Diffusion pump oil synthesis method

A synthesis method and technology of diffusion pump oil, applied in the direction of silicon organic compounds, etc., can solve the problems of difficulty in rectification separation, high energy consumption, low product purity, etc., and achieve the effect of reducing purification energy consumption and energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

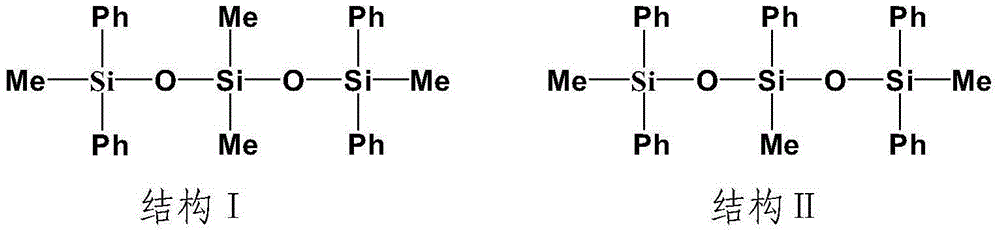

[0064] Example 1: Synthesis of 274 diffusion pump oil

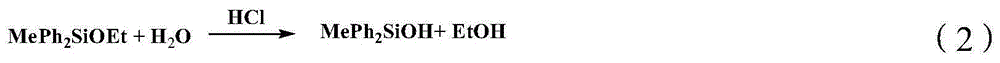

[0065] This embodiment is the synthesis of 274 diffusion pump oil, which specifically includes the following steps:

[0066] (1) Prepare liquid A with 150ml of absolute ethanol, 54g of distilled water (3mol) and 2 drops of concentrated hydrochloric acid (concentration of 36.5 to 37.5%) and add them to a 250ml constant pressure dropping funnel for later use.

[0067] Add 1283.8g of methyltriethoxysilane (7.2mol) into a 2000ml three-necked flask, stir and slowly drop A liquid under cooling in an ice-water bath, and continue to react in an ice-water bath for 2 hours after dripping for 3 hours. Finally, the reaction product is distilled to 90°C to remove most of the ethanol, and the temperature is reduced to 60°C, and then the remaining ethanol and excess methyltriethoxysilane are removed by distillation under reduced pressure. The temperature of the solution reaches 120°C, the vacuum degree is -0.095MPa, and the solution is mainta...

Embodiment 2

[0073] Example 2: Synthesis of 274 diffusion pump oil

[0074] The difference between this embodiment and embodiment 1 is that 1123.3 g of methyltriethoxysilane (6.3 mol) is added in step (1), and the yield is 85% based on methyltriethoxysilane.

Embodiment 3

[0075] Example 3: Synthesis of 274 diffusion pump oil

[0076] The difference between this embodiment and embodiment 1 is that 2139.6 g of methyltriethoxysilane (12 mol) is added in step (1), and the yield is 51% based on methyltriethoxysilane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com