Method for extracting lithium from alumina production process and preparing battery-grade lithium carbonate

A production process, lithium carbonate technology, applied in the preparation of alkali metal aluminate/alumina/aluminum hydroxide, lithium carbonate;/acid carbonate, aluminate/alumina/aluminum hydroxide purification, etc. Direction, can solve the problems of high cost, lengthy lithium recovery process, low recovery rate, etc., and achieve the effect of low cost, low investment, and high-efficiency desorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

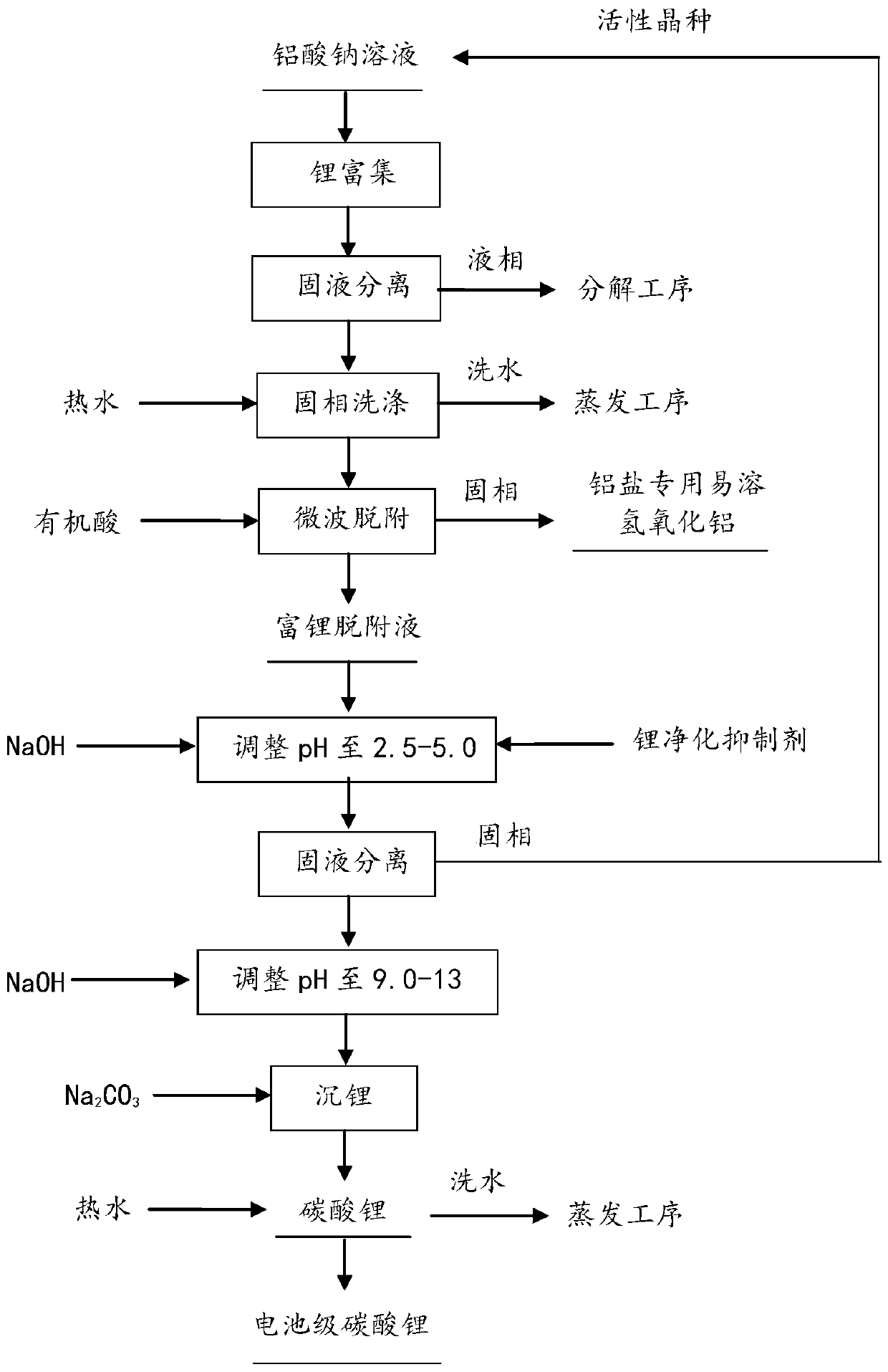

Image

Examples

Embodiment 1

[0037] Na 2 o k The concentration is 100g / L, α k =2.2, Li + The sodium aluminate solution with a concentration of 0.04g / L reacted with 1.0g / L aluminum hydroxide active seed crystals at a temperature of 80°C for 180min, the average particle size of the aluminum hydroxide active seed crystals was 2.0μm, and the removal of lithium The rate is 95.0%, and the active crystals of aluminum hydroxide are enriched through three cycles to obtain lithium-rich aluminum hydroxide, and the lithium content in the lithium-rich aluminum hydroxide is 0.5%. Lithium-rich aluminum hydroxide is washed and immersed in formic acid with a concentration of 0.1mol / L to make a slurry. The liquid-solid ratio of formic acid to lithium-rich aluminum hydroxide is 1, and the slurry is placed in a microwave reactor for lithium desorption. For the reaction, the frequency of the microwave reactor is 1500 MHz, the desorption reaction conditions are as follows: the reaction temperature is 50° C., the microwave r...

Embodiment 2

[0039] Na 2 o k The concentration is 110g / L, α k =2.1, Li +The sodium aluminate solution with a concentration of 0.04g / L reacted with 1.0g / L aluminum hydroxide active seed crystals at a temperature of 80°C for 180min, the average particle size of the aluminum hydroxide active seed crystals was 2.0μm, and the removal of lithium The rate is 95.2%. After the active crystals of aluminum hydroxide are enriched through three cycles, lithium-rich aluminum hydroxide is obtained, and the lithium content in the lithium-rich aluminum hydroxide is 0.5%. Lithium-rich aluminum hydroxide is washed and immersed in formic acid with a concentration of 0.3mol / L to make a slurry. The liquid-solid ratio of formic acid to lithium-rich aluminum hydroxide is 1.5. The slurry is placed in a microwave reactor for lithium desorption For the reaction, the frequency of the microwave reactor is 1500 MHz, the desorption reaction conditions are as follows: the reaction temperature is 60° C., the microwave ...

Embodiment 3

[0041] Na 2 o k The concentration is 120g / L, α k =2.0, Li + The sodium aluminate solution with a concentration of 0.05g / L reacted with 1.0g / L aluminum hydroxide active seed crystals at a temperature of 80°C for 180min, the average particle size of the aluminum hydroxide active seed crystals was 2.0μm, and the removal of lithium The rate is 95.4%. After the active crystals of aluminum hydroxide are enriched through three cycles, lithium-rich aluminum hydroxide is obtained, and the lithium content in the lithium-rich aluminum hydroxide is 0.6%. Lithium-rich aluminum hydroxide is washed and immersed in formic acid with a concentration of 0.5mol / L to make a slurry. The liquid-solid ratio of formic acid to lithium-rich aluminum hydroxide is 2. The slurry is placed in a microwave reactor for lithium desorption For the reaction, the frequency of the microwave reactor is 1500 MHz, the desorption reaction conditions are as follows: the reaction temperature is 70° C., the microwave r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com