Method for making lithium aluminide compound with high lithium content

a lithium aluminide and compound technology, applied in the direction of electrolysis process, electrolysis components, etc., can solve the problems of insufficient lithium aluminide compound preparation, limited application of lithium aluminide compound, high energy consumption and time of ball grinding method, etc., to achieve the effect of reducing the danger of conventional processes and the cost of storage and transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

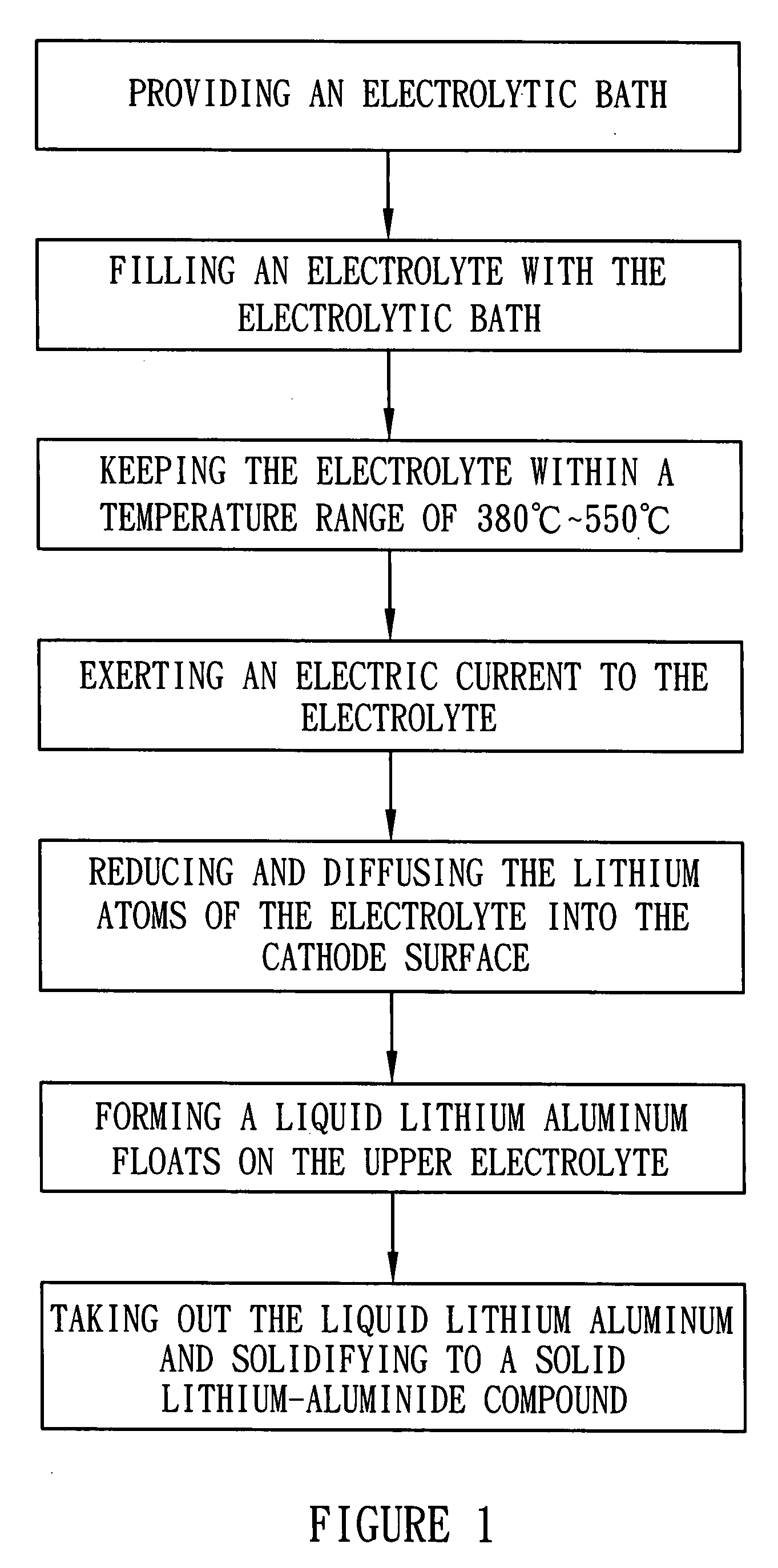

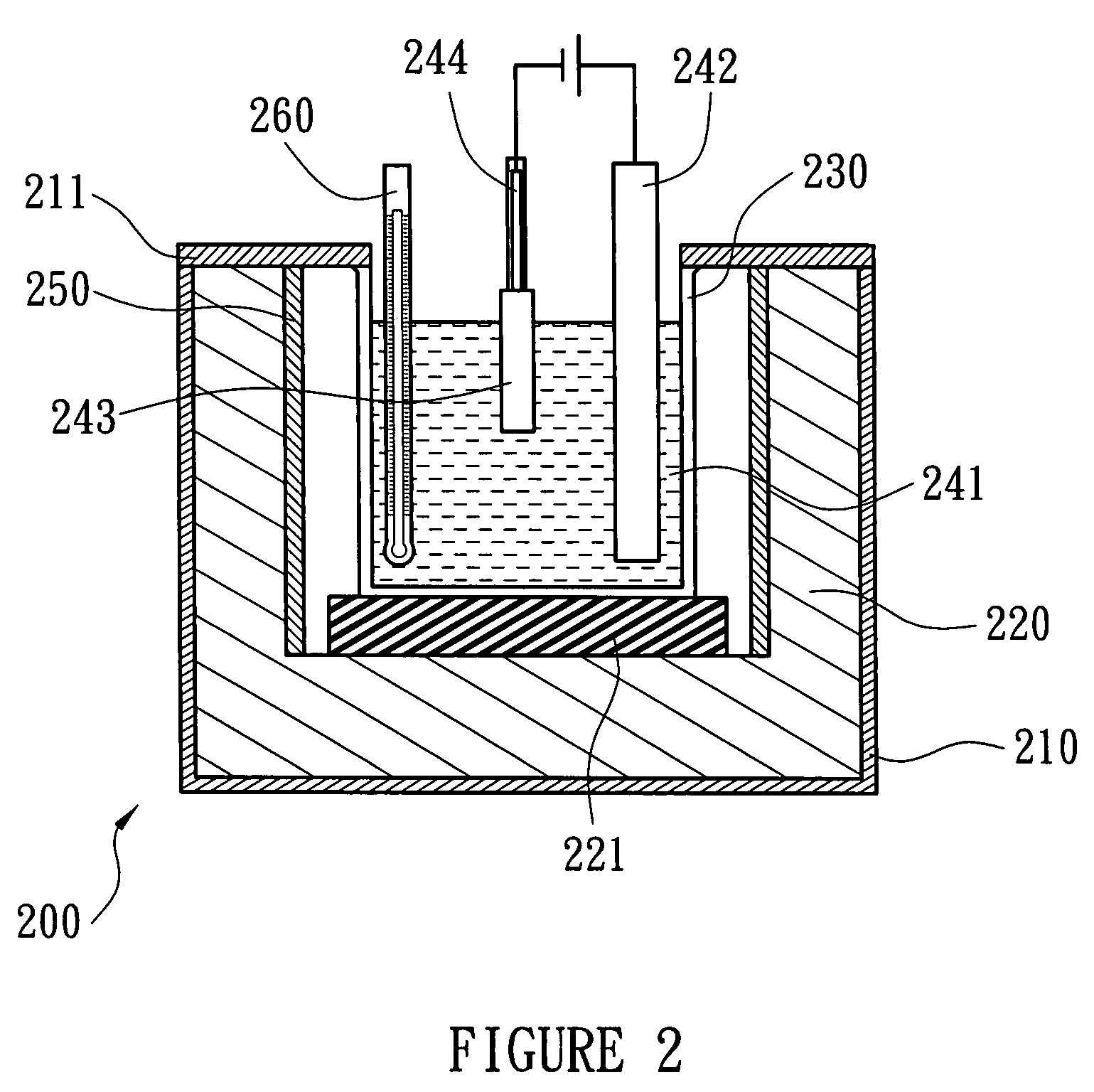

[0018]Reference will now be made in detail to the present embodiments of the invention, examples of which are illustrated in the accompanying drawings. Wherever possible, the same reference numbers are used in the drawings and the description to refer to the same or like parts.

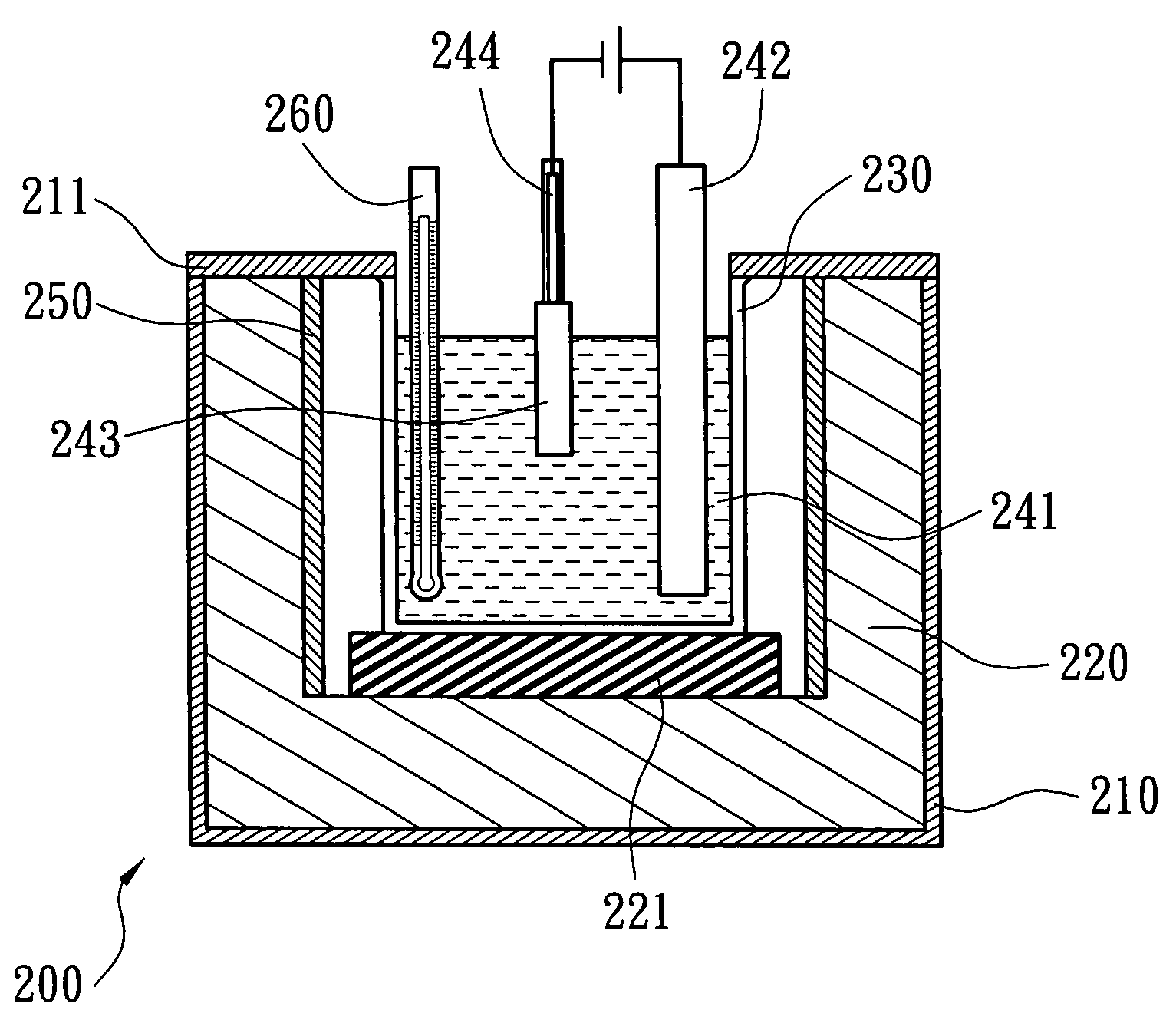

[0019]Refer to FIG. 1. FIG. 1 is a flowchart of steps in accordance with an embodiment of the present invention. The steps of the embodiment include providing an electrolytic bath with an electrolyte and the temperature of the electrolyte is kept within a range of 380° C.˜550° C.; and exerting an electric current with current density of 0.08 A˜0.1 A per unit area of cathode surface (cm2) to the electrolyte to perform a diffusive electrolysis. The lithium ions of the electrolyte are reduced into lithium atoms and diffused into the aluminum cathode. The lithium content of the aluminum cathode is increased with diffusive electrolysis and forms liquid lithium aluminide floated on the upper of the electrolyte. Fina...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com