Lithium flow battery reactor and electrode suspension liquid lithium intercalated synthesis method

A technology of electrode suspension and flow battery, which is applied in the manufacture of regenerative fuel cells, non-aqueous electrolyte batteries, electrolyte batteries, etc., can solve the problems that hinder the subsequent use of lithium-ion flow batteries, decrease battery capacity, and reduce cycle life. Achieve the effects of avoiding the reaction of water vapor and oxygen, increasing energy density, and increasing the number of cycles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] In this embodiment, the positive electrode suspension used as the above-mentioned battery reactor is graphite electrode suspension.

[0042] The voltage change of lithium / graphite battery is relatively stable, and the reaction of lithium ion intercalation into graphite material mainly occurs below 0.2V. During the first charge and discharge process, there is an irreversible capacity loss of 15% to 20%, part of which is used for the initial lithium ions to react with organic solvents on the surface of the carbon to form an SEI film, and the other part is used to exfoliate the graphite structure Decomposition of solvents on the surface.

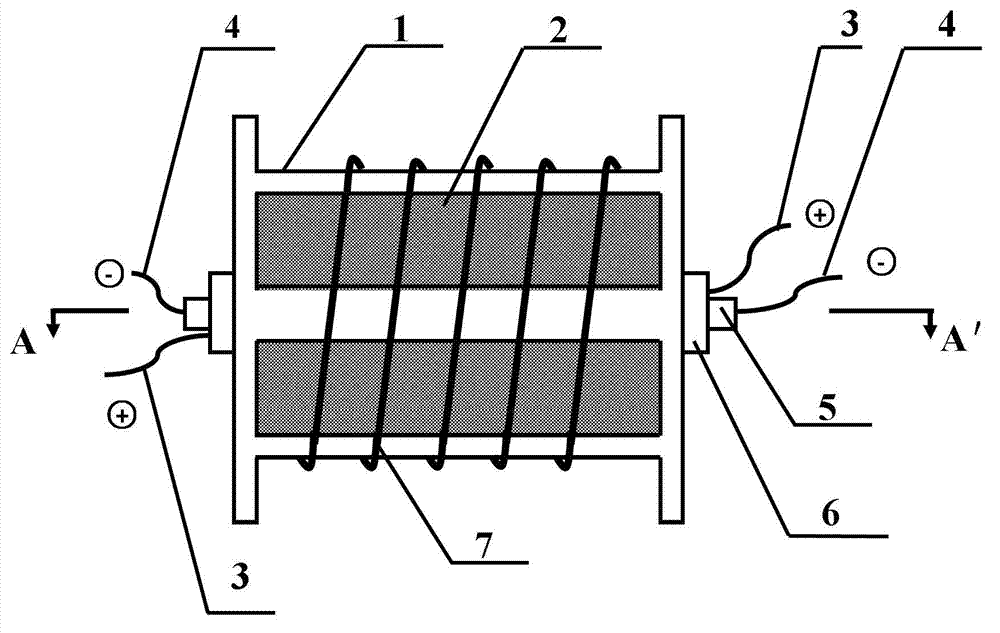

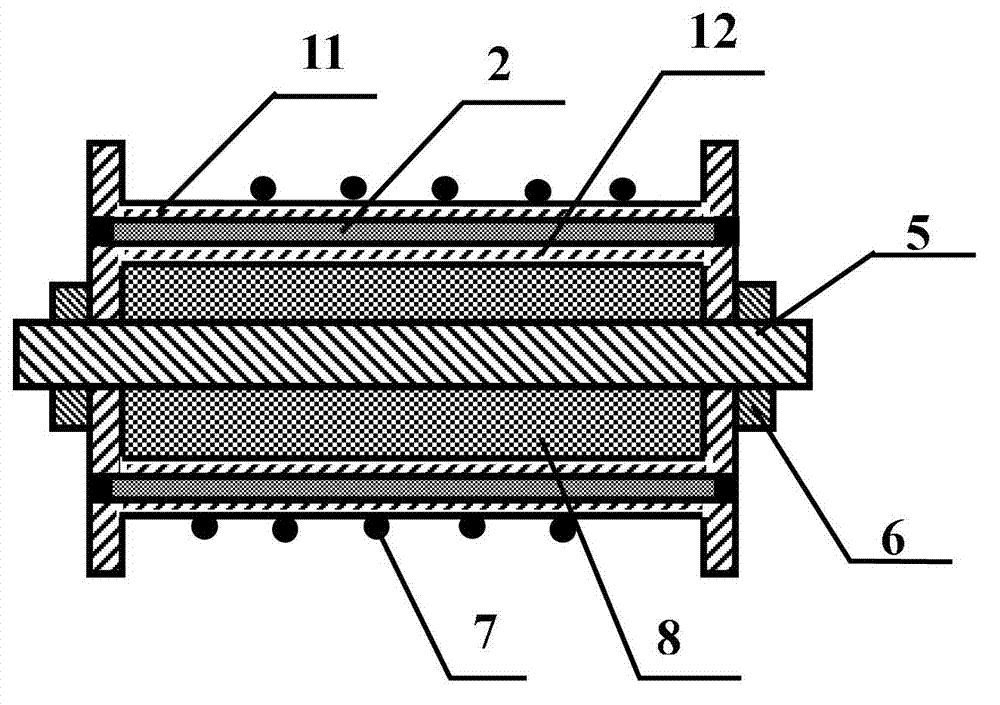

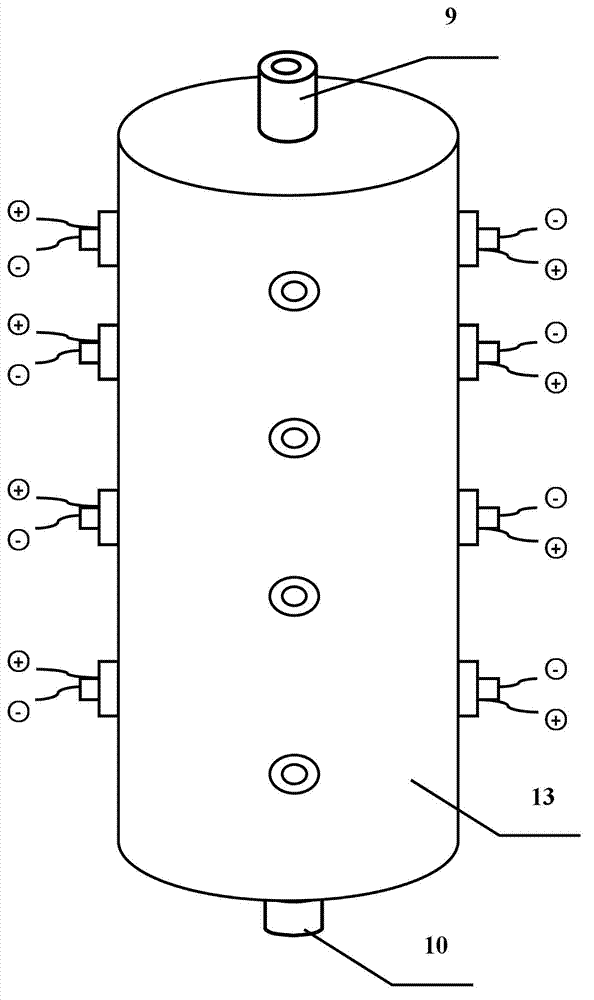

[0043] When the lithium flow battery reactor is working, the graphite electrode suspension enters from the positive electrode liquid inlet of the reaction tank, reacts with the lithium negative electrode in the reaction tank, and flows out from the positive electrode liquid outlet on the lower end of the reaction tank after the reaction ...

Embodiment 2

[0047] In this embodiment, the positive electrode suspension used as the above-mentioned battery reactor is a simple Si electrode suspension.

[0048] Silicon is one of the most abundant elements in the earth's crust, with a wide range of sources and cheap prices. Among the elements that can be alloyed to store lithium, the theoretical lithium storage capacity of silicon is more than 10 times that of graphite, and the voltage platform of silicon is slightly higher than that of graphite. It is difficult to cause lithium precipitation on the surface during charging, and the safety performance is high.

[0049] Silicon and lithium are combined to form Li 12 Si 7 , Li 7 Si 3 , Li 13 Si 4 and Li 22 Si 5 etc., where Li 22 Si 5 The corresponding lithium storage capacity reaches 4200mAh / g. When the lithium flow battery reactor is working, the silicon electrode suspension enters from the positive electrode liquid inlet of the reaction tank, reacts with the lithium negative el...

Embodiment 3

[0054] In the present embodiment, the positive electrode suspension used as the above-mentioned battery reactor is Li 4 Ti 5 o 12 electrode suspension.

[0055] Li 4 Ti 5 o 12 The spinel structure with defects can be written as Li[Li 1 / 3 Ti 5 / 3 ]O 4 . Li 4 Ti 5 o 12 With a three-dimensional diffusion channel for lithium ions, although the electronic conductivity is poor, it has a good Li + Ionic conductivity, exotic Li + The ions are embedded in the spinel structure, and the diffusion in the ion channel is carried out by vacancy transition or ion interstitial hopping. With Li + With the increase of ion intercalation, Li 4 Ti 5 o 12 gradually transforms from insulator to Li with good conductivity 7 Ti 5 o 12 , which can be written as Li 2 [Li 1 / 3 Ti 5 / 3 ]O 4 . Li 2 [Li 1 / 3 Ti 5 / 3 ]O 4 The electrical conductivity is good, the conductivity is about 10 -2 S / cm.

[0056] When the lithium flow battery reactor is working, Li 4 Ti 5 o 12 The electrode...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com