Method for purification of dichlorosilane from dry method recovered material

A dry recovery technology for dichlorodihydrosilane, which is applied in the direction of halosilane and halide silicon compounds, can solve the problems of multiple theoretical plates and reflux ratios, large heat loads, and difficulties in removing impurities in the separation tower, and reduce the The effect of production cost, equipment cost reduction and purification energy consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

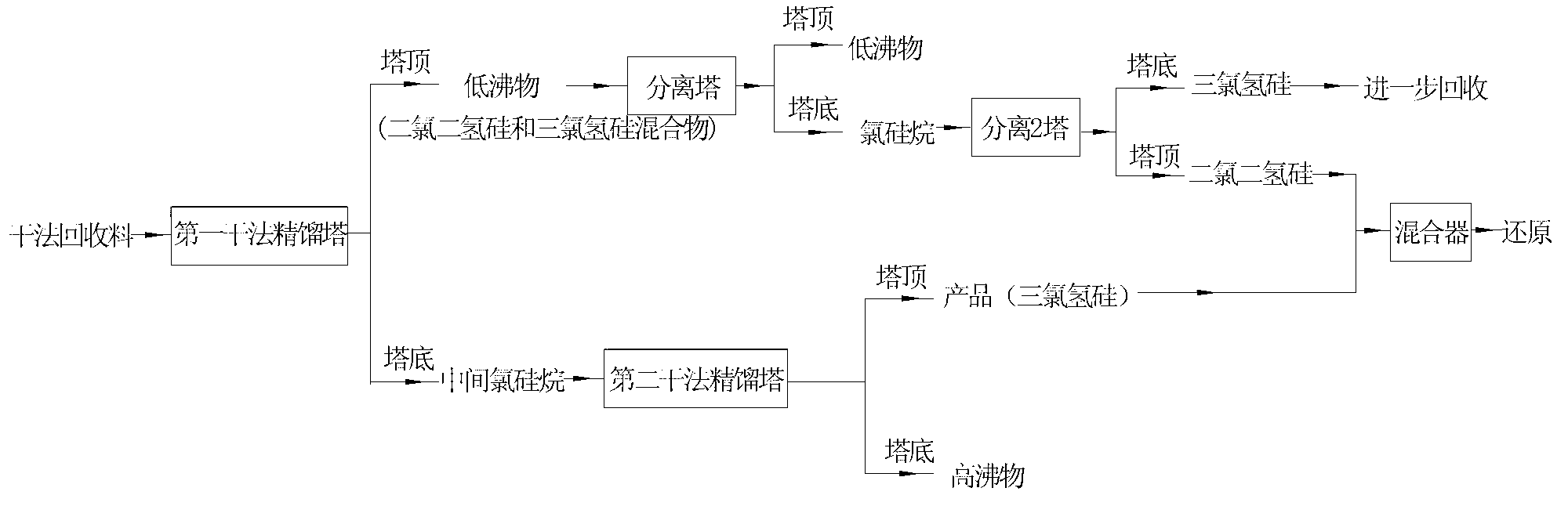

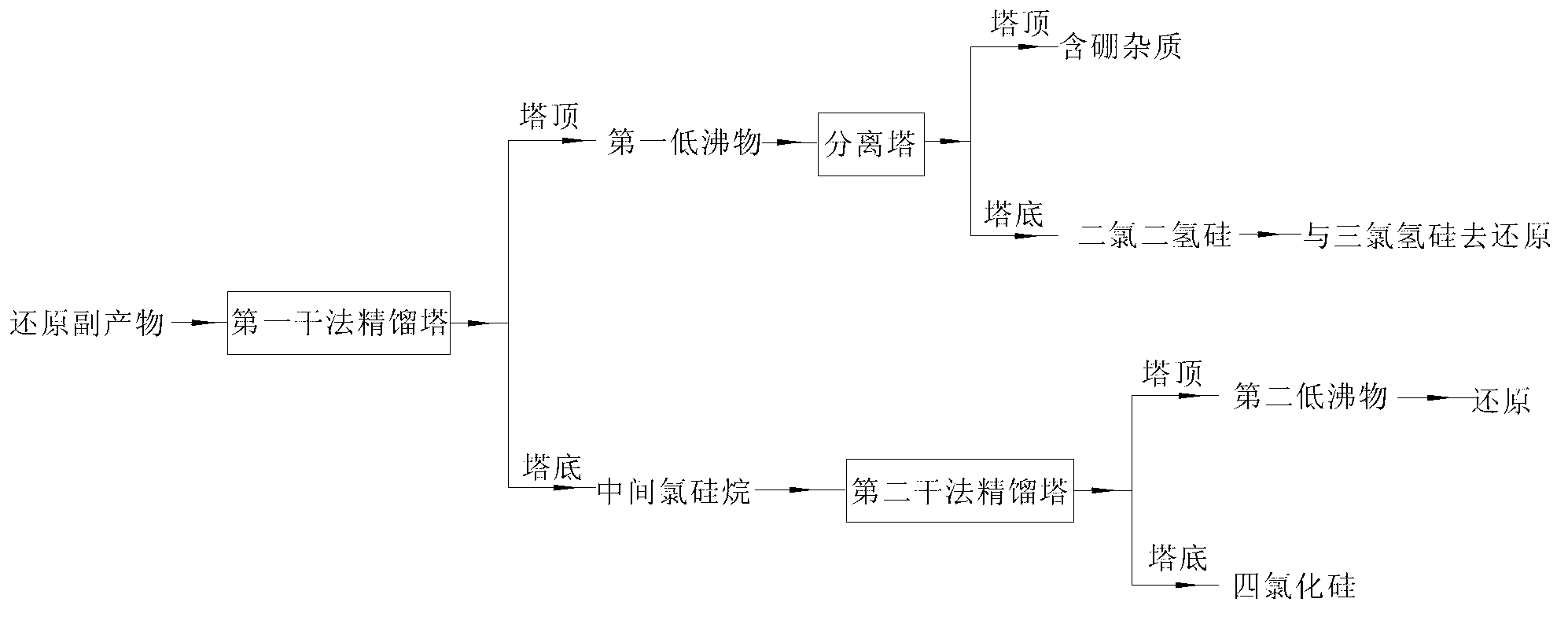

[0037] Adopt the method for purifying dichlorodihydrosilane according to the present invention, utilize such as figure 2 The flow chart shown carries out the purification of dichlorodihydrosilane.

[0038] The dry reclaimed material in the polysilicon production process is sent to the first dry rectification tower for rectification, and the processing capacity of the first dry rectification tower is controlled to be 15m 3 / h.

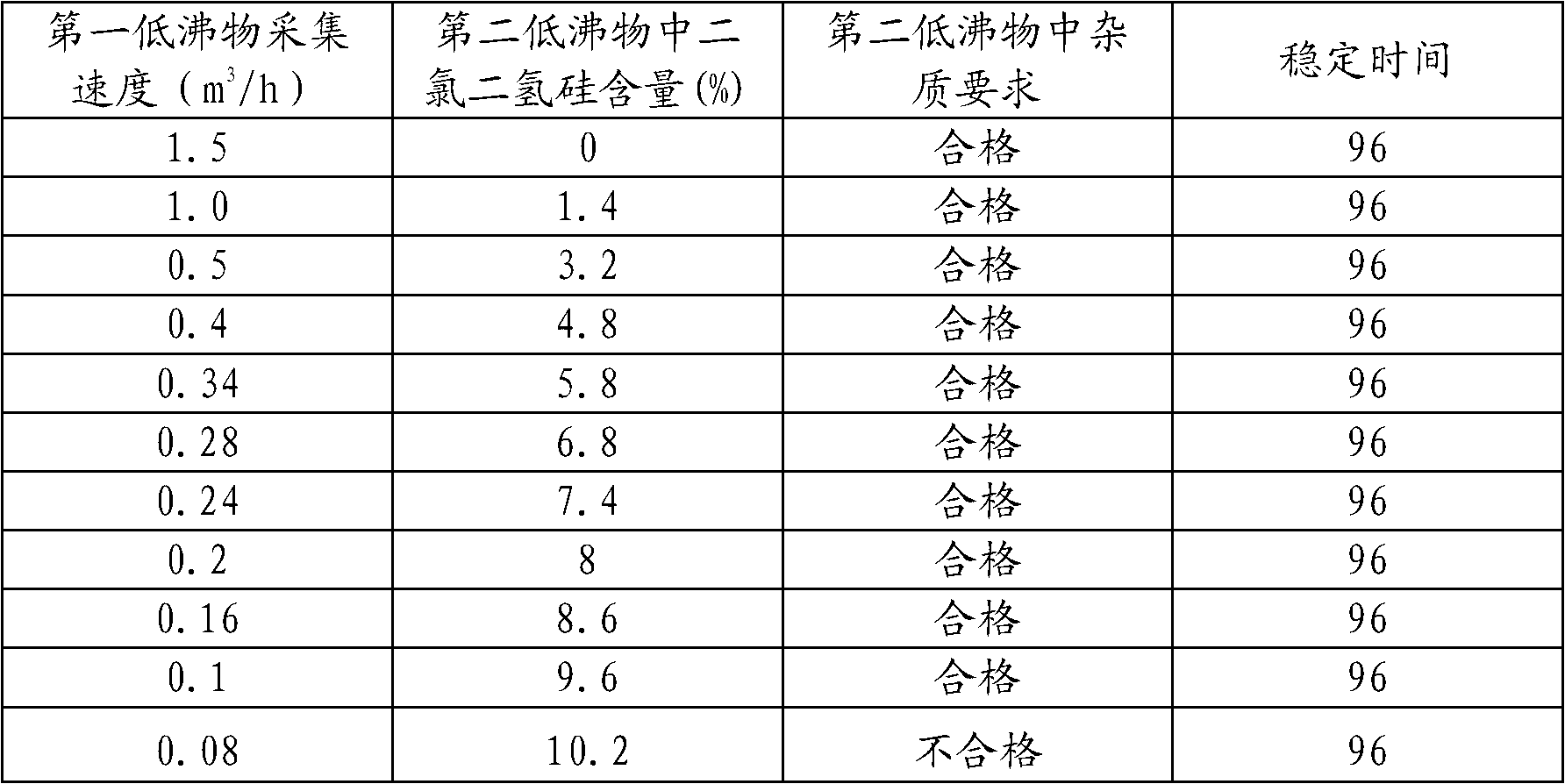

[0039] 0.1~0.5m 3 The extraction speed of / h extracts the first low boiler after rectification from the top of the first dry distillation column, and discharges the intermediate chlorosilane from the bottom of the column. The first low boiler contains dichlorodihydrogen silicon and boron-containing impurities.

[0040] The first low boiling point is 0.1 ~ 0.5m 3 / h speed into the separation tower for separation, and 0.1 ~ 0.45m 3 The speed of / h extracts dichlorodihydrosilane from the bottom of the separation tower, and extracts a small amount of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com