Multi-ash biomass granular fuel combustor

A technology of biomass particles and burners, which is applied in the field of burners, can solve the problems of burner clogging, slagging, and the inability of burners to achieve high-efficiency, automatic, and continuous combustion, and achieve stable and reliable working performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

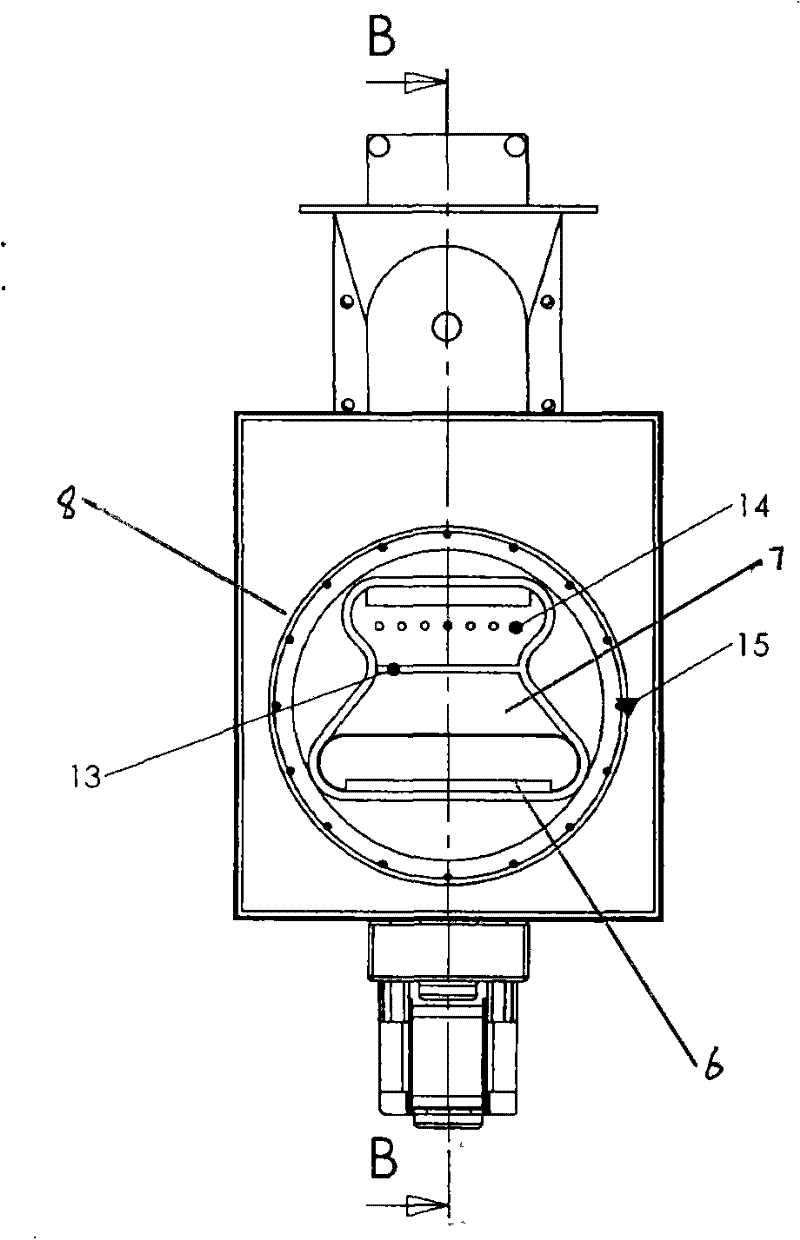

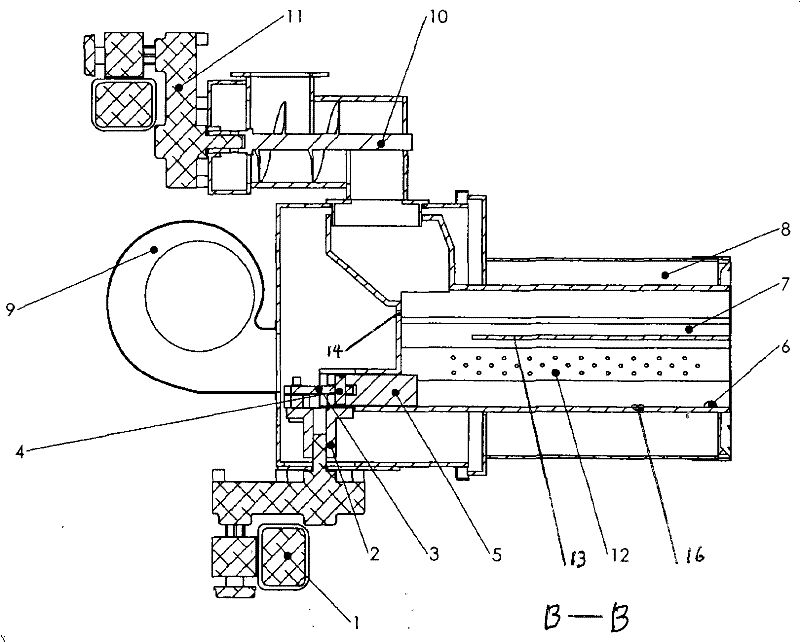

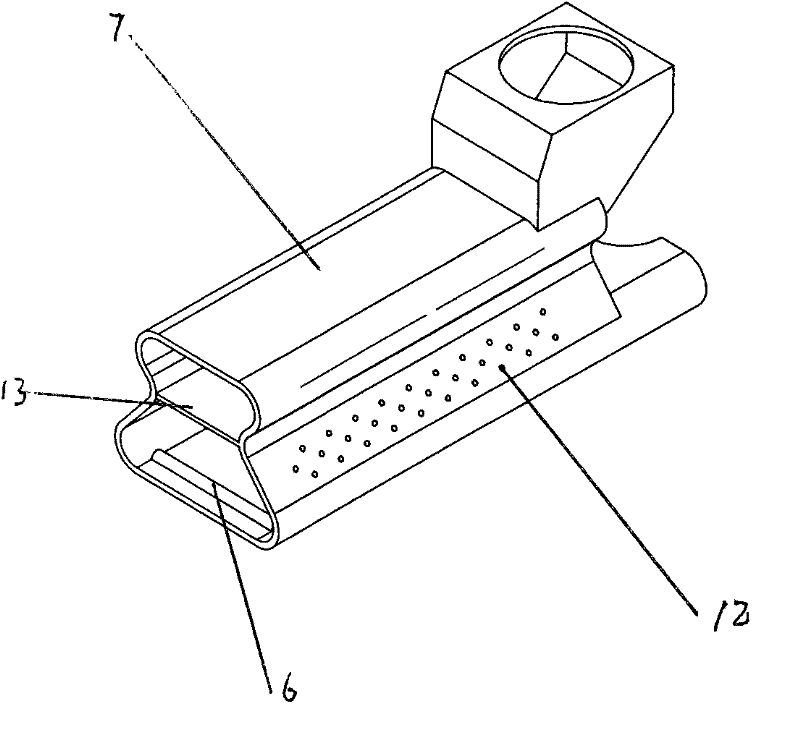

[0013] Such as figure 2 , image 3 , Figure 4 As shown, the combustion chamber 7 is a flat-bottomed elongated cavity, the upper rear of the cavity is facing the feeding port of the feeding device 10, the front end of the cavity is open, and the piston 5 driven by the ash pushing motor 1 is installed in the combustion chamber 7. At the end, the bottom surface of the piston 5 and the arc-shaped surfaces on both sides match with the flat-bottomed material bed 16 in the combustion chamber 7 and the adjacent arc-shaped surfaces on both sides. The combustion chamber 7 is covered with a cylindrical air cover 8, and the two sides of the combustion chamber 7 are evenly distributed with three rows of primary air holes 12 for supplying air to the fuel. There is a row of secondary air holes 14, and tertiary air holes 15 are distributed around the wind cover 8 circles. In order to prevent the particulate fuel from falling out, a baffle plate 6 is provided at the front end of the flat-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com