Sintered flue gas full-process purification system and method thereof

A technology for sintering flue gas and purification system, which is applied in the field of sintering flue gas purification, can solve the problems of inability to purify sintering flue gas in the whole process, high energy consumption, and substandard purification results, and achieves good desulfurization effect, high denitration efficiency, and operation. The effect of cost control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

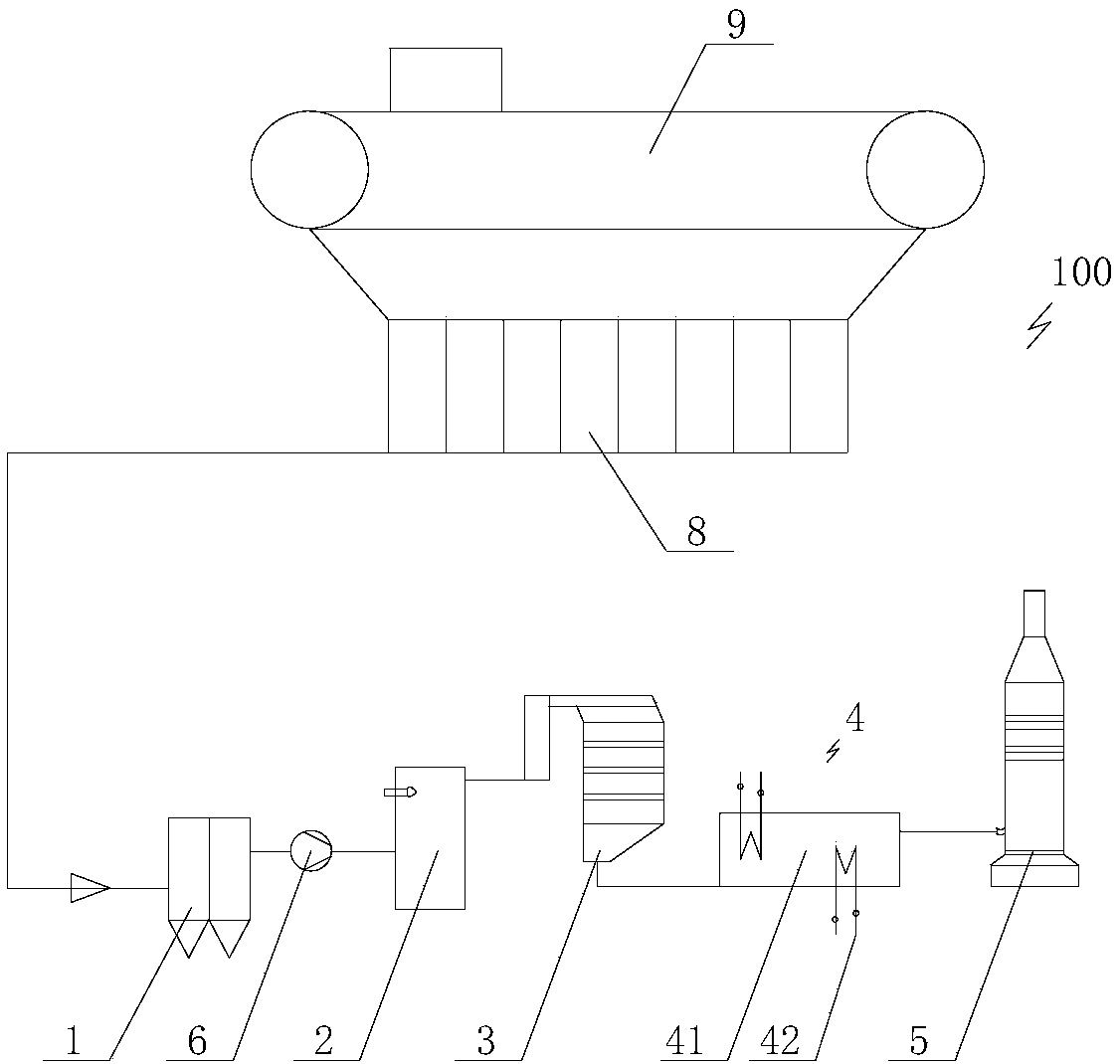

[0058] As a specific implementation of this embodiment, the sintering flue gas drawn from the wind box 8 of the sintering machine is collected together. At this time, the SO in the sintering flue gas 2 The concentration is 1500mg / Nm 3 , NOx concentration is 450mg / Nm 3 , the dust concentration is 3000mg / Nm 3 , the flue gas temperature is 120°C, the sintering flue gas is directly introduced into the dust removal device 1 (electrostatic dust removal device) through the booster fan 6, and the dust concentration is reduced to 100mg / Nm 3 , and then send the sintering flue gas into the second sintering flue gas channel of the heating device 2 (heating furnace), and use blast furnace gas (or combustible gases such as coke oven gas, converter gas, and various purge gases) to burn the second sintering gas. The sintering flue gas in the flue gas channel is heated to 320°C, and the heated sintering flue gas enters the denitrification device 3 equipped with a medium-temperature (conventi...

Embodiment 2

[0060] As another specific implementation of this embodiment, the sintering flue gas drawn from the wind box 8 of the sintering machine is collected together. At this time, the SO in the sintering flue gas 2 The concentration is 1000mg / Nm 3 , NOx concentration is 350mg / Nm 3 , the dust concentration is 2000mg / Nm 3 , the flue gas temperature is 160°C, the sintering flue gas is directly introduced into the dust removal device 1 (electrostatic dust removal device) through the booster fan 6, and the dust concentration is reduced to 50mg / Nm 3 , and then send the sintering flue gas into the second sintering flue gas channel of the heating device 2 (heating furnace), and use blast furnace gas (or combustible gases such as coke oven gas, converter gas, and various purge gases) to burn the second sintering gas. The sintering flue gas in the flue gas channel is heated to 260°C, and the heated sintering flue gas enters the denitrification device 3 equipped with a low-temperature catalys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com