Device and method for removing sulfur oxides in high-humidity flue gas

A technology of sulfur oxides and high humidity, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the difficulties in the treatment of high ammonia nitrogen and high sulfate wastewater, low desulfurization solution concentration cannot reach saturation concentration, and high energy consumption And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The technical solutions of the present invention will be further described below in conjunction with the embodiments.

[0045] It is used in the side line treatment unit of the tail gas ammonia desulfurization device after sulfur recovery and incineration in a refining and chemical enterprise. Liquid ammonia is used as the desulfurizer, the by-product is ammonium sulfate, and the flue gas treatment capacity is 1000Nm 3 / h (wet basis), the volume fraction of water vapor in the original flue gas is 28.5%, the temperature is 200°C, SO 2 The content is 10000mg / Nm 3 , SO 3 The content is 200mg / Nm 3 , no dust in the flue gas.

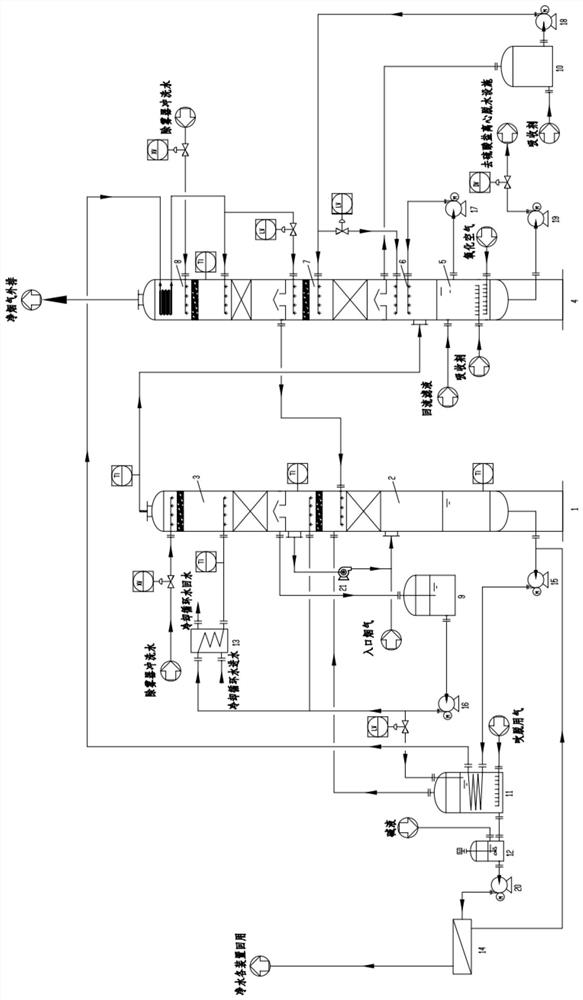

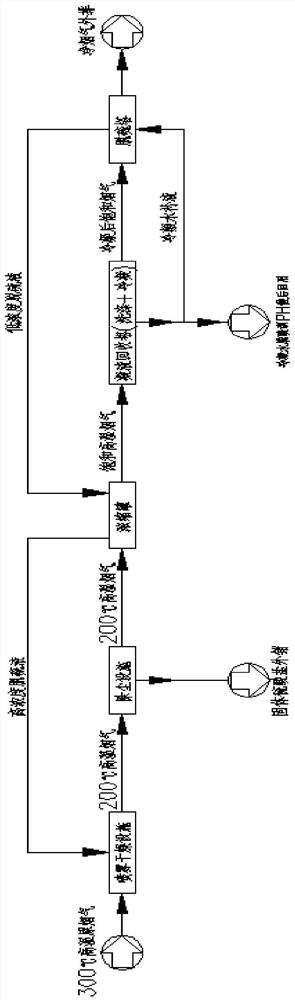

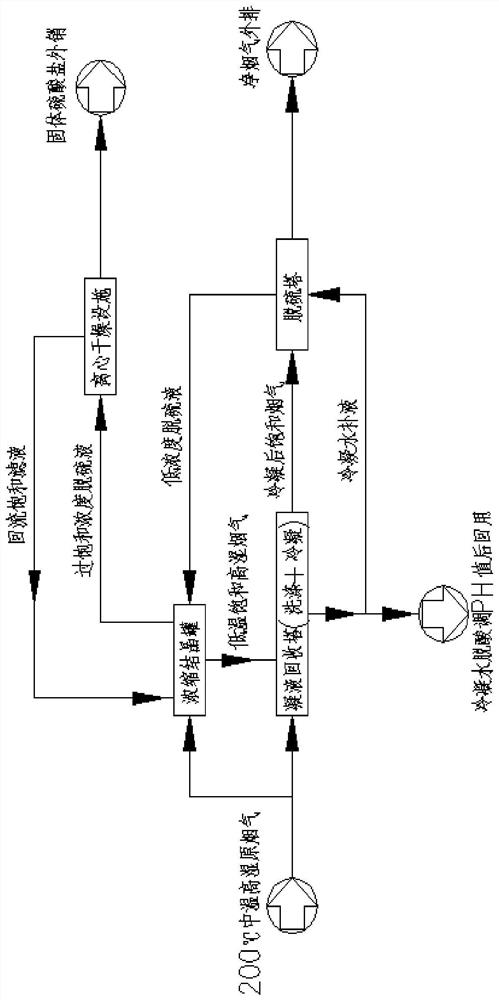

[0046] Process see figure 1 , the diagram shows the process flow of the present invention for removing sulfur oxides in high-humidity flue gas:

[0047] The original flue gas enters the washing section 2 of the condensate recovery tower 1, and the washing section 2 is a two-stage washing, and the gas-liquid separation is realized through the liqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com