Multi-field joint lubricating oil dehydration and purification device

A technology combined with dehydration and purification devices, which is applied in the direction of lubricating compositions, chemical instruments and methods, filtration and separation, etc., can solve the problems of high energy consumption, low precision of centrifugal treatment, and high water content in turbine oil, reaching the applicable level wide, shorten the demulsification time, reduce the effect of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The combination of multi-fields proposed by the present invention realizes the purification treatment of lubricating oil with high water content. The dehydration and purification of lubricating oil with high water content can achieve less energy consumption and better effect through reasonable integration.

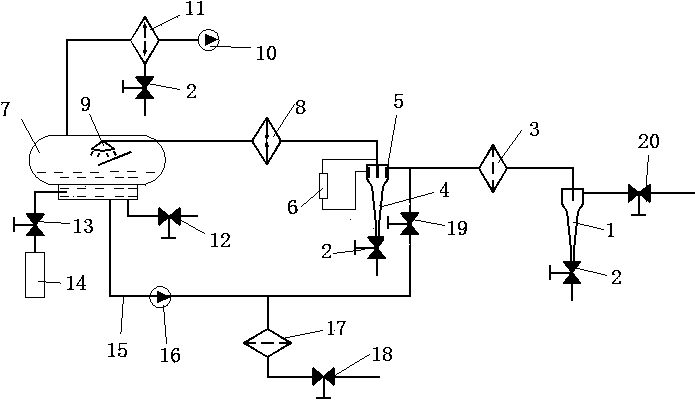

[0017] The specific structure of the lubricating oil multi-field combined dehydration and purification device of the present invention can be referred to at the same time figure 1 , it includes a primary cyclone 1, the bottom outlet of the primary cyclone 1 is provided with a drain valve 2, the upper overflow port of the primary cyclone 1 is connected to the coarse filter 3 through a pipeline, and the outlet of the coarse filter 3 is connected to the coarse filter 3 through a pipeline 4 inlets of the secondary cyclone. A pulse electrode 5 is provided in the secondary cyclone 4 , and the pulse electrode 5 is connected to a high-voltage pulse power supply 6 . The b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com