Method and device for preparing high-purity hydrogen from biomass

A biomass, high-purity technology, applied in the fields of biofuels, production of combustible gas, chemical instruments and methods, etc., can solve the problems of many components in hydrogen-rich gas products, complicated reaction process, quantitative hydrogen production process, etc., to achieve simplification Pressure swing adsorption purification system, high yield, the effect of increasing the reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

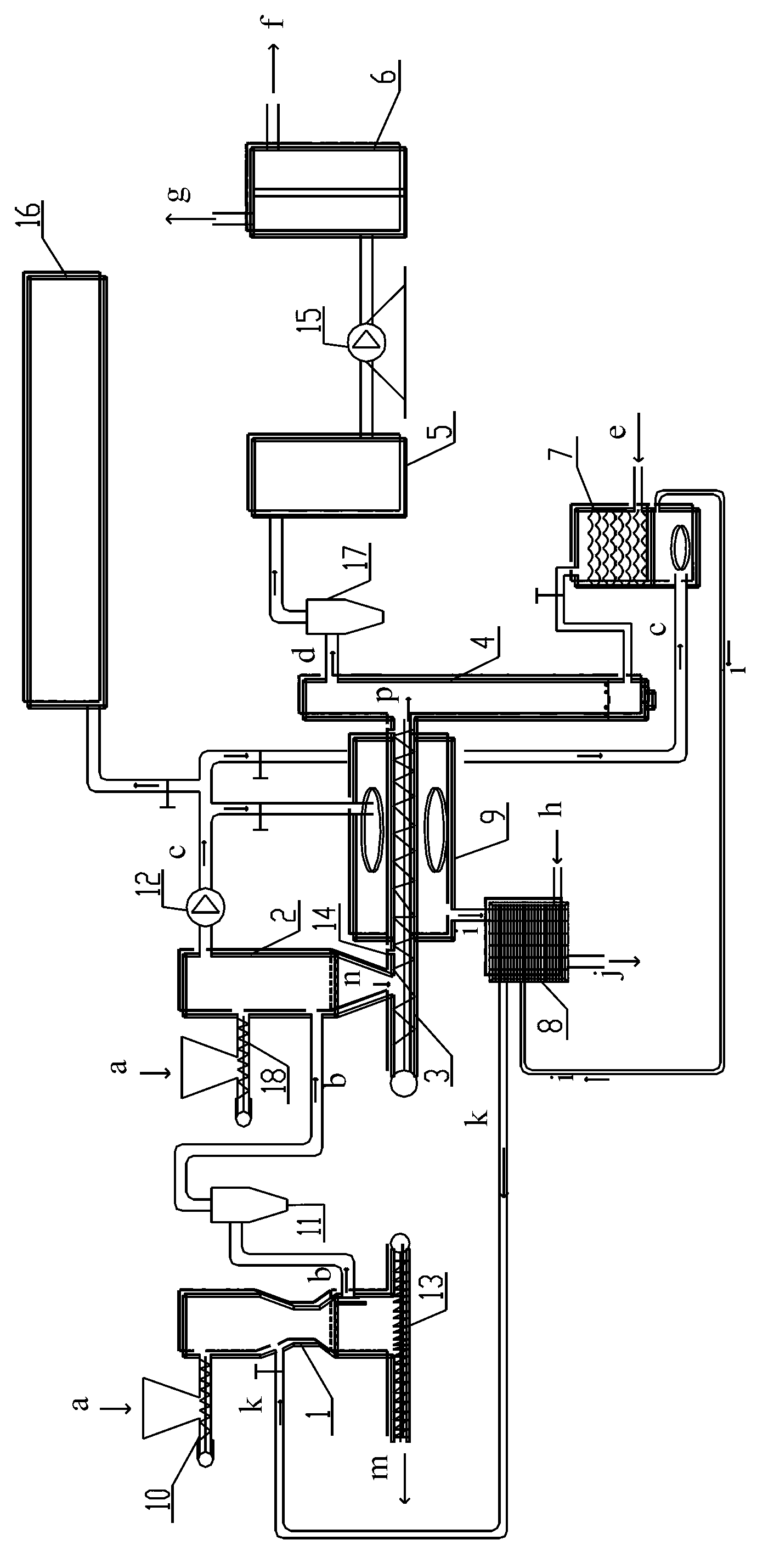

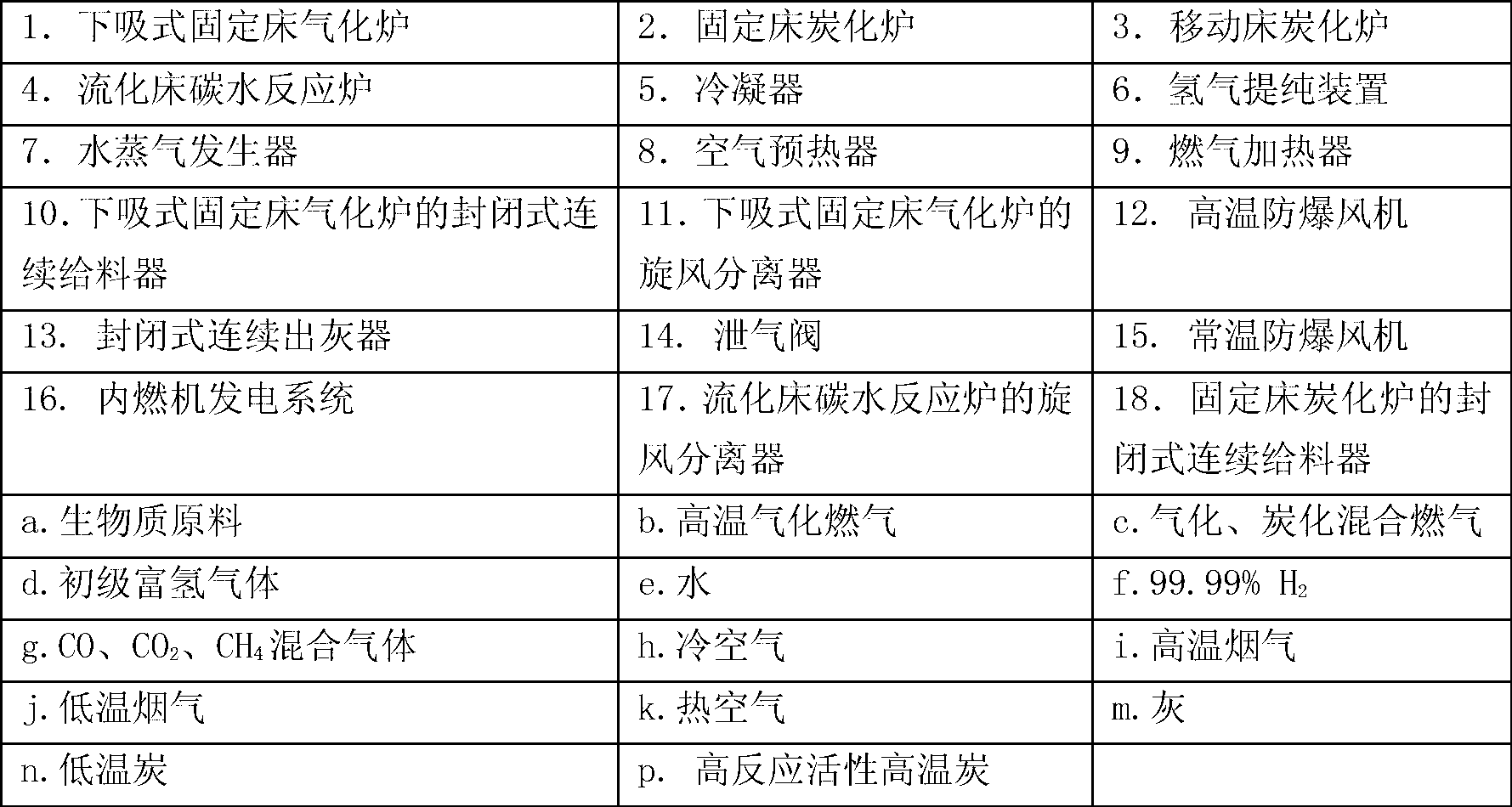

Image

Examples

Embodiment 1

[0044] Using sawdust as biomass raw material, the process is as described above, and the main reaction parameters are as follows:

[0045] (1) Biomass gasification process:

[0046] The gasification equivalent ER is 0.2, and the gasification reaction temperature is 700°C. The temperature of the generated gasified gas is 680°C, and the gas yield is 2.3Nm 3 (gas) / kg (wood chips).

[0047] (2) Slow low temperature carbonization process:

[0048] The carbonization heating rate is 5°C / min, and the carbonization temperature is 350°C. The yield of low-temperature charcoal is 0.4kg (low-temperature charcoal) / kg (wood chips).

[0049] (3) Rapid high-temperature carbonization process:

[0050] The carbonization heating rate is 100°C / min, and the carbonization temperature is 900°C. The yield of high-reactivity high-temperature charcoal is 0.9kg (high-temperature charcoal) / kg (low-temperature charcoal).

[0051] (4) Carbon water reaction process

[0052] The molar ratio of water v...

Embodiment 2

[0056] Using rice husk as biomass raw material, the main reaction parameters are as follows:

[0057] (1) Biomass gasification process:

[0058] The gasification equivalent ER is 0.22, and the gasification reaction temperature is 740°C. The temperature of the generated gasification gas is 690°C, and the gas yield is 1.9Nm 3 (gas) / kg (rice husk).

[0059] (2) Slow low temperature carbonization process:

[0060] The carbonization heating rate is 7°C / min, and the carbonization temperature is 370°C. The yield of low-temperature charcoal is 0.3kg (low-temperature charcoal) / kg (rice husk).

[0061] (3) Rapid high-temperature carbonization process:

[0062] The carbonization heating rate is 148°C / min, and the carbonization temperature is 930°C. The yield of high-reactivity high-temperature charcoal is 0.7kg (high-temperature charcoal) / kg (low-temperature charcoal).

[0063] (4) Carbon water reaction process

[0064] The molar ratio of water vapor to carbon is 6:1, and the sup...

Embodiment 3

[0068] With crushed cotton stalks as biomass raw material, the main reaction parameters are as follows:

[0069] (1) Biomass gasification process:

[0070] The gasification equivalent ER is 0.25, and the gasification reaction temperature is 800°C. The temperature of the generated gasification gas is 720°C, and the gas yield is 2.1Nm 3 (gas) / kg (cotton straw).

[0071] (2) Slow low temperature carbonization process:

[0072] The carbonization heating rate is 10°C / min, and the carbonization temperature is 400°C. The yield of low-temperature charcoal is 0.33kg (low-temperature charcoal) / kg (cotton straw).

[0073] (3) Rapid high-temperature carbonization process:

[0074] The carbonization heating rate is 200°C / min, and the carbonization temperature is 1000°C. The yield of high-reactivity high-temperature charcoal is 0.8kg (high-temperature charcoal) / kg (low-temperature charcoal).

[0075] (4) Carbon water reaction process

[0076] The molar ratio of water vapor to carbon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com