Slag-bonding resistant biomass particle combustion device

A biomass particle and combustion device technology, applied in combustion chambers, combustion methods, combustion equipment, etc., can solve the problems of serious slagging, inability to achieve high-efficiency, automatic, continuous combustion, burner blockage, etc., to achieve high-efficiency energy conversion and Stable and reliable effect of utilization and work performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

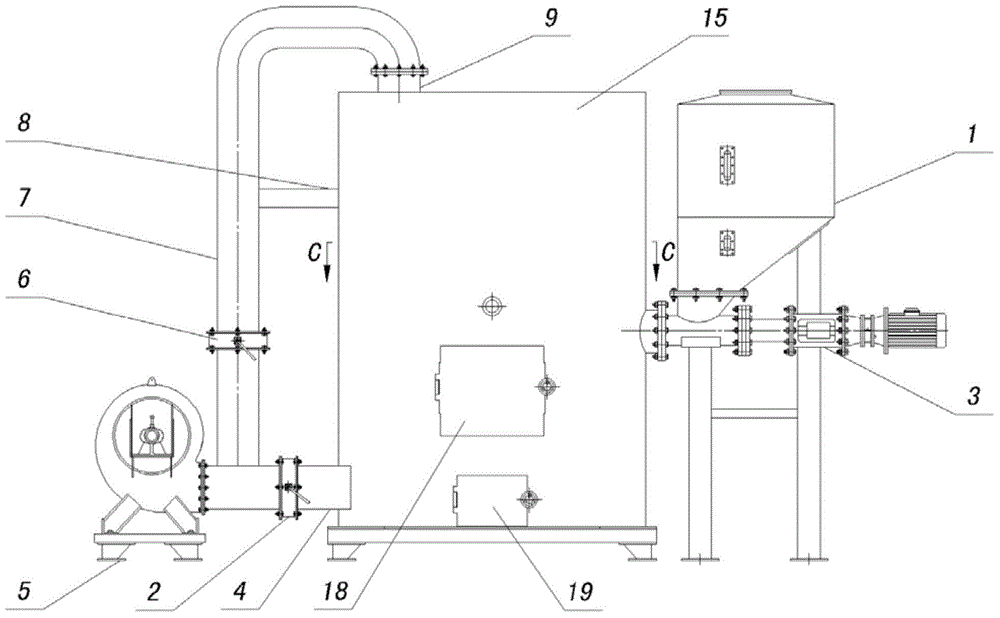

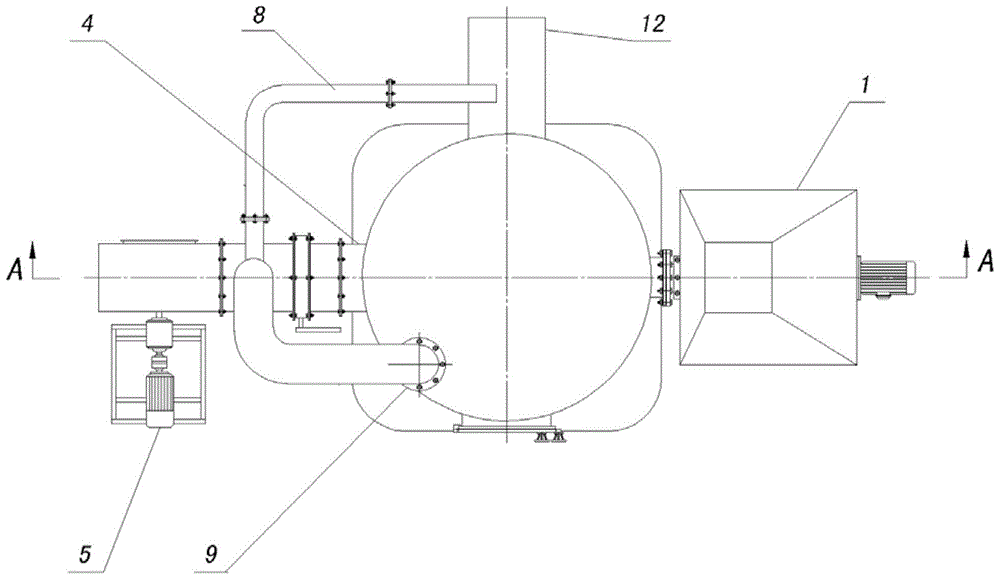

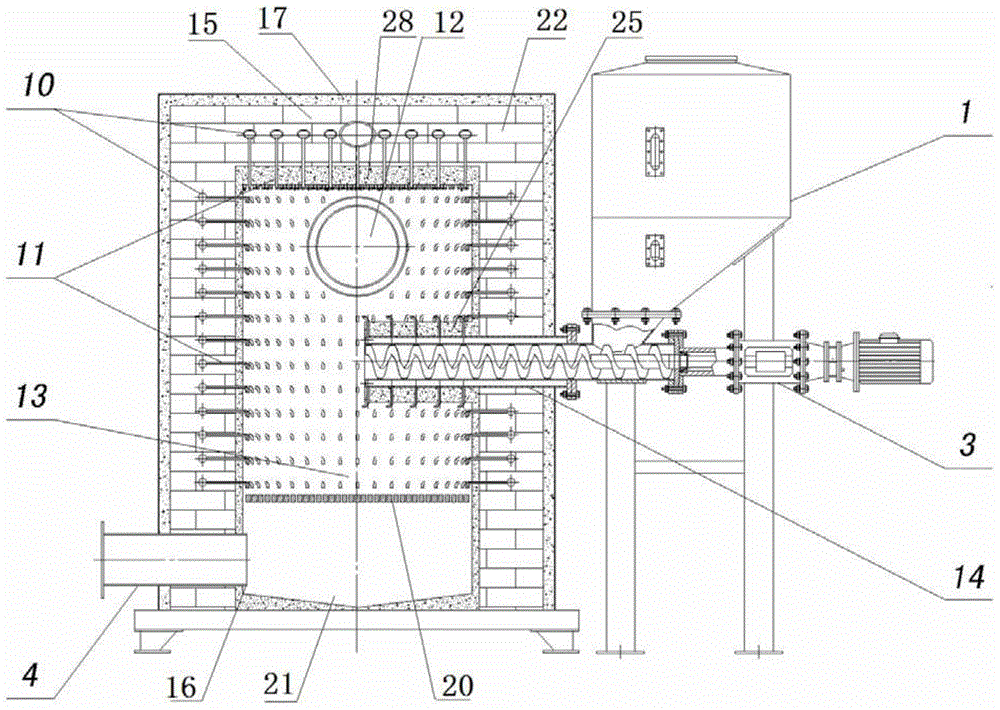

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

[0016] See figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 , an anti-slagging biomass particle combustion device, comprising a feeding device, an air supply device, and a combustion chamber, the feeding device includes a biomass particle silo 1, and the bottom of the biomass particle silo 1 is connected with a screw feeding device 3 feed port connection; the combustion chamber includes a combustion chamber body 15, the combustion chamber body 15 includes a furnace wall 22 and a shell 17 with a refractory material layer 28 on the inner surface, and the space inside the refractory material layer 28 is the combustion chamber chamber 13 and the ash collection chamber 21, a fire grate 20 is provided at the bottom of the combustion chamber chamber 13, a secondary air inlet 9 is provided at the top of the combustion chamber body 15, a fire pipe 12 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com