Automatic-ash discharging biomass particle combustor

A biomass particle and burner technology, applied in combustion chambers, combustion methods, combustion equipment, etc., can solve the problems of inability to achieve high-efficiency, automatic, continuous combustion, coking, and burner blockage, and achieve stable and reliable working performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

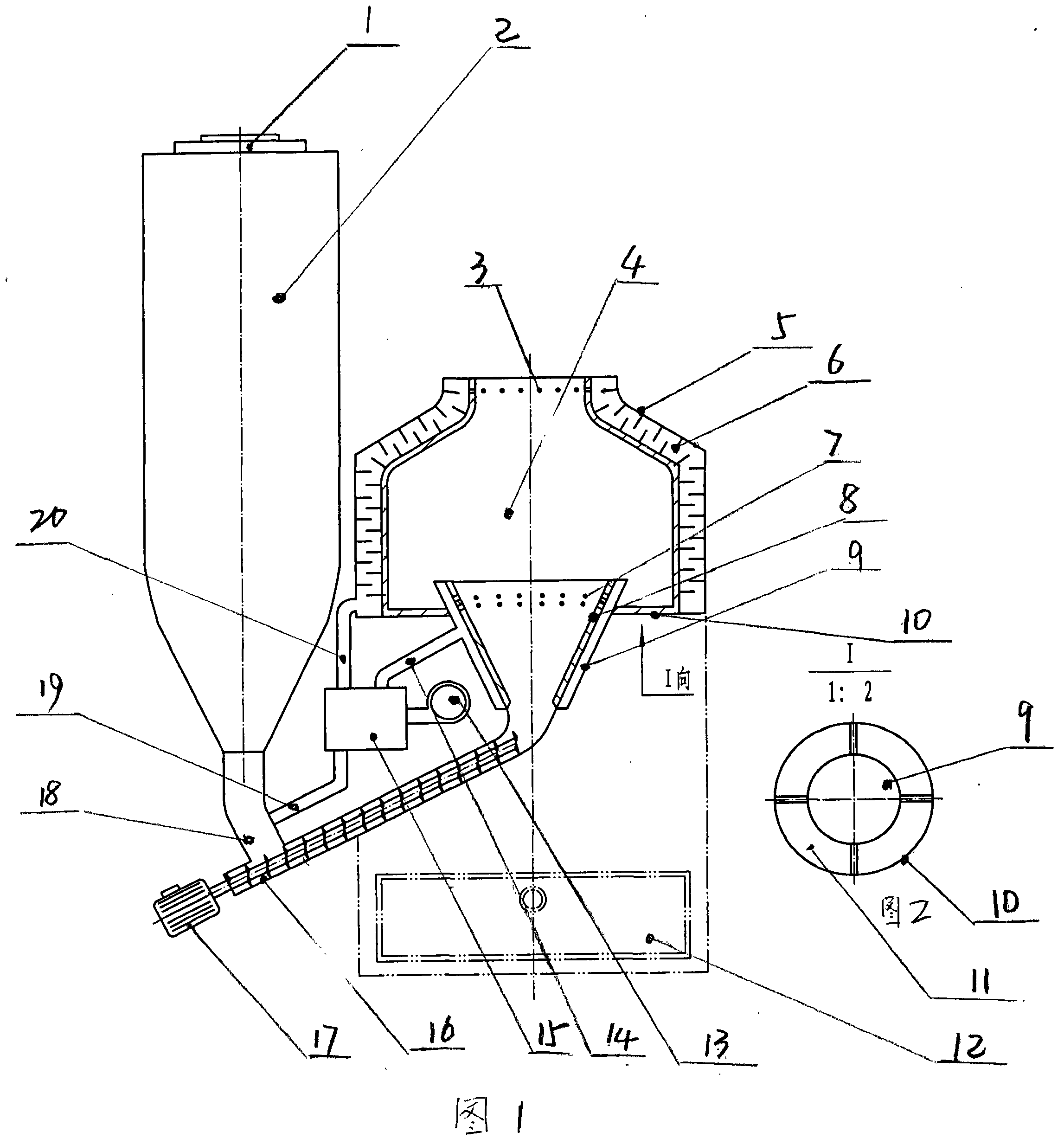

[0012] As shown in the figure, the combustion chamber 4 of the self-discharging ash-rich biomass particle burner has a cone-shaped upper and lower section and a column-shaped cavity in the middle section. The outer periphery of the combustion chamber 4 is covered with an air hood 5, and a spiral labyrinth air passage 6 is arranged in the air hood 5. The upper end of the combustion chamber 4 is open, and the tertiary air holes 3 are arranged in the open opening. The lower part of the combustion chamber 4 is a cone-shaped combustion cup 8 , and a wind hood 9 is sleeved around the cone-shaped combustion cup 8 , and the wind hood 9 is located on the ash leakage tray 10 . There are two air holes 7 in the upper part of the conical combustion cup 8, and the bottom is communicated with the screw conveyor 16. The feed port 18 at the lower part of the silo 2 is communicated with the air distribution chamber 15 by a primary air pipe 19 . In addition, the air distribution chamber 15 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com