Preparation method of lithium metal negative electrode based on lithium-philic three-dimensional carbon-based current collector

A lithium metal negative electrode and current collector technology, which is applied in the lithium metal battery negative electrode and its preparation field based on lithium-philic three-dimensional carbon-based current collectors, can solve the problems of poor lithium-philicity and the inability of metal lithium to infiltrate the skeleton, and achieve high lithium content The effect of inhibiting the growth of lithium dendrites and alleviating the volume expansion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

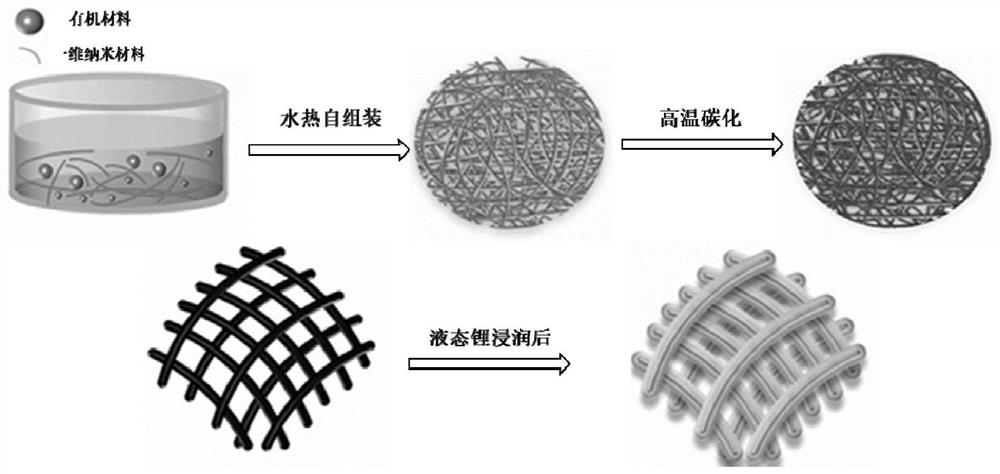

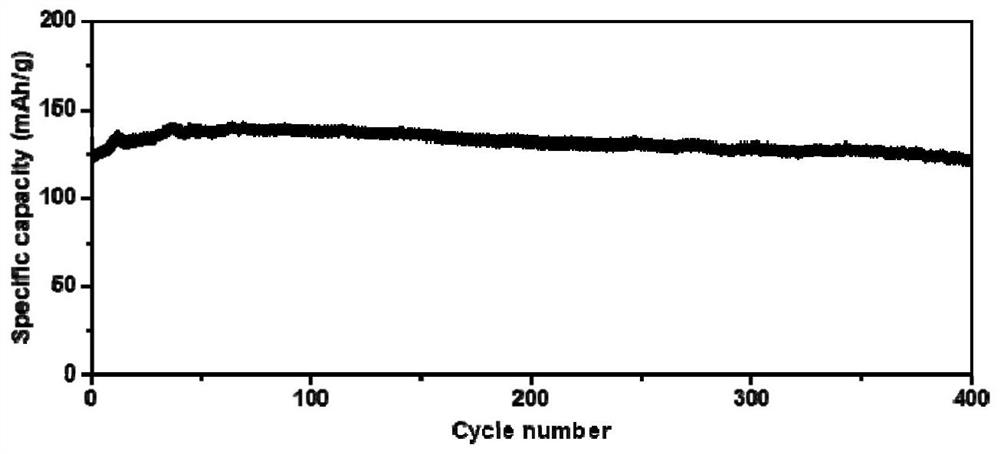

[0026] 1) Preparation of three-dimensional precursor framework materials

[0027] Through the TEMPO oxidation method, prepare a well-dispersed bacterial cellulose aqueous solution with a concentration of 2mg / ml; add 50ml of bacterial cellulose aqueous solution, 0.55g of resorcinol, and 0.75ml of formaldehyde into a beaker, stir evenly, and put the mixed solution into into the reaction kettle, heated at 100 degrees Celsius for 10 hours, and the precursor skeleton material obtained after freeze-drying;

[0028] 2) Preparation of lithium-philic three-dimensional carbon-based current collectors

[0029] Put the precursor skeleton material into a tube furnace, pass through nitrogen protective gas, and carry out high-temperature carbonization at a constant temperature of 800°C for 2 hours to obtain a lithium-friendly three-dimensional carbon-based current collector;

[0030] 3) Preparation of composite lithium metal anode

[0031] Put the lithium-friendly three-dimensional carbon-...

Embodiment 2

[0034] 1) Preparation of three-dimensional precursor framework materials

[0035] Add 50ml of carbon nanotube aqueous solution, 0.275g of resorcinol, and 0.375ml of formaldehyde into a beaker, stir evenly, put the mixed solution into the reaction kettle, heat at 100 degrees Celsius for 10 hours, and obtain the precursor skeleton material after freeze-drying ;

[0036] 2) Preparation of lithium-philic three-dimensional carbon-based current collectors

[0037] Put the precursor skeleton material into a tube furnace, pass through nitrogen protective gas, and carry out high-temperature carbonization at a constant temperature of 800°C for 2 hours to obtain a lithium-friendly three-dimensional carbon-based current collector;

[0038] 3) Preparation of composite lithium metal anode

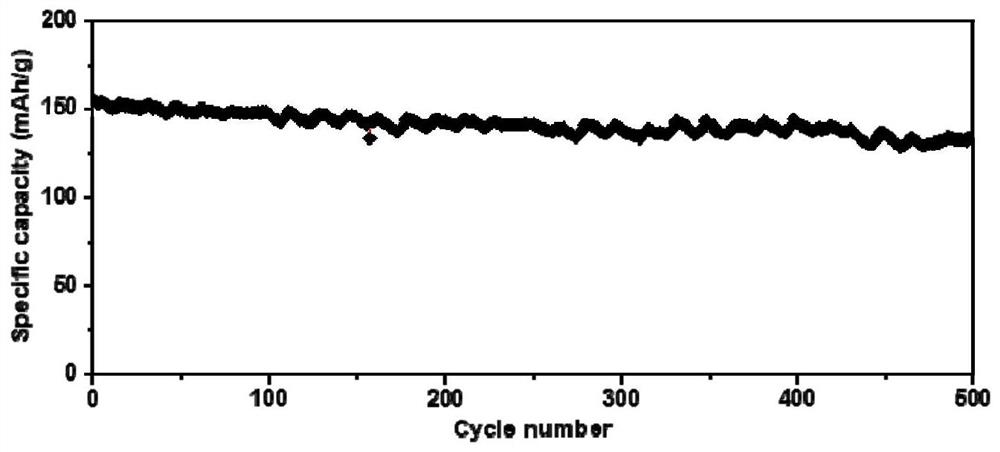

[0039] Put the lithium-friendly three-dimensional carbon-based current collector into the molten metal lithium at 300°C in the glove box, and the liquid metal lithium can be poured into the current col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com