Purification method for acetic acid synthesized by low pressure methanol carbonylation

A purification method and oxo synthesis technology, applied in the separation/purification of carboxylic acid compounds, organic chemistry, etc., can solve the problems of increased methyl acetate and methyl iodide, pollution, increased content, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

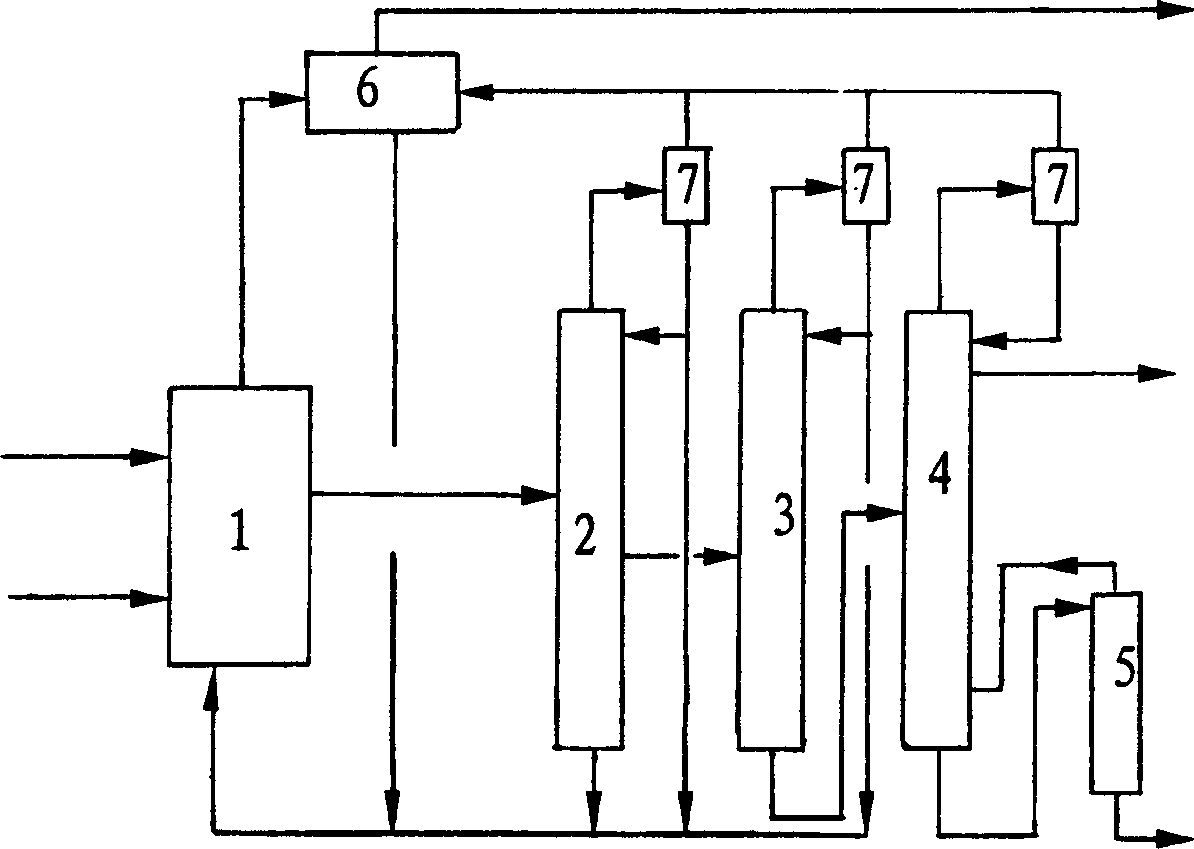

Method used

Image

Examples

Embodiment 1

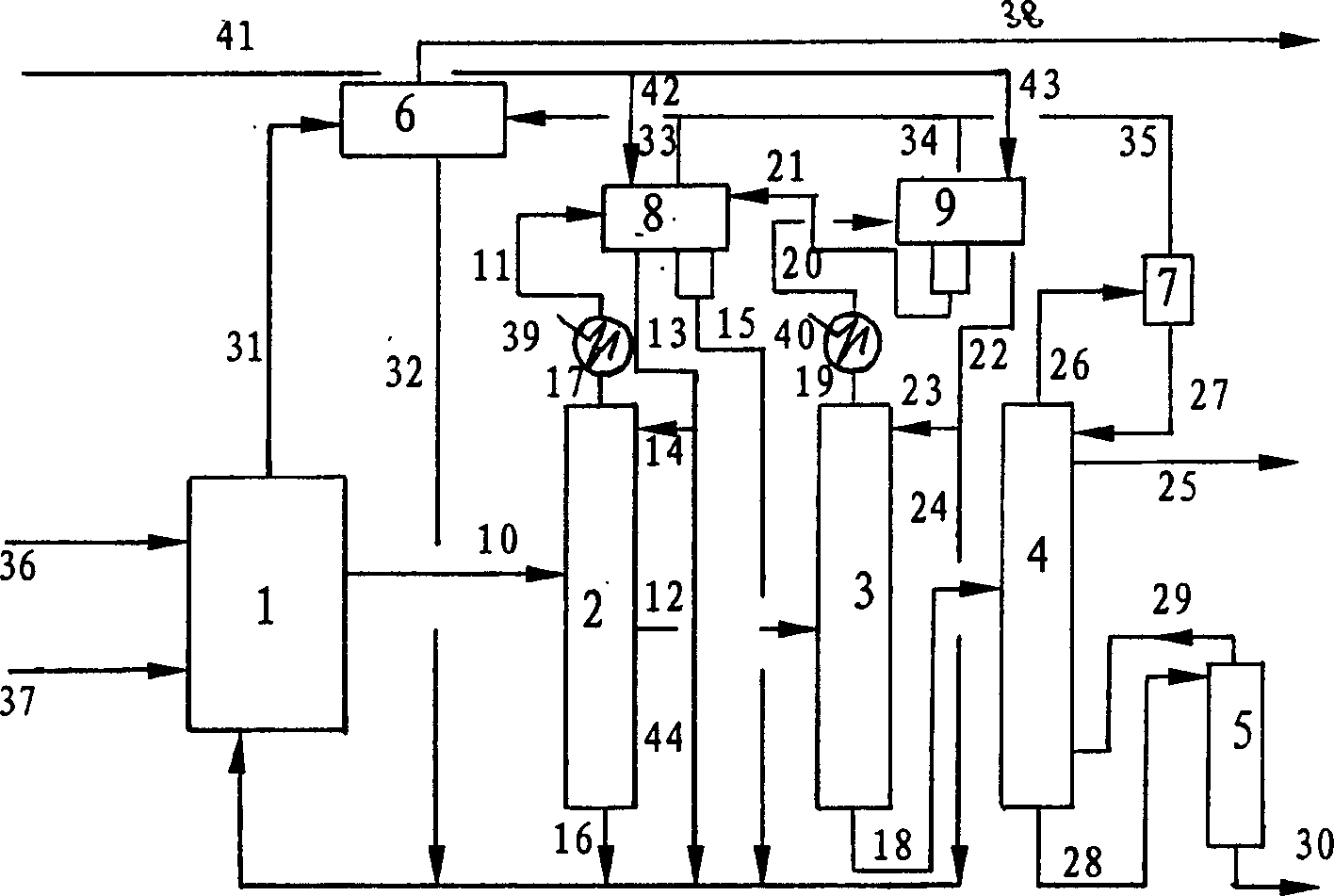

[0054] The reaction solution consists of: 70.5wt% acetic acid, 1wt% methyl acetate, 12wt% methyl iodide, 14wt% water, Fe0.0025wt%, Ni0.0024wt%, Cr0.0050wt%, Mo0.0100wt%, I - 2.5wt%, Rh0.04wt%.

[0055] Carry out experiments according to the embodiment, and keep the temperature in the decanter 8 at about 40° C., and keep the temperature in the decanter 9 less than 45° C. Keep the flow rate of logistics 41 at 100kg / h, and keep the flow rate of logistics 42 at 100kg / h. The catalyst composition, the composition of stream 12, the density of stream 15, the concentration of stream 21, the composition of stream 25, and the composition of stream 30 were tested. And obtain product 25127kg, waste acid 300.2kg. What table 1 records is the material flow and process condition of embodiment 1.

[0056] Embodiment 1 is as a kind of contrast of the present invention, and decanter (9) is not used as decanter.

[0057] name

Embodiment 2

[0059] The reaction solution consists of: 59.8wt% acetic acid, 1.94wt% methyl acetate, 10.37wt% methyl iodide, 7.17wt% water, K + 0.5000wt%, Li + 0.3700wt%, Fe 0.1357wt%, Ni 0.0798wt%, Cr 0.0916wt%, I - 10.83wt%, Rh 0.0650wt%.

[0060] Carry out experiments according to the embodiment, and keep the temperature in the decanter 8 at about 36° C., and keep the temperature in the decanter 9 less than 45° C. Keep the flow rate of logistics 41 at 100kg / h, and keep the flow rate of logistics 42 at 75kg / h. The catalyst composition, the composition of stream 12, the density of stream 15, the concentration of stream 21, the composition of stream 25, and the composition of stream 30 were tested. And obtain product 25 179.5kg, spent acid 30 0.23kg. What table 2 records is the material flow and process condition of embodiment 2.

[0061] name

Embodiment 3

[0063] The reaction solution consists of: 64.9wt% acetic acid, 3.0wt% methyl acetate, 14.0wt% methyl iodide, 8.4wt% water, 0.0341wt% propionic acid, K + 0.4000wt%, Li + 0.3600wt%, Fe 0.1551wt%, Ni 0.1027wt%, Cr 0.1085wt%, Mo 0.0708wt%, I - 9.5wt%, Rh 0.0740wt%.

[0064] Carry out experiments according to the embodiment, and keep the temperature in the decanter 8 at about 32° C., and keep the temperature in the decanter 9 less than 45° C. Keep the flow rate of logistics 41 at 90kg / h, and keep the flow rate of logistics 42 at 50kg / h. The catalyst composition, the composition of stream 12, the density of stream 15, the concentration of stream 21, the composition of stream 25, and the composition of stream 30 were tested. And obtain product 25 225.8kg, spent acid 30 0.25kg. What table 3 records is the material flow and process condition of embodiment 3.

[0065] name

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com