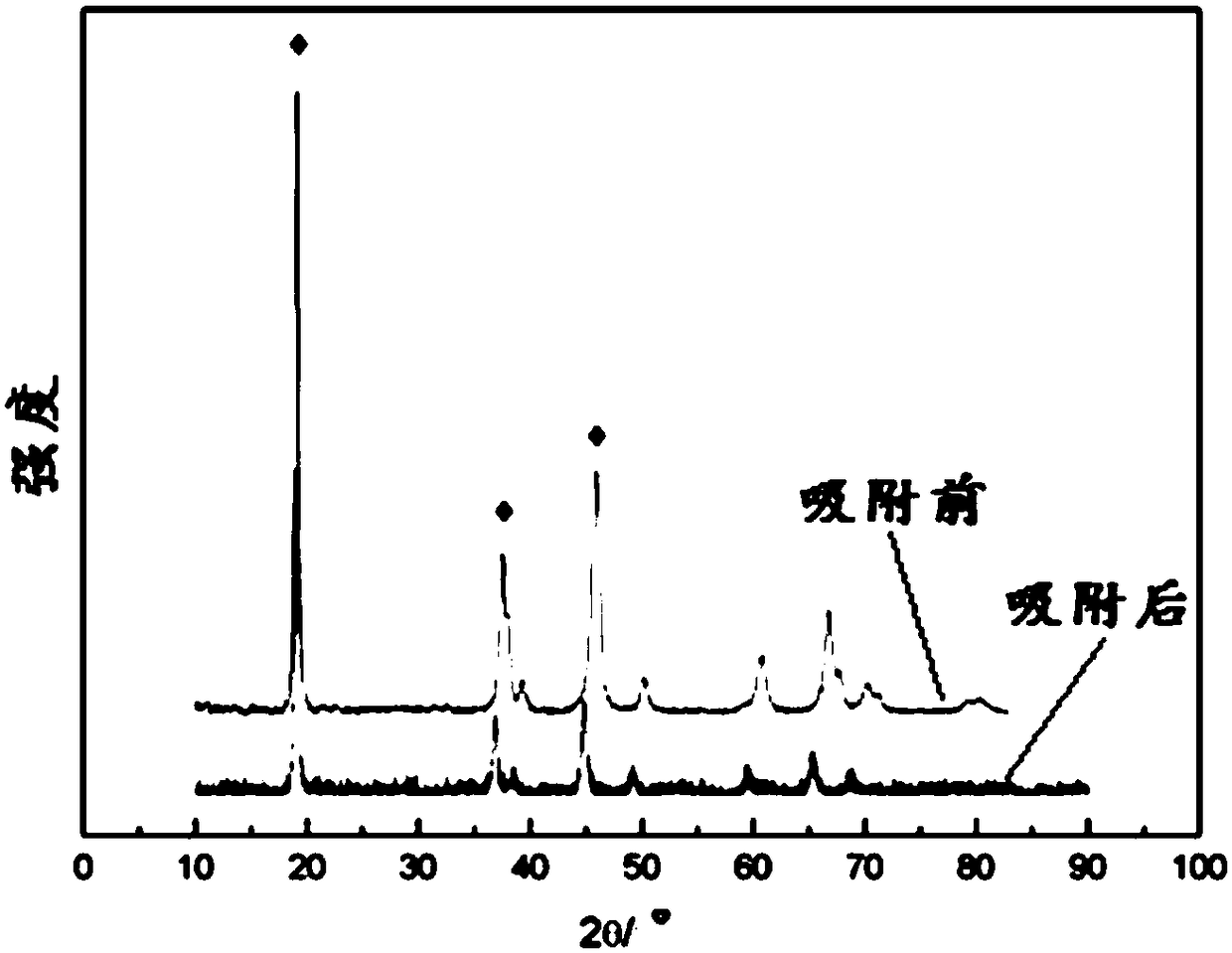

[0035] (3) Dry the obtained co-precipitation product in a vacuum drying oven, set parameters: 150°C, 6h, and then place it in a muffle furnace for constant temperature roasting, set roasting pa...

Embodiment 2

[0042] The present embodiment provides a kind of method for preparing lithium ion sieve adsorbent, comprises the following steps:

[0043] (1) Take by weighing 2.82g lithium citrate, 8.27g manganese acetate (lithium manganese molar ratio 1:1.125), take pure water as solvent, fully mix;

[0044] (2) Place the mixed solution in a computerized microwave, ultrasonic, ultraviolet combined catalytic synthesizer, and heat it under the joint action of microwave and ultrasonic wave. First, heat it in a closed environment for 0.5h, and then adjust it to an open system and heat it for 1h to obtain co-precipitation The product, in which microwave parameters are: frequency 2450MHz, power 700W, ultrasonic parameters are: frequency 25KHz, power 700W;

[0045] (3) Dry the obtained co-precipitation product in a vacuum drying oven, set parameters: 150°C, 5h, and then place it in a muffle furnace for constant temperature roasting, set roasting parameters: 280°C, 6h, and naturally cool after roas...

Embodiment 3

[0049] The present embodiment provides a kind of method for preparing lithium ion sieve adsorbent, comprises the following steps:

[0050] (1) Take by weighing 2.82g lithium citrate, 9.19g manganese acetate (lithium manganese molar ratio 1:1.25), take pure water as solvent, fully mix uniformly;

[0051] (2) Place the mixed solution in a computerized microwave, ultrasonic, ultraviolet combined catalytic synthesizer, and heat it under the joint action of microwave and ultrasonic wave. First, heat it in a closed environment for 0.5h, and then adjust it to an open system and heat it for 1h to obtain co-precipitation The product, wherein the microwave parameters are: frequency 2450MHz, power 600W, ultrasonic parameters are: frequency 25KHz, power 600W;

[0052] (3) Dry the obtained co-precipitation product in a vacuum drying oven, set parameters: 150°C, 5h, and then place it in a muffle furnace for constant temperature roasting, set roasting parameters: 320°C, 6h, and naturally coo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com