Method for recycling lithium carbonate from lithium iron phosphate battery

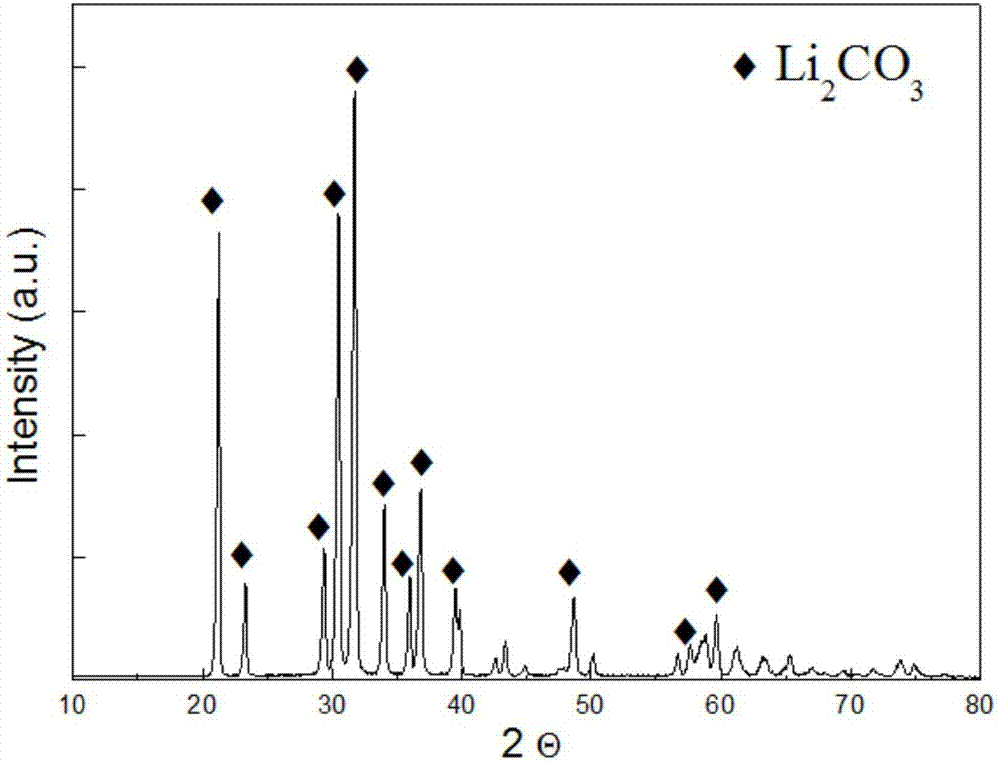

A technology of lithium iron phosphate battery and lithium iron phosphate, which is applied in the direction of lithium carbonate; Recycling cost, the effect of uniform size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

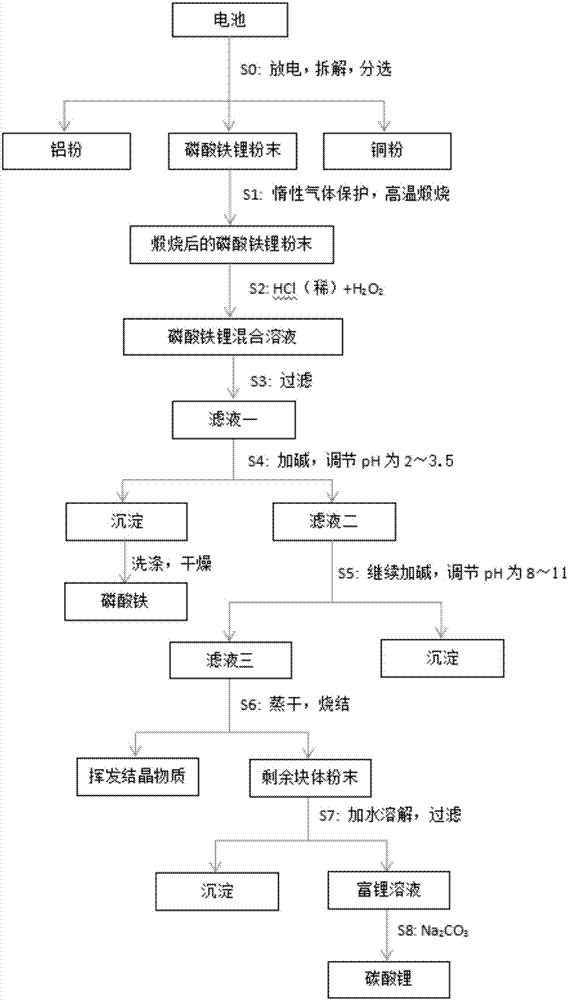

Method used

Image

Examples

Embodiment 1

[0042] S0: Discharge 100 lithium iron phosphate batteries to below 2.0V, put them into a crusher for crushing and dismantling, and then pass through a combination of vibration screening and airflow separation equipment to realize lithium iron phosphate powder, aluminum powder and copper powder in the battery separation.

[0043] S1: Put the lithium iron phosphate powder in S0 into a vacuum tube furnace, put in an argon atmosphere, and treat at a high temperature of 500°C for 8 hours.

[0044] S2: add 50mL of dilute hydrochloric acid solution with a concentration of 3mol / L and a hydrogen peroxide solution with a mass fraction of 30% while stirring the lithium iron phosphate powder treated in S1 respectively, and stir for 2 hours to react, the solution pH The value reaches between 0.5 and 1. Wherein, the mass ratio of dilute hydrochloric acid solution and hydrogen peroxide solution is 1:1.

[0045] S3: Filter the mixed solution obtained in S2 and take the filtrate to obtain th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com