Discontinuous variable-pitch biomass particle fuel combustor

A biomass particle and burner technology, applied in the field of burners, can solve problems such as high efficiency, automatic, continuous combustion, burner blockage, coking, etc., and achieve stable and reliable working performance, simple and reliable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

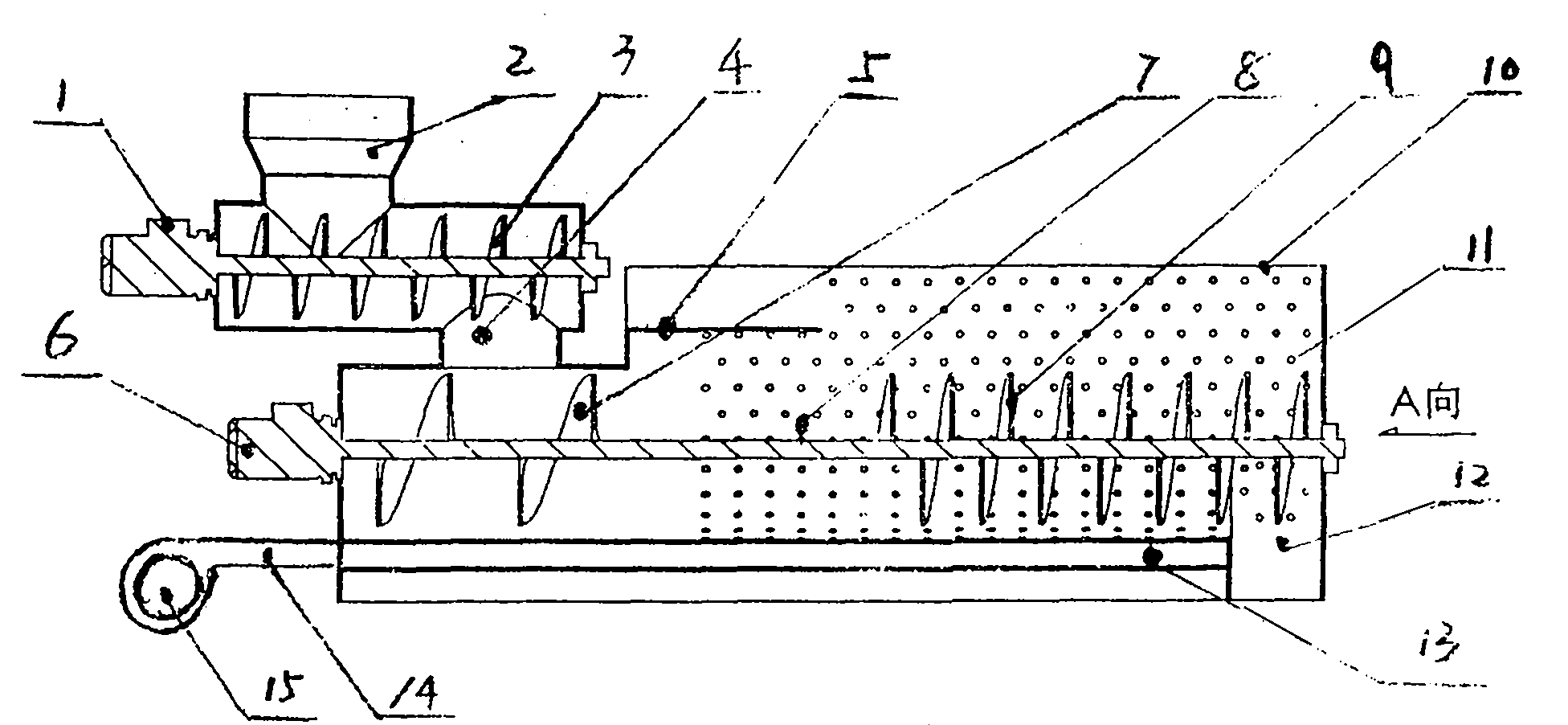

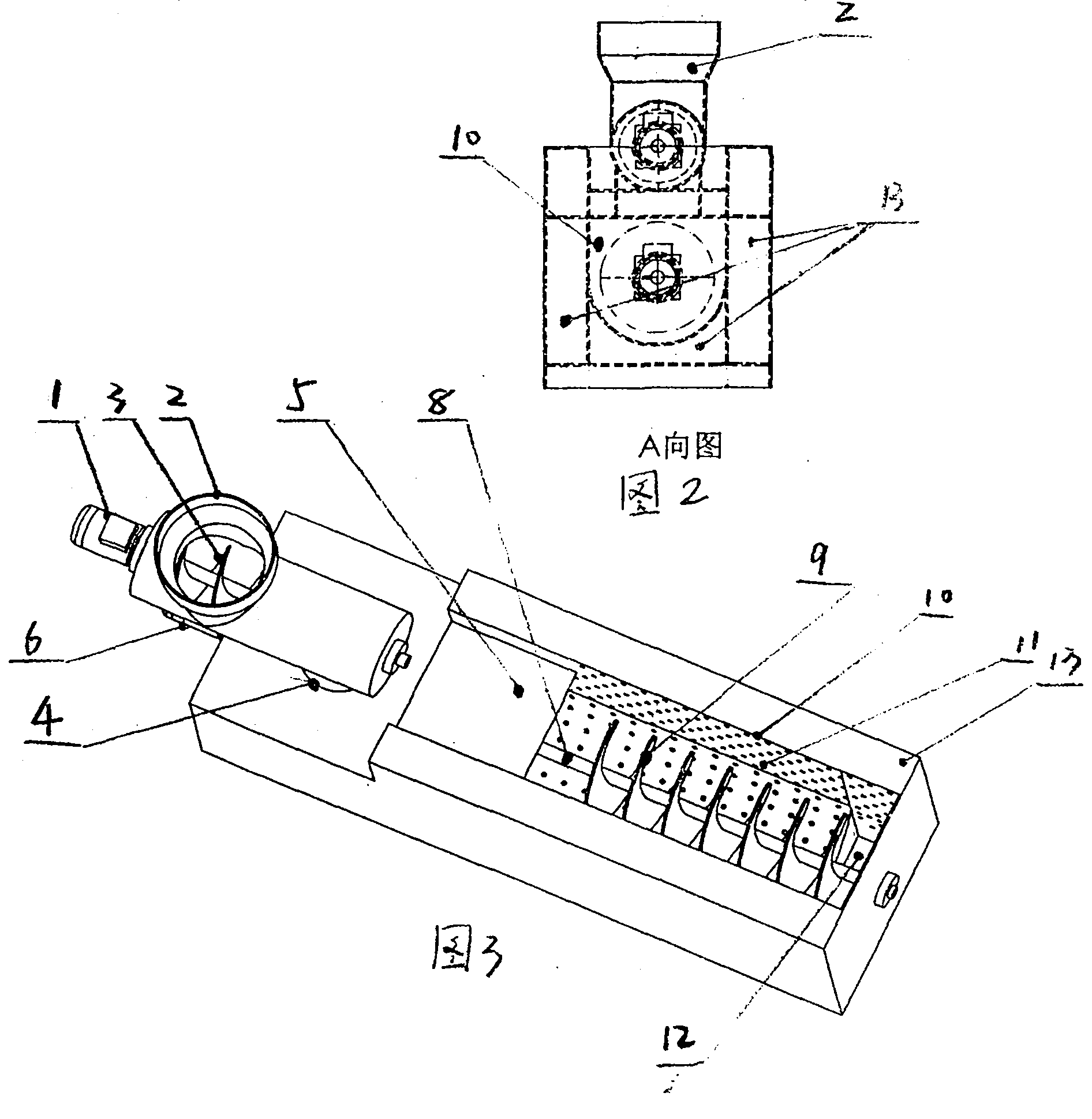

[0013] like figure 1 , image 3 As shown in , the combustion chamber 10 of the non-continuous variable-pitch biomass pellet fuel burner is a semicircular elongated cavity at the bottom, and the rear and upper part of the combustion chamber 10 communicates with the feeding screw 3 through the secondary feed port 4, and the feeding screw 3 Connected with the feeding motor 1, the rear and upper part of the feeding screw 3 is the primary feed port 2, the fuel that falls into the feeding screw 3 from the primary feed port 2 enters the secondary feed port 4 forward under the push of the feeding screw 3, Finally fall into the middle of the pusher screw 7 at the bottom of the combustion chamber 10, the pusher screw 7 is connected with the pusher motor 6, and the pusher motor 6 drives the pusher screw 7 to rotate, and the fuel in the pusher screw 7 moves forward. After being compacted by the compacting plate 5, the fuel reaches the stagnant combustion zone 8 without helical blades. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com