Comprehensive recovery method of waste lithium manganate and lithium iron phosphate positive electrode material

A lithium iron phosphate and recovery method technology, which is applied in the field of comprehensive recovery of waste lithium manganese oxide and lithium iron phosphate positive electrode materials to prepare battery-grade lithium carbonate, can solve the problems of simple process, high comprehensive recovery rate, difficult control of process conditions, and energy utilization. High efficiency and other problems, to achieve the effect of simple production process and conditions, suitable for popularization and use, and high energy utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

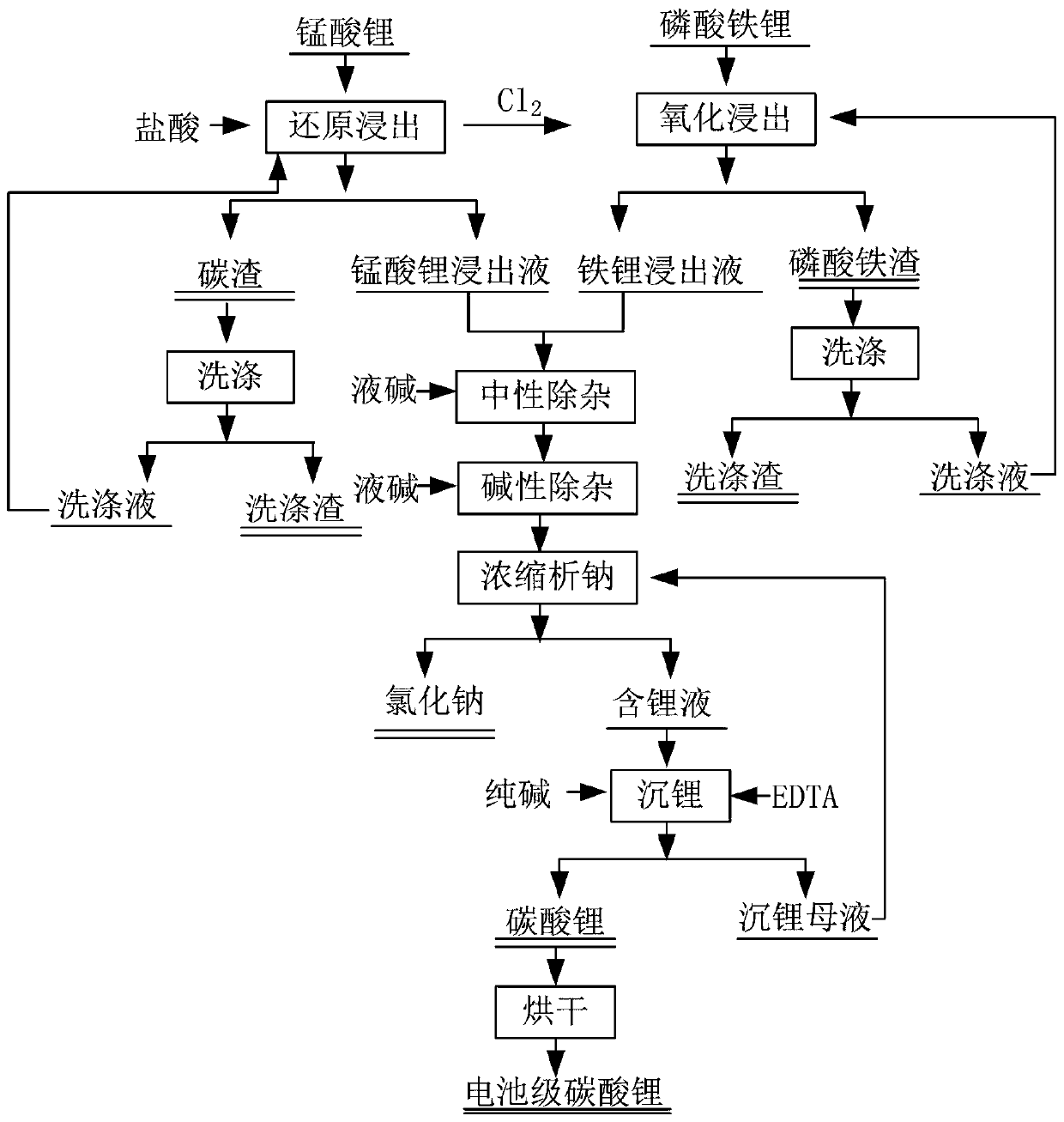

[0061] This specific embodiment is to comprehensively recycle the lithium manganate and lithium iron phosphate positive electrode materials obtained by physical dismantling and recycling of different types of waste lithium batteries. The general steps can be seen in the appendix figure 1 , figure 1 It is a process flow chart, and the specific steps are:

[0062] (1) Lithium iron phosphate powder mixing: put 100Kg of lithium iron phosphate powder (Li: 4.0%) in a sealed stirring reactor a, add water to make slurry, the liquid-solid ratio is 3:1, and start stirring.

[0063] (2) Reductive leaching of lithium manganate: put 38Kg of lithium manganate (Li: 3.5%) in a closed reaction kettle b, add water to adjust the slurry until the liquid-solid ratio is 1:1, start stirring to adjust the slurry, and then slowly add 31% Concentrated hydrochloric acid, the amount of hydrochloric acid added is: the total molar ratio of concentrated hydrochloric acid to lithium manganate is 8:1, with t...

Embodiment 2

[0073] This specific embodiment is to comprehensively recycle the lithium manganate and lithium iron phosphate positive electrode materials obtained by physical dismantling and recycling of different types of waste lithium batteries. The general steps can be seen in the appendix figure 1 , figure 1 It is a process flow chart, and the specific steps are:

[0074] (1) Lithium iron phosphate powder mixing: put 100Kg of lithium iron phosphate powder (Li: 3.8%) in a sealed stirring reactor a, add water to make slurry, the liquid-solid ratio is 2:1, and start stirring.

[0075] (2) Reductive leaching of lithium manganate: put 40Kg of lithium manganate (Li: 3.7%) in a closed reaction kettle b, add water to adjust the slurry until the liquid-solid ratio is 1:1, start stirring to adjust the slurry, and then slowly add 25% Concentrated hydrochloric acid, the amount of hydrochloric acid added is: the total molar ratio of concentrated hydrochloric acid to lithium manganate is 9:1, with t...

Embodiment 3

[0085] This specific embodiment is to comprehensively recycle the lithium manganate and lithium iron phosphate positive electrode materials obtained by physical dismantling and recycling of different types of waste lithium batteries. The general steps can be seen in the appendix figure 1 , figure 1 It is a process flow chart, and the specific steps are:

[0086] (1) Lithium iron phosphate powder mixing: put 100Kg of lithium iron phosphate powder (Li: 3.65%) in a sealed stirring reactor a, add water to make slurry, the liquid-solid ratio is 4:1, and start stirring.

[0087] (2) Reductive leaching of lithium manganate: put 50Kg of lithium manganate (Li: 3.3%) in a closed reaction kettle b, add water to adjust the slurry until the liquid-solid ratio is 3:1, start stirring to adjust the slurry, and then slowly add 20% Concentrated hydrochloric acid, the amount of hydrochloric acid added is: the total molar ratio of concentrated hydrochloric acid to lithium manganate is 10:1, with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com