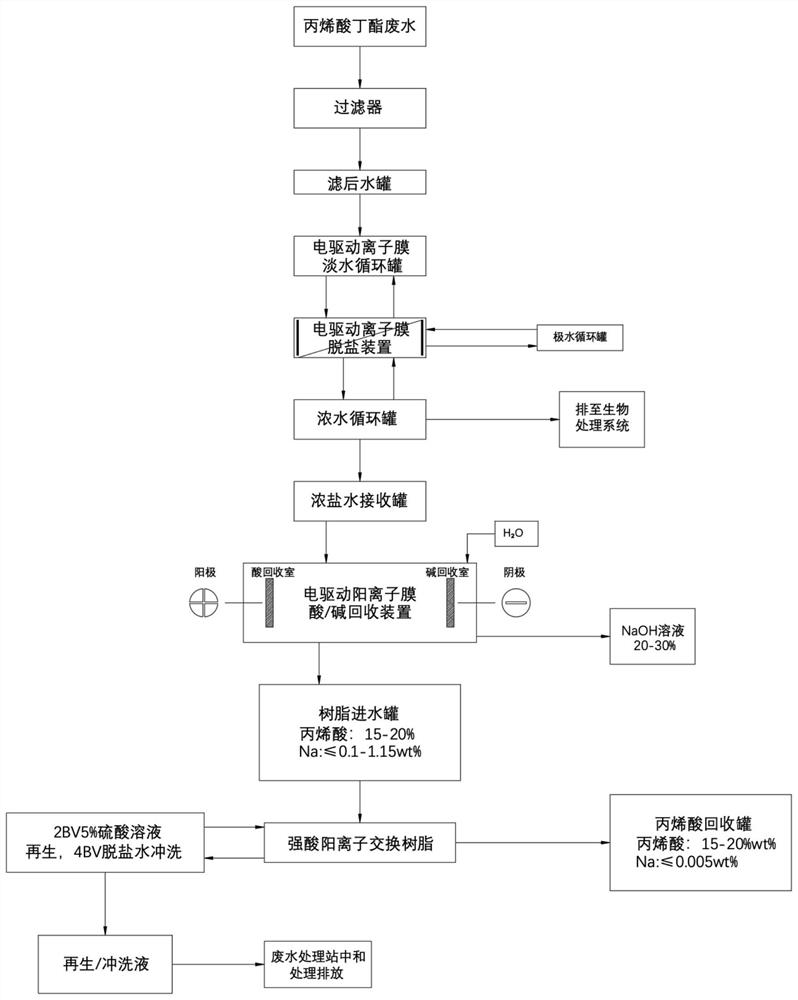

Electrically-driven ionic membrane device and butyl acrylate wastewater treatment process

An electric drive, ion membrane technology, applied in ion exchange water/sewage treatment, magnetic field/electric field water/sewage treatment, water/sewage treatment, etc., can solve the problems of incinerator failure, unstable biological treatment process and high cost, Achieving great environmental protection benefits, avoiding current efficiency drop, and reducing pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0064] The invention provides an electrically driven ionic membrane device, an electrically driven cationic membrane device and a treatment process for butyl acrylate wastewater. The electrically driven ionic membrane device includes a fresh water circulation tank, a concentrated water circulation tank, an extreme water tank and a concentrated brine receiving tank, wherein,

[0065] Fresh water circulation tank, concentrated water circulation tank, polar water tank and concentrated brine receiving tank are all equipped with valves and pumps;

[0066] The electrode anode adopts coated titanium electrode;

[0067] The cathode adopts pure titanium or coated titanium electrode;

[0068] The electrolyte used in the pole water tank is one of sodium sulfate or sodium hydroxide, wherein,

[0069] The concentration of sodium sulfate is 0.1 to 0.3mol / L,

[0070] The concentration of sodium hydroxide is 0.6 to 1.2 mol / L.

[0071] The pressure of fresh water pump, concentrated water pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com