Cyclone centrifugal deashing biomass granular fuel burner

A biomass particle, cyclone centrifugation technology, applied in combustion chambers, combustion methods, combustion equipment, etc., can solve the problems of inability to achieve efficient, automatic, continuous combustion, burner blockage, slagging, etc., and achieve stable and reliable working performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

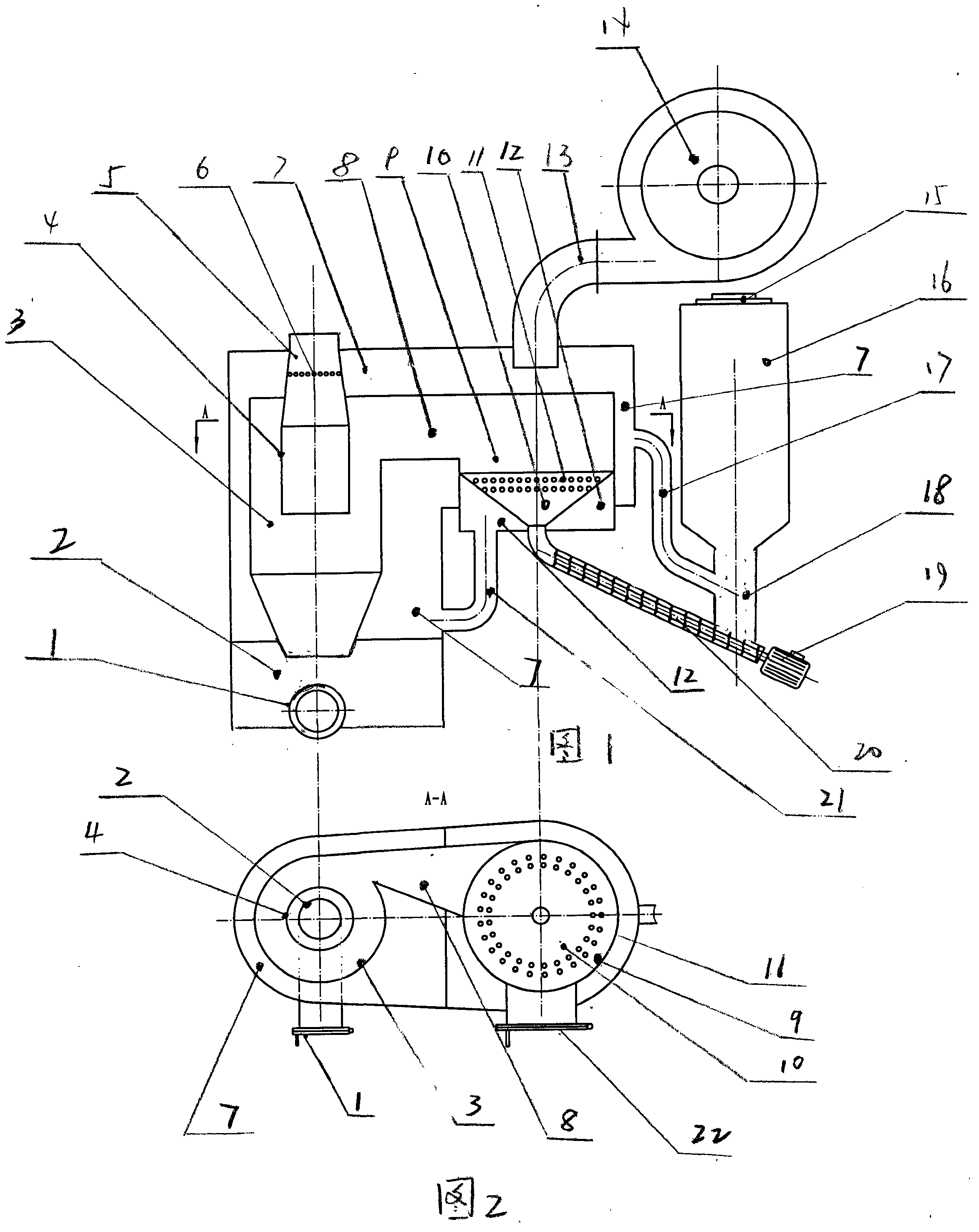

[0012] like figure 1 , figure 2 As shown in , the combustion chamber of the cyclone centrifugal ash removal type biomass pellet fuel burner is composed of three parts: the initial combustion chamber 9, the rotary combustion chamber 3, and the wedge-shaped flame flow channel 8. The primary combustion chamber 9 is a cavity with a cone-shaped bottom and a cylindrical top. The bottom is a cone-shaped combustion cup 10. The combustion cup 10 is covered with a windshield 12. The upper part of the windshield 12 is provided with a secondary air hole 11 and a windshield 12. It communicates with the main air cover 7 via the secondary air pipe 21 . The lower part of the conical combustion cup 10 is connected with the screw conveyor 20 . The rotary combustion chamber 3 is also a cavity with a cone-shaped bottom and a column-shaped top, and the ash storage chamber 2 is below the cone-shaped bottom. The upper part of the rotary combustion chamber 3 is a fire outlet 5, and three air hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com