Tubular purification method and tubular purification tank

A purification tank and tube type technology, applied in the field of purification, can solve the problems such as the large increase in the concentration of ions in the supernatant and the supernatant, the long purification process and the large number of tanks, etc., so as to solve the volume imbalance of the solution, shorten the purification process, and eliminate the Effects of Environmental Pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

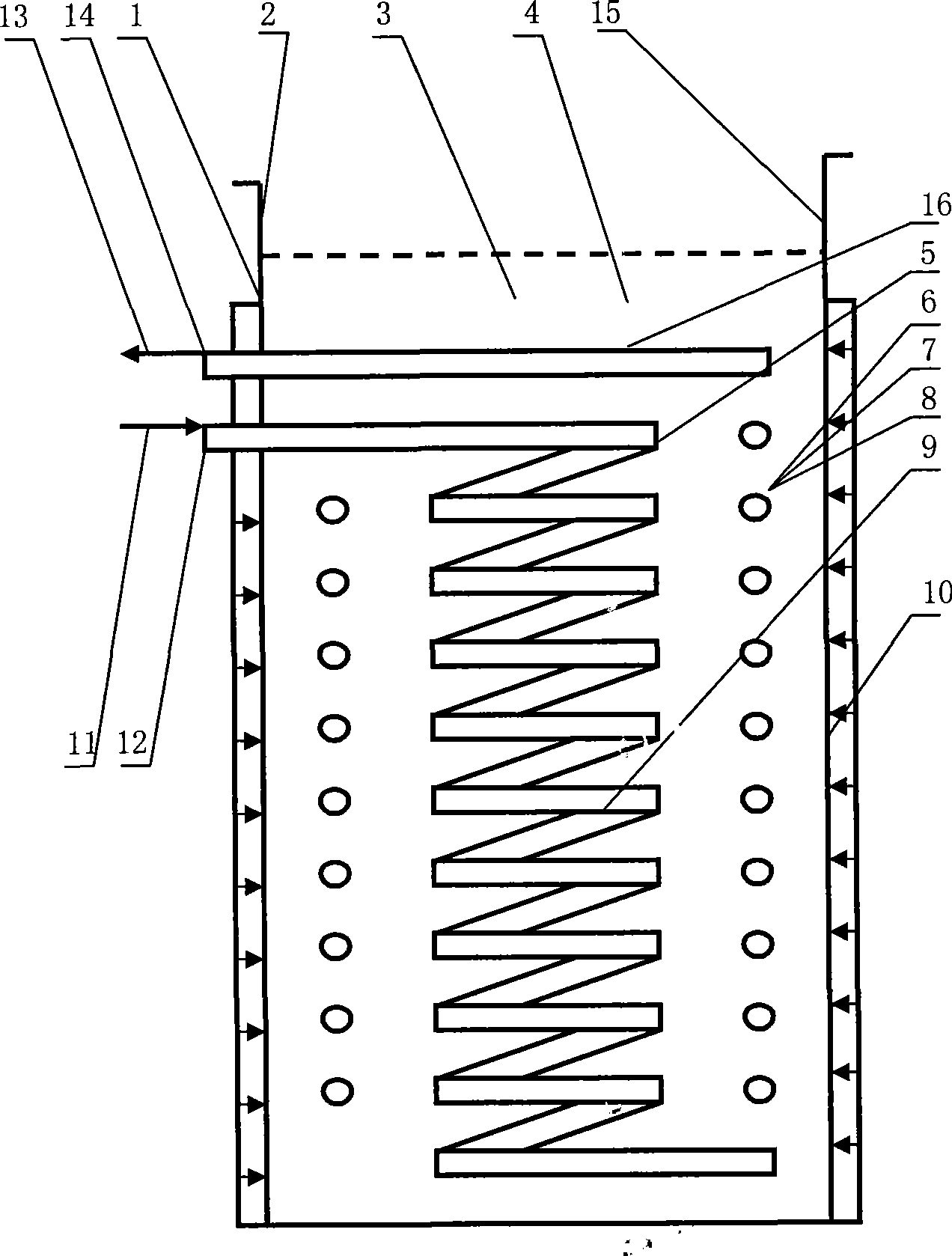

[0024] pass figure 1 It can be seen that the present invention is a tube type purification method. In the tubular purification method, the impurity-removing solution 11 completes the set purification process during the irreversible flow through the tubular purification tank 1 . The impurity-removing solution 11 is a solution containing at least one granular solute, the solution may be a zinc sulfate solution 12, and the granular solute may be a zinc powder solute. The tube-type purification tank 1 comprises a chamber 2 filled with a liquid medium 3, at least one ultrasonic wave source device 10 immersed in the liquid medium 3 and at least one tube-type purification tank filled with the impurity-removing solution 11 immersed in the liquid medium 3. device 5. The purification process refers to the process in which the impurity removal solution 11 is subjected to effective ultrasonic isolation irradiation in the irreversible flow process. The effective ultrasonic isolation irra...

Embodiment 2

[0028] Embodiment 2 is an embodiment of the present invention for purifying zinc sulfate solution in hydrometallurgy. Its structure is as figure 1 shown, from figure 1It can be seen that the technical principle of the second embodiment is the same as that of the first embodiment. The chamber 2 of the tubular septic tank 1 is an open chamber 15 . The impurity-removing zinc sulfate solution added with additives such as zinc powder according to the impurity content enters the tubular purification tank 1 at a set flow rate. During the irreversible flow through the tubular device 5, it is efficiently mixed by the static mixing device 16, and the zinc The powder is in a uniform distribution state, and is subjected to a wave source frequency of 20kHz and a wave source sound intensity of 4w / cm 2 Ultrasonic isolation irradiation, zinc powder quickly replaces the ionic impurities in the zinc sulfate solution to be removed, and produces the zinc sulfate solution after removal. When t...

Embodiment 3

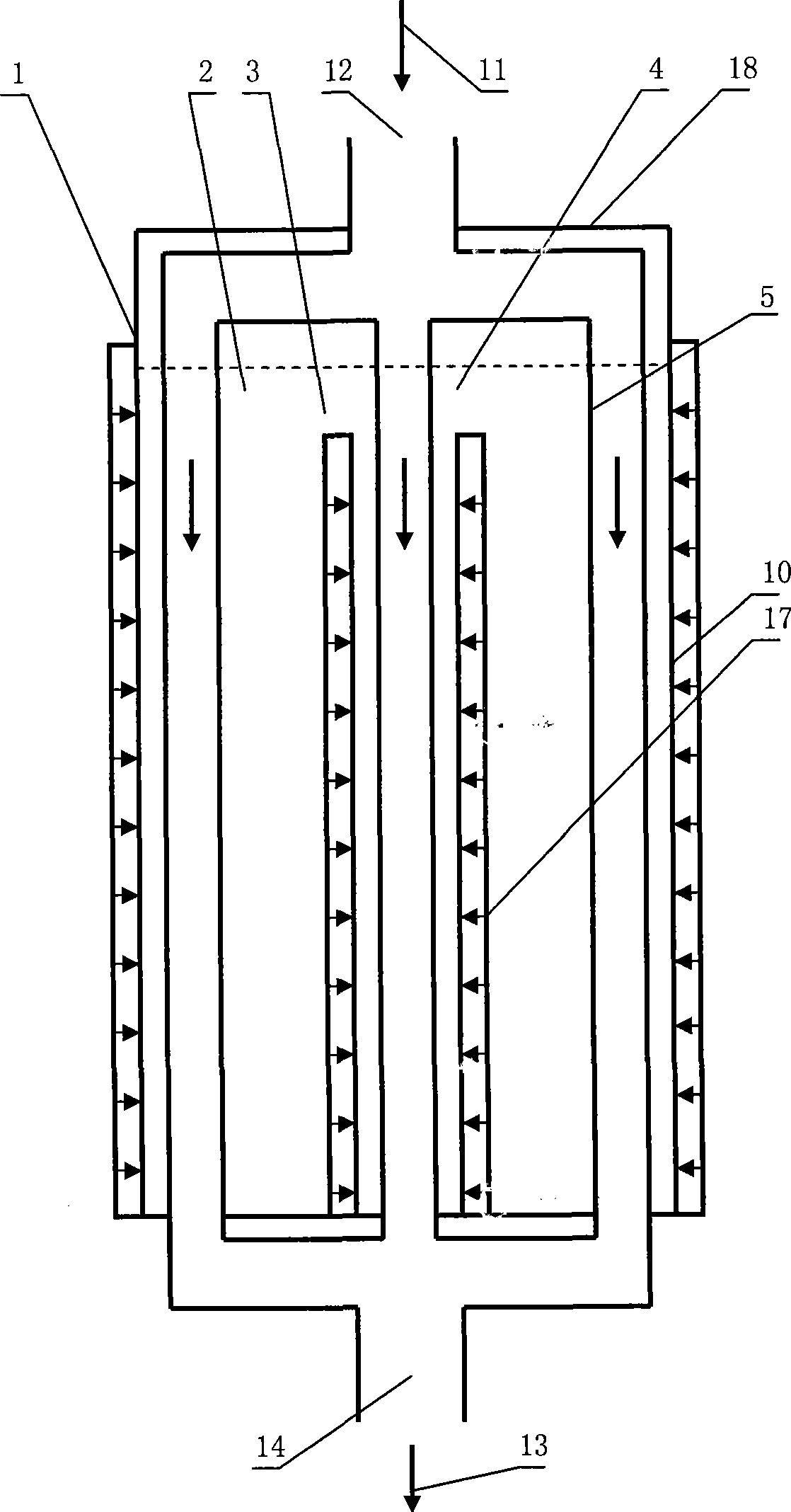

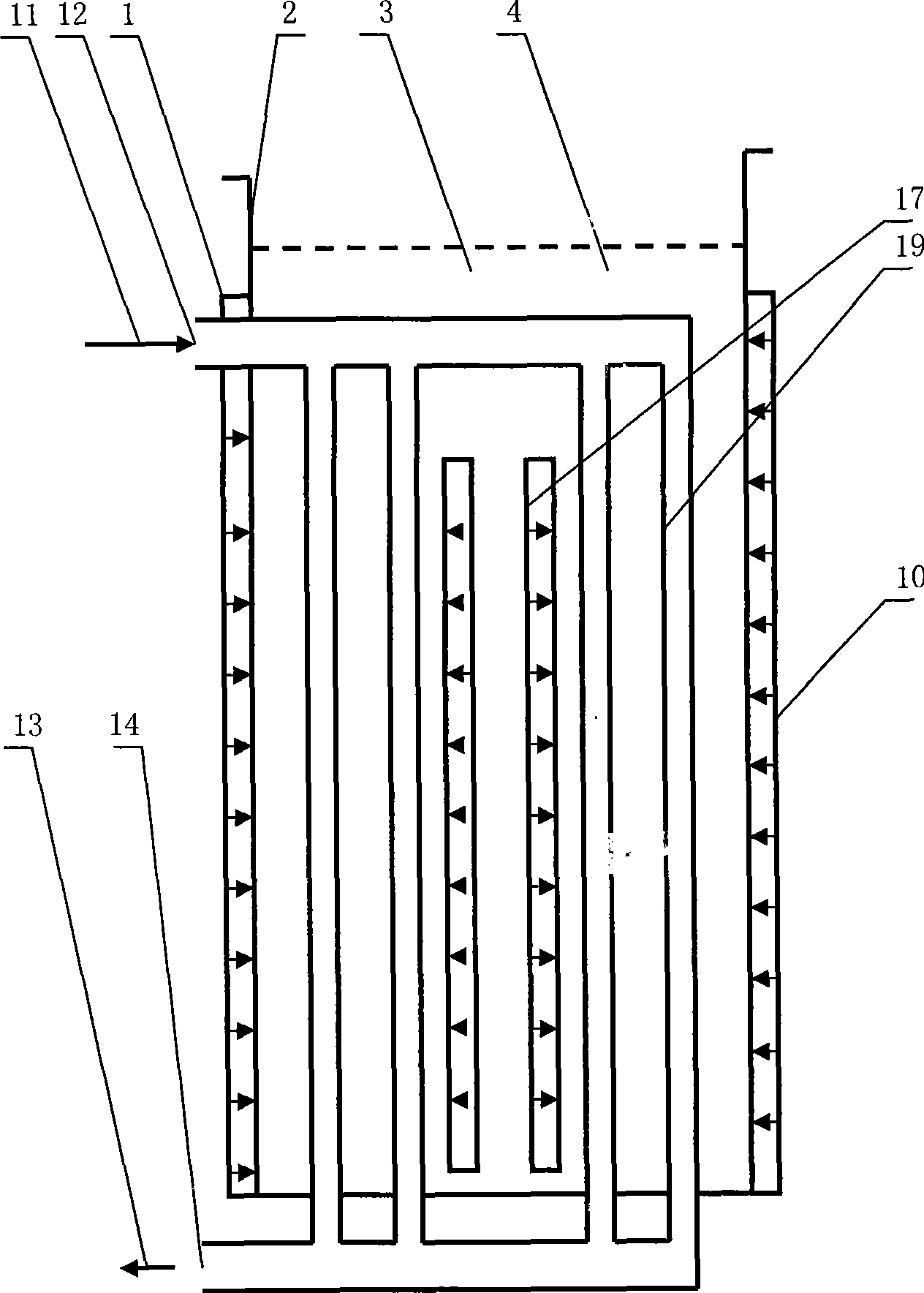

[0031] figure 2 is another embodiment of the present invention. From figure 2 It can be seen that the present invention is a tube-type purification tank with two ultrasonic wave source devices. The technical principle of the third embodiment is the same as that of the first and second embodiments. It’s just that the pipe device 5 that the impurity-removing solution 11 flows irreversibly is a straight pipe device; In the area irradiated by the ultrasonic wave source devices 10 and 17, the ultrasonic wave source devices 10 and 17 are inner and outer two-layer ultrasonic wave source devices, forming a multilayer superimposed ultrasonic emission wave source; The frequency of the wave source is 15kHz, and the sound intensity of the wave source is 4w / cm 2 Ultrasonic waves emitted by the ultrasonic wave source device 17 are isolated and irradiated; the impurity removal solution 11 is subjected to a wave source frequency of 20kHz and a wave source sound intensity of 2w / cm in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com