Patents

Literature

48results about How to "Reduce purification energy consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

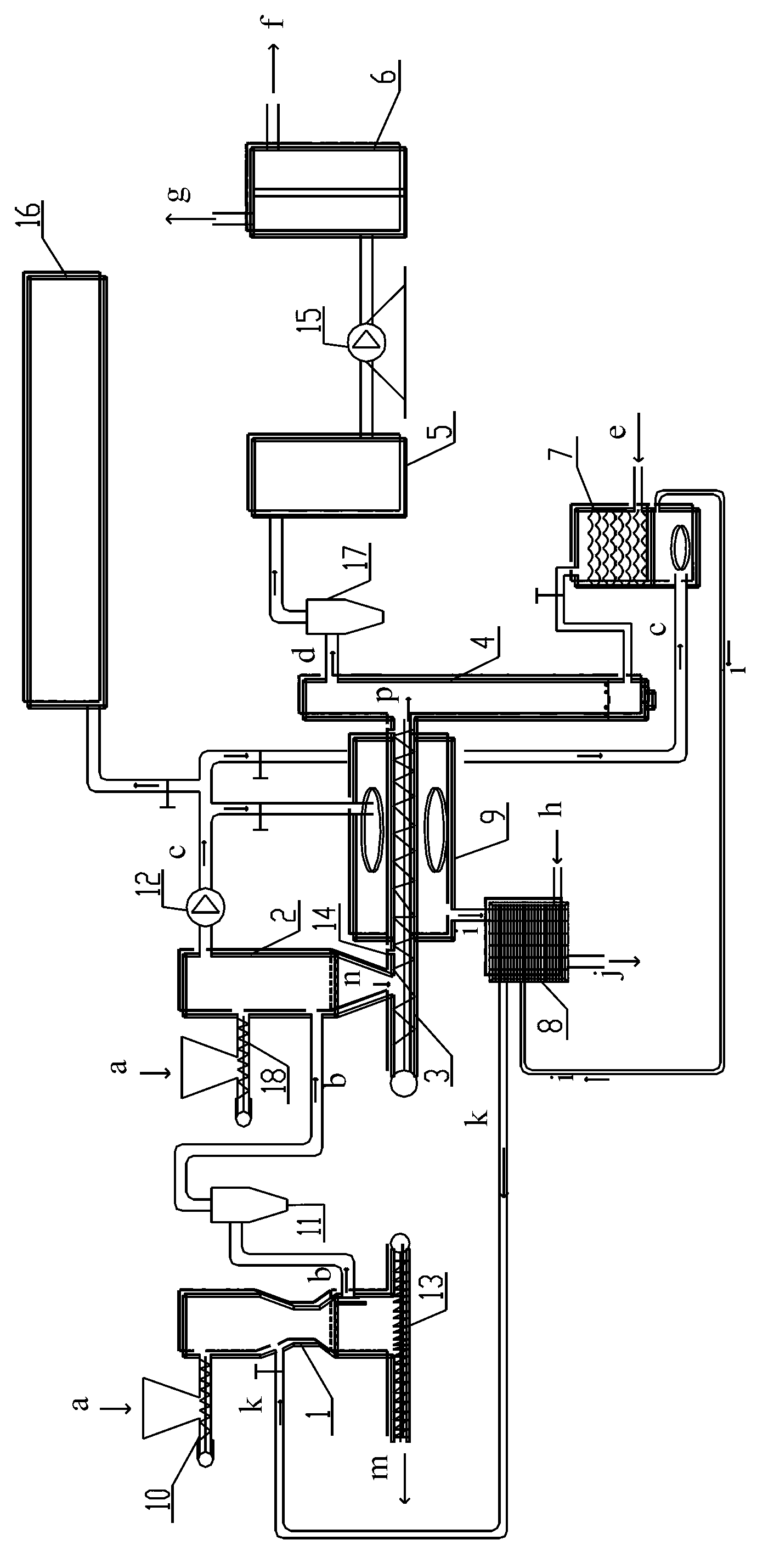

Method and device for preparing high-purity hydrogen from biomass

InactiveCN103011072ARapid responseHigh reactivityHydrogen separationDirect heating destructive distillationThermal energyCarbonization

The invention discloses a method and a device for preparing high-purity hydrogen from biomass. A thermal chemical hydrogen preparation process of biomass is divided into three steps, namely biomass gasification, step-by-step biomass carbonization and water-charcoal reaction. The combustible gas generated by biomass gasification provides heat energy required by the whole production line, and electricity is generated by gas to provide electric energy required by all power equipment, so that biomass is the only energy source of the whole process and ensures zero consumption of external power. The step-by-step biomass carbonization process overcomes the defects of low yield and low biomass charcoal reaction activity of the conventional carbonization process, and greatly improves the reaction activity of the biomass charcoal while ensuring a high yield of biomass charcoal by coupling a slow low-temperature carbonization reaction and a fast high-temperature carbonization reaction; therefore, the water-charcoal reaction is accelerated and the energy consumption in the water-charcoal reaction process is reduced. The content of hydrogen of the generated primary hydrogen-rich gas is over 85%, and can even be more than or equal to 99.99% after purification of a hydrogen purification device.

Owner:TIANJIN UNIV

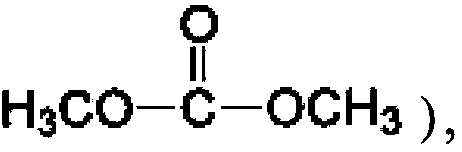

Method for simultaneously producing dimethyl carbonate and dimethyl ether through urea alcoholysis process, catalyst used thereby, and preparation method of catalyst

InactiveCN103623802ASimple structureOperating conditions are easy to controlOrganic compound preparationMetal/metal-oxides/metal-hydroxide catalystsMethyl carbamateAlkali metal oxide

The invention provides a method for simultaneously producing dimethyl carbonate and dimethyl ether through a urea alcoholysis process, a catalyst used thereby, and a preparation method of the catalyst. The method for simultaneously producing dimethyl carbonate and dimethyl ether through a urea alcoholysis process adopts a two-stage slurry bed reactor or fixed bed reactor technology, and in the preparation process, when dimethyl carbonate and dimethyl ether are prepared from methyl carbamate and methanol in a second-stage fixed bed reactor, a multi-component composite oxide catalyst using one or more of transition metal oxides, rare earth oxides, alkali metal oxides, alkaline earth oxides, IVA group metal oxides, VA group non-metal oxides or IIIA group non-metal oxides and Al2O3 as active components is filled into the fixed bed reactor, so the methyl carbamate conversion rate is improved, and the dimethyl carbonate and dimethyl ether selectivity is substantially improved.

Owner:YASHENTECH CORP

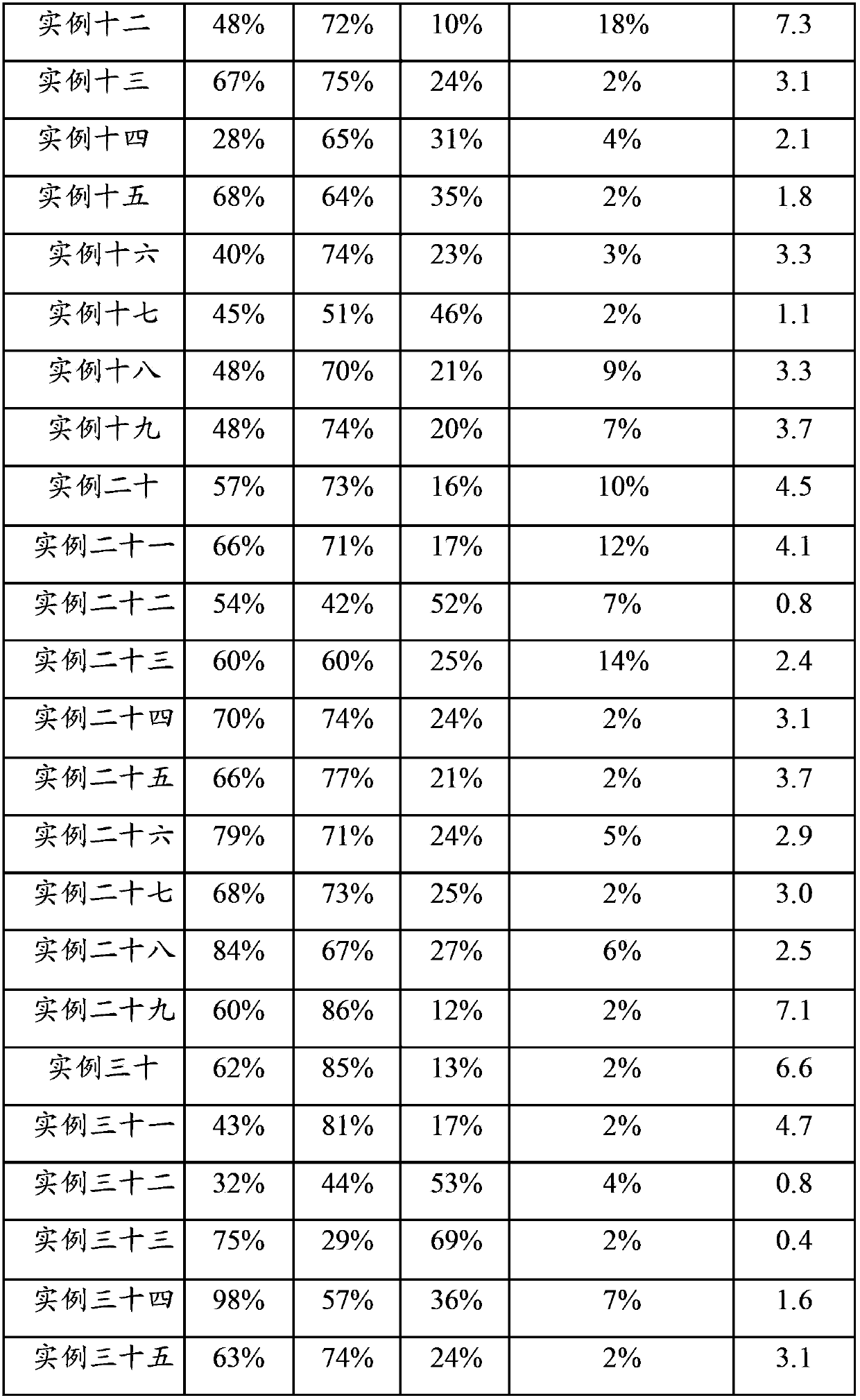

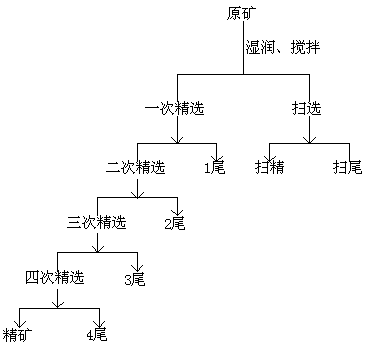

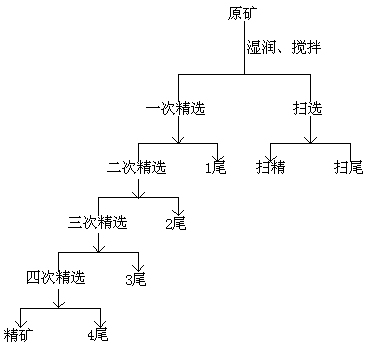

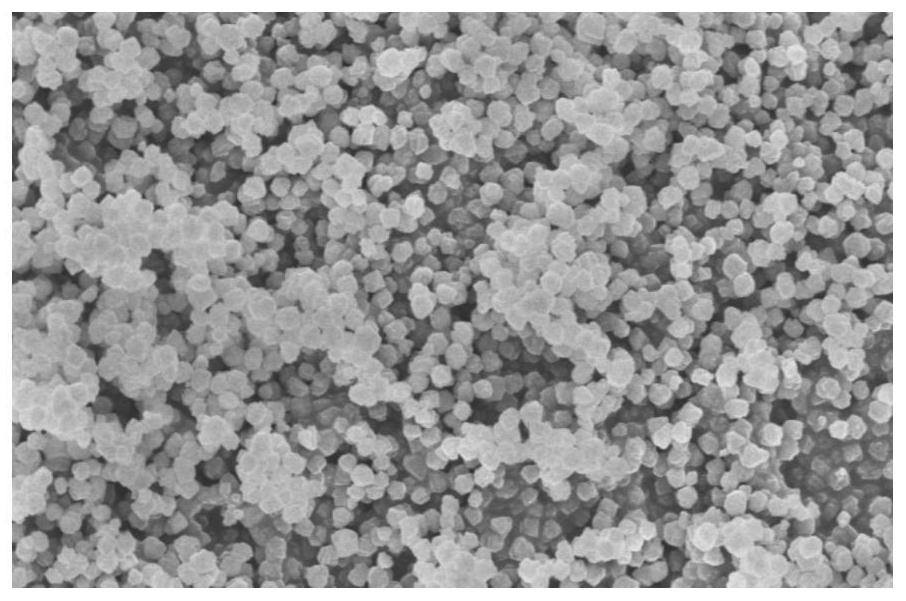

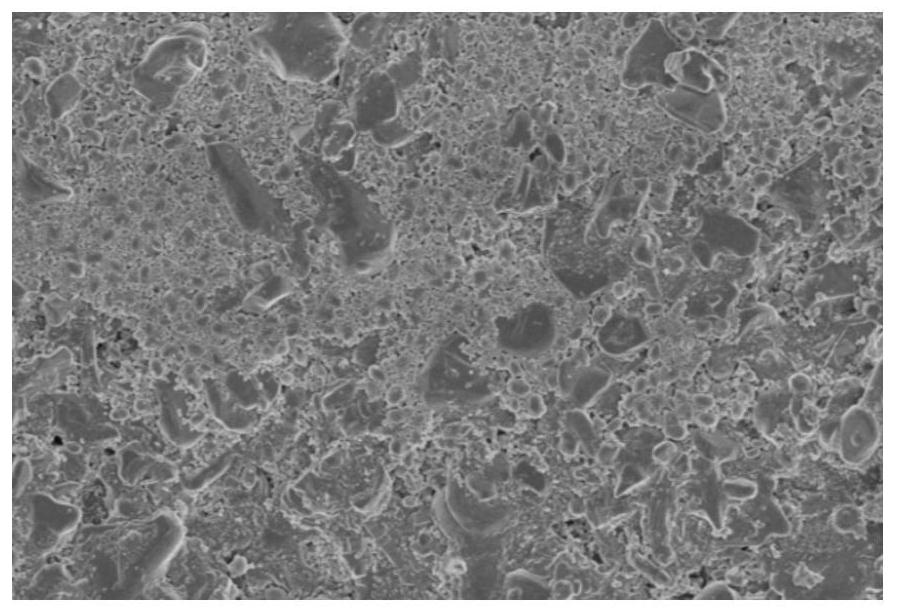

A process for preparing high-purity microcrystalline graphite with low energy consumption and in a large scale, and the high-purity microcrystalline graphite

InactiveCN107555426ALarge specific surface areaHigh purityCarbon compoundsPurification methodsGraphite

The invention relates to the technical field of microcrystalline graphite purification, and discloses a process for preparing high-purity microcrystalline graphite with low energy consumption and in alarge scale, and the high-purity microcrystalline graphite. According to the process, microcrystalline graphite raw ore is firstly crushed and ground, and flotation including one time of roughing, four times of cleaning and one time of scavenging is performed in match to increase the purity of the raw ore to the utmost through a physical method; an improved acid leaching purification method is adopted, the alkali leaching efficiency is increased, energy consumption is reduced, and the graphite recovery yield is increased; and finally a high-temperature purification method adopting a step-by-step heating manner is utilized to further reduce energy consumption for graphite purification, and the high-purity microcrystalline graphite the fixed carbon content of which is 99.993% or above can be finally obtained. The process overcomes a problem that microcrystalline graphite in the prior art is not high in purity, high in energy consumption and high in cost. Through improvements on the prior art, the process achieves an objective of reducing energy consumption and the cost, and achieves industrial production.

Owner:HUNAN GUOSHENG GRAPHITE TECH CO LTD

A method for producing anhydrous hydrogen fluoride and silicon tetrafluoride by utilizing fluosilicic acid

InactiveCN102275877AImprove conversion rateLow costFluorine/hydrogen-fluorideHalogenated silanesSlagHexafluorosilicic acid

The invention discloses a method for producing anhydrous hydrogen fluoride and silicon tetrafluoride by utilizing fluosilicic acid. The method of the invention is specifically to firstly react fluosilicic acid solution with sodium sulfate at normal temperature to obtain sodium fluosilicate and dilute sulfuric acid. Filtration, dilute sulfuric acid is concentrated to make concentrated sulfuric acid, then mixed with filter cake sodium fluorosilicate ointment, added to the pre-reactor, reacted at 50-200 ° C to generate silicon tetrafluoride gas, and the silicon tetrafluoride gas passes through the degassing tower Silicon tetrafluoride products are obtained after treatment; the remaining materials in the pre-reactor are transported to the rotary furnace, and then hydrogen fluoride gas is released in the rotary furnace at 150-350 °C, and the hydrogen fluoride gas is purified to produce anhydrous hydrogen fluoride products. The remaining slag in the rotary kiln is discharged through the furnace tail. The fluosilicic acid solution used in the present invention is derived from the by-products of phosphate fertilizer or anhydrous hydrogen fluoride, the cost of raw materials is low, a new source of fluorine is opened up, and the obtained anhydrous hydrogen fluoride and silicon tetrafluoride products have wide application fields and outstanding economic benefits , high value-added products.

Owner:DO FLUORIDE CHEM CO LTD

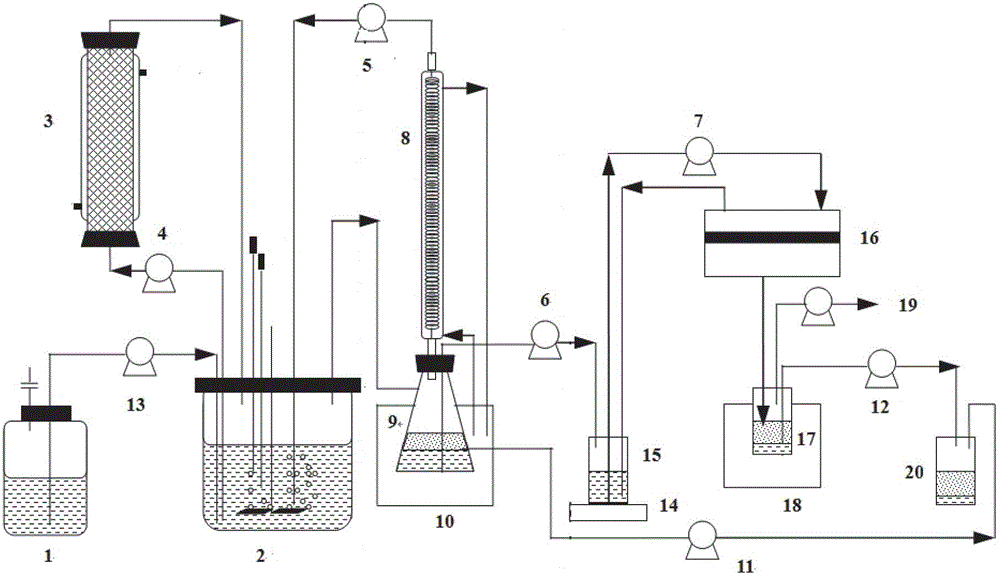

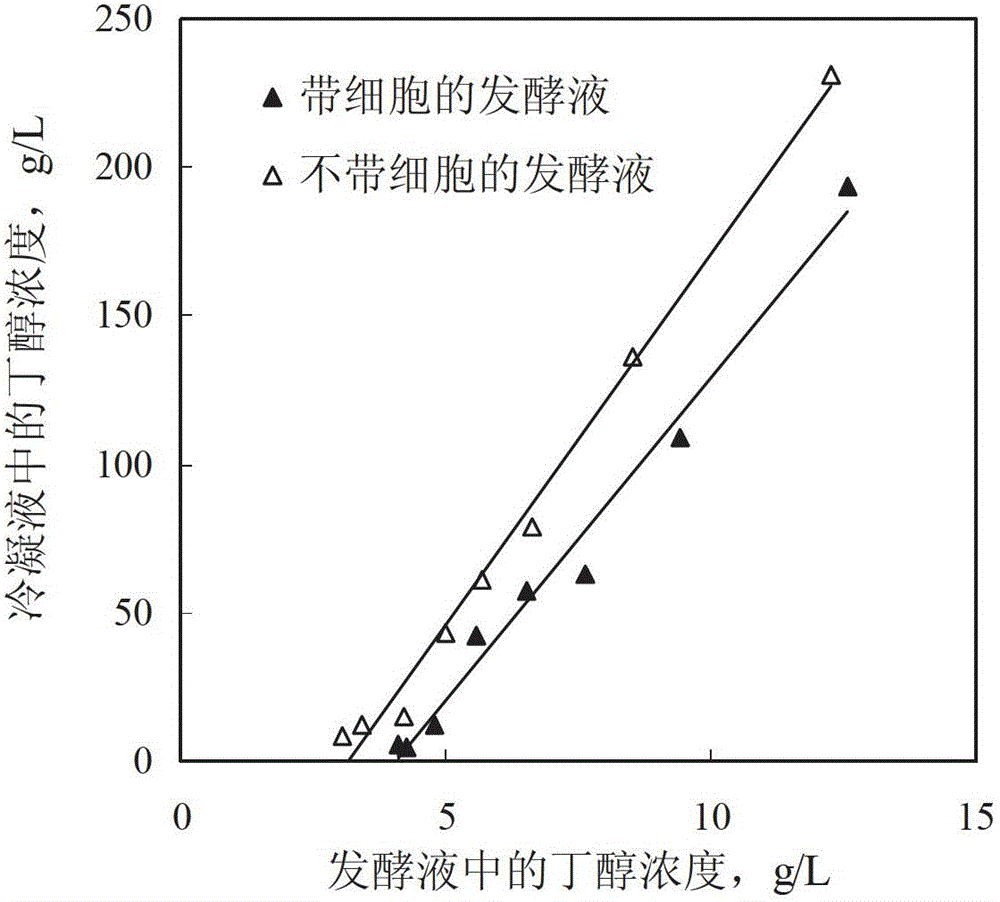

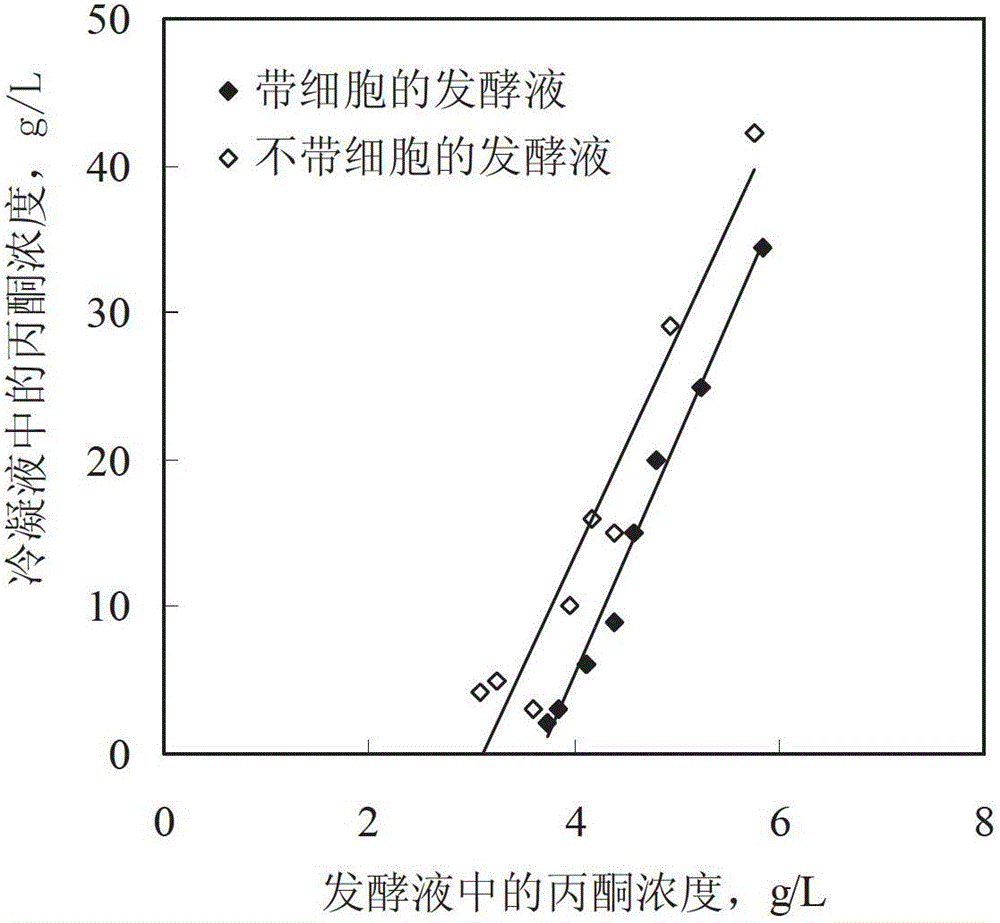

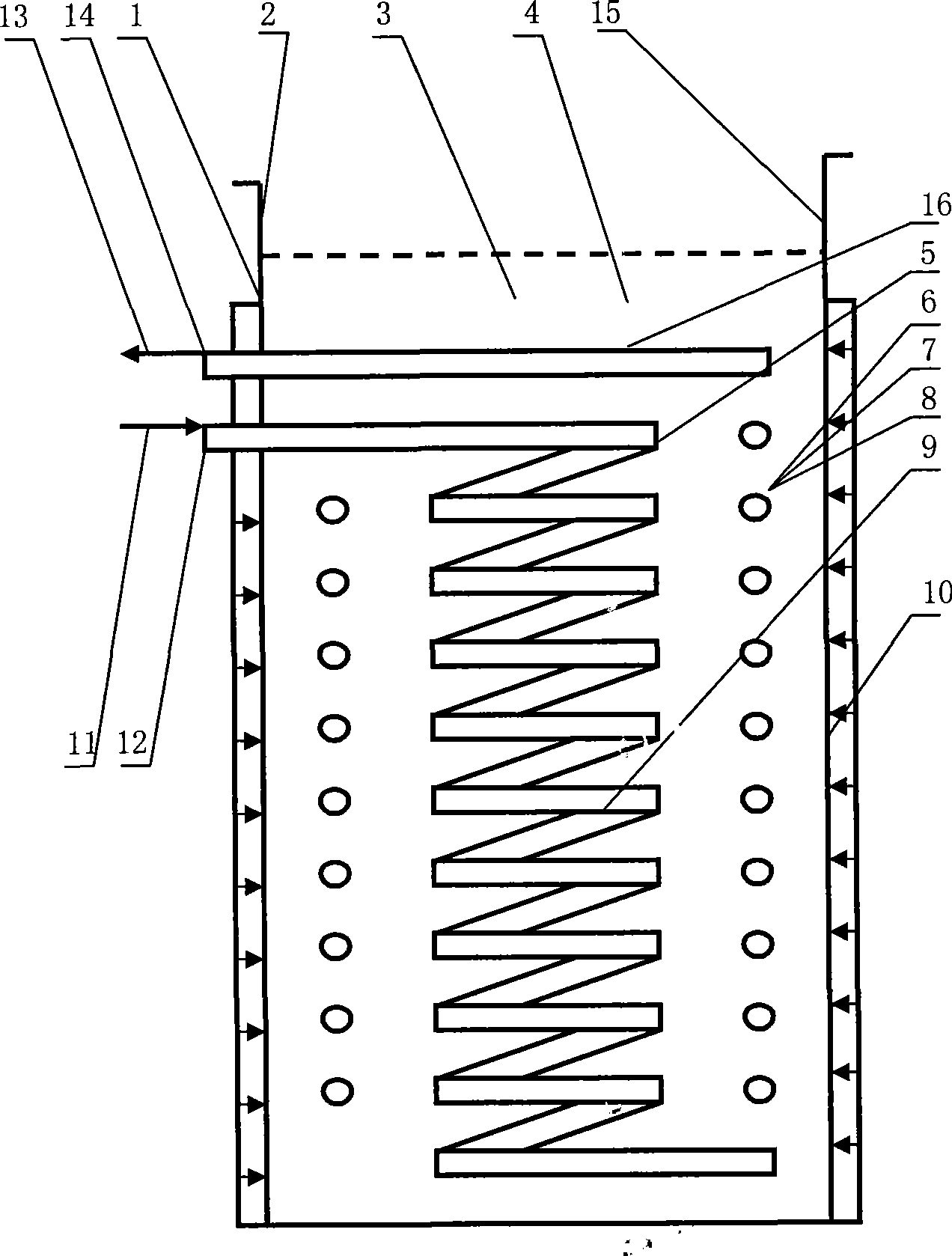

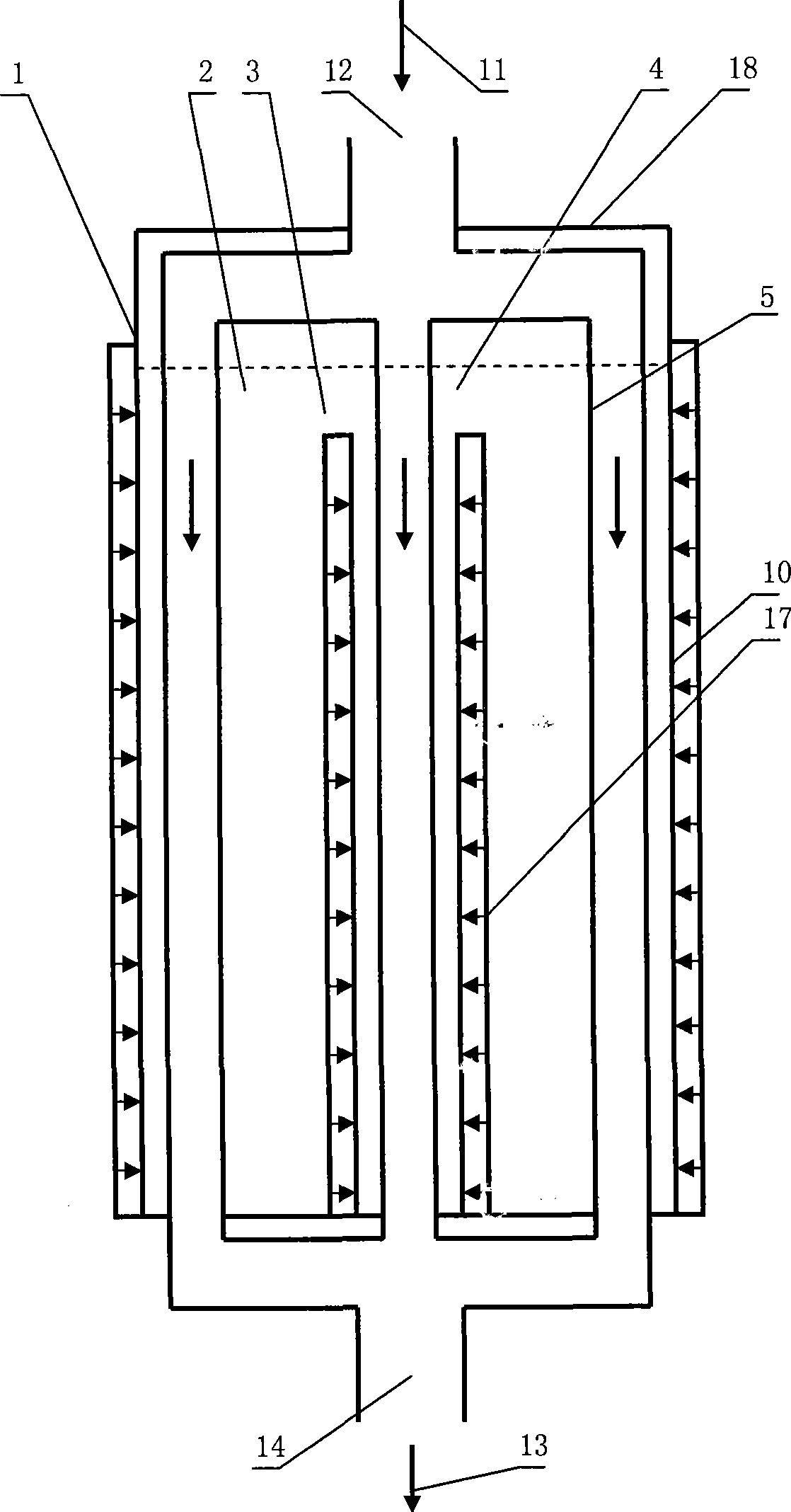

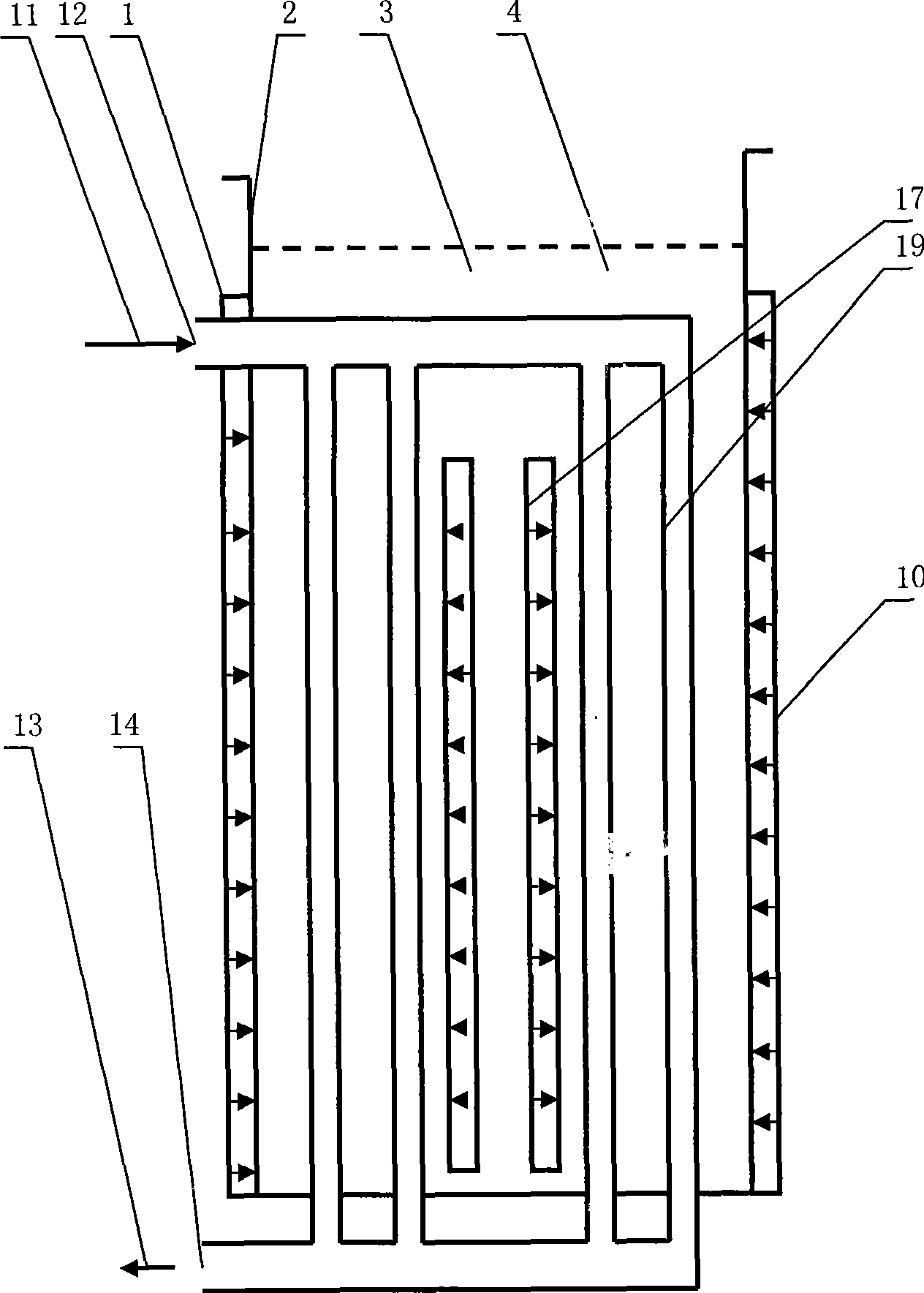

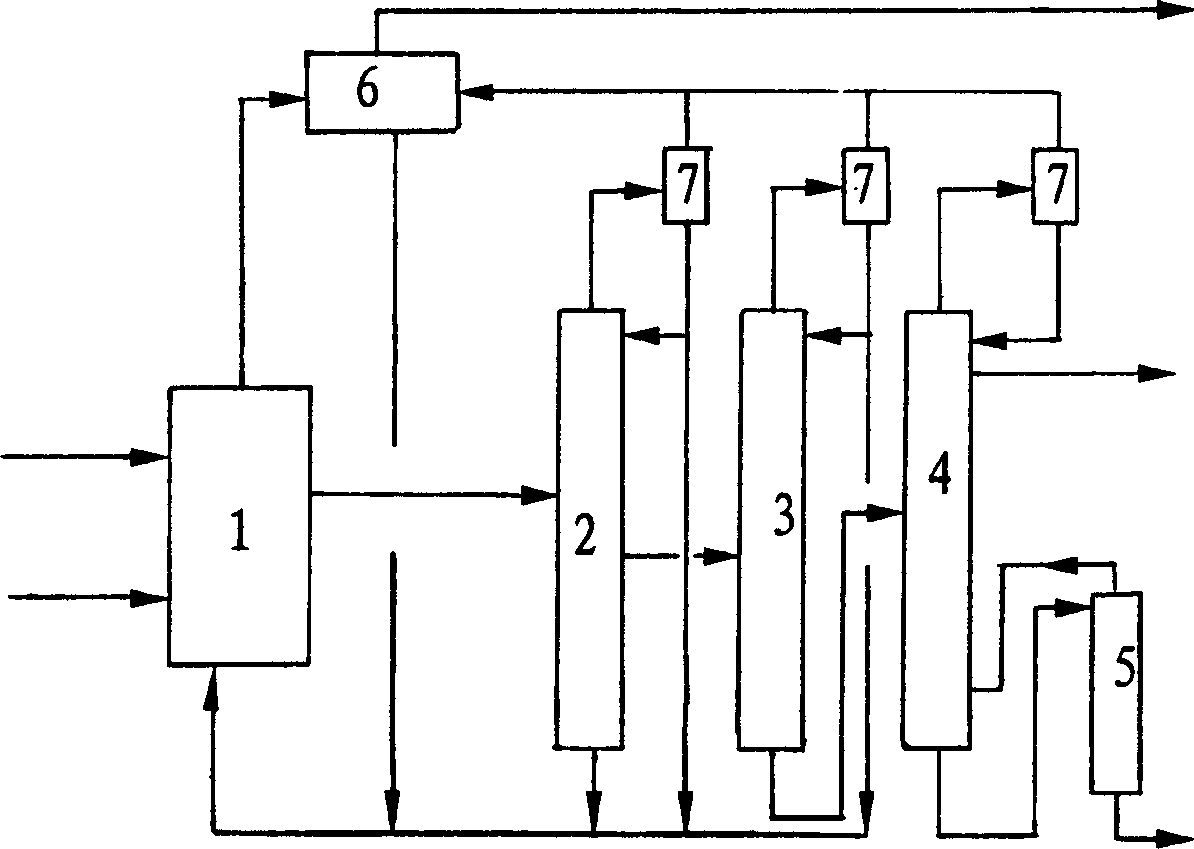

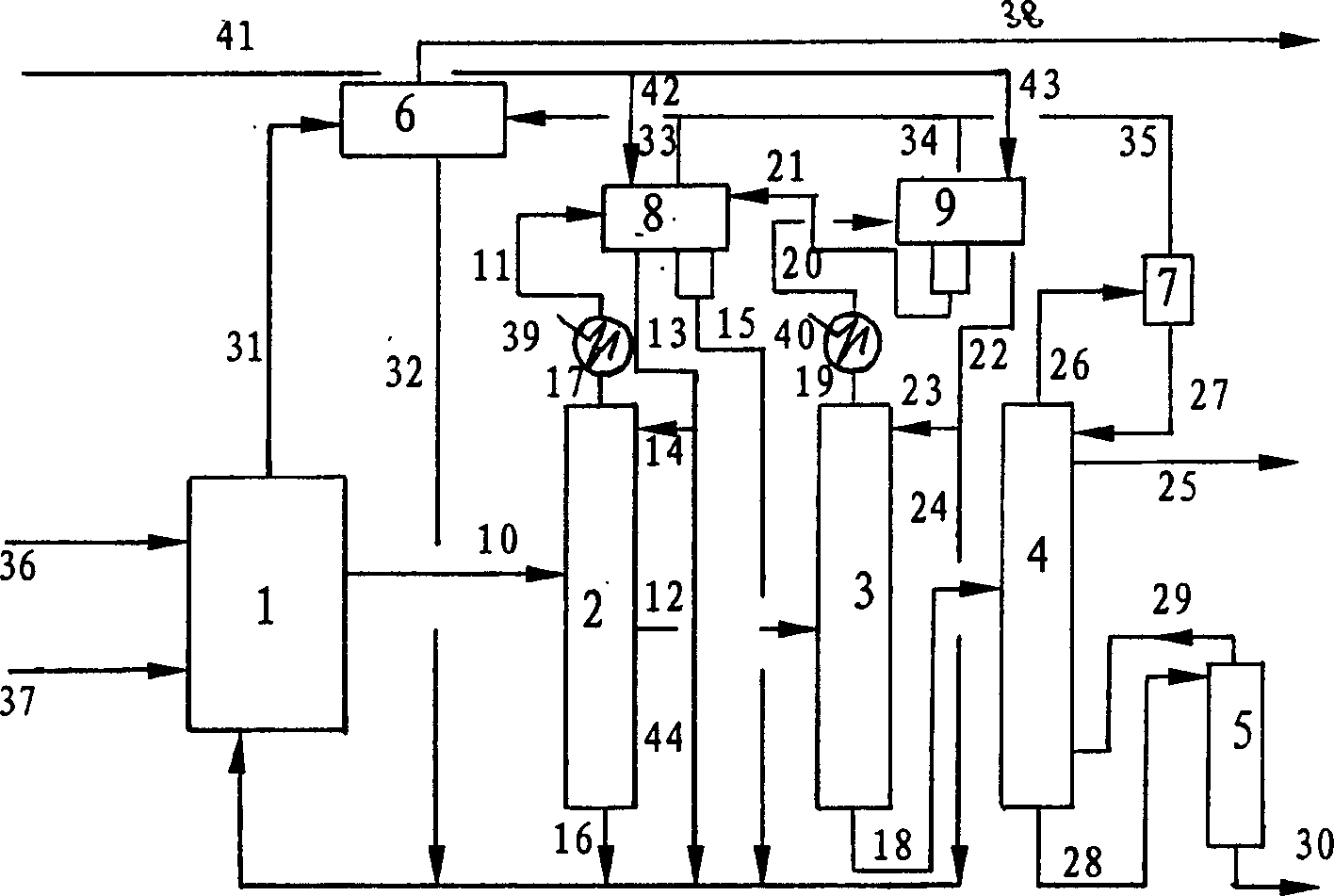

Separation and purification device and separation and purification method for butanol and acetone

ActiveCN102911854AIncrease production capacityImprove efficiencyBioreactor/fermenter combinationsBiological substance pretreatmentsPurification methodsButanol

Disclosed are a separation and purification device and a separation and purification method for butanol and acetone. The separation and purification device comprises a fermentation device and a gas stripping and pervaporation coupling purification device. The separation and purification method implemented by the separation and purification device includes culturing acetone and butanol producing strains at first, and then fermenting the acetone and butanol producing strains to obtain butanol and acetone; performing online separation and purification for the acetone and butanol by gas stripping and pervaporation coupling purification; performing gas stripping for gas generated by the acetone and butanol producing strains during fermentation, filling the gas into a fermentation system to form bubbles, performing gas stripping for the butanol and the acetone in fermentation liquor of the acetone and butanol producing strains, and performing condensation gas stripping by a condensing plant to obtain butanol and acetone; purifying the butanol and the acetone by pervaporation membranes; and recycling permeate of the pervaporation membranes in a condensing mode or directly filling the permeate into a next-stage separation device. Raw material liquid used in the pervaporation process is lower-layer water-phase condensate obtained by gas stripping. The separation and purification device and the separation and purification method have the advantages that the butanol and acetone separation and purification efficiency is effectively improved, and novel technical support is provided for separating and purifying butanol, acetone and products of the butanol and the acetone which are produced by existing biological methods.

Owner:DALIAN UNIV OF TECH

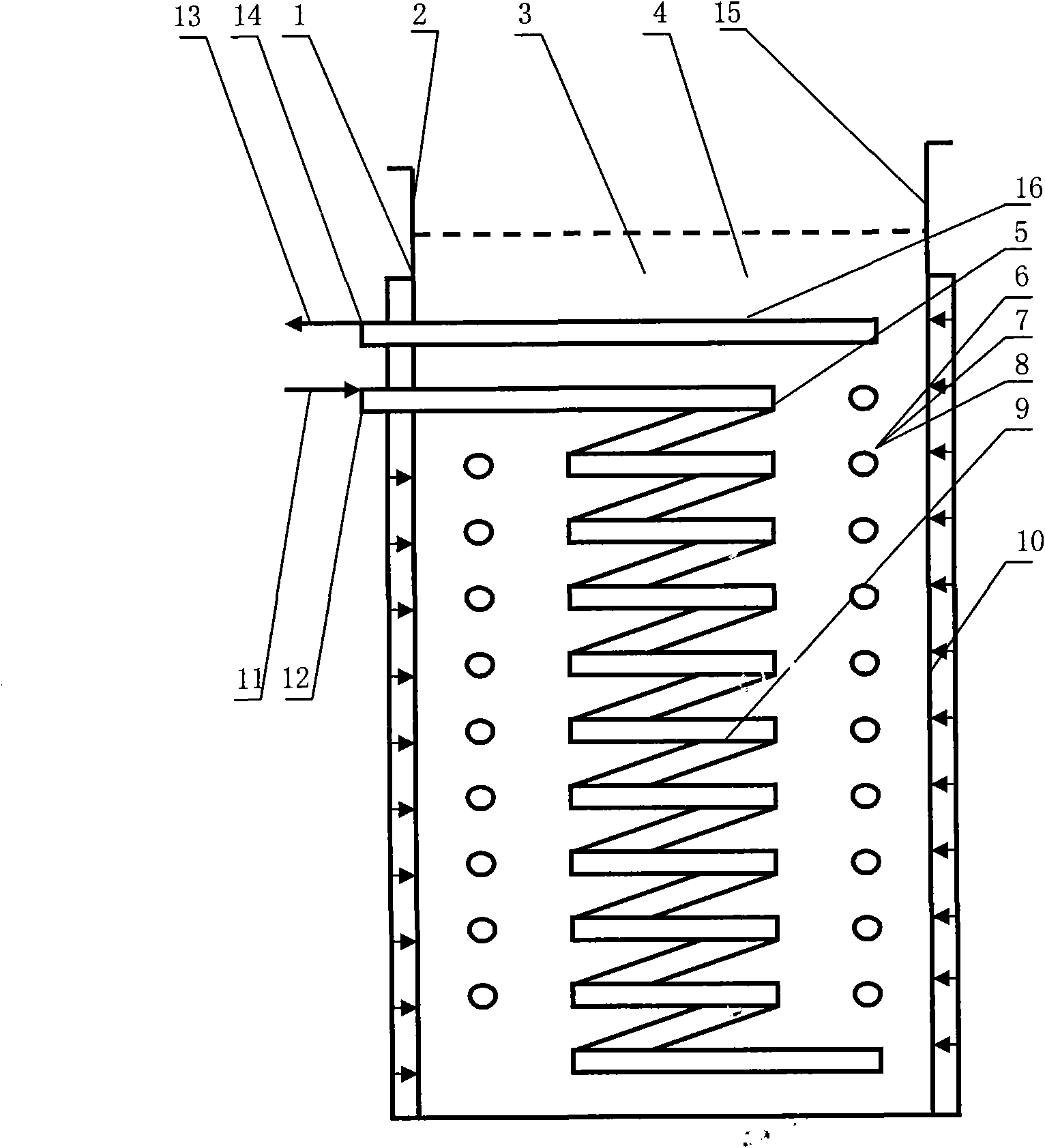

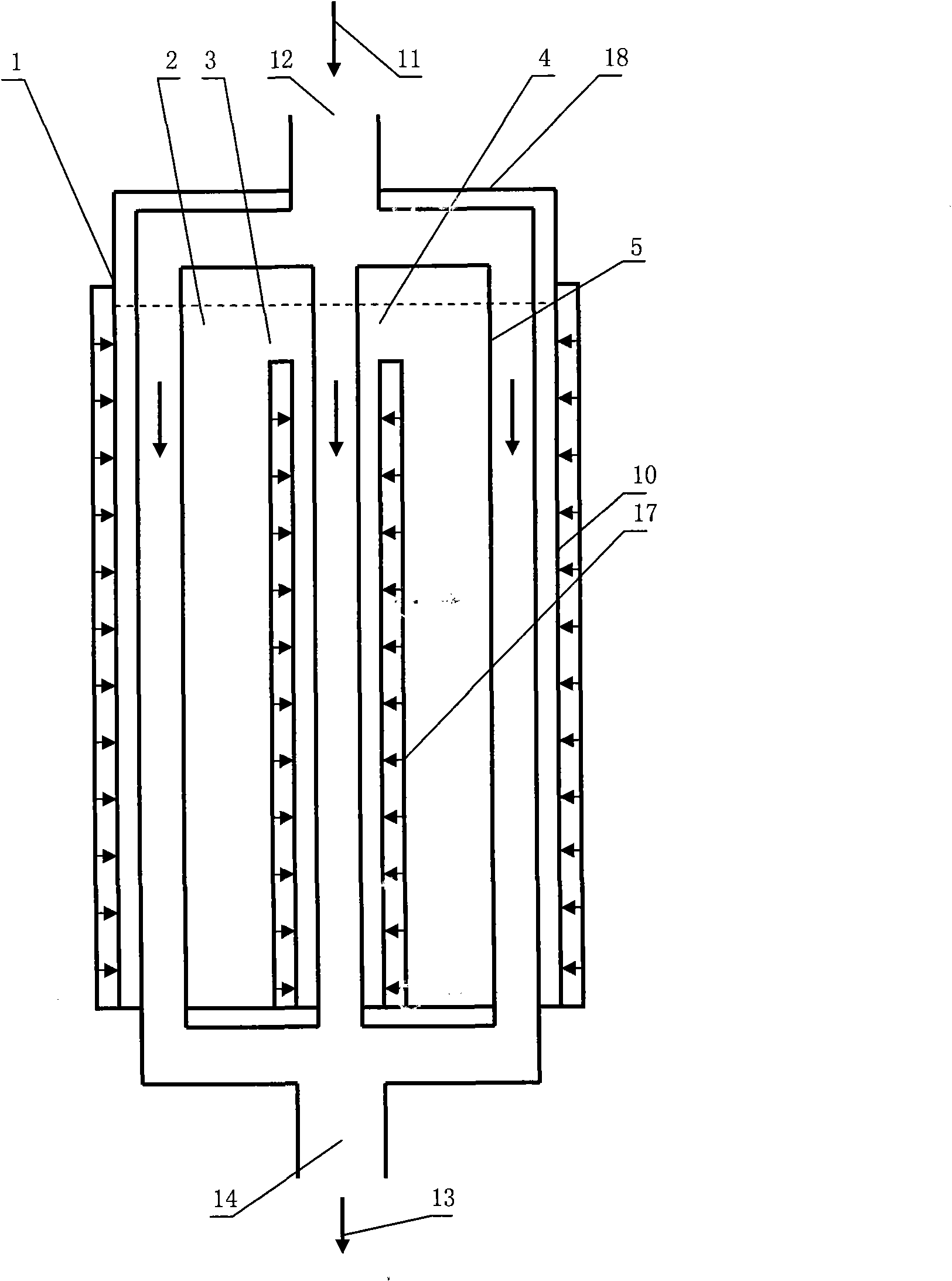

Tubular purification method and tubular purification tank

InactiveCN101476038ASmall volumeReduce in quantityProcess efficiency improvementLiquid mediumPurification methods

The invention provides a pipe type purifying method, the set purifying process of the solution to be purified is completed in a nonconservative pipe type purifying groove.The solution to be purified is a solution containing at least one granular solute; the pipe type purifying groove comprises a cavity full of liquid medium, at least one ultrasound wave source apparatus immersed in the liquid medium and at least one coiled apparatus full of the solution to be purified; the purifying process is that in the nonconservative flow process, the solution to be purified is irradiated in a insulation state by effective ultrasonic wave.

Owner:佛山市兴民科技有限公司

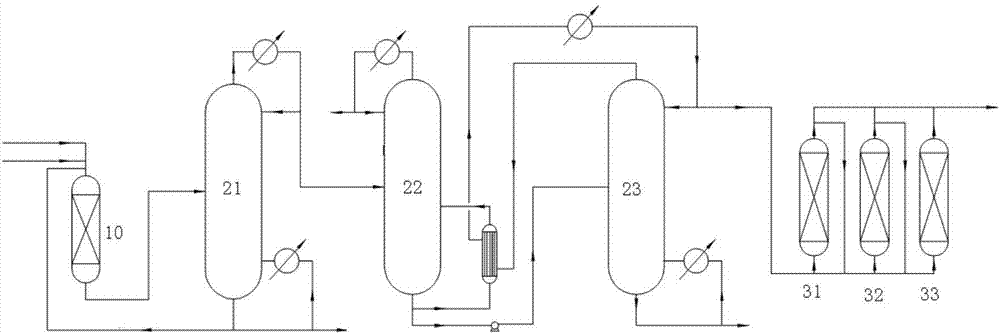

Electronic grade hexachlorodisilane extraction and purification method and electronic grade hexachlorodisilane extraction and rectification system

ActiveCN108358209ASeparation difficulty coefficient is smallReduce energy consumptionTitanium tetrachlorideHalogenated silanesHigh densityPurification methods

The invention discloses an electronic grade hexachlorodisilane extraction and purification method and an electronic grade hexachlorodisilane extraction and rectification system. Purified electronic grade hexachlorodisilane includes 3N, 4N and 5N grades; extraction, rectification and purification are carried out by a low-density extracting agent A and a high-density extracting agent B; specifically, the steps of removing low-boiling point impurities in hexachlorodisilane, removing low-density impurities in hexachlorodisilane, removing extracting agent A impurities in hexachlorodisilane, removing high-boiling point impurities in hexachlorodisilane, removing high-density impurities in hexachlorodisilane, removing extracting agent B impurities in hexachlorodisilane and outputting electronic grade hexachlorodisilane are conducted, and the extracting agents are rectified and recovered, so that the extracting agent A and the extracting agent B are obtained. Compared with the conventional rectification and adsorption process, the extraction and rectification method disclosed by the invention has the advantages that less energy for purification is consumed, the purification cost is only about 12 to 25 percent of the cost of the conventional rectification method, the quality grade of the product produced with the same energy consumption is high, less loss is caused in the process of purification, and the yield of the purified hexachlorodisilane product is higher.

Owner:李金金

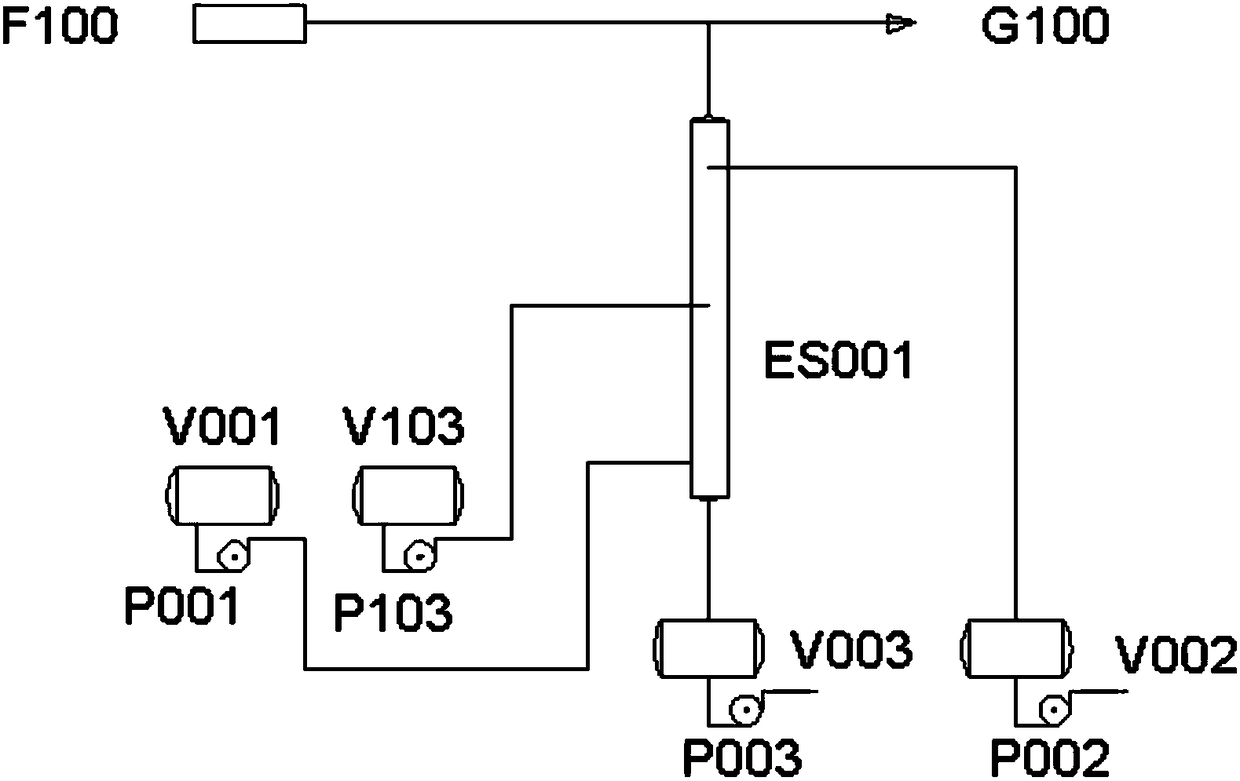

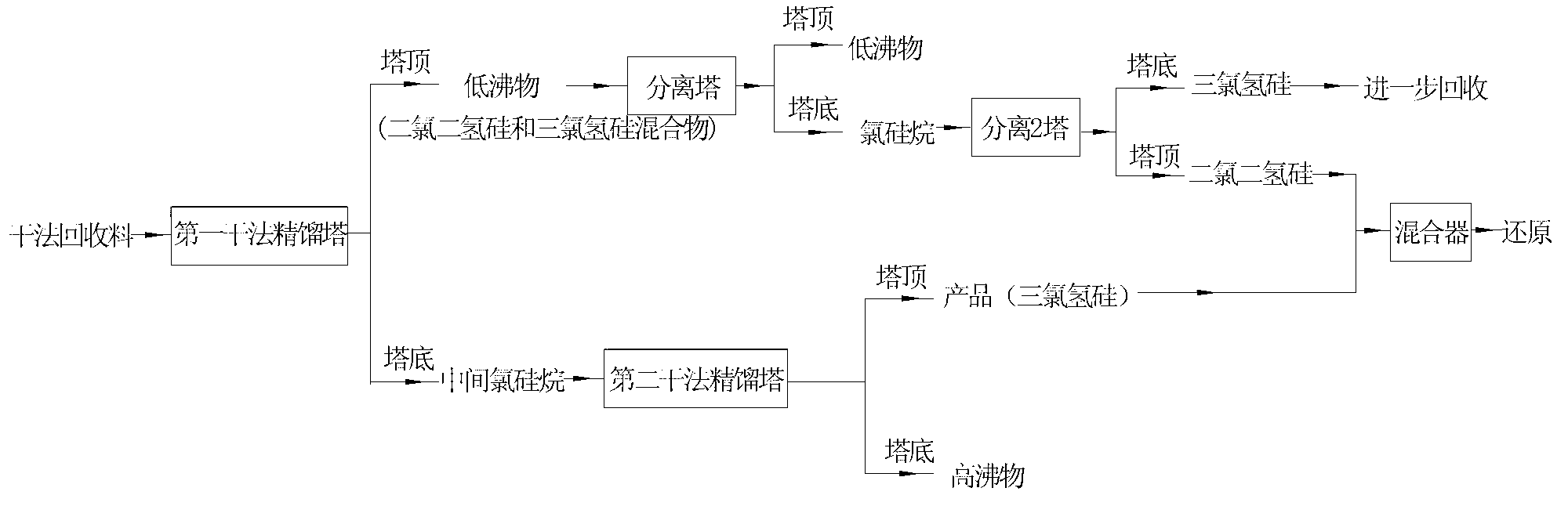

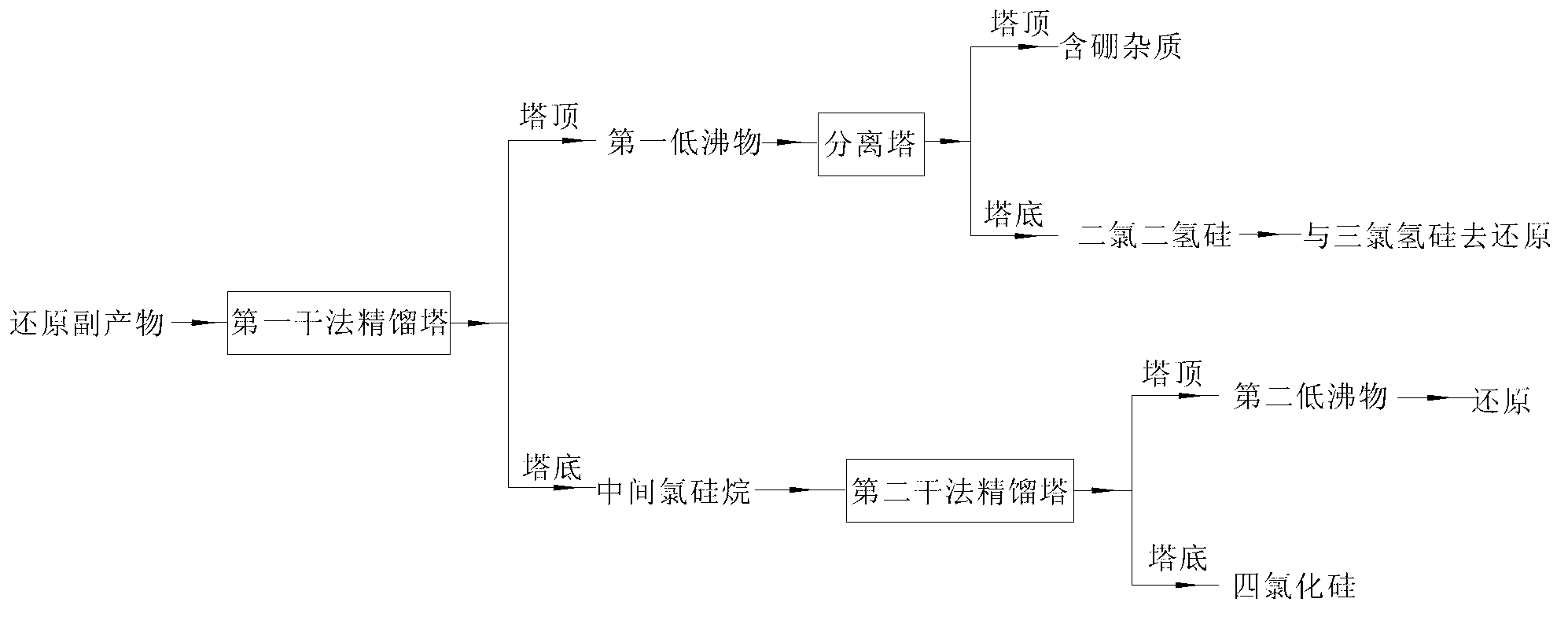

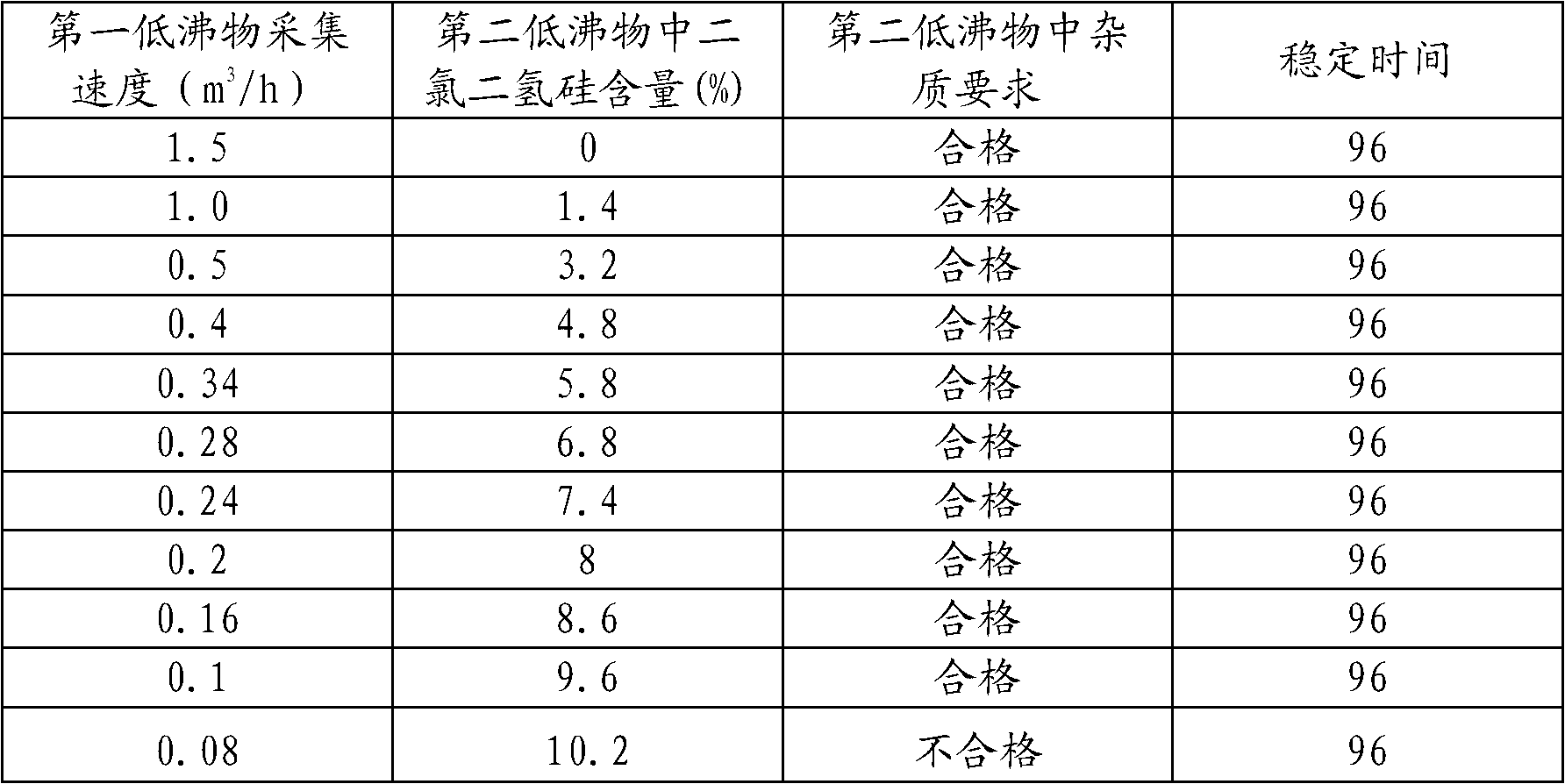

Method for purification of dichlorosilane from dry method recovered material

The invention discloses a method for purification of dichlorosilane from dry method recovered materials, and comprises the following steps of: a) obtaining a dry-method recovered material by recovering from reduction tail gas of the polysilicon production process by a dry method, feeding the recovered material into a first dry method rectifying tower for rectification, recovering a first low-boiling-point substance from the tower top of the first dry method rectifying tower, and recovering intermediate chlorosilane from the tower bottom of the first dry method rectifying tower; b) feeding the first low-boiling-point substance into a separation column for separation, recovering boron impurity from the top of the separation column, and recovering dichlorosilane from the bottom of the separation column; c) feeding the intermediate chlorosilane into a second dry method rectifying tower for rectification, recovering a second low-boiling-point substance from the tower top of the second dry method rectifying tower, and recovering silicon tetrachloride from the tower bottom of the second dry method rectifying tower. According to the method of the invention, the second low-boiling-point substance is a mixture of dichlorosilane and trichlorosilane which can be directly fed into a reducing furnace for reduction reaction, thereby saving the process of mixing the dichlorosilane and the trichlorosilane.

Owner:CHINA ENFI ENGINEERING CORPORATION +1

Process method for co-preparing liquid hydrocyanic acid and sodium cyanide

ActiveCN104724724AReduce purification energy consumptionIncrease profitAlkali metal cyanidesHydrogen cyanide preparation/purification/separationAqueous sodium hydroxideSodium cyanide

The invention discloses a process method for co-preparing liquid hydrocyanic acid and sodium cyanide. The process method is characterized by comprising the following step: performing an ammonia removal procedure and a deep cooling procedure on light oil cracking hydrocyanic acid mixed gas which is taken as a raw material, so as to obtain the liquid hydrocyanic acid, wherein the ammonia removal procedure comprises the specific steps of absorbing the hydrocyanic acid mixed gas by sulphuric acid aqueous solution; the deep cooling procedure is cooling the hydrocyanic acid mixed gas to minus 10 to minus 20 DEG C, after the hydrocyanic acid mixed gas is cooled, a part of the hydrocyanic acid gas becomes a liquid to obtain the liquid hydrocyanic acid, and the other part of the hydrocyanic acid gas is a tail gas containing hydrocyanic acid; the deeply-cooled tail gas containing hydrocyanic acid is absorbed by sodium hydroxide aqueous solution to prepare a sodium cyanide aqueous solution. According to the process method disclosed by the invention, by using a method of combining direct deep cooling under a micro-negative pressure with tail gas absorption, a purification efficiency for hydrocyanic acid and a utilization efficiency for hydrocyanic acid can be remarkably increased, meanwhile, energy consumption during a purification process for hydrocyanic acid is greatly reduced and can be reduced by 90% to the greatest extent; moreover, the utilization rate of hydrocyanic acid is greater than 99.9%.

Owner:枣阳市金鹿化工有限公司

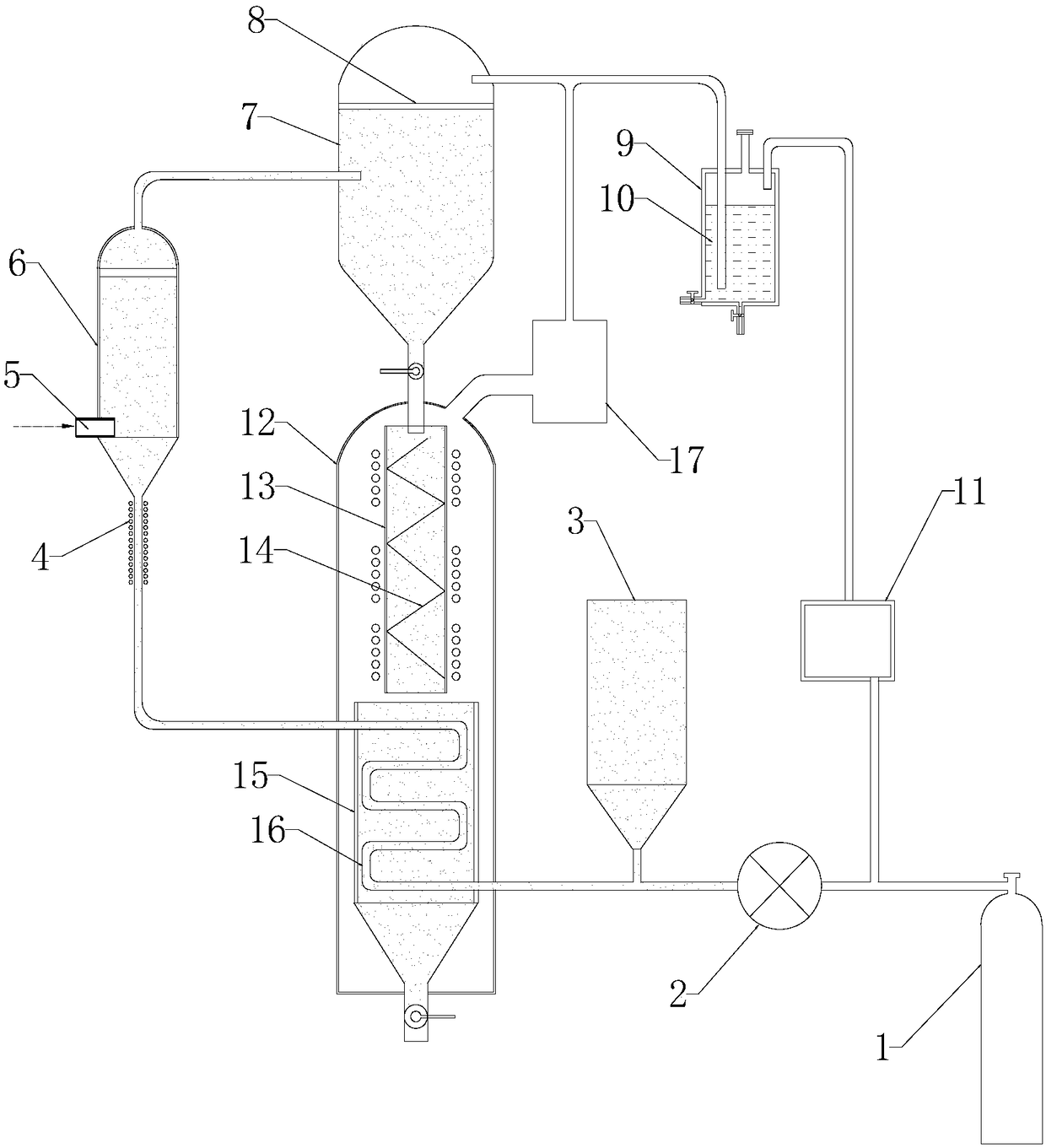

Graphite purifying device and method

The invention discloses a graphite purifying device and a graphite purifying method, and relates to the field of metallurgical graphite purification. The graphite purifying device comprises a low-temperature reactive ion gas generator, a fluidized bed reactor, a product collector, a high-temperature heating zone and a gas-solid separator; a graphite raw material runs through a heat exchange pipe inside the product collector and then enters the fluidized bed reactor, reactive ion gas is ionized by the low-temperature reactive ion gas generator, enters the fluidized bed reactor and reacts with impurities in the raw material graphite, waste gas enters a waste gas recycling device through the gas-solid separator and is purified, and inert gas is discharged from the waste gas recycling device and is reused; meanwhile, graphite in the gas-solid separator enters the high-temperature heating zone for high-temperature purification; the graphite after the high-temperature purification enters theproduct collector and exchanges heat with the raw material graphite. Through adoption of a low-temperature reactive ion gas and fluidized bed combined technology, low-energy consumption, low-pollution and low-cost clean graphite smelting purification is achieved.

Owner:XIAMEN UNIV

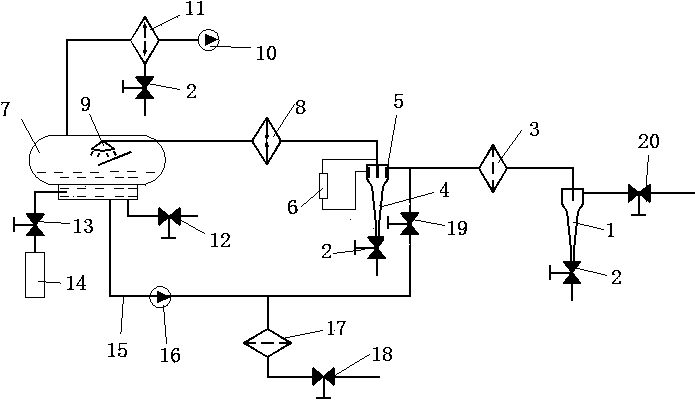

Multi-field joint lubricating oil dehydration and purification device

ActiveCN103289808BThoroughly dehydratedRealize deep purification and dehydrationFiltration circuitsLubricant compositionNitrogen generatorHigh water content

The invention discloses a multi-field joint lubricating oil dehydration and purification device. Lubricating oil is sequentially connected with a primary swirler, a strainer, a secondary swirler and a vacuum tank through pipelines, wherein a pulse electrode is arranged in the secondary swirler, a heater is arranged on a pipeline between the secondary swirler and the vacuum tank, the upper part of the vacuum tank is connected with a vacuum pump through a pipeline, a condenser is arranged on the pipeline for connecting the vacuum tank with the vacuum pump, the bottom of the vacuum tank is connected with an oil drain valve and a nitrogen generator and provided with a backflow pipe, and an oil pump is arranged on the backflow pipe and connected with the oil drain valve through an oil outlet pipe. The multi-field joint lubricating oil dehydration and purification device can be used for thoroughly dehydrating the lubricating oil, realizing deep purification and dehydration, and greatly shortening demulsification time so as to quickly finish the lubricating oil purification treatment and reduce the energy consumption of the oil purification. The multi-field joint lubricating oil dehydration and purification device can be used for removing trace moisture in the lubricating oil, and also can be applied to the dehydration and purification treatment of the lubricating oil with high water content, thus being wide in applicable range.

Owner:CHONGQING UNIV OF TECH

Purification method for acetic acid synthesized by low pressure methanol carbonylation

ActiveCN1865215AReduce concentrationSimple purification methodCarboxylic compound separation/purificationChemistryEvaporator

This invention relates to a method for purifying methanol carbonyl synthesized acetic acid at low pressure, comprising: flash distill the reaction solution containing catalyst in the flash evaporator to produce the gas-phase crude acetic acid with impurities, produce wet acetic acid with impurities by lightness-removing column distillation, then send the wet acetic acid to the dehydration column for further dehydration and impurities removing, use the current method to further purify the dehydrated and impurities removed acetic acid to be acceptable high-grade product, wherein the gas phase is cooled at the top of the dehydration column and sent to a second distillation decanter, which separates the liquid to be a low-density phase mainly comprising of water and acetic acid and a high-density phase mainly comprising of methyliodide and methyl acetate; the gas phase is cooled at the top of the said lightness-removing column and then sent to the first distillation decanter which separates the liquid to be a low-density phase mainly comprising of water and acetic acid and a high-density phase mainly comprising of methyliodide and methyl acetate, decant the high-density phase produced by the second distillation decanter to the first distillation decanter.This method is characterized of simplified method and purification energy consumption decreasing.

Owner:SHANGHAI HUAYI ENERGY CHEM

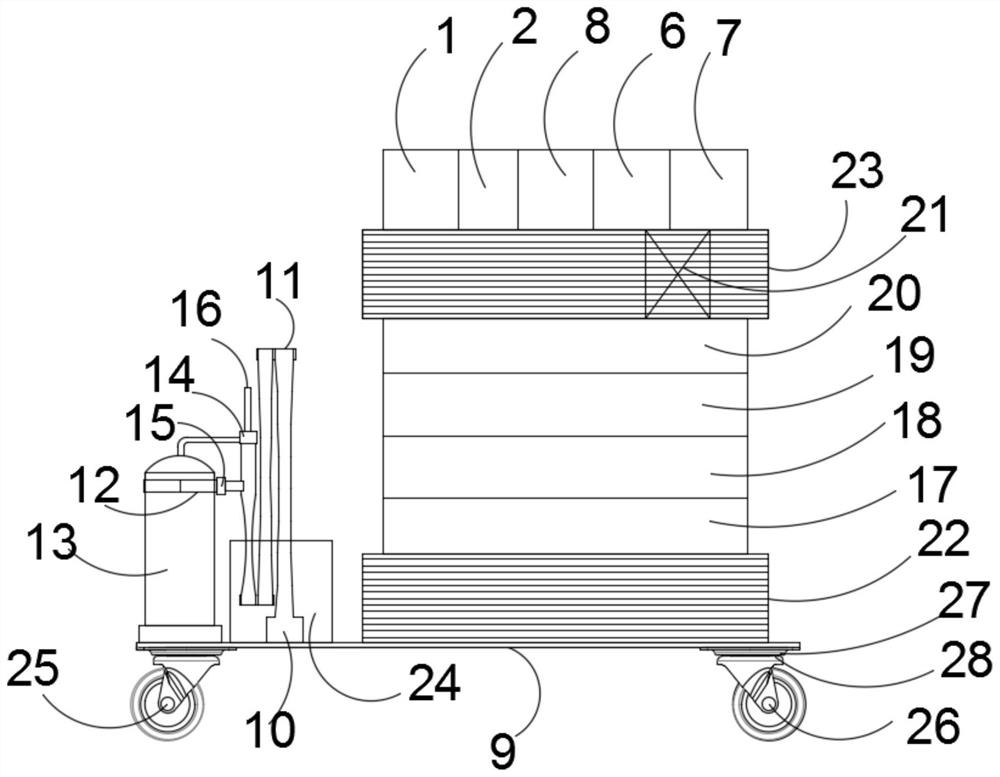

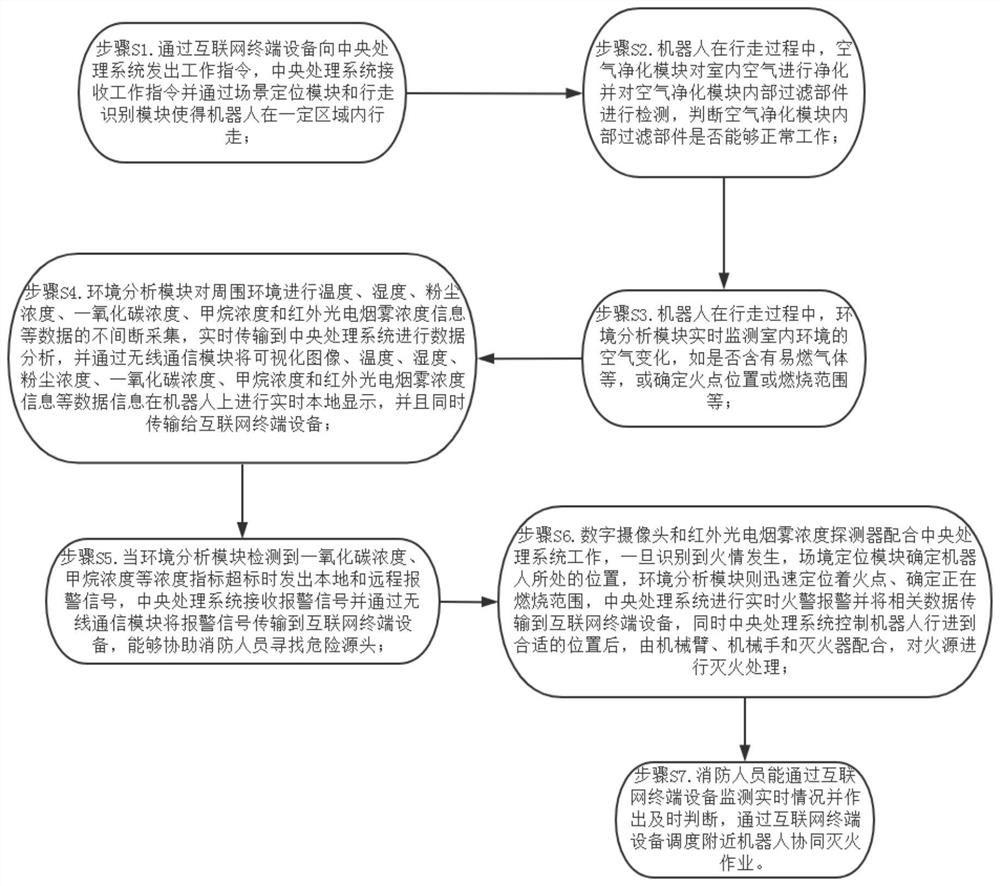

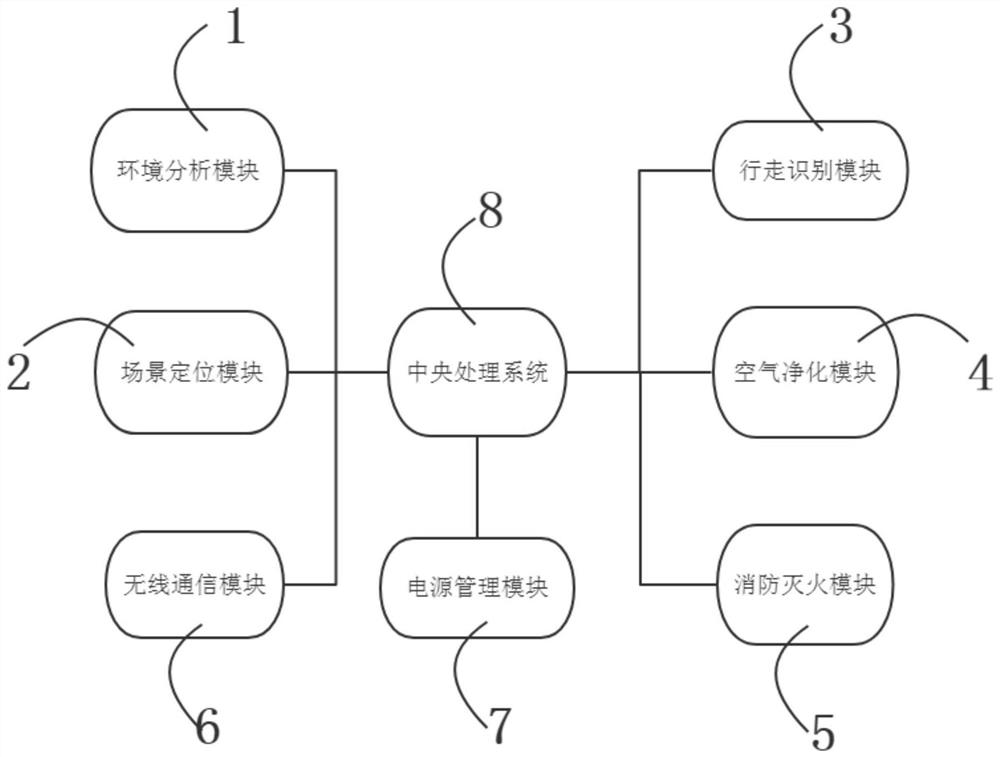

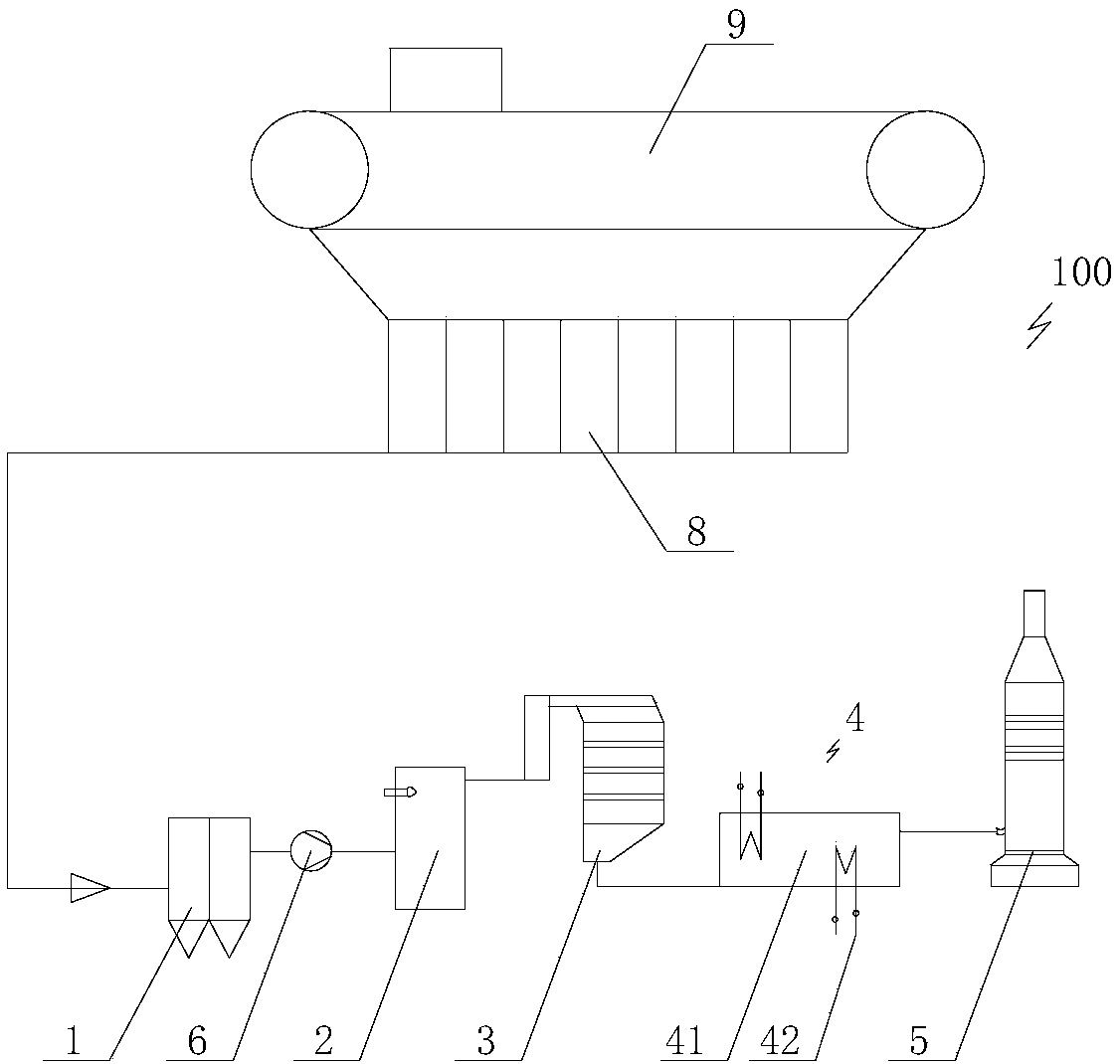

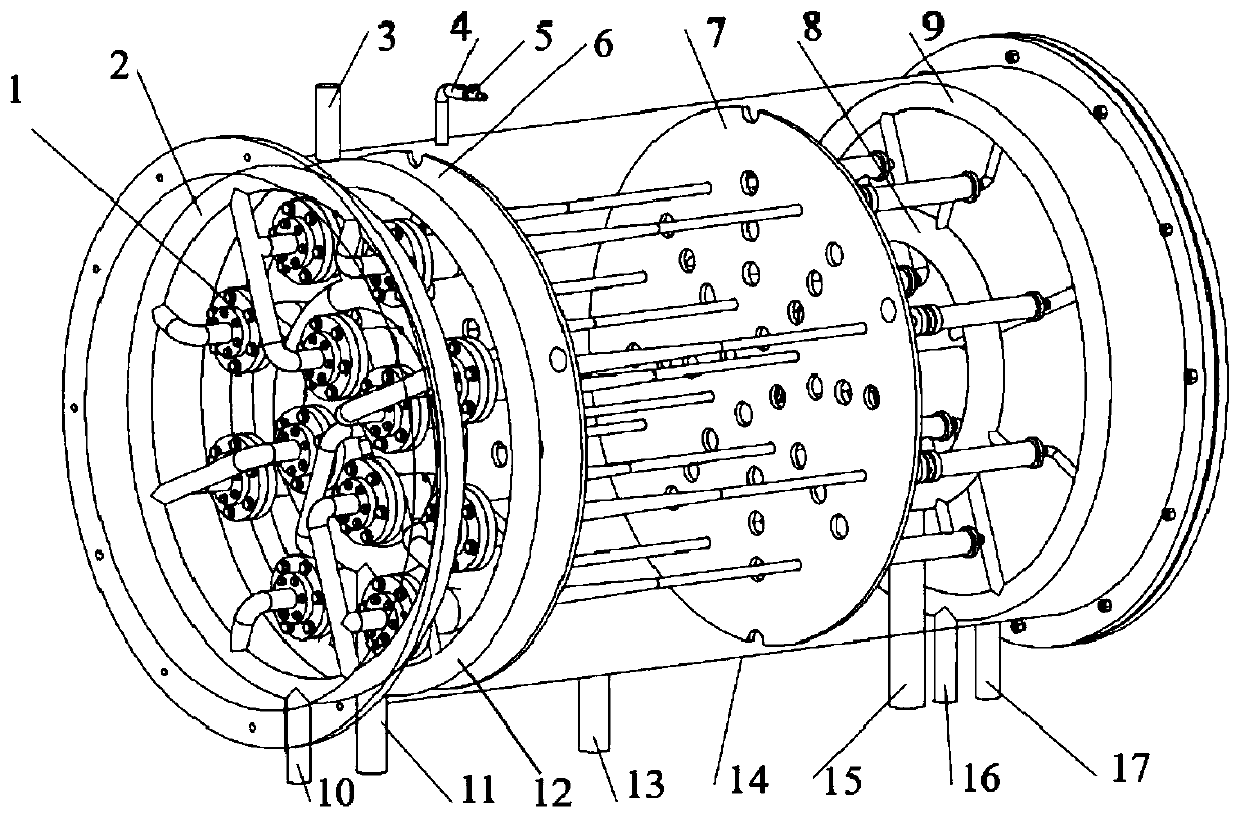

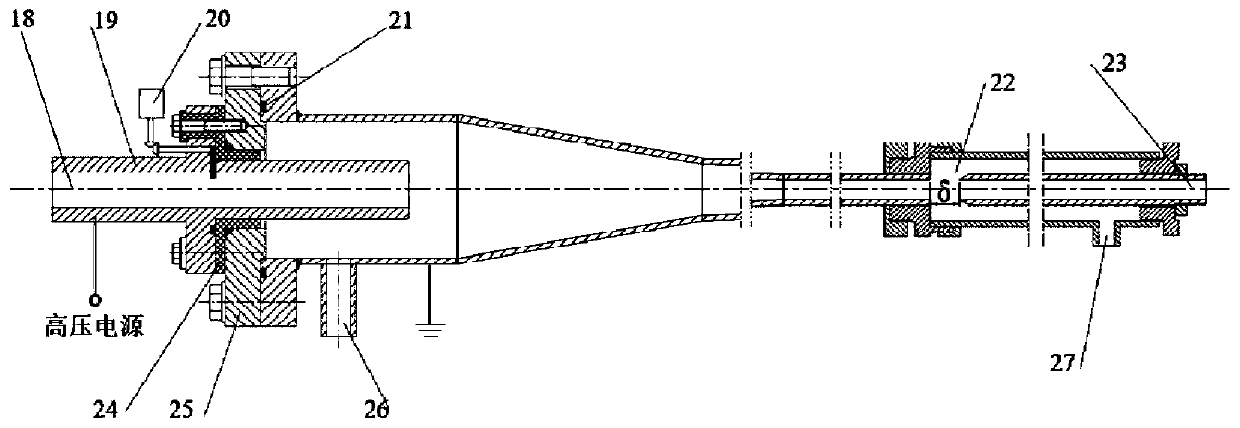

Air purifying robot with fire fighting function and using method thereof

PendingCN111854005APowerfulReduce power consumptionMechanical apparatusSpace heating and ventilation safety systemsRobot handAir cleaning

The invention provides an air purifying robot with a fire fighting function. The air purifying robot comprises an air purifying module, a fire fighting module and a robot main body, the fire fightingmodule comprises a base, a mechanical arm, a mechanical hand, a fire extinguisher, a fire extinguishing control valve and a hydraulic valve, the base is installed on the robot main body by rotating by360 degrees, the mechanical arm is installed on the base and rotates by 360 degrees along with the base, the mechanical arm is provided with the hydraulic valve which controls joints of the mechanical arm to rotate and adjusts the mechanical arm to stretch and retract, the fire extinguisher is arranged on one side of the base, a safety pin of the fire extinguisher is provided with the mechanicalhand, the mechanical hand is connected with the mechanical arm through the hydraulic valve, the tail end, away from the base, of the mechanical arm is provided with a fire extinguishing nozzle, and aspraying port of the fire extinguisher is connected with the fire extinguishing nozzle through the fire extinguishing control valve. The problems of the low comprehensive utilization rate, high energyconsumption and high air purifying cost of an existing purifier are solved, and the problems that a fire source cannot be found in time, and personnel casualties and huge loss in property are causedare solved.

Owner:桑瑞思医疗科技有限公司

Sintered flue gas full-process purification system and method thereof

PendingCN107830739AMeet the requirements of emission indicatorsGood desulfurization and denitrification effectIncreasing energy efficiencyWaste heat treatmentFlue gasNitrogen oxide

The invention provides a sintered flue gas full-process purification system and a method of the sintered flue gas full-process purification system. An inlet of the sintered flue gas full-process purification system is provided with a dedusting device capable of performing dedusting processing on sintered flue gas, an inlet of the dedusting device communicates with a sintering machine air bellow capable of leading out the full-process flue gas of a sinter, and an outlet of the dedusting device communicates with a temperature raising device capable of performing temperature-raising processing onthe sintered flue gas. An outlet of the temperature raising device communicates with a denitrification device capable of performing denitrification processing on the sintered flue gas, an outlet of the denitrification device communicates with a waste heat recycling device capable of lowering the temperature of the sintered flue gas through heat exchange, and an outlet of the waste heat recyclingdevice communicates with a desulfuration device capable of performing desulfuration processing on the sintered flue gas. By means of the sintered flue gas full-process purification system and the method of the sintered flue gas full-process purification system, full-process purification of the sintered flue gas is achieved, purification energy consumption is lowered, the nitrogen oxide dischargingconcentration of the flue gas is lower than 100 mg / <Nm>3, and the emission index requirements of the nitrogen oxides are met.

Owner:MCC CAPITAL ENGINEERING & RESEARCH

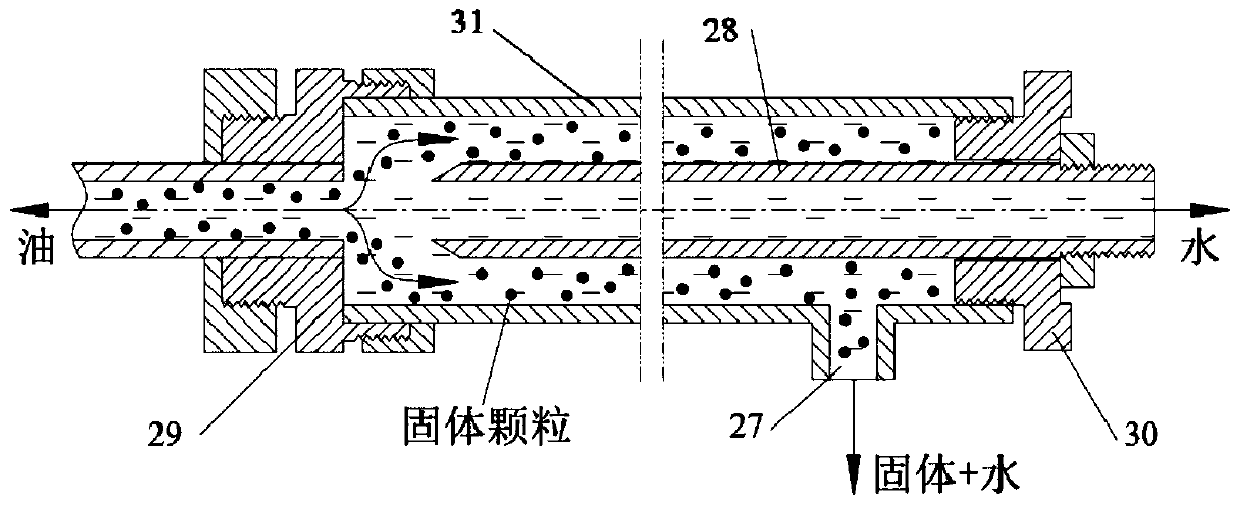

Liquid-liquid-solid three-phase separation device for waste oil

PendingCN109913263ALow viscosityReduce purification energy consumptionReversed direction vortexLiquid separation by electricitySocial benefitsOil emulsion

The invention discloses a liquid-liquid-solid three-phase separation device for industrial waste oil. The liquid-liquid-solid three-phase separation device comprises an oil bath heating tank, swirlingseparation units and solid removing units, wherein a plurality of swirling separation units are arranged inside the oil bath heating tank; the swirling separation units are fixed into the oil bath heating tank; the solid removing units are connected with bottom flowing pipes of the swirling separation units; the solid removing units are used for separating solid particles from liquid inflowing from the bottom flowing pipes; solid removing outer pipes are arranged at the bottom flowing ends of the swirling separation units; second connecting components are arranged at the tail ends of the solid removing outer pipes; solid removing inner pipes are arranged at bottom flowing ports of the bottom flowing pipes to form solid removing gaps. According to the liquid-liquid-solid three-phase separation device provided by the invention, in allusion to the characteristics of an industrial waste oil emulsion, the defects of the conventional separation process are overcome, and emulsion droplets are rapidly gathered and enlarged under the action of an electric field; liquid-liquid-solid three-phase separation is achieved; liquid-liquid-solid three-phase separation device not only can achieve demulsification and dehydration treatment of the industrial waste oil emulsion, but also can achieve the separation of solid particles, and has a very good application prospect, a good economic value and good social benefits.

Owner:CHONGQING TECH & BUSINESS UNIV

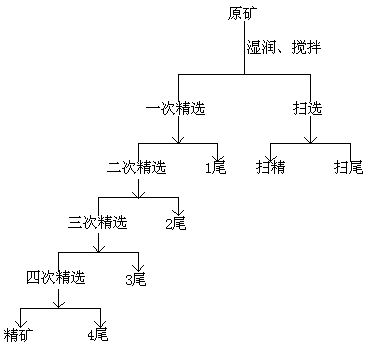

A process for preparing high-purity microcrystalline graphite in large quantities with low energy consumption and high-purity microcrystalline graphite

InactiveCN107555426BLarge specific surface areaHigh purityCarbon compoundsGraphiteEnergy consumption

The invention relates to the technical field of microcrystalline graphite purification, and discloses a process for preparing high-purity microcrystalline graphite with low energy consumption and in alarge scale, and the high-purity microcrystalline graphite. According to the process, microcrystalline graphite raw ore is firstly crushed and ground, and flotation including one time of roughing, four times of cleaning and one time of scavenging is performed in match to increase the purity of the raw ore to the utmost through a physical method; an improved acid leaching purification method is adopted, the alkali leaching efficiency is increased, energy consumption is reduced, and the graphite recovery yield is increased; and finally a high-temperature purification method adopting a step-by-step heating manner is utilized to further reduce energy consumption for graphite purification, and the high-purity microcrystalline graphite the fixed carbon content of which is 99.993% or above can be finally obtained. The process overcomes a problem that microcrystalline graphite in the prior art is not high in purity, high in energy consumption and high in cost. Through improvements on the prior art, the process achieves an objective of reducing energy consumption and the cost, and achieves industrial production.

Owner:HUNAN GUOSHENG GRAPHITE TECH CO LTD

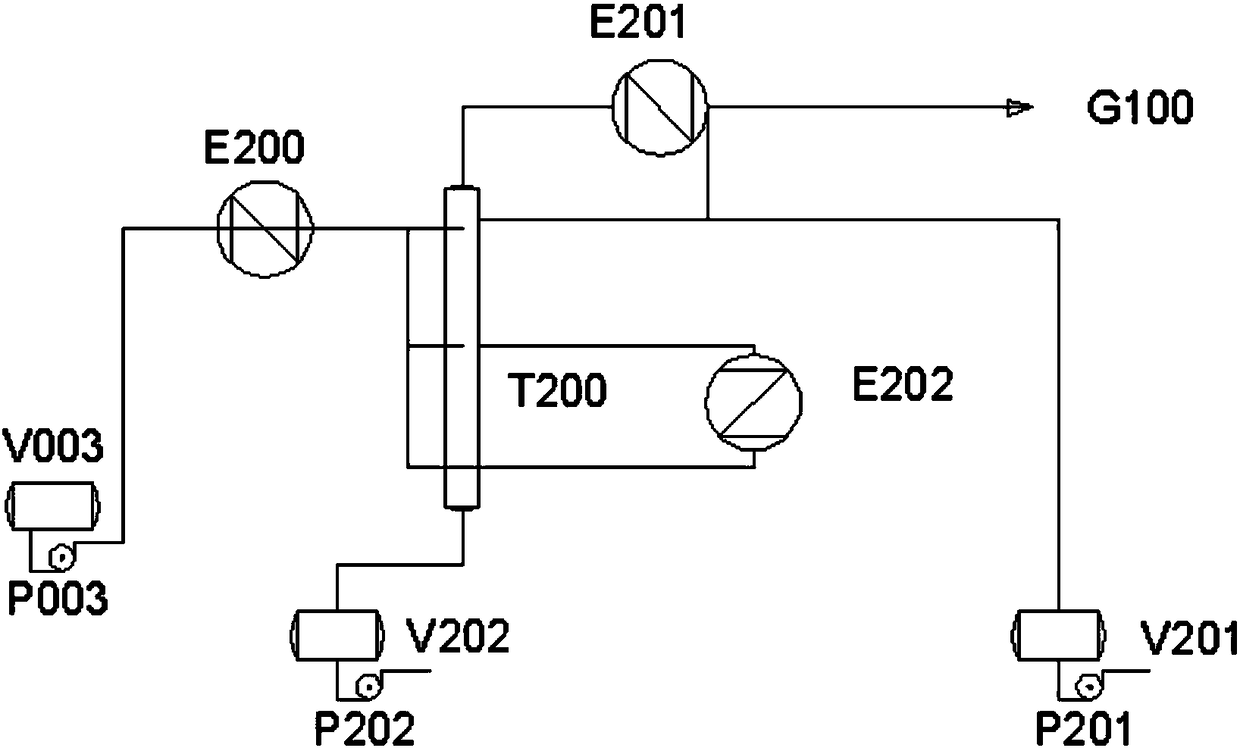

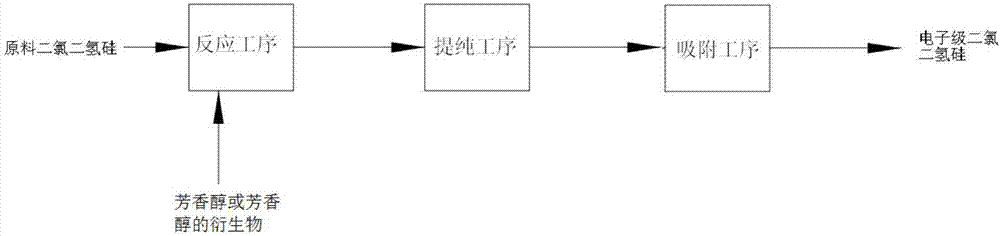

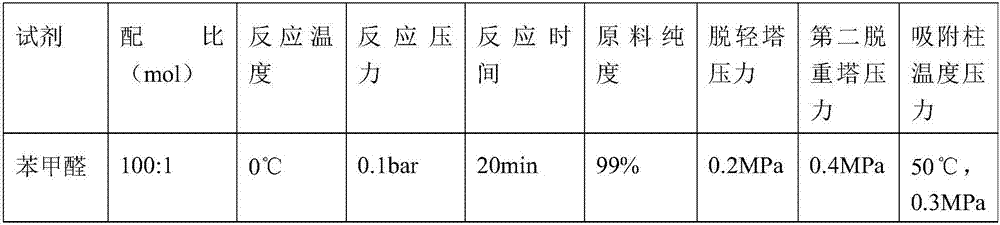

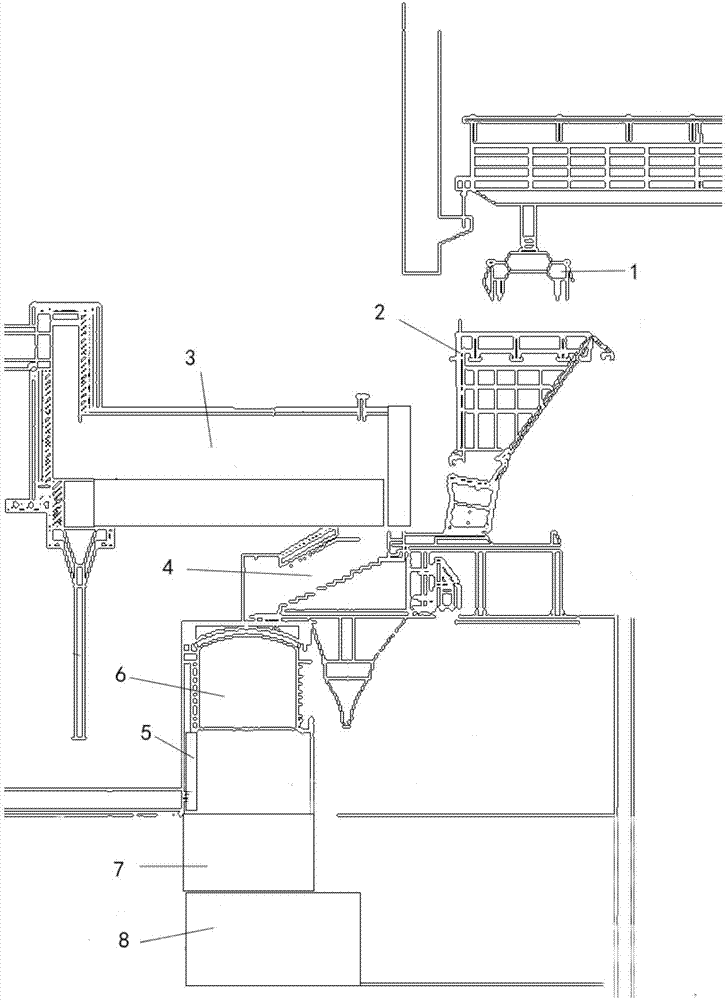

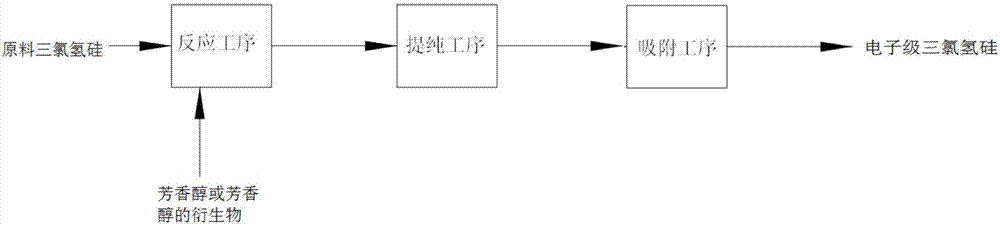

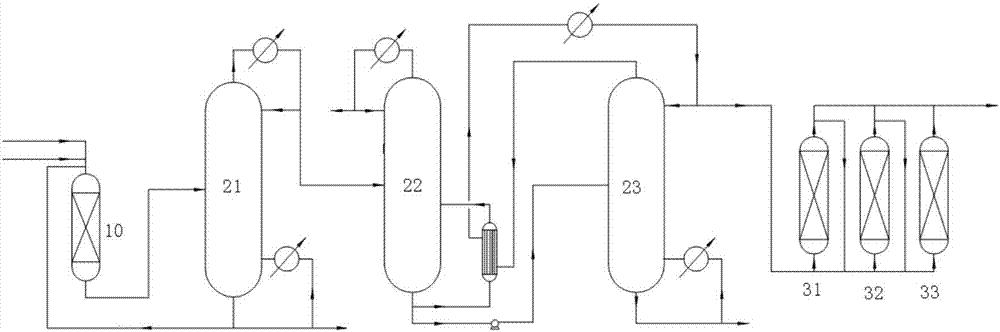

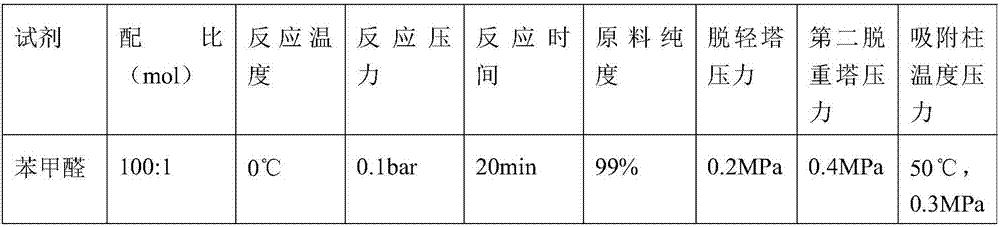

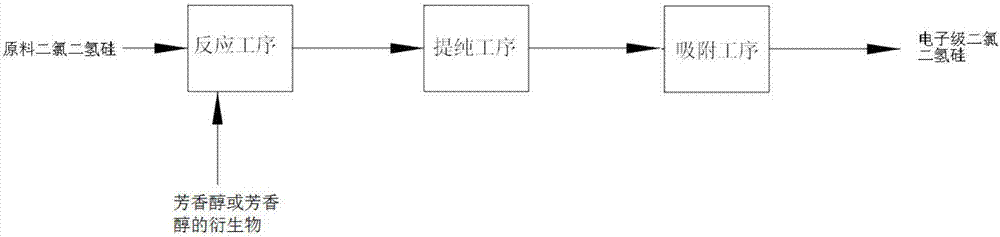

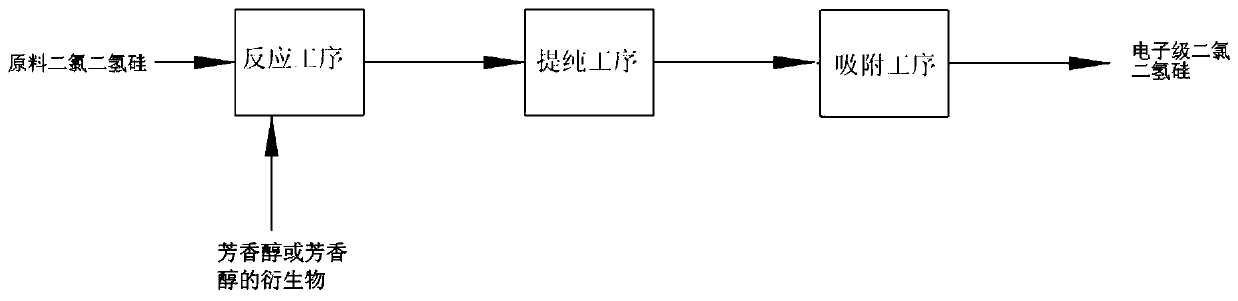

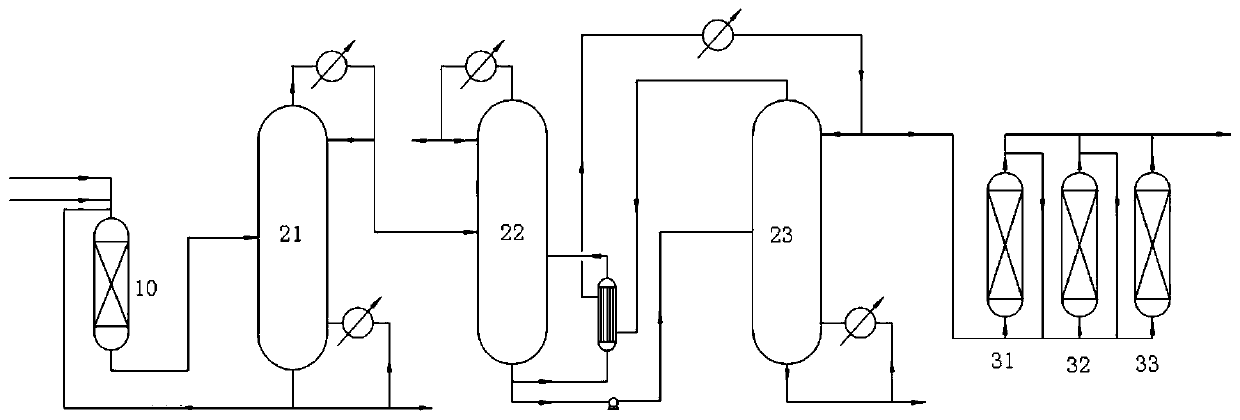

Method for preparing electron-level dichlorosilane

ActiveCN107055550AReduce energy consumptionSave heating energy lossHalogenated silanesDichlorosilaneElectron

The invention discloses a method for preparing electron-level dichlorosilane. The method comprises the following steps of S1, enabling aromatic aldehyde or derivative of aromatic aldehyde and raw material of dichlorosilane to react, so as to obtain a reaction product; S2, removing one part of heavy component from the reaction product, and then removing a light component and the remained heavy component, so as to obtain a purifying product; S3, sending the purifying product into an adsorbing and purifying unit, and removing impurities, so as to obtain the electron-level dichlorosilane. By adopting the technical scheme, the method has the advantages that the process is greatly shortened by the technology, the equipment investment is reduced, the energy consumption in running is decreased, and the product quality can reach the electron level.

Owner:CHINA SILICON CORP LTD +1

Furfural five-tower continuous rectification process

InactiveCN111943918AIncrease concentrationImprove the purification effectOrganic chemistryClimate change adaptationPtru catalystAcid catalyzed

The invention discloses a furfural five-tower continuous rectification process, and relates to the field of furfural rectification, and the furfural five-tower continuous rectification process comprises the following steps: step 1, preparing aldehyde steam from corncobs, and pretreating the aldehyde steam; 2, carrying out five-tower continuous rectification refining; and 3, performing furfural wastewater treatment. Aldehyde steam is prepared from corncobs, the aldehyde steam is pretreated, superheated steam loaded with a vapor-state acid catalyst is introduced into a stirring kettle, the superheated steam is recycled, and the furfural concentration in mixed gas is condensed, so that the furfural concentration in a furfural aqueous solution is increased, further refining is facilitated, thefurfural purification effect is better, and the furfural purification energy consumption is effectively reduced.

Owner:宁夏宏民生物科技有限公司

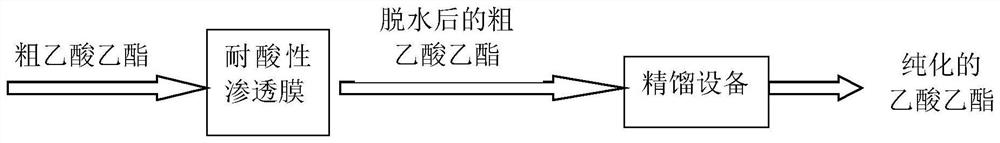

Method for purifying ethyl acetate

ActiveCN112500292AHigh yieldImprove the efficiency of removing other impuritiesSemi-permeable membranesMembranesEthyl acetateSolvent

The invention provides a method for purifying ethyl acetate. The method comprises the following steps: dehydrating crude ethyl acetate to be treated through an acid-resistant permeable membrane, and removing other impurities through a rectification technique. Compared with a single rectification process, the method has the advantages that water in ethyl acetate is removed in advance through an acid-resistant permeable membrane dehydration technology, so that a ternary or higher azeotropic system formed by ethyl acetate, water, ethanol and the like is broken through, the efficiency of removingother impurities through the rectification technology is remarkably improved, and the yield of ethyl acetate is increased; besides, moisture in the crude ethyl acetate solvent can be effectively removed by the crude ethyl acetate through the acid-resistant permeable membrane, other substances do not need to be added, new pollution is not generated, subsequent additional treatment is not needed, the permeable membrane can be continuously operated, the dehydration efficiency is high, the energy consumption is low, the ethyl acetate purification energy consumption is greatly reduced, and the purification cost is reduced.

Owner:宁波大膜科技有限公司

Fire grate and pyrolysis combined waste incineration equipment

The invention provides fire grate and pyrolysis combined waste incineration equipment. With a pyrolyzing furnace as a major, a grate furnace is installed at the feeding end of the pyrolyzing furnace obliquely; the feeding end of the grate furnace is connected with a waste guide bin, an inlet of the waste guide bin is upward, and a gantry crane claw is arranged above the inlet of the waste guide bin; a slag outlet of the pyrolyzing furnace is connected with an automatic slag discharging machine; a storage tank is arranged below the automatic slag discharging machine; a secondary combustor is installed on the upper left portion of the grate furnace; and the upper portion of the pyrolyzing furnace is provided with a circulating pipeline, high-temperature flue gas enters a buring section of the pyrolyzing furnace through the heat circulating pipeline. By means of the equipment, combustibles are greatly reduced, and toxic and harmful ingredients in flue gas are thoroughly burnt. Purification energy consumption of flue gas of the rear end is reduced, the whole equipment is in the same space but different sections, heat is utilized to the greatest extent, and resource utilization is achieved.

Owner:广东清风来环保科技有限公司

Technological method for jointly preparing liquid hydrogen cyanide and bisisobutyronitrile hydrazine

ActiveCN104724726AIncrease profitReduce purification energy consumptionCyanic/isocyanic acidPreparation by hydrogen cyanide additionHCN poisoningHydrogen cyanide gas

The invention provides a technological method for jointly preparing liquid hydrogen cyanide and bisisobutyronitrile hydrazine. The technological method comprises the steps that a light oil cracking hydrogen cyanide gas mixture is used as a raw material and undergoes an ammonia removal process and a cryogenic process to obtain liquid hydrogen cyanide, wherein in the ammonia removal process, the hydrogen cyanide gas mixture is absorbed with a sulfuric acid aqueous solution; in the cryogenic process, the hydrogen cyanide gas mixture is cooled to minus 10-minus 20 DEG C, after the hydrogen cyanide gas mixture is cooled, a part of the hydrogen cyanide gas becomes liquid to obtain liquid hydrogen cyanide, and the other part of the hydrogen cyanide gas is the tail gas containing hydrogen cyanide; the tail gas containing hydrogen cyanide, which undergoes cryogenic treatment, is absorbed with a ketazine aqueous solution to obtain an aqueous solution containing bisisobutyronitrile hydrazine, and the aqueous solution containing bisisobutyronitrile hydrazine undergoes cooling, crystallization and centrifugal filtration to obtain a bisisobutyronitrile hydrazine crystalline solid. By adopting the technological method, the purification efficiency and the utilization efficiency of hydrogen cyanide can be obviously improved, meanwhile, the energy consumption in the hydrogen cyanide purification process is greatly reduced and can be reduced by 90% at most, and the utilization rate of hydrogen cyanide is more than 99.9%.

Owner:枣阳市金鹿化工有限公司

Method for preparing electron-level trichlorosilane

The invention discloses a method for preparing electron-level trichlorosilane. The method comprises the following steps of S1, enabling aromatic aldehyde or derivative of aromatic aldehyde and raw material of trichlorosilane to react, so as to obtain a reaction product; S2, removing one part of heavy component from the reaction product, and then removing a light component and the remained heavy component, so as to obtain a purifying product; S3, sending the purifying product into an adsorbing and purifying unit, and removing impurities, so as to obtain the electron-level trichlorosilane. By adopting the technical scheme, the method has the advantages that the process is greatly shortened by the technology, the equipment investment is reduced, the energy consumption in running is decreased, and the product quality can reach the electron level.

Owner:CHINA SILICON CORP LTD +1

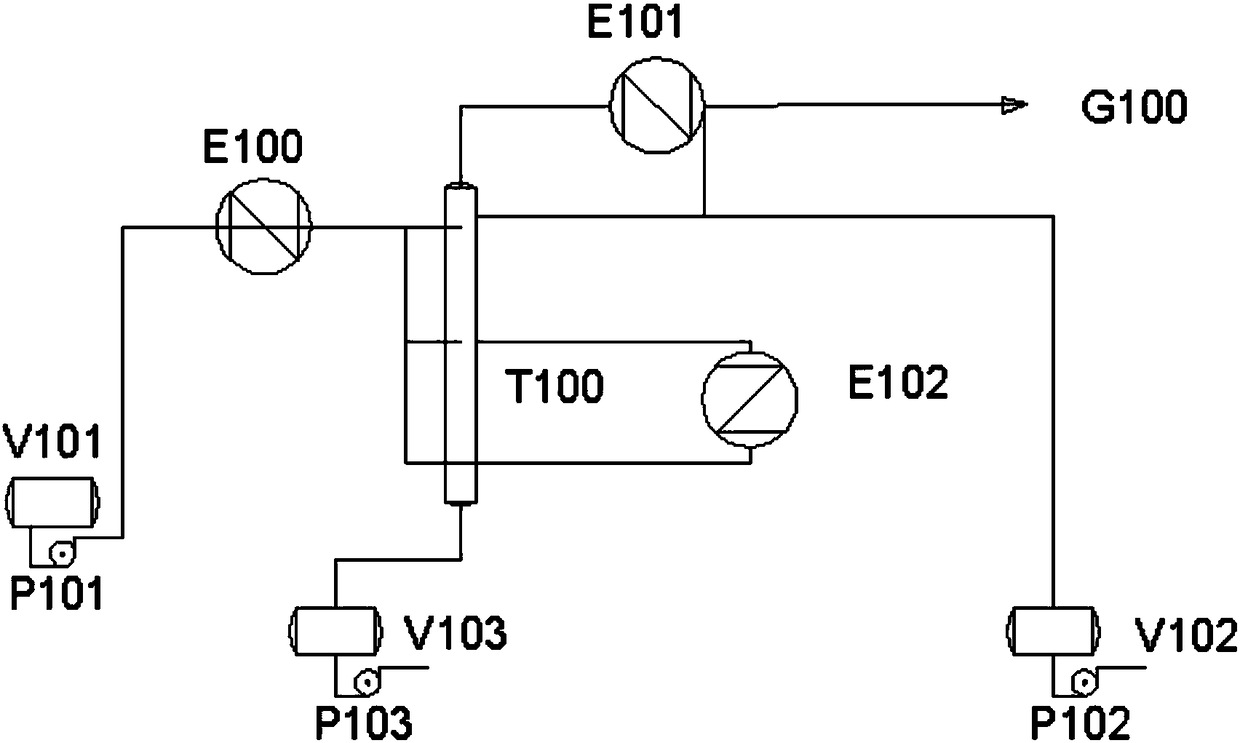

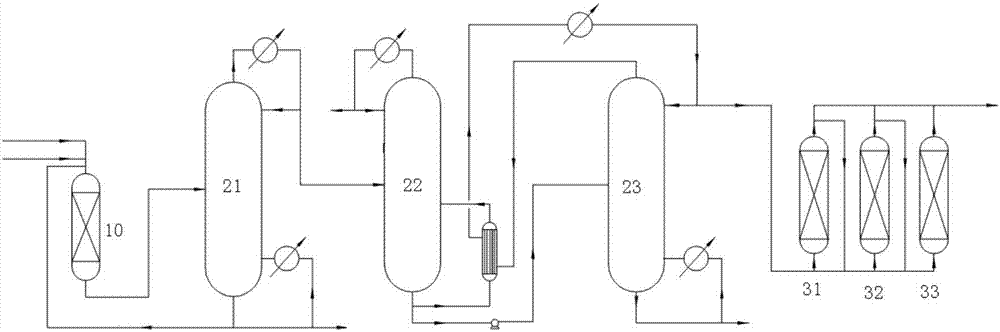

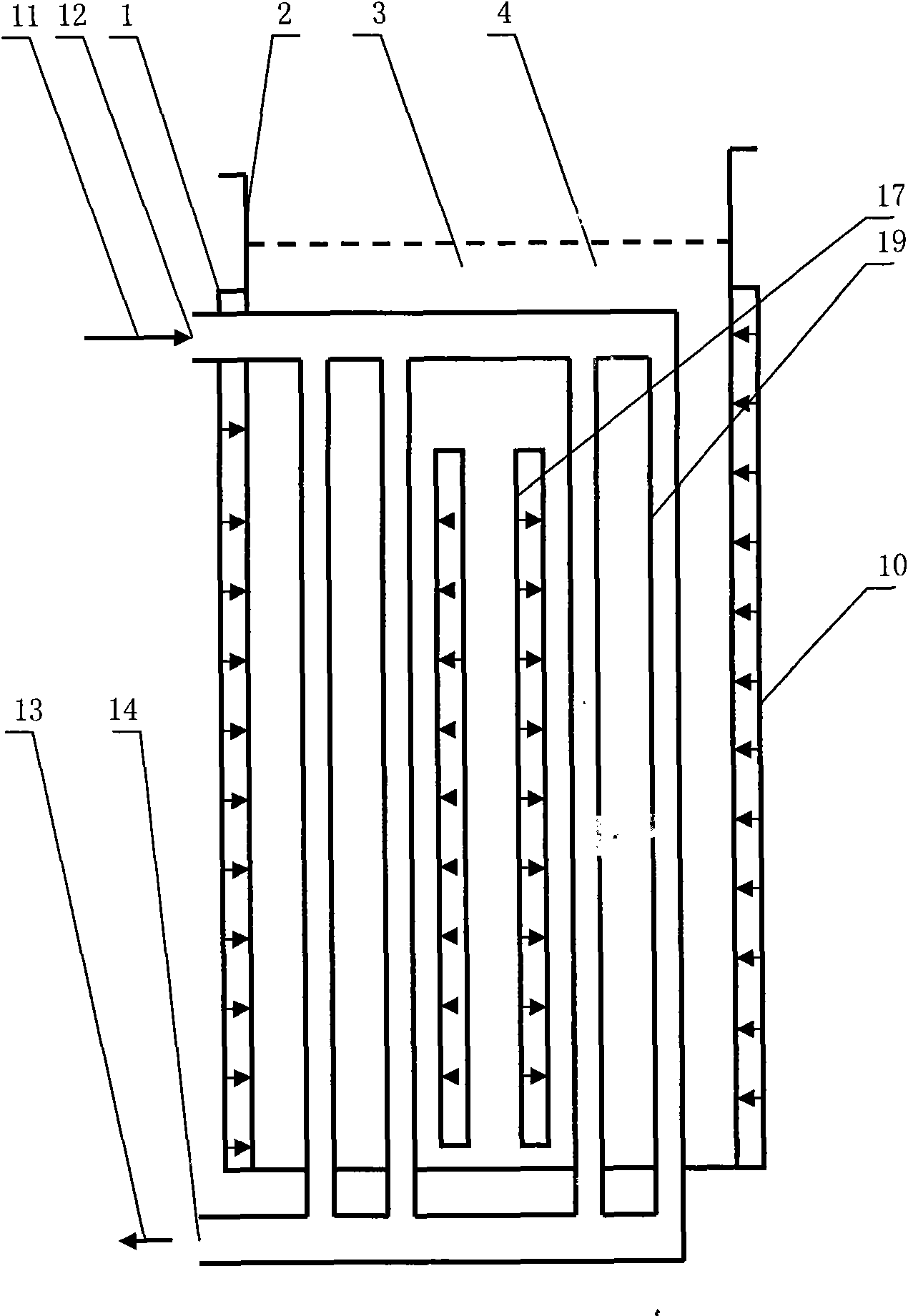

Device for preparing electronic grade dichlorosilane

ActiveCN106904617ASave heating energy lossReduce energy consumptionHalogenated silanesDichlorosilaneTower

The invention discloses a device for preparing electronic grade dichlorosilane; the device comprises a reactor for reaction of an aromatic aldehyde or aromatic aldehyde derivative and raw material dichlorosilane; a purification tower for removal of part of heavy components and then removal of light components and the remaining heavy components in reaction products in the reactor to obtain electronic grade dichlorosilane; and an adsorption and purification unit for further removal of impurities of the electronic grade dichlorosilane; the technology greatly shortens the process, and reduces equipment investment and running energy consumption, and the product quality can achieve the electronic grade.

Owner:CHINA SILICON CORP LTD +1

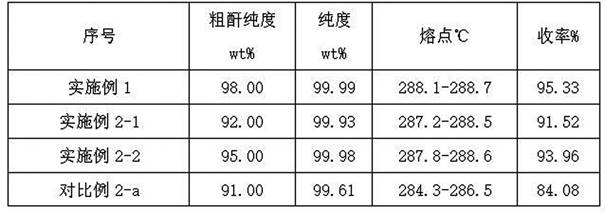

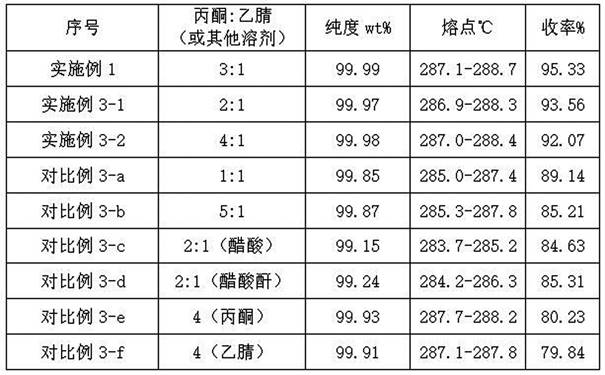

Method for refining pyromellitic dianhydride

ActiveCN114853775ALow impurity contentEliminate grayish and yellowish colorOrganic chemistryChemical industryCarboxylic acidPyromellitic dianhydride

The invention discloses a method for refining pyromellitic dianhydride in the field of chemical production, which comprises the following steps: dissolving, filtering, oxidizing, distilling, crystallizing, filtering and drying to obtain a target product, during dissolving, acetone and acetonitrile are prepared into a mixed solvent according to the weight ratio of (2-4): 1, and the weight ratio of crude anhydride to the mixed solvent is 1: (4-12); during oxidation, ozone-containing air is introduced into the filtrate for oxidation; according to the invention, the reflux temperature lower than the boiling point of acetonitrile can be realized, so that the refining energy consumption is reduced. Ozone is introduced to oxidize methyl carboxylic acid impurities into corresponding aromatic acid, and other aromatic diacid and trianhydride are easily dissolved in acetone and acetonitrile, so that during crystallization, the aromatic acid and trianhydride cannot be separated out and enter pyromellitic dianhydride, a pure product of the pyromellitic dianhydride is white, the obtained pyromellitic dianhydride is low in impurity content, the product quality is improved, and the production cost is reduced. Meanwhile, the purification energy consumption is low; the refined anhydride finished product has the characteristics of good purity, high melting point, high yield and uniform granularity.

Owner:JIANGSU ZHENGDAN CHEM IND CO LTD

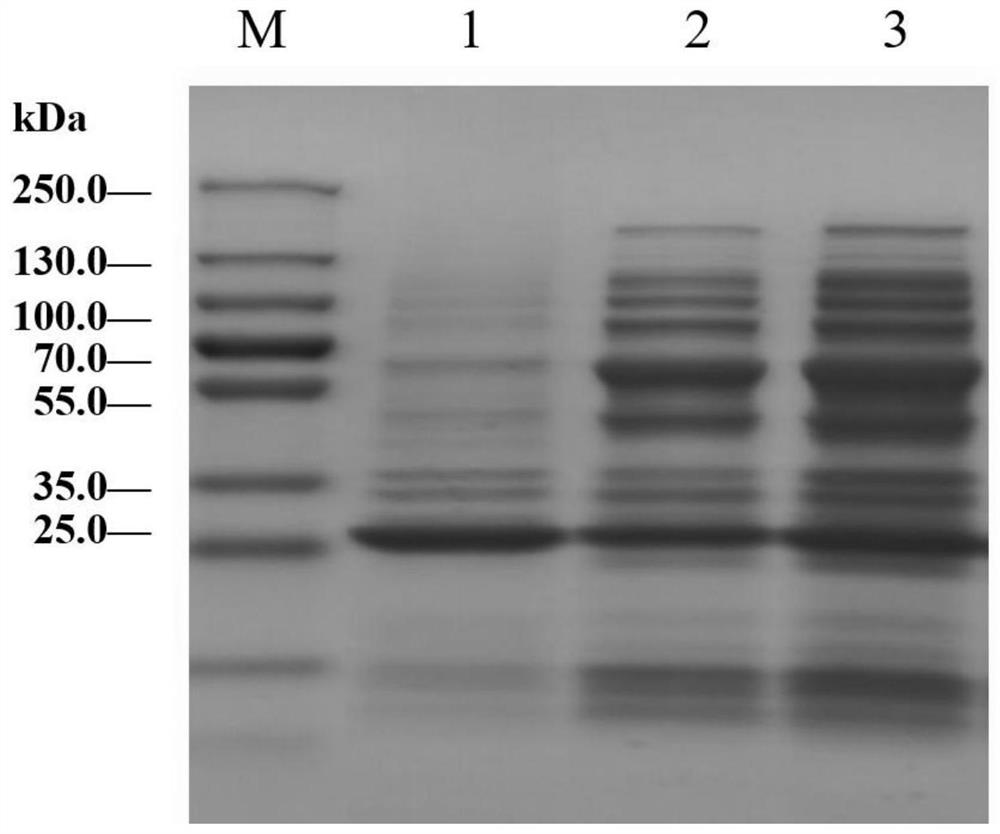

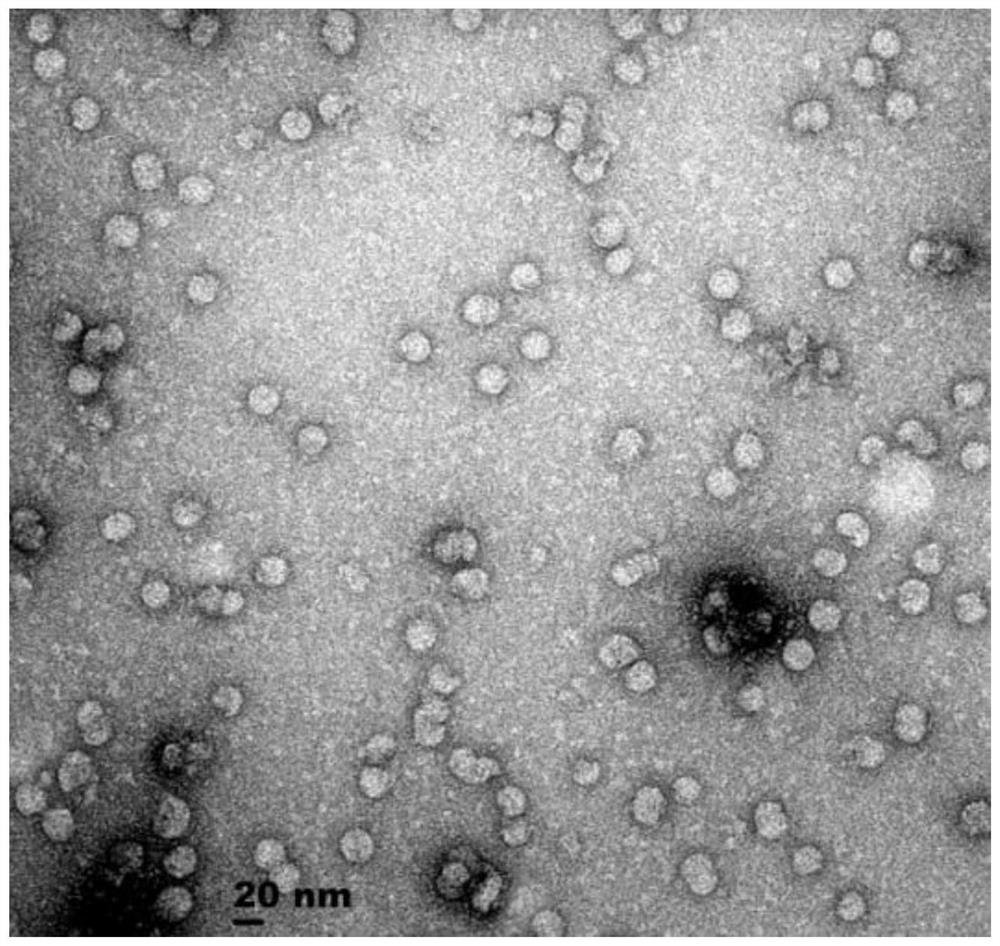

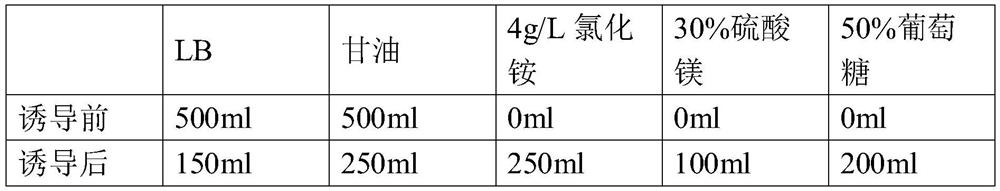

Fermentation medium for Cap protein virus-like particles of porcine circovirus type 2

PendingCN114250259AReduce the difficulty of purificationReduce purification energy consumptionVirus peptidesMicroorganism based processesAmmonium sulfateNaCl - Sodium chloride

The invention discloses a fermentation medium for porcine circovirus type 2 Cap protein virus-like particles (Cap-VLP), which comprises the following components in parts by weight: 7 to 13 parts of tryptone, 7 to 13 parts of yeast extract, 7 to 13 parts of sodium chloride, 7 to 13 parts of glycerol, 15 to 25 parts of disodium hydrogen phosphate, 6 to 12 parts of monopotassium phosphate and 4 to 8 parts of magnesium sulfate. The additive comprises the following components in parts by weight: 3-9 parts of ammonium sulfate, 1-4 parts of copper sulfate, 1-4 parts of cobalt chloride and 0.001-0.002 part of biotin. The invention also discloses a method for fermenting Cap protein virus-like particles by using the culture medium. The culture medium and the method do not need a purification step, and are more efficient compared with a traditional method.

Owner:成都史纪生物制药有限公司

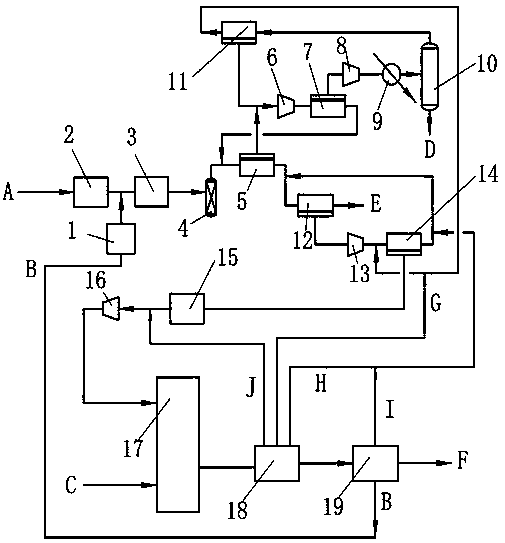

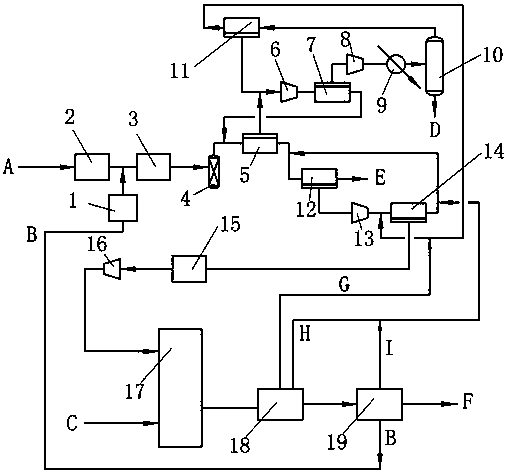

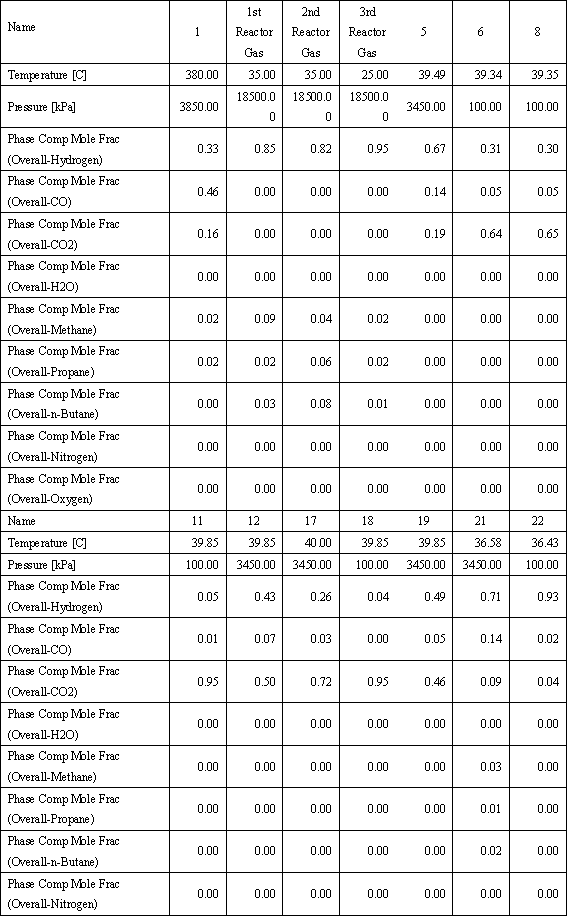

Heavy oil hydrogenation system and a hydrogenation method capable of self-producing hydrogen

ActiveCN111378492ALow costReduce purification energy consumptionEthylene productionTreatment with hydrotreatment processesWater-gas shift reactionHydrogenation reaction

The invention discloses a heavy oil hydrogenation system and a hydrogenation method capable of self-producing hydrogen. The heavy oil hydrogenation system comprises a coal gasification reaction unit,a heavy oil gasification reaction unit, a water-gas shift reaction unit, a three-stage carbon dioxide separation membrane, a two-stage hydrogen separation membrane, a four-stage compression unit, a liquid separation tank, a filtering unit, a condensation unit, a desulfurization unit, a heating unit, a heavy oil hydrogenation reaction unit and a fractionation unit. The invention also discloses a hydrogenation method by adopting the system. According to the heavy oil hydrogenation system and the hydrogenation method, the hydrogen partial pressure can be greatly improved, the hydrogenation reaction efficiency and the product quality are further improved, meanwhile, carbon dioxide is a byproduct, and carbon emission of a hydrogenation device is reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Tubular purification method and tubular purification tank

InactiveCN101476038BSmall volumeReduce in quantityEnergy based chemical/physical/physico-chemical processesProcess efficiency improvementLiquid mediumPurification methods

The invention provides a pipe type purifying method, the set purifying process of the solution to be purified is completed in a nonconservative pipe type purifying groove.The solution to be purified is a solution containing at least one granular solute; the pipe type purifying groove comprises a cavity full of liquid medium, at least one ultrasound wave source apparatus immersed in the liquid medium and at least one coiled apparatus full of the solution to be purified; the purifying process is that in the nonconservative flow process, the solution to be purified is irradiated in a insulation state by effective ultrasonic wave.

Owner:佛山市兴民科技有限公司

A device for preparing electronic grade dichlorodihydrosilane

ActiveCN106904617BSave heating energy lossReduce energy consumptionHalogenated silanesPhysical chemistryEngineering

The invention discloses a device for preparing electronic grade dichlorosilane; the device comprises a reactor for reaction of an aromatic aldehyde or aromatic aldehyde derivative and raw material dichlorosilane; a purification tower for removal of part of heavy components and then removal of light components and the remaining heavy components in reaction products in the reactor to obtain electronic grade dichlorosilane; and an adsorption and purification unit for further removal of impurities of the electronic grade dichlorosilane; the technology greatly shortens the process, and reduces equipment investment and running energy consumption, and the product quality can achieve the electronic grade.

Owner:CHINA SILICON CORP LTD +1

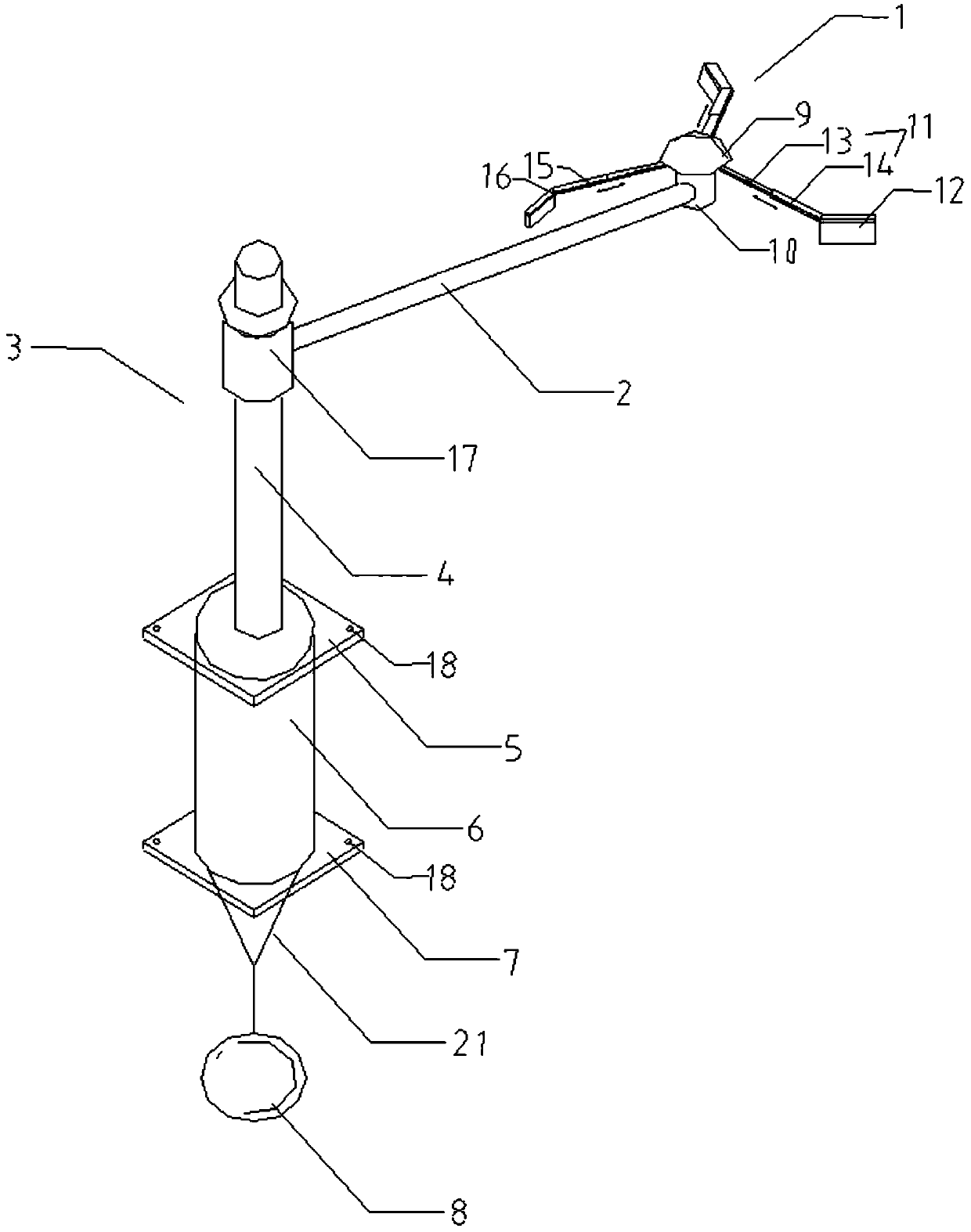

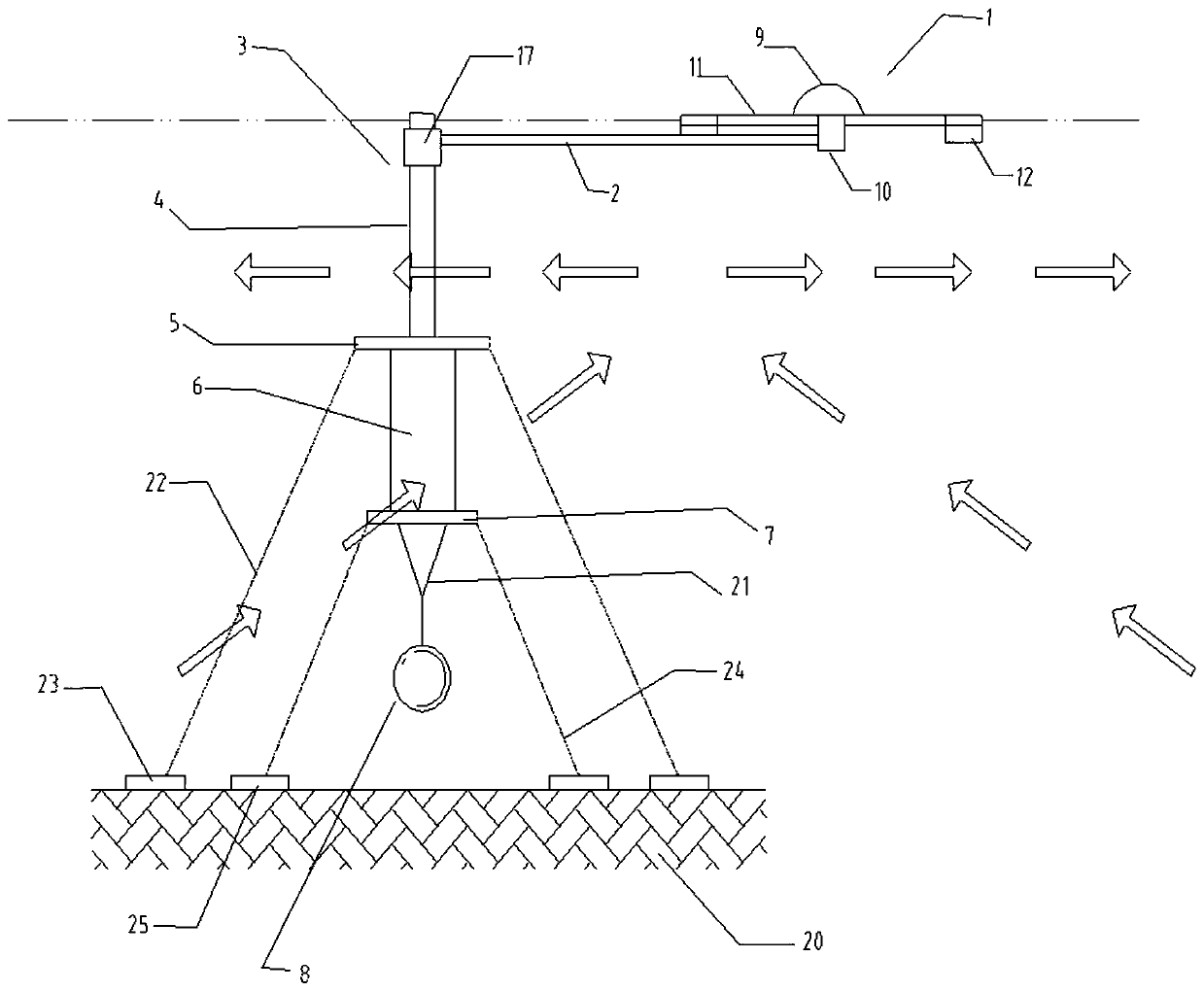

Water purification device and purification method thereof

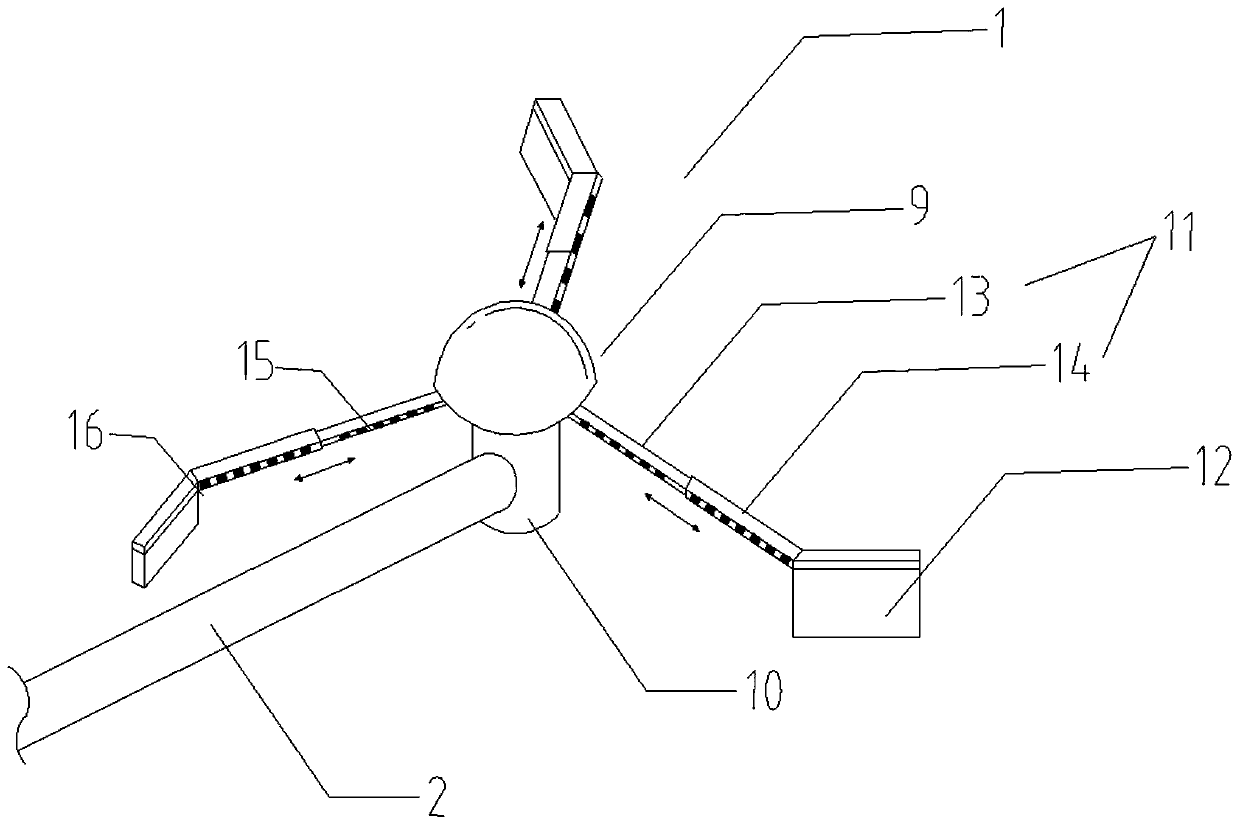

PendingCN109775867AMaximize purification efficiencyReduce purification energy consumptionTreatment using aerobic processesSustainable biological treatmentPurification methodsPropeller

The invention belongs to the field of sewage disposal and discloses a water purification device and a purification method thereof. The purification device comprises a propeller blade rotating structure, a connecting rod and a rotary fixing mechanism, wherein the propeller blade rotating structure is connected with the rotary fixing mechanism through the connecting rod; the rotary fixing mechanismcomprises a first rod piece, a first connecting plate, a second rod piece, a second connecting plate and a balance fixing ball, wherein the first rod piece, the first connecting plate, the second rodpiece, the second connecting plate and the balance fixing ball are sequentially connected with one another; one end of the connecting rod is sleeved with the first rod piece; the propeller blade rotating structure comprises a rotating piece, a control piece, a propeller rod and propeller blades; the rotating piece is connected with the control piece and the propeller rod, and the propeller rod isconnected with the propeller blades; the other end of the connecting rod is connected with the control piece. According to the purification device, through the cooperative operation of the components,the energy consumption is effectively reduced, the cost is reduced, the purification capacity is improved, the purification area is enlarged, and the water purification device and the purification method are applicable to various sewage disposal environments, high in practicability and great in implementation performance. The purification method has the advantages of simple flow and no side effect.

Owner:黑龙江土友生物科技有限公司

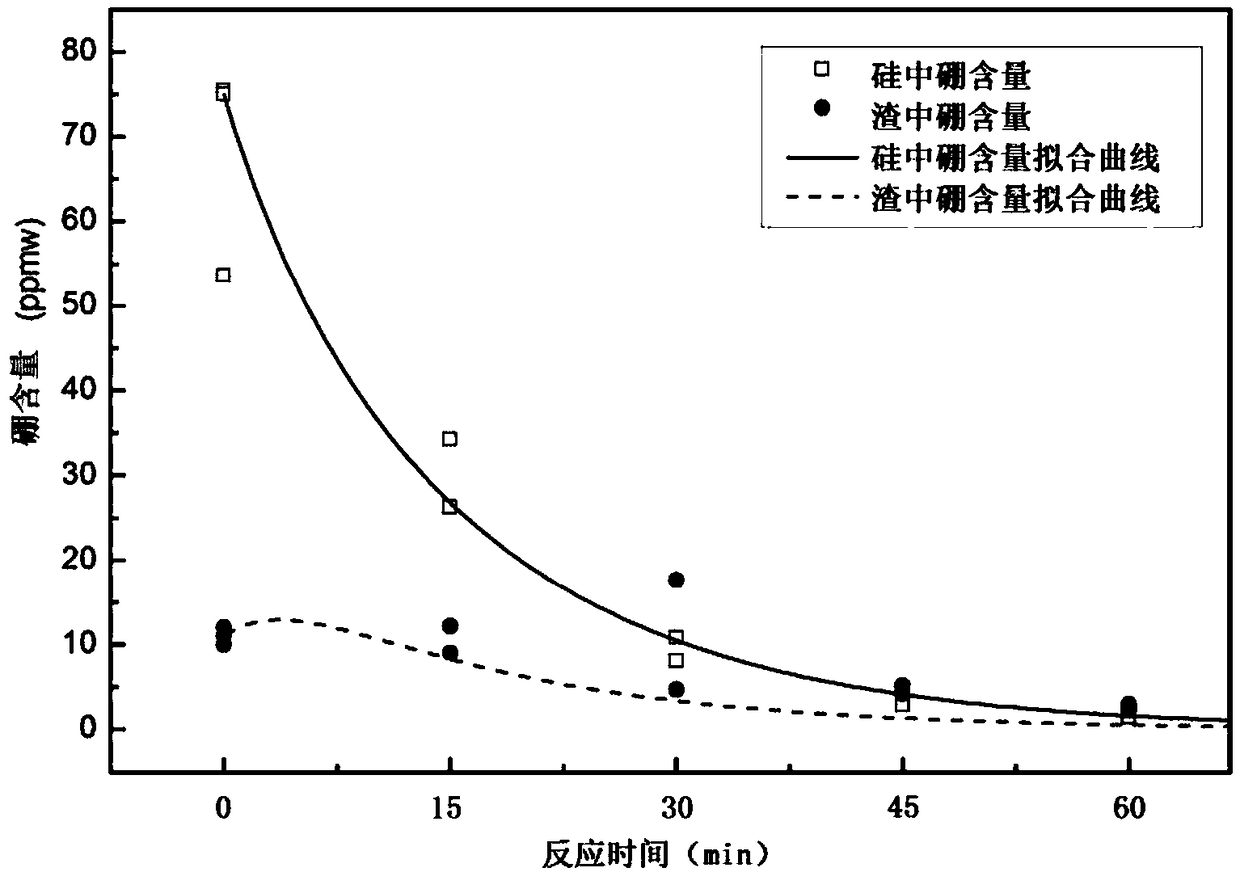

A method for synergistically purifying polysilicon with volatile slag gas

InactiveCN108249447BReduce boron impuritiesReduce purification energy consumptionSilicon compoundsSlagBoron

The invention relates to a method for purifying polycrystalline silicon, particularly relates to a method for purifying polycrystalline silicon by coordination of volatile slag formation and gas blowing, and belongs to the technical field of metallurgy. A technical problem solved by the invention is to provide the method for purifying polycrystalline silicon by coordination of volatile slag formation and gas blowing. The method comprises the following steps: step a, mixing raw material silicon with a slag forming agent of a volatile slag system, heating to melt in an inert gas atmosphere to obtain a melt; and step b, blowing an ammonia gas mixed gas into the melt, performing heat preservation and reacting for 60-120 min, then cooling and performing silicon-slag separation to obtain purified polycrystalline silicon. The method provided by the invention purifies the polycrystalline silicon by coordination of volatile slag formation and gas blowing, realizes coordination of chlorination,oxidation and nitridation in the process of purifying the polycrystalline silicon, and can greatly reduce boron impurity in silicon within a short treatment time so as to greatly reduce energy consumption during purification.

Owner:SICHUAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com