Carrier for loading precipitates, preparation method of carrier and method for loading flocculent precipitates

A carrier and flocculation technology, which is applied in the field of loaded sediment carrier, loaded flocculation and sedimentation, can solve the problems of high project cost and occupied area, strong impact, sewage treatment effect and treatment efficiency are difficult to continue to improve, and achieve the effect of convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

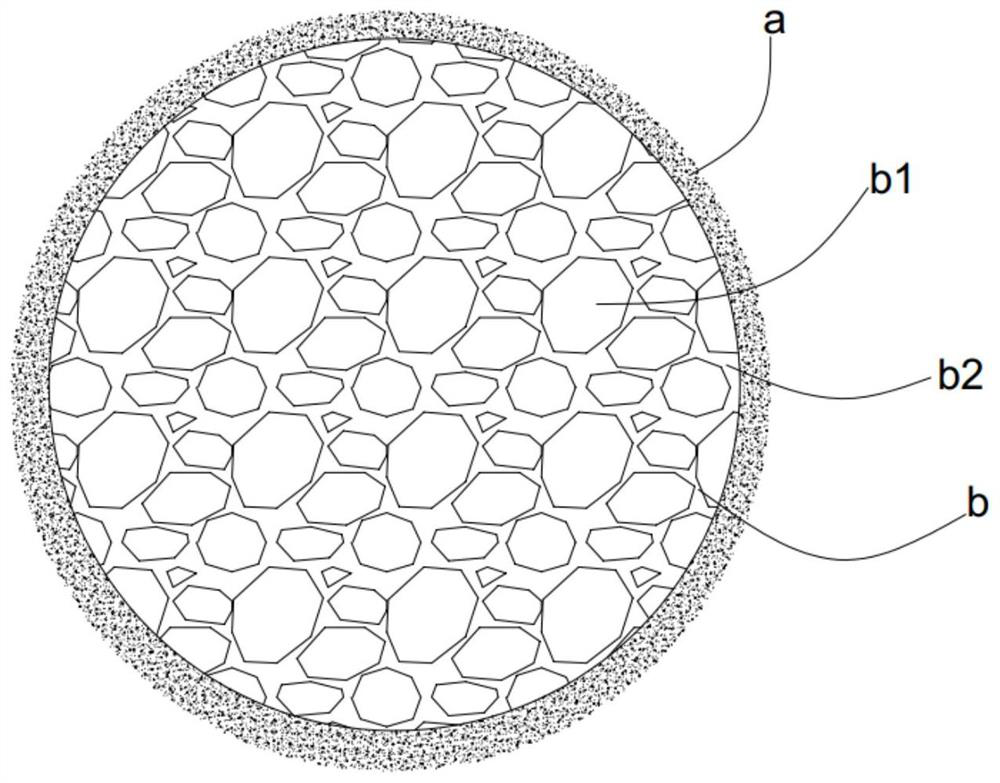

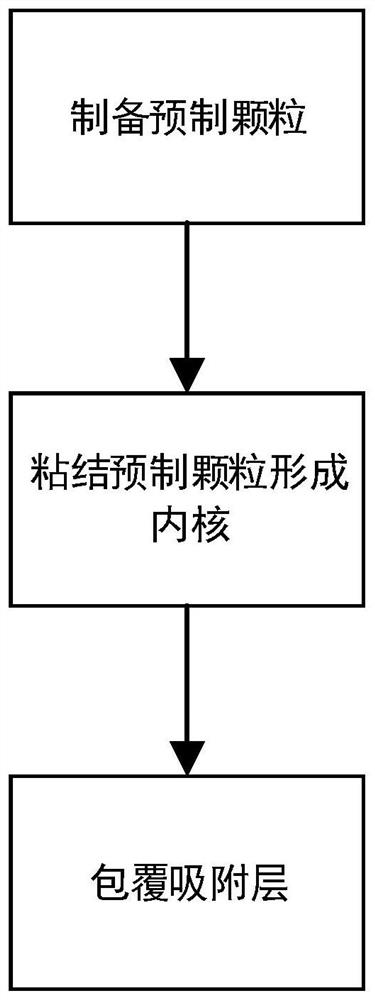

[0056] In addition, if figure 2 As shown, the present application also provides a method for preparing a precipitate-loaded carrier, the preparation method is used to prepare the above-mentioned precipitate-loaded carrier, and the preparation method includes the steps of:

[0057] S1, compressing the prefabricated granule b1 with waste gas recovery powder;

[0058] S2, using the auxiliary agent b2 to bond a plurality of the prefabricated particles b1 together to form the inner core b;

[0059] S3, coating the adsorption layer a on the outer surface of the inner core b.

[0060] Specifically, the step S1 includes:

[0061] S11, waste gas recovery powder pretreatment: use the powder recovered from waste gas as raw material, dry it to constant weight, grind it to an average particle size ≤ 1um, and set aside;

[0062] S12, pressing compacts: placing the ground exhaust gas recovery powder in a mold, and pressing them into compacts with a relative density ≥ 80%;

[0063] S13, ...

Embodiment 1

[0171] A method for preparing a precipitating carrier, the preparation method comprising the steps of:

[0172] S1, use waste gas recovery powder to press prefabricated particles: use the powder recovered from the waste gas of a steel smelting plant as raw material, dry it to constant weight, grind it to an average particle size of ≤1um, put it in a mold, and press it to a relative density of 80% briquette; put the pressed briquette in a pulverizer and crush it into granules, then sieve through a 500-mesh sieve, collect the undersize material for high-temperature sintering, and continue to pulverize the oversize material; high-temperature sintering in the sintering furnace After sintering at 500°C for 2 hours, prefabricated particles were obtained;

[0173] S2, using additives to bond multiple prefabricated granules together to form the inner core: weigh a certain amount of additives according to 10% of the mass of the prefabricated granules, mix the additives and prefabricated ...

Embodiment 2

[0176] A method for preparing a precipitating carrier, the preparation method comprising the steps of:

[0177] S1, use waste gas recovery powder to press prefabricated particles: use the powder recovered from the waste gas of a steel smelting plant as raw material, dry it to constant weight, grind it to an average particle size of ≤1um, put it in a mold, and press it to a relative density of 90% of the briquette; put the compacted briquette in a pulverizer and crush it into granules, and then sieve it through a 500-mesh sieve, collect the undersize for high-temperature sintering, and continue to pulverize the oversize; high-temperature sintering in the sintering furnace After sintering at 600°C for 1 hour, prefabricated particles were obtained;

[0178] S2, using additives to bond multiple prefabricated granules together to form the inner core: weigh a certain amount of additives according to 30% of the mass of the prefabricated granules, mix the additives and prefabricated g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com